washer NISSAN TEANA 2008 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 845 of 5121

BCS-28

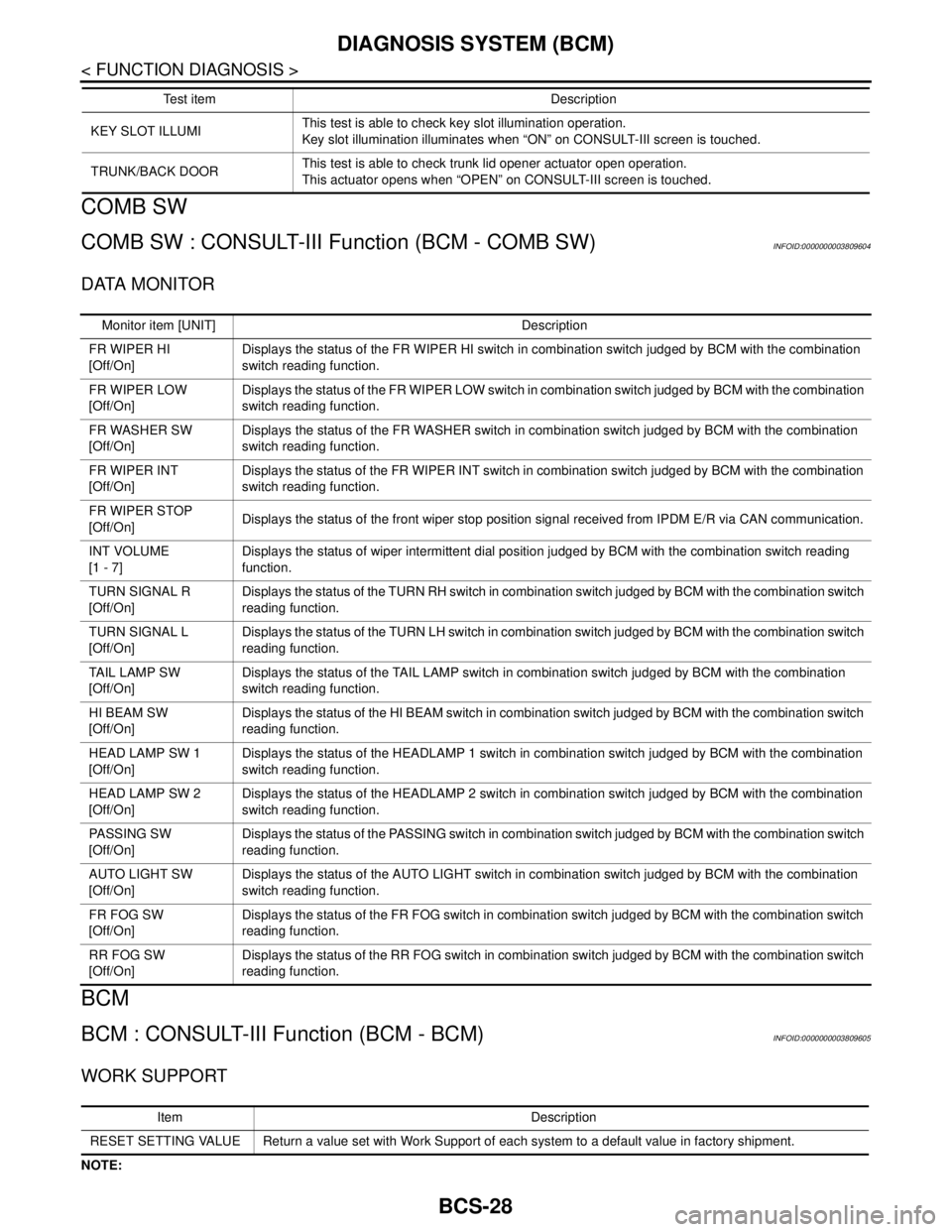

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

COMB SW

COMB SW : CONSULT-III Function (BCM - COMB SW)INFOID:0000000003809604

DATA MONITOR

BCM

BCM : CONSULT-III Function (BCM - BCM)INFOID:0000000003809605

WORK SUPPORT

NOTE:KEY SLOT ILLUMIThis test is able to check key slot illumination operation.

Key slot illumination illuminates when “ON” on CONSULT-III screen is touched.

TRUNK/BACK DOORThis test is able to check trunk lid opener actuator open operation.

This actuator opens when “OPEN” on CONSULT-III screen is touched. Te s t i t e m D e s c r i p t i o n

Monitor item [UNIT] Description

FR WIPER HI

[Off/On]Displays the status of the FR WIPER HI switch in combination switch judged by BCM with the combination

switch reading function.

FR WIPER LOW

[Off/On]Displays the status of the FR WIPER LOW switch in combination switch judged by BCM with the combination

switch reading function.

FR WASHER SW

[Off/On]Displays the status of the FR WASHER switch in combination switch judged by BCM with the combination

switch reading function.

FR WIPER INT

[Off/On]Displays the status of the FR WIPER INT switch in combination switch judged by BCM with the combination

switch reading function.

FR WIPER STOP

[Off/On]Displays the status of the front wiper stop position signal received from IPDM E/R via CAN communication.

INT VOLUME

[1 - 7]Displays the status of wiper intermittent dial position judged by BCM with the combination switch reading

function.

TURN SIGNAL R

[Off/On]Displays the status of the TURN RH switch in combination switch judged by BCM with the combination switch

reading function.

TURN SIGNAL L

[Off/On]Displays the status of the TURN LH switch in combination switch judged by BCM with the combination switch

reading function.

TAIL LAMP SW

[Off/On]Displays the status of the TAIL LAMP switch in combination switch judged by BCM with the combination

switch reading function.

HI BEAM SW

[Off/On]Displays the status of the HI BEAM switch in combination switch judged by BCM with the combination switch

reading function.

HEAD LAMP SW 1

[Off/On]Displays the status of the HEADLAMP 1 switch in combination switch judged by BCM with the combination

switch reading function.

HEAD LAMP SW 2

[Off/On]Displays the status of the HEADLAMP 2 switch in combination switch judged by BCM with the combination

switch reading function.

PASSING SW

[Off/On]Displays the status of the PASSING switch in combination switch judged by BCM with the combination switch

reading function.

AUTO LIGHT SW

[Off/On]Displays the status of the AUTO LIGHT switch in combination switch judged by BCM with the combination

switch reading function.

FR FOG SW

[Off/On]Displays the status of the FR FOG switch in combination switch judged by BCM with the combination switch

reading function.

RR FOG SW

[Off/On]Displays the status of the RR FOG switch in combination switch judged by BCM with the combination switch

reading function.

Item Description

RESET SETTING VALUE Return a value set with Work Support of each system to a default value in factory shipment.

Page 859 of 5121

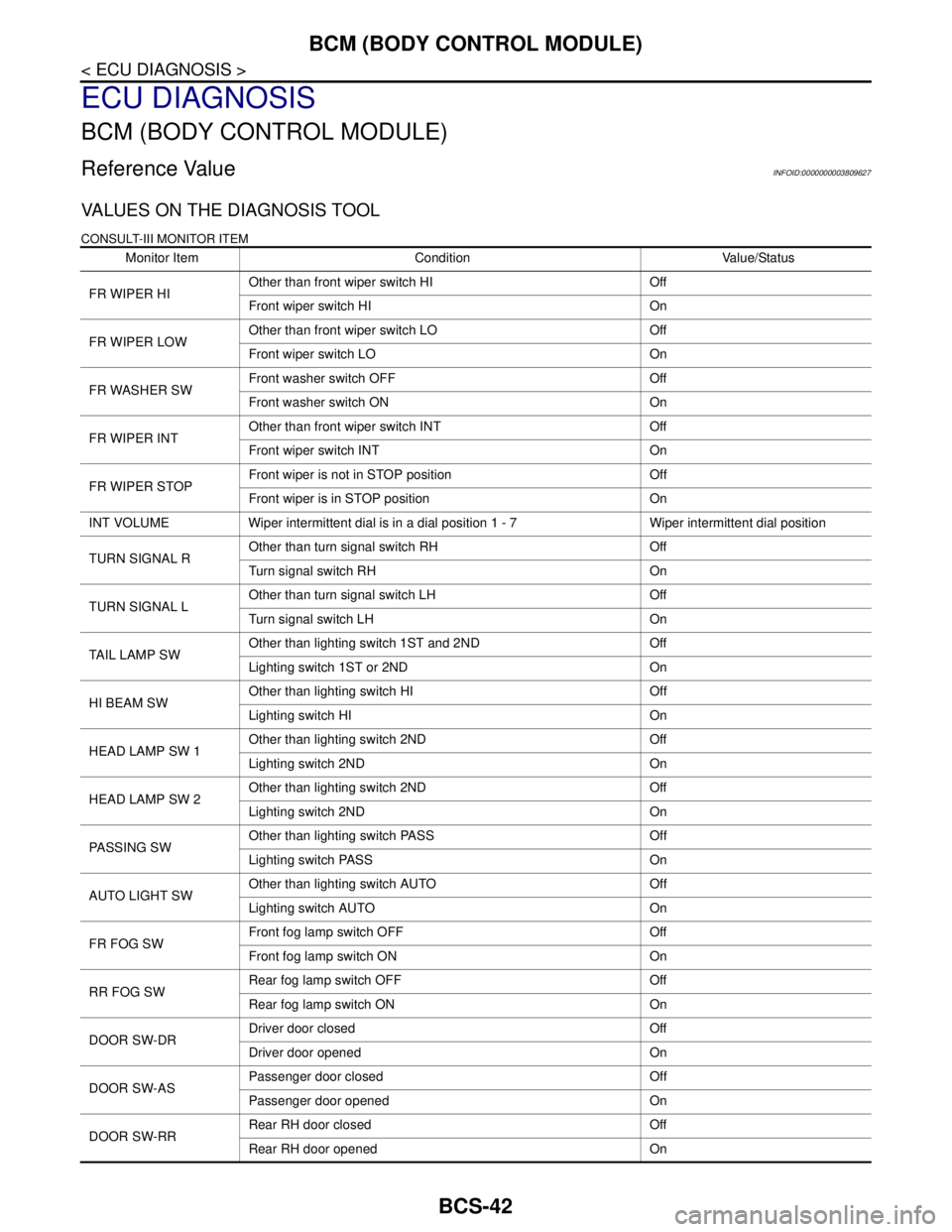

BCS-42

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

ECU DIAGNOSIS

BCM (BODY CONTROL MODULE)

Reference ValueINFOID:0000000003809627

VALUES ON THE DIAGNOSIS TOOL

CONSULT-III MONITOR ITEM

Monitor Item Condition Value/Status

FR WIPER HIOther than front wiper switch HI Off

Front wiper switch HI On

FR WIPER LOWOther than front wiper switch LO Off

Front wiper switch LO On

FR WASHER SWFront washer switch OFF Off

Front washer switch ON On

FR WIPER INTOther than front wiper switch INT Off

Front wiper switch INT On

FR WIPER STOPFront wiper is not in STOP position Off

Front wiper is in STOP position On

INT VOLUME Wiper intermittent dial is in a dial position 1 - 7 Wiper intermittent dial position

TURN SIGNAL ROther than turn signal switch RH Off

Turn signal switch RH On

TURN SIGNAL LOther than turn signal switch LH Off

Turn signal switch LH On

TAIL LAMP SWOther than lighting switch 1ST and 2ND Off

Lighting switch 1ST or 2ND On

HI BEAM SWOther than lighting switch HI Off

Lighting switch HI On

HEAD LAMP SW 1Other than lighting switch 2ND Off

Lighting switch 2ND On

HEAD LAMP SW 2Other than lighting switch 2ND Off

Lighting switch 2ND On

PASSING SWOther than lighting switch PASS Off

Lighting switch PASS On

AUTO LIGHT SWOther than lighting switch AUTO Off

Lighting switch AUTO On

FR FOG SWFront fog lamp switch OFF Off

Front fog lamp switch ON On

RR FOG SWRear fog lamp switch OFF Off

Rear fog lamp switch ON On

DOOR SW-DRDriver door closed Off

Driver door opened On

DOOR SW-ASPassenger door closed Off

Passenger door opened On

DOOR SW-RRRear RH door closed Off

Rear RH door opened On

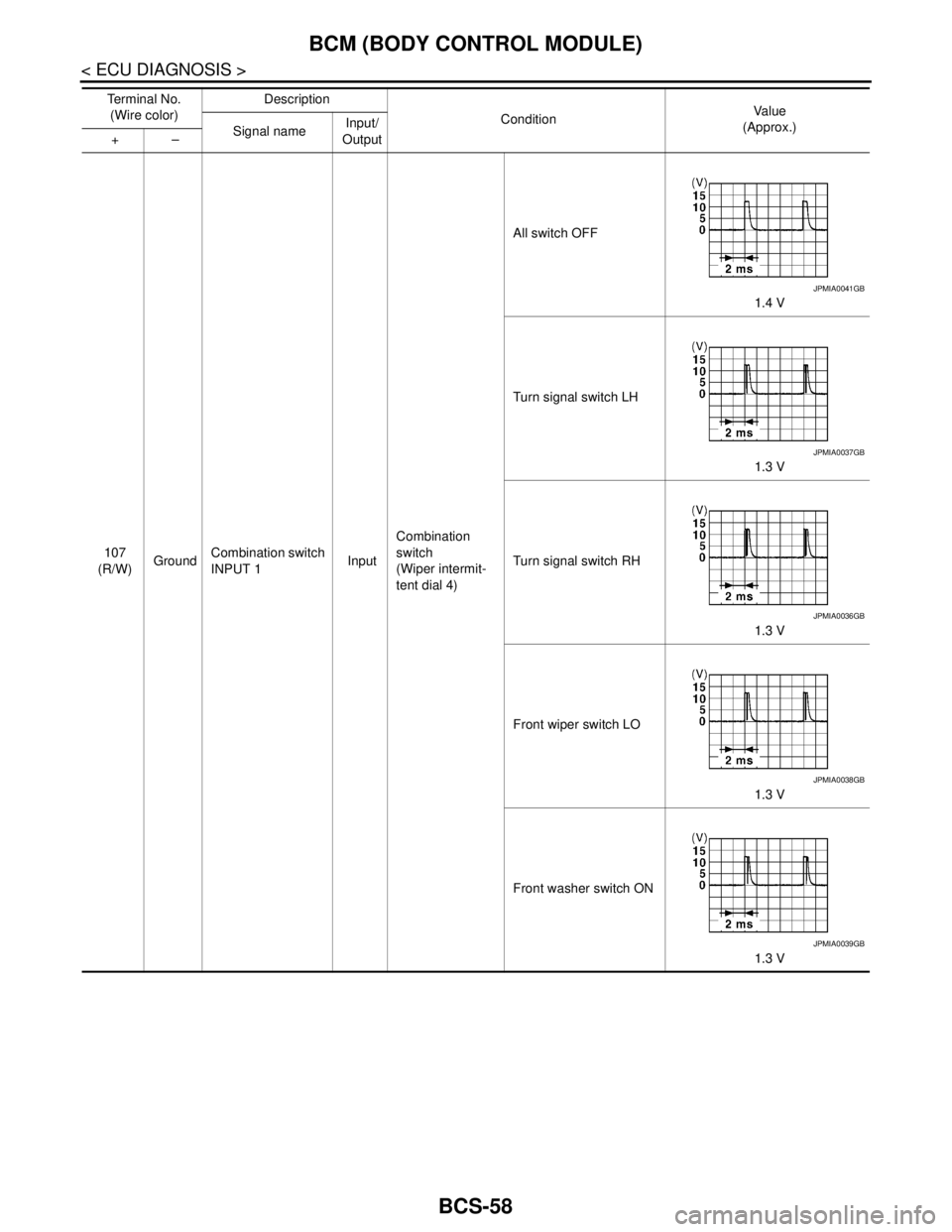

Page 875 of 5121

BCS-58

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

107

(R/W)GroundCombination switch

INPUT 1InputCombination

switch

(Wiper intermit-

tent dial 4)All switch OFF

1.4 V

Turn signal switch LH

1.3 V

Turn signal switch RH

1.3 V

Front wiper switch LO

1.3 V

Front washer switch ON

1.3 V Te r m i n a l N o .

(Wire color)Description

ConditionVa l u e

(Approx.)

Signal nameInput/

Output +–

JPMIA0041GB

JPMIA0037GB

JPMIA0036GB

JPMIA0038GB

JPMIA0039GB

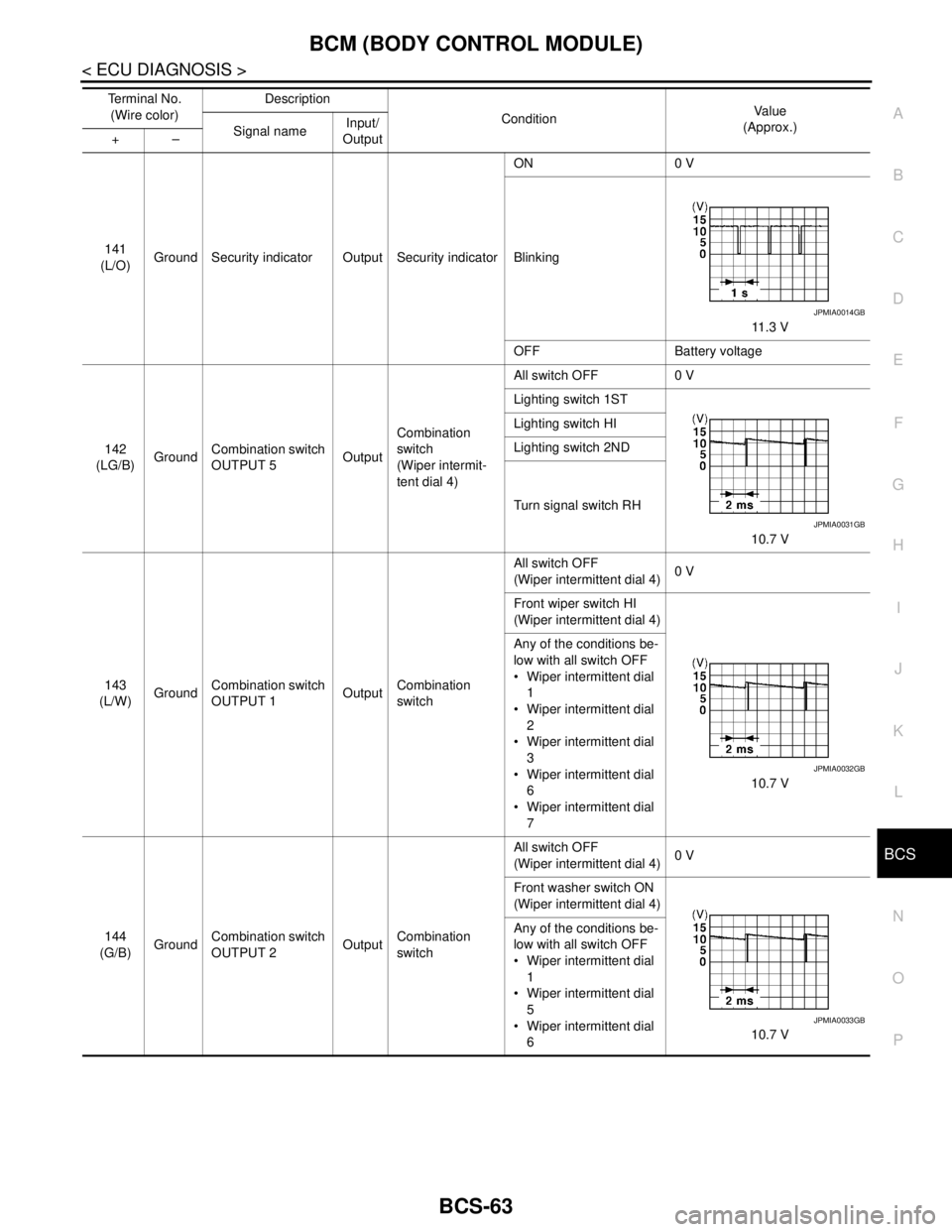

Page 880 of 5121

BCS

BCM (BODY CONTROL MODULE)

BCS-63

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N141

(L/O)Ground Security indicator Output Security indicatorON 0 V

Blinking

11.3 V

OFF Battery voltage

142

(LG/B)GroundCombination switch

OUTPUT 5OutputCombination

switch

(Wiper intermit-

tent dial 4)All switch OFF 0 V

Lighting switch 1ST

10.7 V Lighting switch HI

Lighting switch 2ND

Turn signal switch RH

143

(L/W)GroundCombination switch

OUTPUT 1OutputCombination

switchAll switch OFF

(Wiper intermittent dial 4)0 V

Front wiper switch HI

(Wiper intermittent dial 4)

10.7 V Any of the conditions be-

low with all switch OFF

Wiper intermittent dial

1

Wiper intermittent dial

2

Wiper intermittent dial

3

Wiper intermittent dial

6

Wiper intermittent dial

7

144

(G/B)GroundCombination switch

OUTPUT 2OutputCombination

switchAll switch OFF

(Wiper intermittent dial 4)0 V

Front washer switch ON

(Wiper intermittent dial 4)

10.7 V Any of the conditions be-

low with all switch OFF

Wiper intermittent dial

1

Wiper intermittent dial

5

Wiper intermittent dial

6 Te r m i n a l N o .

(Wire color)Description

ConditionVa l u e

(Approx.)

Signal nameInput/

Output +–

JPMIA0014GB

JPMIA0031GB

JPMIA0032GB

JPMIA0033GB

Page 893 of 5121

BCS-76

< SYMPTOM DIAGNOSIS >

COMBINATION SWITCH SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

COMBINATION SWITCH SYSTEM SYMPTOMS

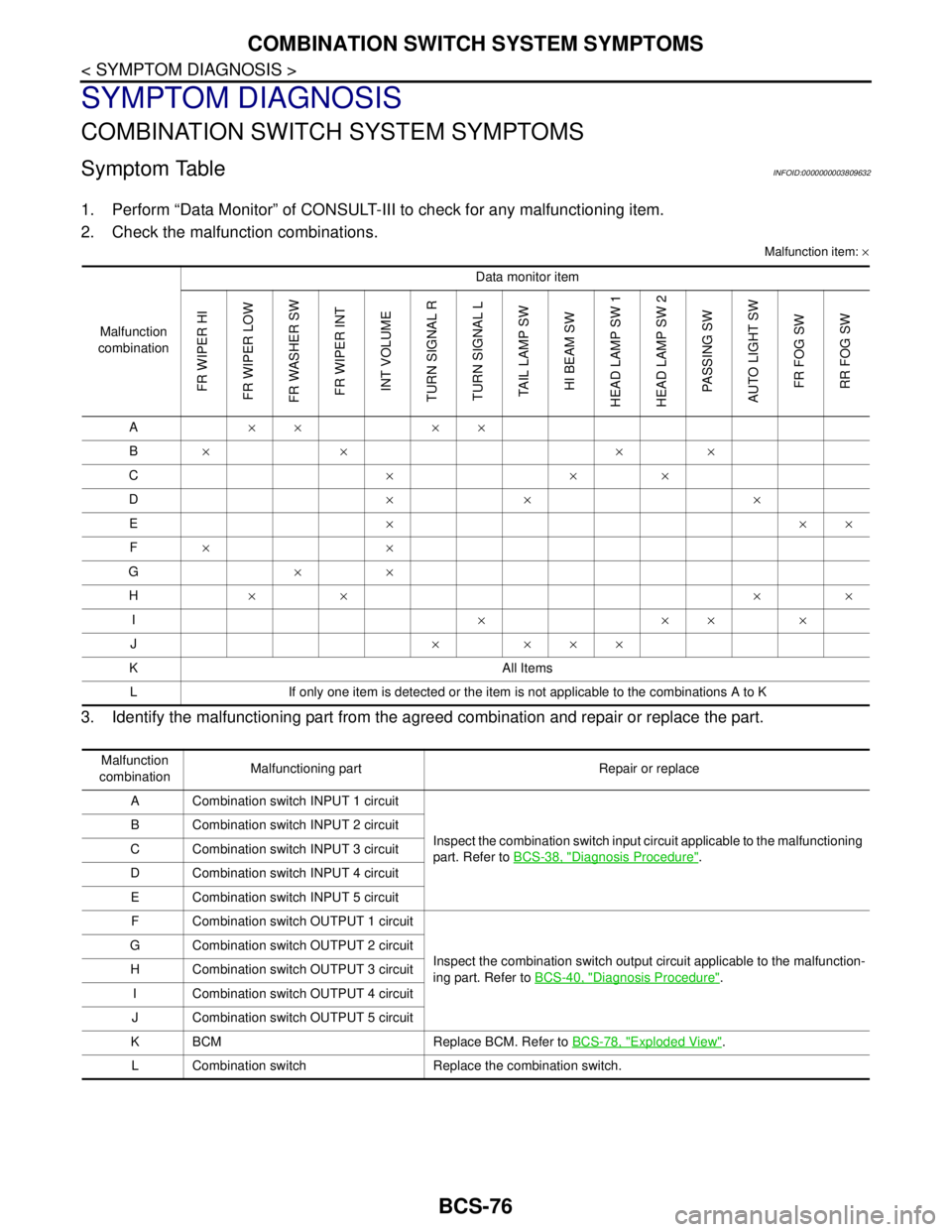

Symptom TableINFOID:0000000003809632

1. Perform “Data Monitor” of CONSULT-III to check for any malfunctioning item.

2. Check the malfunction combinations.

Malfunction item: ×

3. Identify the malfunctioning part from the agreed combination and repair or replace the part.

Malfunction

combinationData monitor item

FR WIPER HI

FR WIPER LOW

FR WASHER SW

FR WIPER INT

INT VOLUME

TURN SIGNAL R

TURN SIGNAL L

TAIL LAMP SW

HI BEAM SW

HEAD LAMP SW 1

HEAD LAMP SW 2

PASSING SW

AUTO LIGHT SW

FR FOG SW

RR FOG SW

A×× ××

B×× ××

C×××

D×× ×

E×××

F××

G××

H×× ××

I××××

J× ×××

K All Items

L If only one item is detected or the item is not applicable to the combinations A to K

Malfunction

combinationMalfunctioning part Repair or replace

A Combination switch INPUT 1 circuit

Inspect the combination switch input circuit applicable to the malfunctioning

part. Refer to BCS-38, "

Diagnosis Procedure". B Combination switch INPUT 2 circuit

C Combination switch INPUT 3 circuit

D Combination switch INPUT 4 circuit

E Combination switch INPUT 5 circuit

F Combination switch OUTPUT 1 circuit

Inspect the combination switch output circuit applicable to the malfunction-

ing part. Refer to BCS-40, "

Diagnosis Procedure". G Combination switch OUTPUT 2 circuit

H Combination switch OUTPUT 3 circuit

I Combination switch OUTPUT 4 circuit

J Combination switch OUTPUT 5 circuit

K BCM Replace BCM. Refer to BCS-78, "

Exploded View".

L Combination switch Replace the combination switch.

Page 915 of 5121

BRAKE PIPING

BR-19

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

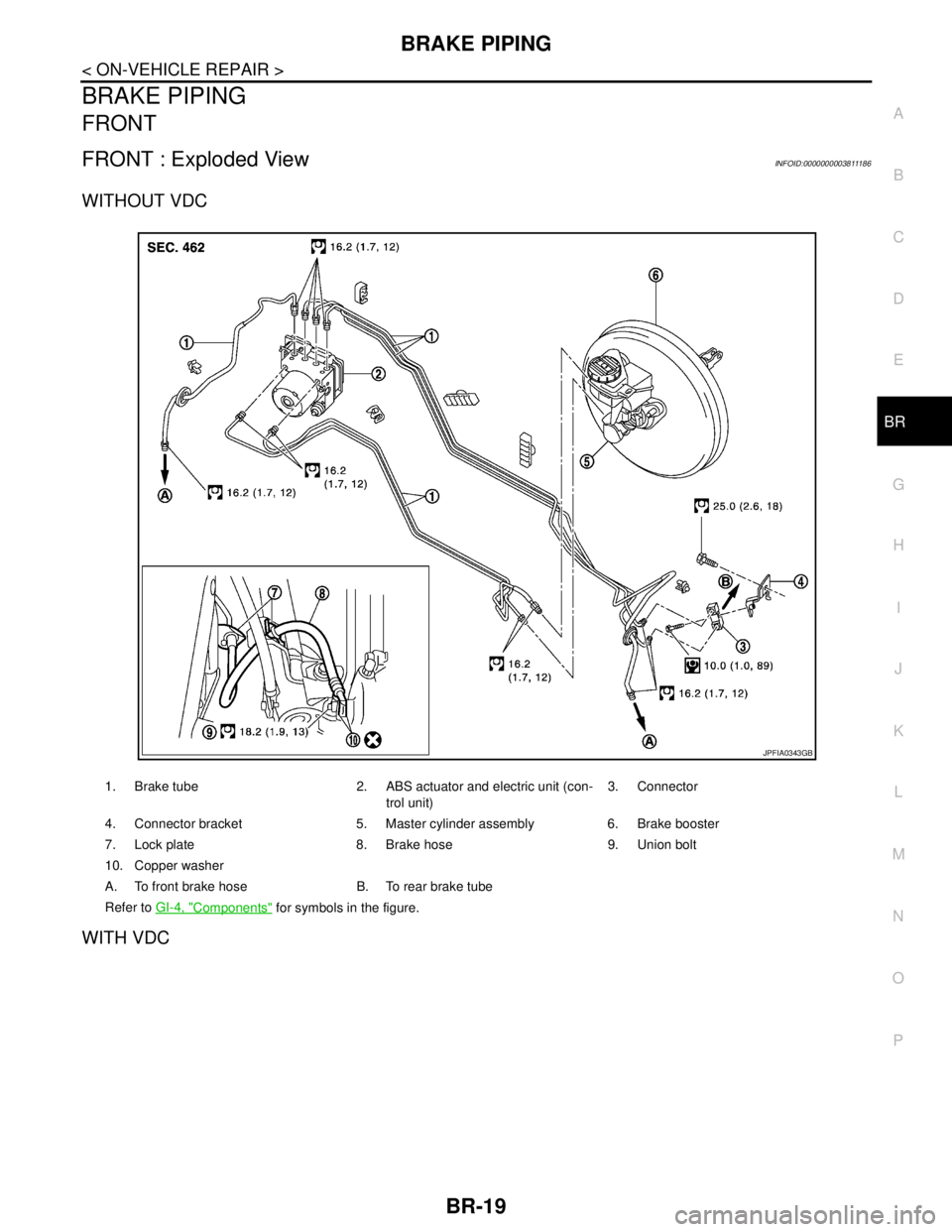

BRAKE PIPING

FRONT

FRONT : Exploded ViewINFOID:0000000003811186

WITHOUT VDC

WITH VDC

1. Brake tube 2. ABS actuator and electric unit (con-

trol unit)3. Connector

4. Connector bracket 5. Master cylinder assembly 6. Brake booster

7. Lock plate 8. Brake hose 9. Union bolt

10. Copper washer

A. To front brake hose B. To rear brake tube

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0343GB

Page 916 of 5121

BR-20

< ON-VEHICLE REPAIR >

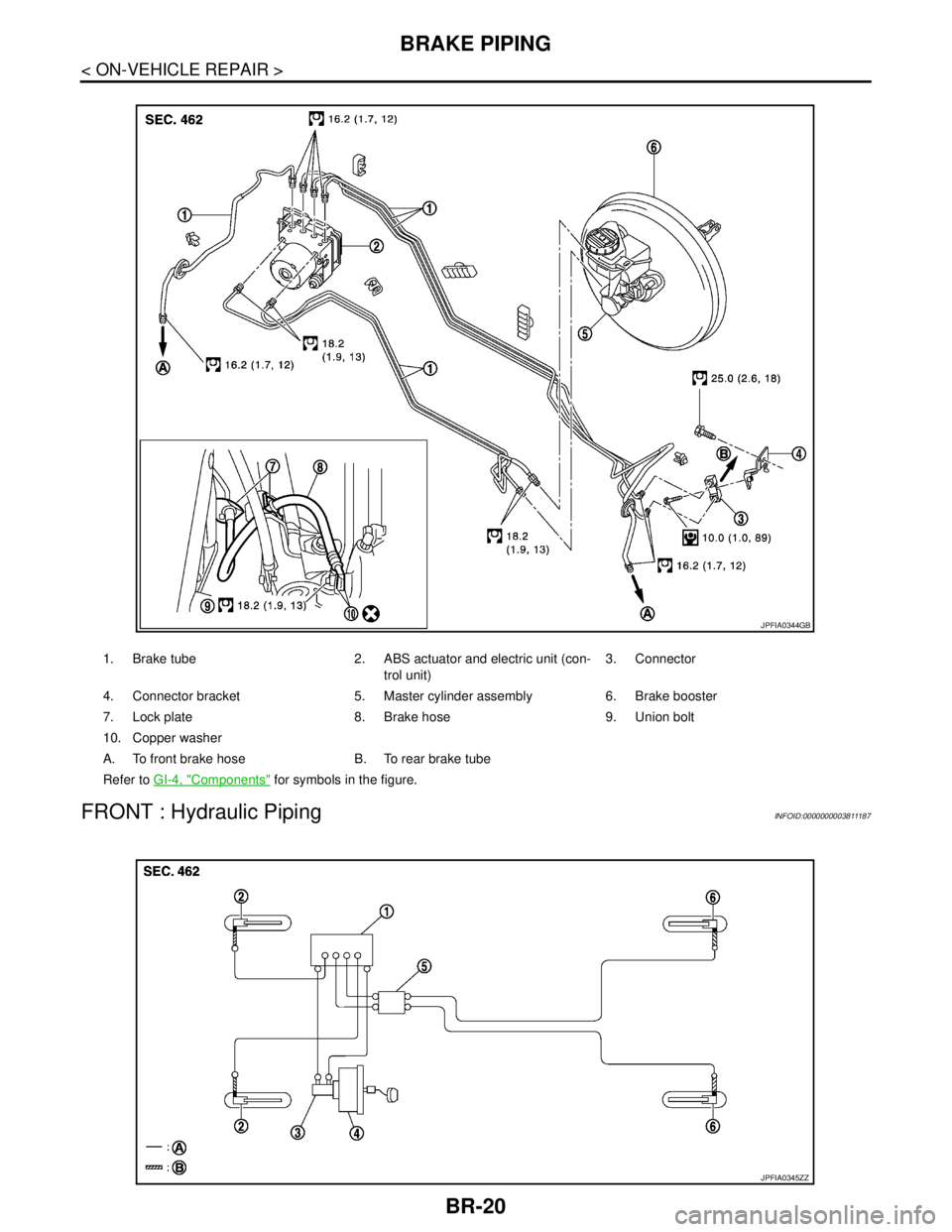

BRAKE PIPING

FRONT : Hydraulic Piping

INFOID:0000000003811187

1. Brake tube 2. ABS actuator and electric unit (con-

trol unit)3. Connector

4. Connector bracket 5. Master cylinder assembly 6. Brake booster

7. Lock plate 8. Brake hose 9. Union bolt

10. Copper washer

A. To front brake hose B. To rear brake tube

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0344GB

JPFIA0345ZZ

Page 917 of 5121

BRAKE PIPINGBR-21

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

FRONT : Removal and InstallationINFOID:0000000003811188

REMOVAL

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Remove tires.

2. Drain brake fluid. Refer to BR-9, "

Draining".

3. Loosen the flare nut with a flare nut wrenc h and separate the brake tube from the hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never bend sharply, twist or strong ly pull out the brake hoses and tubes.

Cover open end of brake tub es and hoses when disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse the copper washer.

2. Align the brake hose pin to the projection (A) of the brake caliper assembly and tighten the union bolt (1) to the specified torque.

3. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hoses and tubes are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

FRONT : InspectionINFOID:0000000003811189

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785N (80 kg, 177 lb) and hold down the pedal for approximately 5

seconds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connect ion to the specified torque and repair any abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

1. ABS actuator and electric unit (con-

trol unit) 2. Front disc brake 3. Master cylinder assembly

4. Brake booster 5. Connector 6. Rear disc brake

A. Brake tube B. Brake hose : Flare nut

: Union bolt

JPFIA0099ZZ

Page 918 of 5121

BR-22

< ON-VEHICLE REPAIR >

BRAKE PIPING

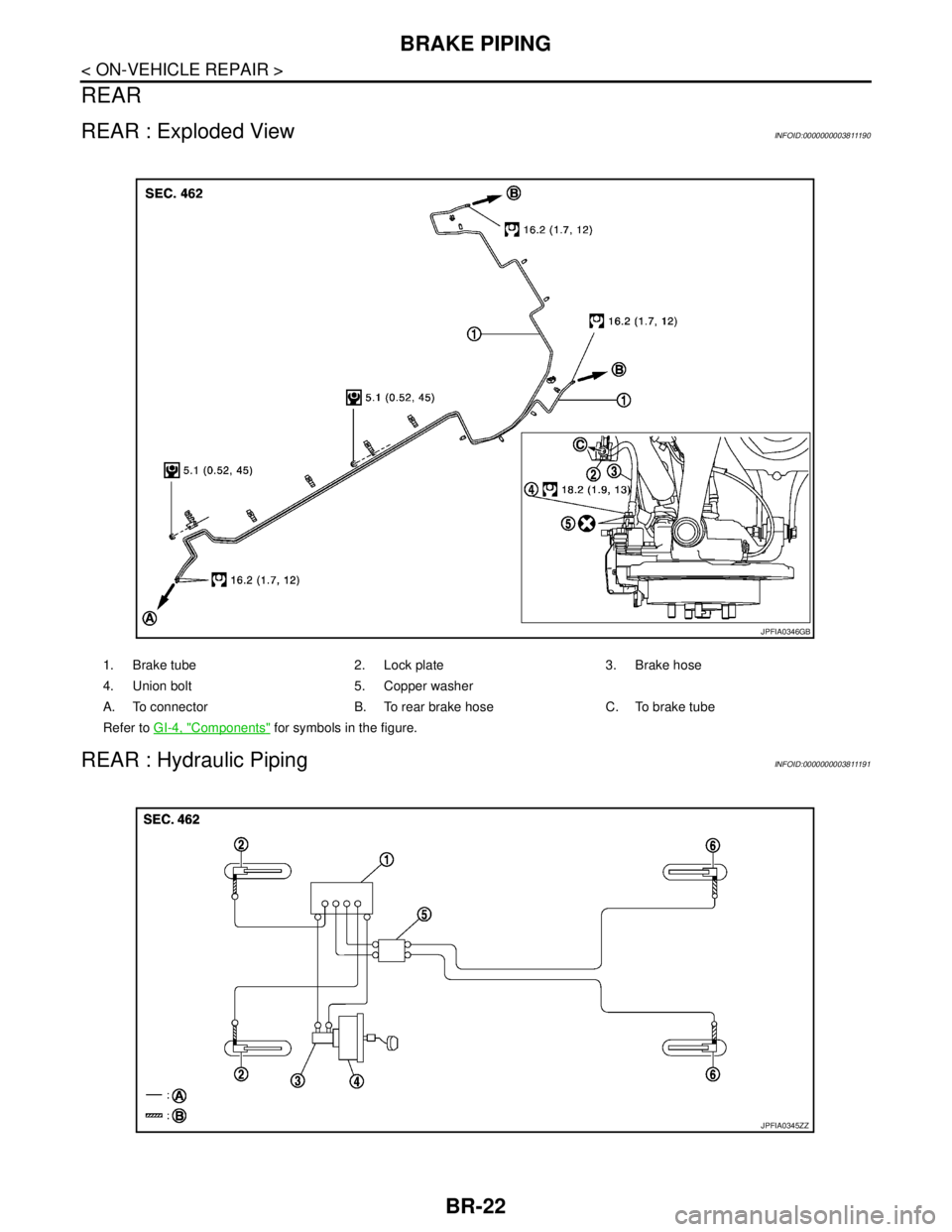

REAR

REAR : Exploded ViewINFOID:0000000003811190

REAR : Hydraulic PipingINFOID:0000000003811191

1. Brake tube 2. Lock plate 3. Brake hose

4. Union bolt 5. Copper washer

A. To connector B. To rear brake hose C. To brake tube

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0346GB

JPFIA0345ZZ

Page 919 of 5121

BRAKE PIPINGBR-23

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

REAR : Removal and InstallationINFOID:0000000003811192

REMOVAL

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Remove tires.

2. Drain brake fluid. Refer to BR-9, "

Draining".

3. Loosen the flare nut with a flare nut wrenc h and separate the brake tube from the hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never sharply bend, twist or strongly pull the brake hoses and tubes.

Cover the open end of brake tubes and hoses wh en disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose from the vehicle.

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse copper washer.

2. Install the brake hose L-pin by aligning it with the brake caliper assembly positioning hole, and tighten the union bolt (1) to the

specified torque.

3. Connect the hose to the brake tube, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake hose

to the bracket with the lock plate.

CAUTION:

Check that the brake hoses and tubes are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

REAR : InspectionINFOID:0000000003811193

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785N (80

kg, 177 lb) and hold down the pedal for approximately 5

seconds with the engine running. Check for any fluid leakage.

CAUTION:

1. ABS actuator and electric unit (con- trol unit) 2. Front disc brake 3. Master cylinder assembly

4. Brake booster 5. Connector 6. Rear disc brake

A. Brake tube B. Brake hose : Flare nut

: Union bolt

JPFIA0012ZZ