washer NISSAN TEANA 2008 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2344 of 5121

![NISSAN TEANA 2008 Workshop Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-315

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

ST/INHI RLYIgnition switch ON Off

At engine cranking INHI → ST

NISSAN TEANA 2008 Workshop Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-315

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

ST/INHI RLYIgnition switch ON Off

At engine cranking INHI → ST](/img/5/57391/w960_57391-2343.png)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-315

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

ST/INHI RLYIgnition switch ON Off

At engine cranking INHI → ST

The status of starter relay or starter control relay cannot be recognized by

the battery voltage malfunction, etc. when the starter relay is ON and the

starter control relay is OFFUNKWN

DETENT SWIgnition switch ON Press the selector button with se-

lector lever in P position

Selector lever in any position oth-

er than POff

Release the selector button with selector lever in P position On

S/L RLY -REQNone of the conditions below are present Off

Open the driver door after the ignition switch is turned OFF (for a few

seconds)

Press the push-button ignition switch when the steering lock is activat-

edOn

S/L STATESteering lock is activated LOCK

Steering lock is deactivated UNLOCK

[DTC: B210A] is detected UNKWN

DTRL REQNOTE:

The item is indicated, but not monitored.Off

OIL P SWIgnition switch OFF, ACC or engine running Open

Ignition switch ON Close

HOOD SWClose the hood Off

Open the hood On

HL WASHER REQNot operating Off

Headlamp washer operating On

THFT HRN REQNot operating Off

Horn is activated with vehicle security (theft warning) system On

HORN CHIRPNot operating Off

Door locking with Intelligent Key (horn chirp mode)

Door locking with key fob (horn chirp mode)On

CRNRNG LMP REQNOTE:

The item is indicated, but not monitored.Off Monitor Item Condition Value/Status

Page 2346 of 5121

![NISSAN TEANA 2008 Workshop Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-317

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

11

(P)GroundSteering lock unit power

supplyOutputIgnition

switch NISSAN TEANA 2008 Workshop Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-317

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

11

(P)GroundSteering lock unit power

supplyOutputIgnition

switch](/img/5/57391/w960_57391-2345.png)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-317

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

11

(P)GroundSteering lock unit power

supplyOutputIgnition

switch

OFFA few seconds after open-

ing the driver doorBattery voltage

Ignition

switch

LOCKPress the push-button ig-

nition switchBattery voltage

Ignition switch ACC or ON 0 V

12

(B/W)Ground Ground — Ignition switch ON 0 V

13

(SB)Ground Fuel pump power supply OutputApproximately 1 second or more after

turning the ignition switch ON0 V

Approximately 1 second after turning

the ignition switch ON

Engine runningBattery voltage

15

(W)Ground Ignition relay power supply OutputIgnition switch OFF 0 V

Ignition switch ON Battery voltage

16

(R)Ground Front wiper auto stop InputIgnition

switch ONFront wiper stop position 0 V

Any position other than

front wiper stop positionBattery voltage

17

(V)GroundHeadlamp washer relay

controlInputIgnition

switch ONHeadlamp washer deacti-

vatedBattery voltage

Headlamp washer activat-

ed0 V

19

(Y)Ground Ignition relay power supply OutputIgnition switch OFF 0 V

Ignition switch ON Battery voltage

20

(B)Ground Ambient sensor ground Output Ignition switch ON 0 V

21

(O)Ground Ambient sensor InputIgnition switch ON

NOTE:

Changes depending to ambient tem-

perature

22

(SB)GroundRefrigerant pressure sen-

sor groundOutputEngine

running Warm-up condition

Idle speed0 V

23

(GR)GroundRefrigerant pressure sen-

sorOutputEngine

running Warm-up condition

Both A/C switch and

blower fan motor switch

ON

(Compressor operates)1.0 - 4.0 V

24

(G)

GroundRefrigerant pressure sen-

sor power supplyInputIgnition switch OFF 0 V

Ignition switch ON 5.0 V

25

(GR)Ground Ignition relay power supply OutputIgnition switch OFF 0 V

Ignition switch ON Battery voltage

27

(W)Ground Ignition relay monitor InputIgnition switch OFF or ACC Battery voltage

Ignition switch ON 0 V Te r m i n a l N o .

(Wire color)Description

ConditionVa l u e

(Approx.)

Signal nameInput/

Output +−

JSNIA0014GB

Page 2350 of 5121

![NISSAN TEANA 2008 Workshop Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-321

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

88

(P)GroundWasher pump power sup-

plyOutput Ignition switch ON Ba NISSAN TEANA 2008 Workshop Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-321

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

88

(P)GroundWasher pump power sup-

plyOutput Ignition switch ON Ba](/img/5/57391/w960_57391-2349.png)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-321

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

88

(P)GroundWasher pump power sup-

plyOutput Ignition switch ON Battery voltage

89

(W)Ground Headlamp HI (RH) OutputIgnition

switch ON Lighting switch HI

Lighting switch PASSBattery voltage

Lighting switch OFF 0 V

90

(O)Ground Headlamp HI (LH) OutputIgnition

switch ON Lighting switch HI

Lighting switch PASSBattery voltage

Lighting switch OFF 0 V

91

(O)Ground Parking lamp (RH) OutputIgnition

switch ONLighting switch 1ST Battery voltage

Lighting switch OFF 0 V

92

(L)Ground Parking lamp (LH) OutputIgnition

switch ONLighting switch 1ST Battery voltage

Lighting switch OFF 0 V

93

(BR)GroundHeadlamp aiming motor

(RH)OutputIgnition

switch ONLighting switch 1ST Battery voltage

Lighting switch OFF 0 V

94

(Y)GroundHeadlamp aiming motor

(LH)OutputIgnition

switch ONLighting switch 1ST Battery voltage

Lighting switch OFF 0 V

99

(W)Ground Ambient sensor ground Input Ignition switch ON 0 V

100

(SB)Ground Ambient sensor OutputIgnition switch ON

NOTE:

Changes depending to ambient tem-

perature

101

(GR)GroundRefrigerant pressure sen-

sor groundInputEngine

running Warm-up condition

Idle speed0 V

102

(R)GroundRefrigerant pressure sen-

sorInputEngine

running Warm-up condition

Both A/C switch and

blower fan motor switch

ON

(Compressor operates)1.0 - 4.0 V

103

(P)GroundRefrigerant pressure sen-

sor power supplyOutputIgnition switch OFF 0 V

Ignition switch ON 5.0 V

104

(LG)

Ground Hood switch OutputClose the hood Battery voltage

Open the hood 0 V Te r m i n a l N o .

(Wire color)Description

ConditionVa l u e

(Approx.)

Signal nameInput/

Output +−

JSNIA0014GB

Page 2355 of 5121

![NISSAN TEANA 2008 Workshop Manual EXL-326

< ECU DIAGNOSIS >[HALOGEN TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM NISSAN TEANA 2008 Workshop Manual EXL-326

< ECU DIAGNOSIS >[HALOGEN TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM](/img/5/57391/w960_57391-2354.png)

EXL-326

< ECU DIAGNOSIS >[HALOGEN TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation

coil circuit.

If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to

alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop position by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 seconds activation and 20 seconds stop five times.

Control part Fail-safe operation

Cooling fan Turns ON the cooling fan relay-2 and the cooling fan relay-3 when ignition switch is

turned ON (Cooling fan operates at HI)

Turns OFF the cooling fan relay-1, the cooling fan relay-2 and the cooling fan relay-3

when the ignition switch is turned OFF (Cooling fan does not operate)

A/C compressor A/C relay OFF

Alternator Outputs the power generation command signal (PWM signal) 0%

Control part Fail-safe operation

Headlamp Turns ON the headlamp low relay when the ignition switch is turned ON

Turns OFF the headlamp low relay when the ignition switch is turned OFF

Headlamp high relay OFF

Parking lamps

License plate lamps

Illuminations

Tail lamps Turns ON the tail lamp relay when the ignition switch is turned ON

Turns OFF the tail lamp relay when the ignition switch is turned OFF

Front wiper The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

The wiper is operated at LO speed until the ignition switch is turned OFF if the fail-

safe control is activated while the front wiper is set in the INT mode and the front wiper

motor is operating.

Front fog lamps Front fog lamp relay OFF

Horn Horn OFF

Ignition relay The status just before activation of fail-safe is maintained.

Starter motor Starter control relay OFF

Steering lock unit Steering lock relay OFF

Headlamp washer relay Headlamp washer relay OFF

Voltage judgment

IPDM E/R judgment Operation

Ignition relay contact sideIgnition relay excitation coil

side

ON ON Ignition relay ON normal —

OFF OFF Ignition relay OFF normal —

ON OFF Ignition relay ON stuck Detects DTC “B2098: IGN RELAY ON”

Turns ON the tail lamp relay for 10 min-

utes

OFF ON Ignition relay OFF stuck Detects DTC “B2099: IGN RELAY OFF”

Page 2400 of 5121

FRONT BUMPER

EXT-11

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

ON-VEHICLE REPAIR

FRONT BUMPER

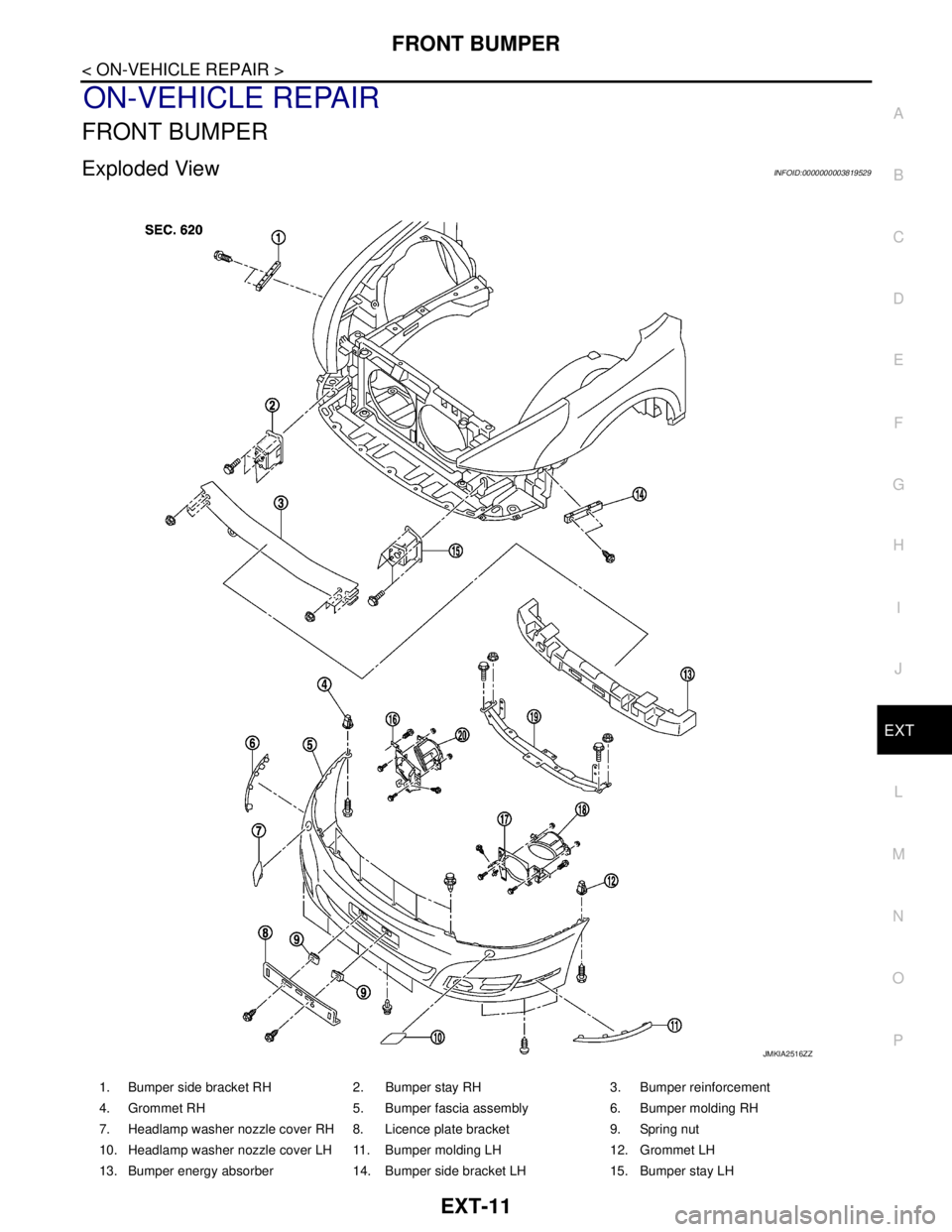

Exploded ViewINFOID:0000000003819529

1. Bumper side bracket RH 2. Bumper stay RH 3. Bumper reinforcement

4. Grommet RH 5. Bumper fascia assembly 6. Bumper molding RH

7. Headlamp washer nozzle cover RH 8. Licence plate bracket 9. Spring nut

10. Headlamp washer nozzle cover LH 11. Bumper molding LH 12. Grommet LH

13. Bumper energy absorber 14. Bumper side bracket LH 15. Bumper stay LH

JMKIA2516ZZ

Page 2401 of 5121

EXT-12

< ON-VEHICLE REPAIR >

FRONT BUMPER

Removal and Installation

INFOID:0000000003819530

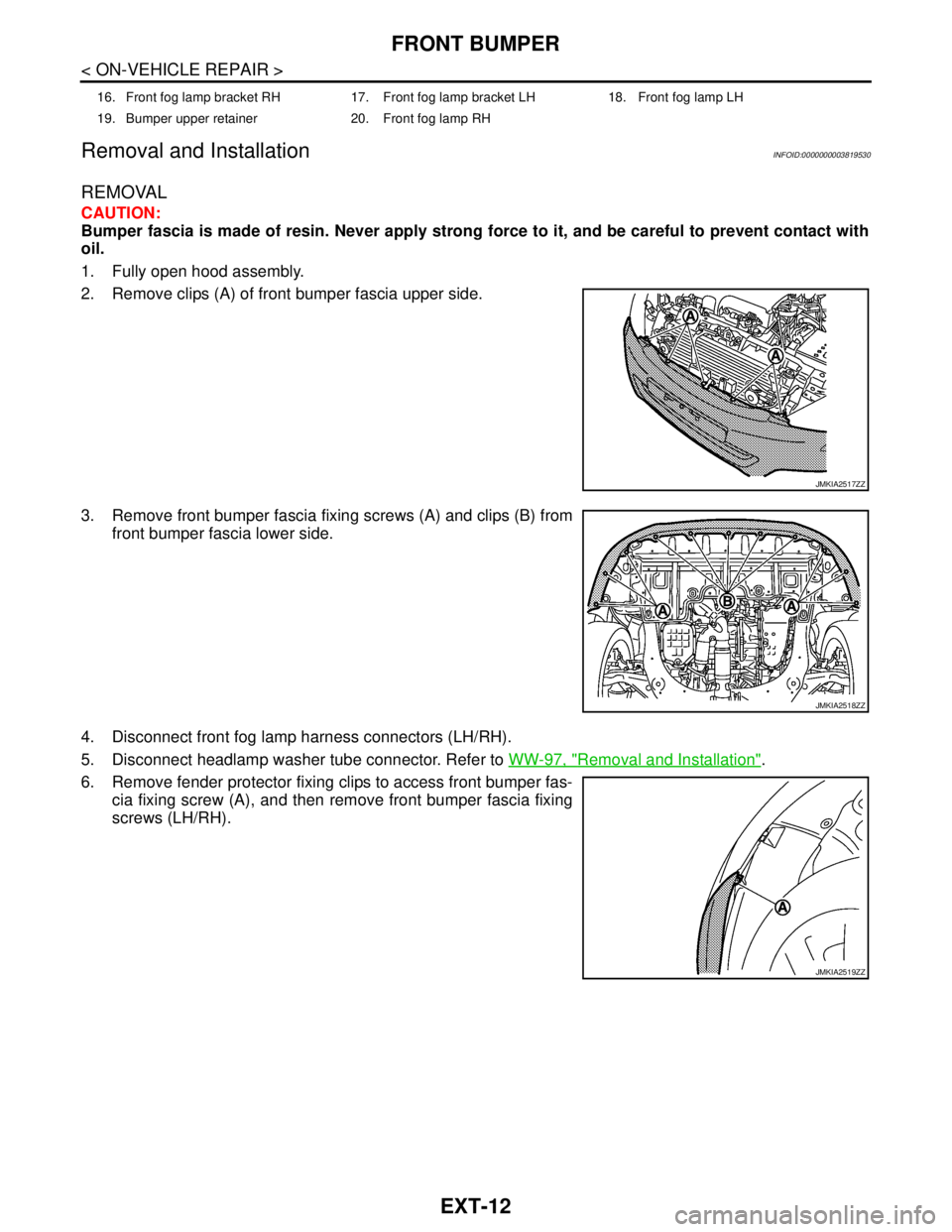

REMOVAL

CAUTION:

Bumper fascia is made of resin. Never apply strong force to it, and be careful to prevent contact with

oil.

1. Fully open hood assembly.

2. Remove clips (A) of front bumper fascia upper side.

3. Remove front bumper fascia fixing screws (A) and clips (B) from

front bumper fascia lower side.

4. Disconnect front fog lamp harness connectors (LH/RH).

5. Disconnect headlamp washer tube connector. Refer to WW-97, "

Removal and Installation".

6. Remove fender protector fixing clips to access front bumper fas-

cia fixing screw (A), and then remove front bumper fascia fixing

screws (LH/RH).

16. Front fog lamp bracket RH 17. Front fog lamp bracket LH 18. Front fog lamp LH

19. Bumper upper retainer 20. Front fog lamp RH

JMKIA2517ZZ

JMKIA2518ZZ

JMKIA2519ZZ

Page 2402 of 5121

FRONT BUMPER

EXT-13

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

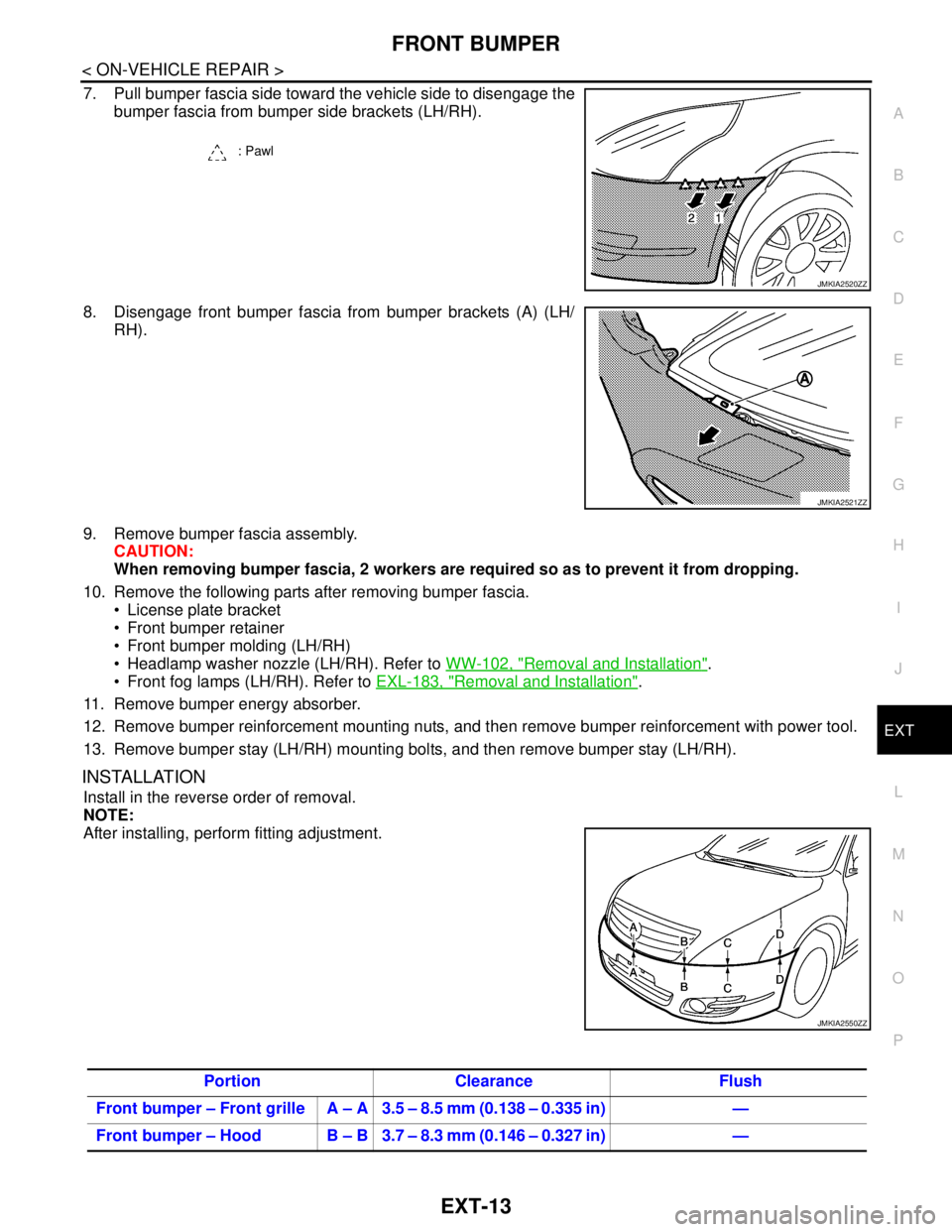

7. Pull bumper fascia side toward the vehicle side to disengage the

bumper fascia from bumper side brackets (LH/RH).

8. Disengage front bumper fascia from bumper brackets (A) (LH/

RH).

9. Remove bumper fascia assembly.

CAUTION:

When removing bumper fascia, 2 workers are required so as to prevent it from dropping.

10. Remove the following parts after removing bumper fascia.

License plate bracket

Front bumper retainer

Front bumper molding (LH/RH)

Headlamp washer nozzle (LH/RH). Refer to WW-102, "

Removal and Installation".

Front fog lamps (LH/RH). Refer to EXL-183, "

Removal and Installation".

11. Remove bumper energy absorber.

12. Remove bumper reinforcement mounting nuts, and then remove bumper reinforcement with power tool.

13. Remove bumper stay (LH/RH) mounting bolts, and then remove bumper stay (LH/RH).

INSTALLATION

Install in the reverse order of removal.

NOTE:

After installing, perform fitting adjustment.

: Pawl

JMKIA2520ZZ

JMKIA2521ZZ

JMKIA2550ZZ

Portion Clearance Flush

Front bumper – Front grille A – A 3.5 – 8.5 mm (0.138 – 0.335 in) —

Front bumper – Hood B – B 3.7 – 8.3 mm (0.146 – 0.327 in) —

Page 2498 of 5121

HOW TO USE THIS MANUAL

GI-5

< HOW TO USE THIS MANUAL >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P

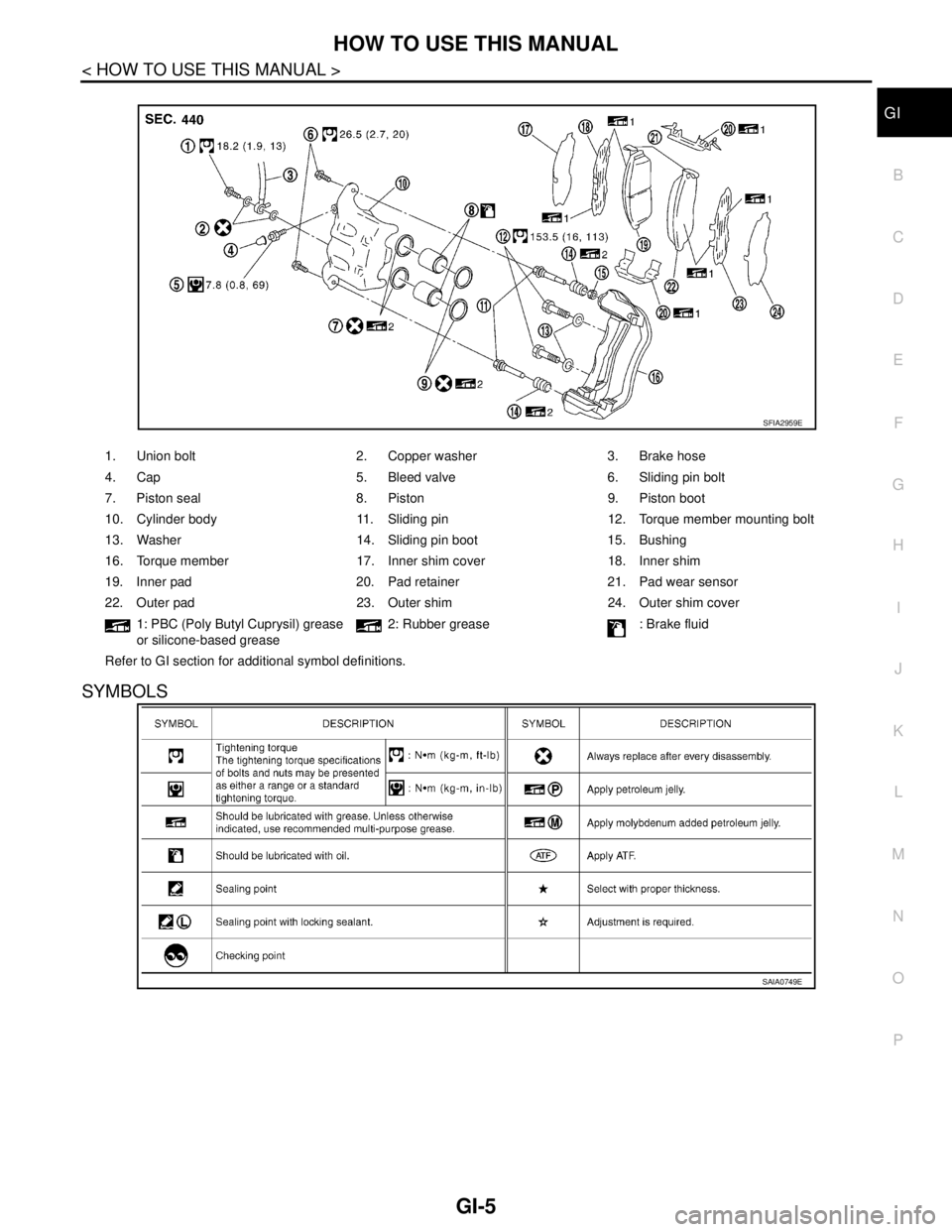

SYMBOLS

1. Union bolt 2. Copper washer 3. Brake hose

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Piston seal 8. Piston 9. Piston boot

10. Cylinder body 11. Sliding pin 12. Torque member mounting bolt

13. Washer 14. Sliding pin boot 15. Bushing

16. Torque member 17. Inner shim cover 18. Inner shim

19. Inner pad 20. Pad retainer 21. Pad wear sensor

22. Outer pad 23. Outer shim 24. Outer shim cover

1: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease2: Rubber grease : Brake fluid

Refer to GI section for additional symbol definitions.

SFIA2959E

SAIA0749E

Page 2508 of 5121

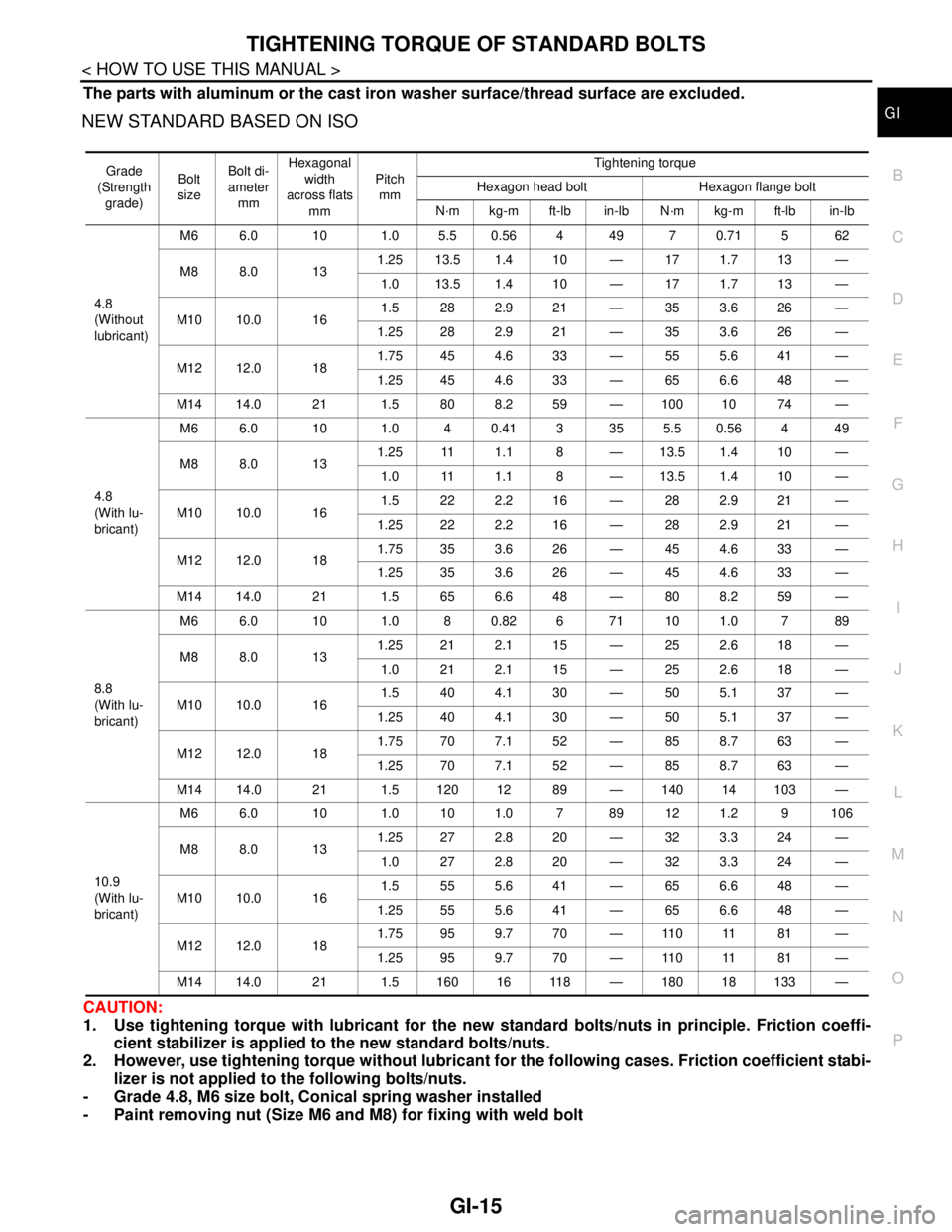

TIGHTENING TORQUE OF STANDARD BOLTS

GI-15

< HOW TO USE THIS MANUAL >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P

The parts with aluminum or the cast iron washer surface/thread surface are excluded.

NEW STANDARD BASED ON ISO

CAUTION:

1. Use tightening torque with lubricant for the new standard bolts/nuts in principle. Friction coeffi-

cient stabilizer is applied to the new standard bolts/nuts.

2. However, use tightening torque without lubricant for the following cases. Friction coefficient stabi-

lizer is not applied to the following bolts/nuts.

- Grade 4.8, M6 size bolt, Conical spring washer installed

- Paint removing nut (Size M6 and M8) for fixing with weld bolt

Grade

(Strength

grade)Bolt

sizeBolt di-

ameter

mmHexagonal

width

across flats

mmPitch

mmTightening torque

Hexagon head bolt Hexagon flange bolt

N·m kg-m ft-lb in-lb N·m kg-m ft-lb in-lb

4.8

(Without

lubricant)M6 6.0 10 1.0 5.5 0.56 4 49 7 0.71 5 62

M8 8.0 131.25 13.5 1.4 10 — 17 1.7 13 —

1.0 13.5 1.4 10 — 17 1.7 13 —

M10 10.0 161.5 282.921 — 353.626 —

1.25 28 2.9 21 — 35 3.6 26 —

M12 12.0 181.75 45 4.6 33 — 55 5.6 41 —

1.25 45 4.6 33 — 65 6.6 48 —

M14 14.0 21 1.5 80 8.2 59 — 100 10 74 —

4.8

(With lu-

bricant)M6 6.0 10 1.0 40.413 355.50.564 49

M8 8.0 131.25 11 1.1 8 — 13.5 1.4 10 —

1.0 11 1.1 8 — 13.5 1.4 10 —

M10 10.0 161.5 222.216 — 282.921 —

1.25 22 2.2 16 — 28 2.9 21 —

M12 12.0 181.75 35 3.6 26 — 45 4.6 33 —

1.25 35 3.6 26 — 45 4.6 33 —

M14 14.0 21 1.5 65 6.6 48 — 80 8.2 59 —

8.8

(With lu-

bricant)M6 6.0 10 1.0 8 0.82 6 71 10 1.0 7 89

M8 8.0 131.25 21 2.1 15 — 25 2.6 18 —

1.0 212.115 — 252.618 —

M10 10.0 161.5 404.130 — 505.137 —

1.25 40 4.1 30 — 50 5.1 37 —

M12 12.0 181.75 70 7.1 52 — 85 8.7 63 —

1.25 70 7.1 52 — 85 8.7 63 —

M14 14.0 21 1.5 120 12 89 — 140 14 103 —

10.9

(With lu-

bricant)M6 6.0 10 1.0 10 1.0 7 89 12 1.2 9 106

M8 8.0 131.25 27 2.8 20 — 32 3.3 24 —

1.0 272.820 — 323.324 —

M10 10.0 161.5 555.641 — 656.648 —

1.25 55 5.6 41 — 65 6.6 48 —

M12 12.0 181.75 95 9.7 70 — 110 11 81 —

1.25 95 9.7 70 — 110 11 81 —

M14 14.0 21 1.5 160 16 118 — 180 18 133 —

Page 2519 of 5121

GI-26

< PRECAUTION >

PRECAUTIONS

Before starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

If the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

To prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

Dispose of drained oil or the solvent used for cleaning parts in an

appropriate manner.

Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray

and possibly a fire.

Clean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

Replace inner and outer races of tapered roller bearings and needle bearings as a set.

Arrange the disassembled parts in accordance with their assembled locations and sequence.

Do not touch the terminals of electrical components which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

After disconnecting vacuum or air hoses, attach a tag to indicate the proper connection.

Use only the fluids and lubricants specified in this manual.

Use approved bonding agent, sealants or their equivalents when required.

Use hand tools, power tools (disassembly only) and recommended

special tools where specified for safe and efficient service repairs.

When repairing the fuel, oil, water, vacuum or exhaust systems,

check all affected lines for leaks.

Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

SEF289H

SGI233

PBIC0190E

SGI234