NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1541 of 1767

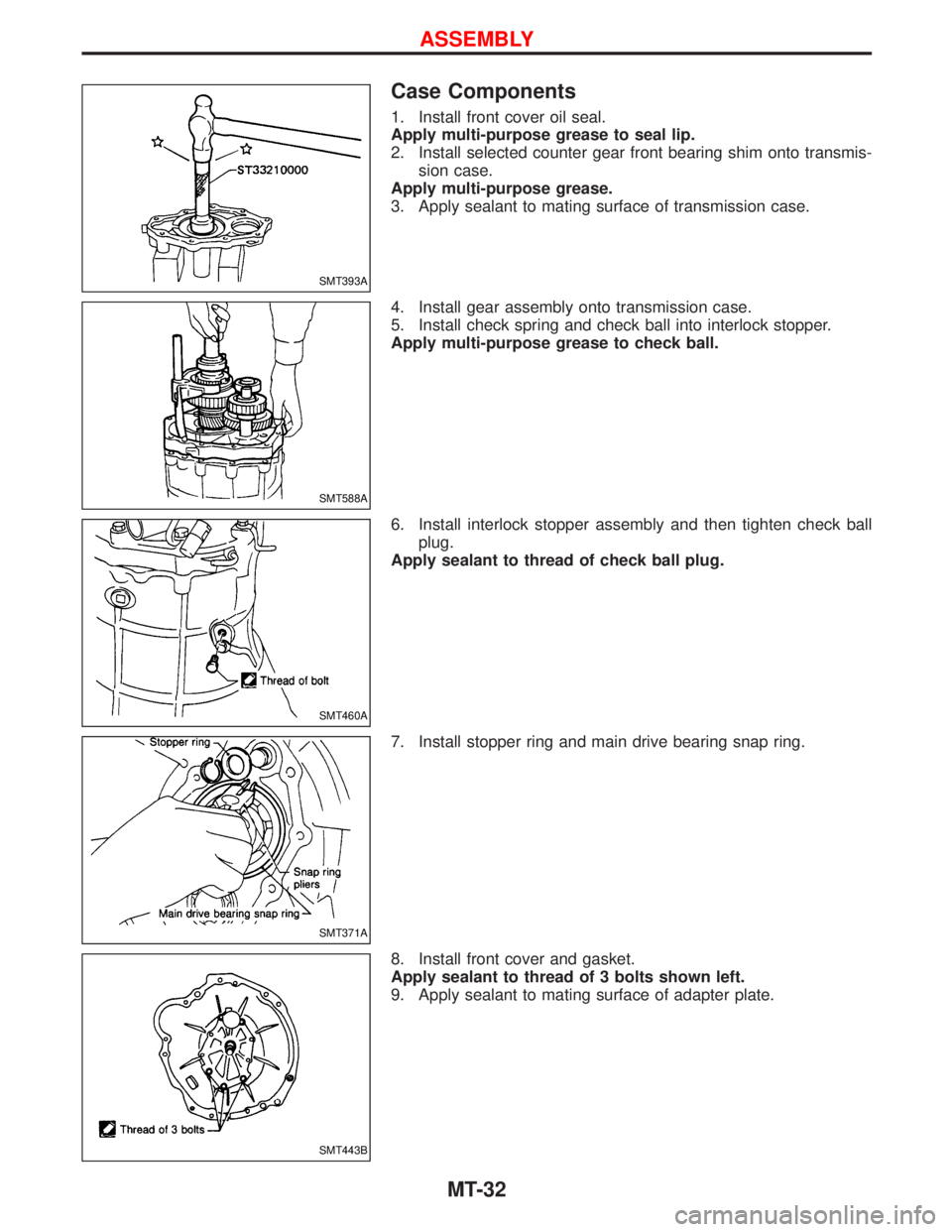

Case Components

1. Install front cover oil seal.

Apply multi-purpose grease to seal lip.

2. Install selected counter gear front bearing shim onto transmis-

sion case.

Apply multi-purpose grease.

3. Apply sealant to mating surface of transmission case.

4. Install gear assembly onto transmission case.

5. Install check spring and check ball into interlock stopper.

Apply multi-purpose grease to check ball.

6. Install interlock stopper assembly and then tighten check ball

plug.

Apply sealant to thread of check ball plug.

7. Install stopper ring and main drive bearing snap ring.

8. Install front cover and gasket.

Apply sealant to thread of 3 bolts shown left.

9. Apply sealant to mating surface of adapter plate.

SMT393A

SMT588A

SMT460A

SMT371A

SMT443B

ASSEMBLY

MT-32

Page 1542 of 1767

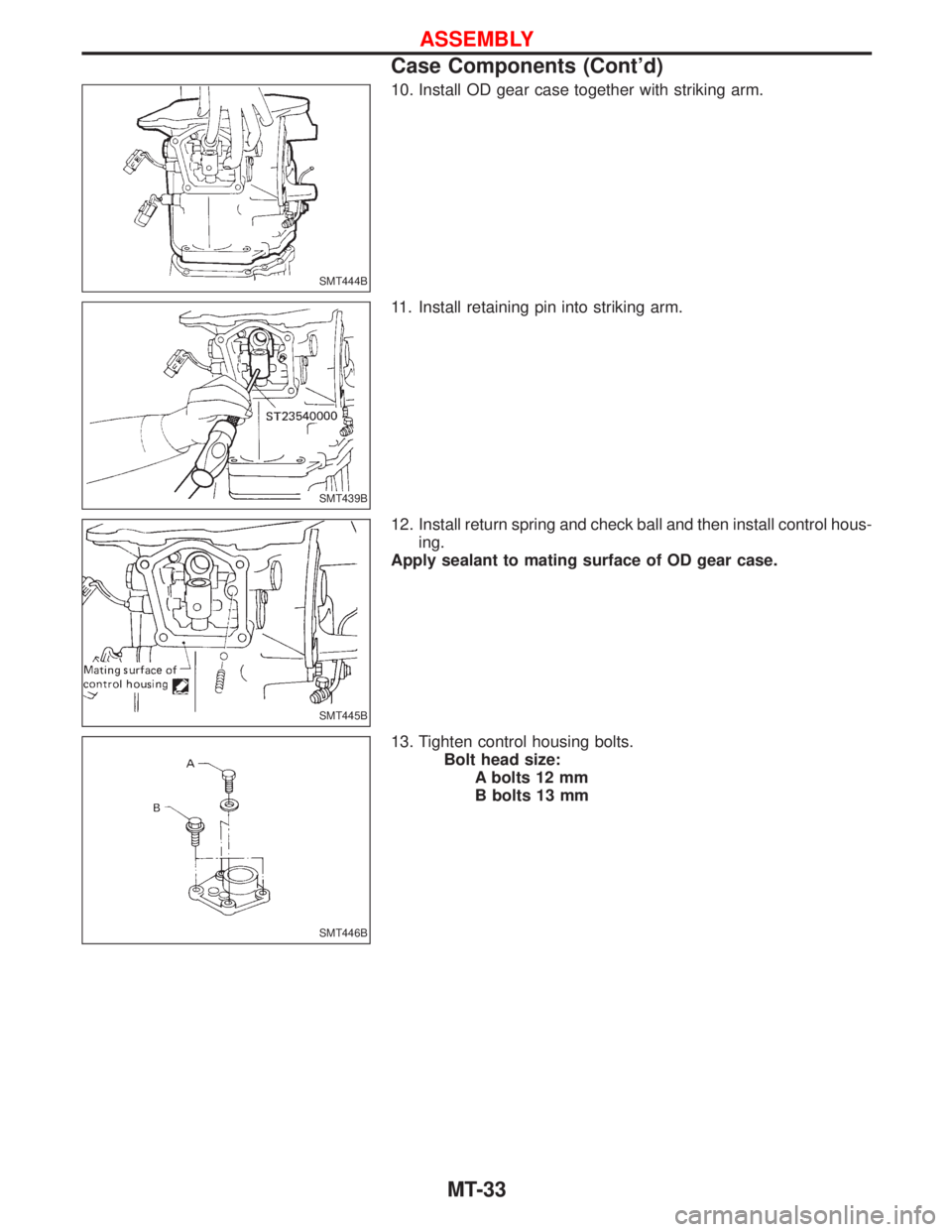

10. Install OD gear case together with striking arm.

11. Install retaining pin into striking arm.

12. Install return spring and check ball and then install control hous-

ing.

Apply sealant to mating surface of OD gear case.

13. Tighten control housing bolts.

Bolt head size:

A bolts 12 mm

B bolts 13 mm

SMT444B

SMT439B

SMT445B

SMT446B

ASSEMBLY

Case Components (Cont'd)

MT-33

Page 1543 of 1767

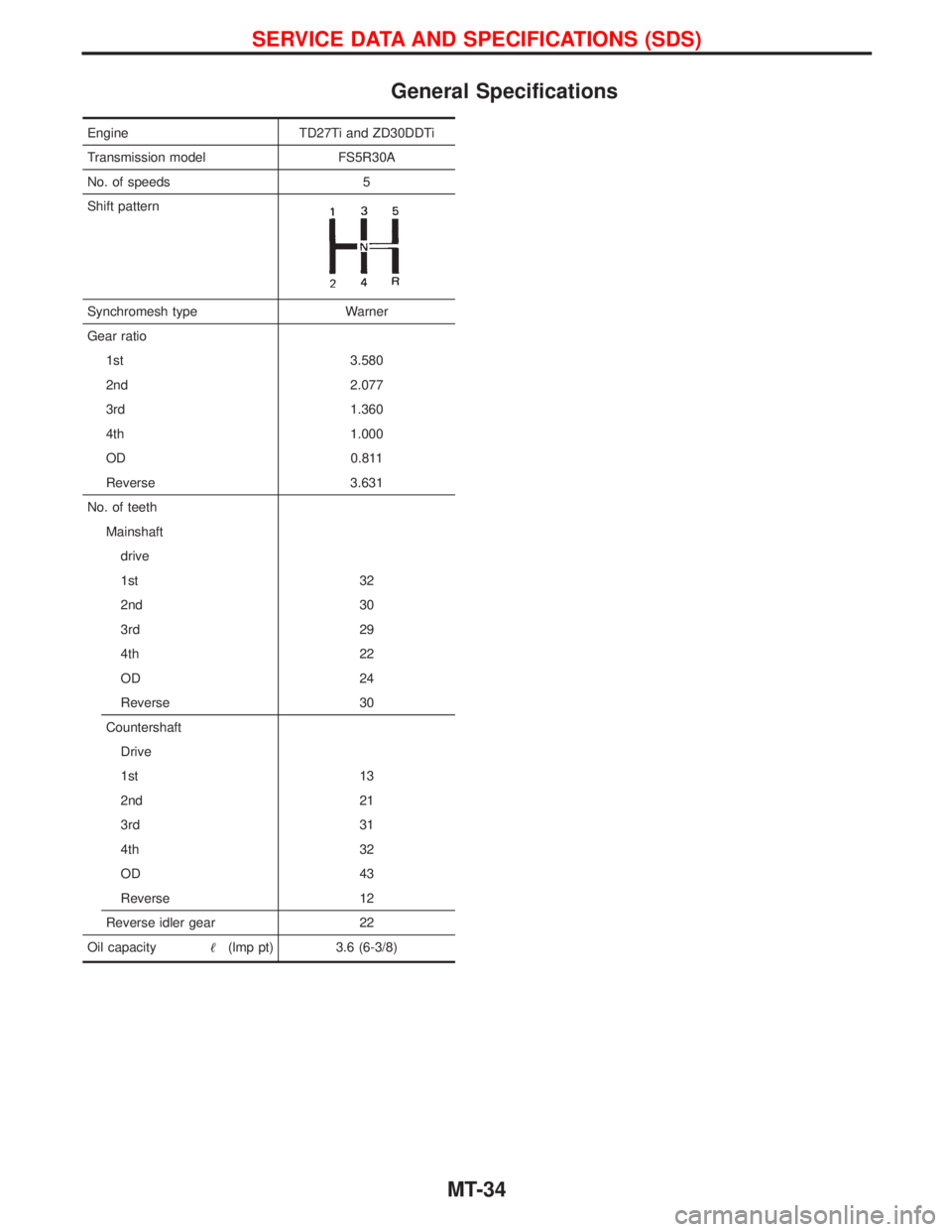

General Specifications

Engine TD27Ti and ZD30DDTi

Transmission model FS5R30A

No. of speeds 5

Shift pattern

Synchromesh type Warner

Gear ratio

1st 3.580

2nd 2.077

3rd 1.360

4th 1.000

OD 0.811

Reverse 3.631

No. of teeth

Mainshaft

drive

1st 32

2nd 30

3rd 29

4th 22

OD 24

Reverse 30

Countershaft

Drive

1st 13

2nd 21

3rd 31

4th 32

OD 43

Reverse 12

Reverse idler gear 22

Oil capacity(lmp pt) 3.6 (6-3/8)

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-34

Page 1544 of 1767

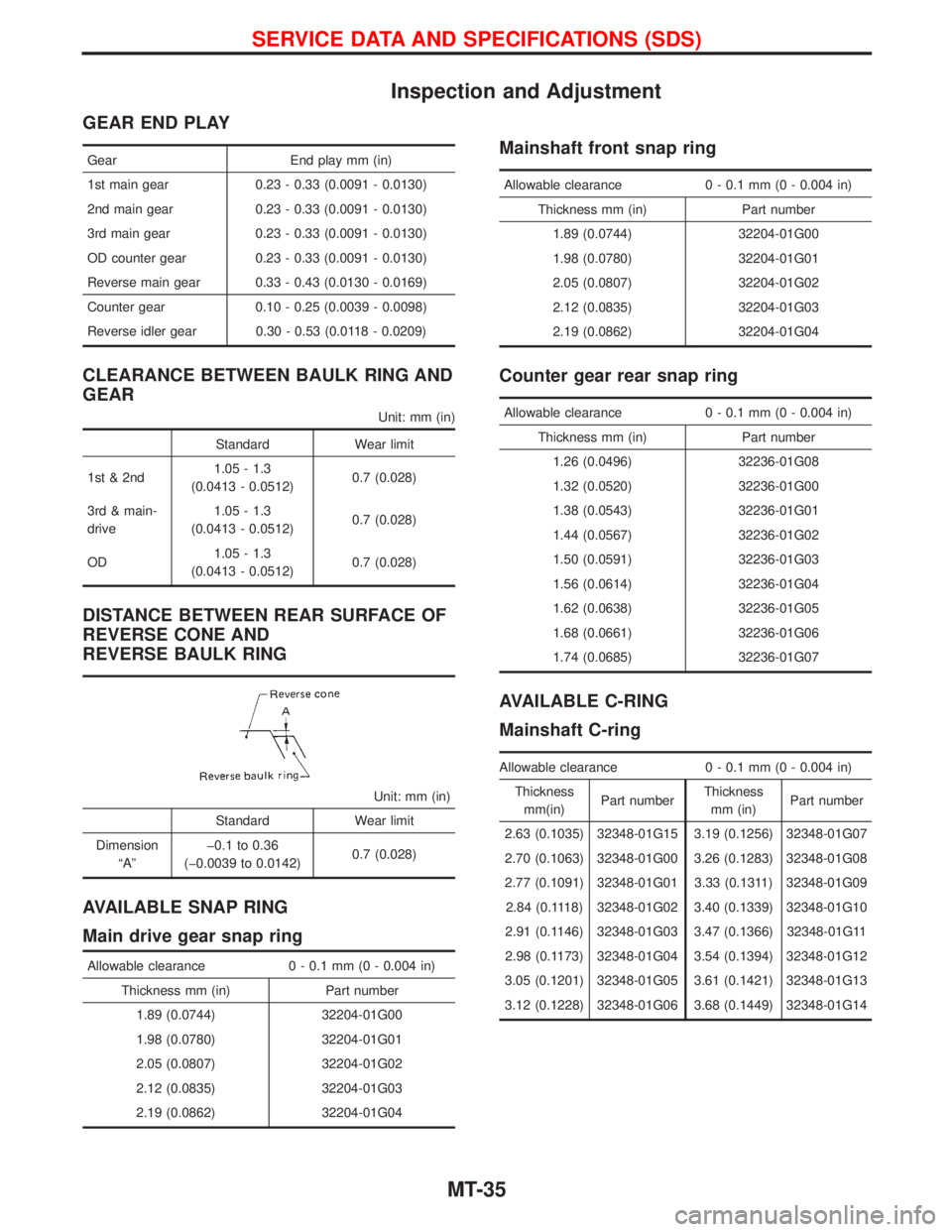

Inspection and Adjustment

GEAR END PLAY

Gear End play mm (in)

1st main gear 0.23 - 0.33 (0.0091 - 0.0130)

2nd main gear 0.23 - 0.33 (0.0091 - 0.0130)

3rd main gear 0.23 - 0.33 (0.0091 - 0.0130)

OD counter gear 0.23 - 0.33 (0.0091 - 0.0130)

Reverse main gear 0.33 - 0.43 (0.0130 - 0.0169)

Counter gear 0.10 - 0.25 (0.0039 - 0.0098)

Reverse idler gear 0.30 - 0.53 (0.0118 - 0.0209)

CLEARANCE BETWEEN BAULK RING AND

GEAR

Unit: mm (in)

Standard Wear limit

1st & 2nd1.05 - 1.3

(0.0413 - 0.0512)0.7 (0.028)

3rd & main-

drive1.05 - 1.3

(0.0413 - 0.0512)0.7 (0.028)

OD1.05 - 1.3

(0.0413 - 0.0512)0.7 (0.028)

DISTANCE BETWEEN REAR SURFACE OF

REVERSE CONE AND

REVERSE BAULK RING

Unit: mm (in)

Standard Wear limit

Dimension

ªAºþ0.1 to 0.36

(þ0.0039 to 0.0142)0.7 (0.028)

AVAILABLE SNAP RING

Main drive gear snap ring

Allowable clearance 0 - 0.1 mm (0 - 0.004 in)

Thickness mm (in) Part number

1.89 (0.0744) 32204-01G00

1.98 (0.0780) 32204-01G01

2.05 (0.0807) 32204-01G02

2.12 (0.0835) 32204-01G03

2.19 (0.0862) 32204-01G04

Mainshaft front snap ring

Allowable clearance 0 - 0.1 mm (0 - 0.004 in)

Thickness mm (in) Part number

1.89 (0.0744) 32204-01G00

1.98 (0.0780) 32204-01G01

2.05 (0.0807) 32204-01G02

2.12 (0.0835) 32204-01G03

2.19 (0.0862) 32204-01G04

Counter gear rear snap ring

Allowable clearance 0 - 0.1 mm (0 - 0.004 in)

Thickness mm (in) Part number

1.26 (0.0496) 32236-01G08

1.32 (0.0520) 32236-01G00

1.38 (0.0543) 32236-01G01

1.44 (0.0567) 32236-01G02

1.50 (0.0591) 32236-01G03

1.56 (0.0614) 32236-01G04

1.62 (0.0638) 32236-01G05

1.68 (0.0661) 32236-01G06

1.74 (0.0685) 32236-01G07

AVAILABLE C-RING

Mainshaft C-ring

Allowable clearance 0 - 0.1 mm (0 - 0.004 in)

Thickness

mm(in)Part numberThickness

mm (in)Part number

2.63 (0.1035) 32348-01G15 3.19 (0.1256) 32348-01G07

2.70 (0.1063) 32348-01G00 3.26 (0.1283) 32348-01G08

2.77 (0.1091) 32348-01G01 3.33 (0.1311) 32348-01G09

2.84 (0.1118) 32348-01G02 3.40 (0.1339) 32348-01G10

2.91 (0.1146) 32348-01G03 3.47 (0.1366) 32348-01G11

2.98 (0.1173) 32348-01G04 3.54 (0.1394) 32348-01G12

3.05 (0.1201) 32348-01G05 3.61 (0.1421) 32348-01G13

3.12 (0.1228) 32348-01G06 3.68 (0.1449) 32348-01G14

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-35

Page 1545 of 1767

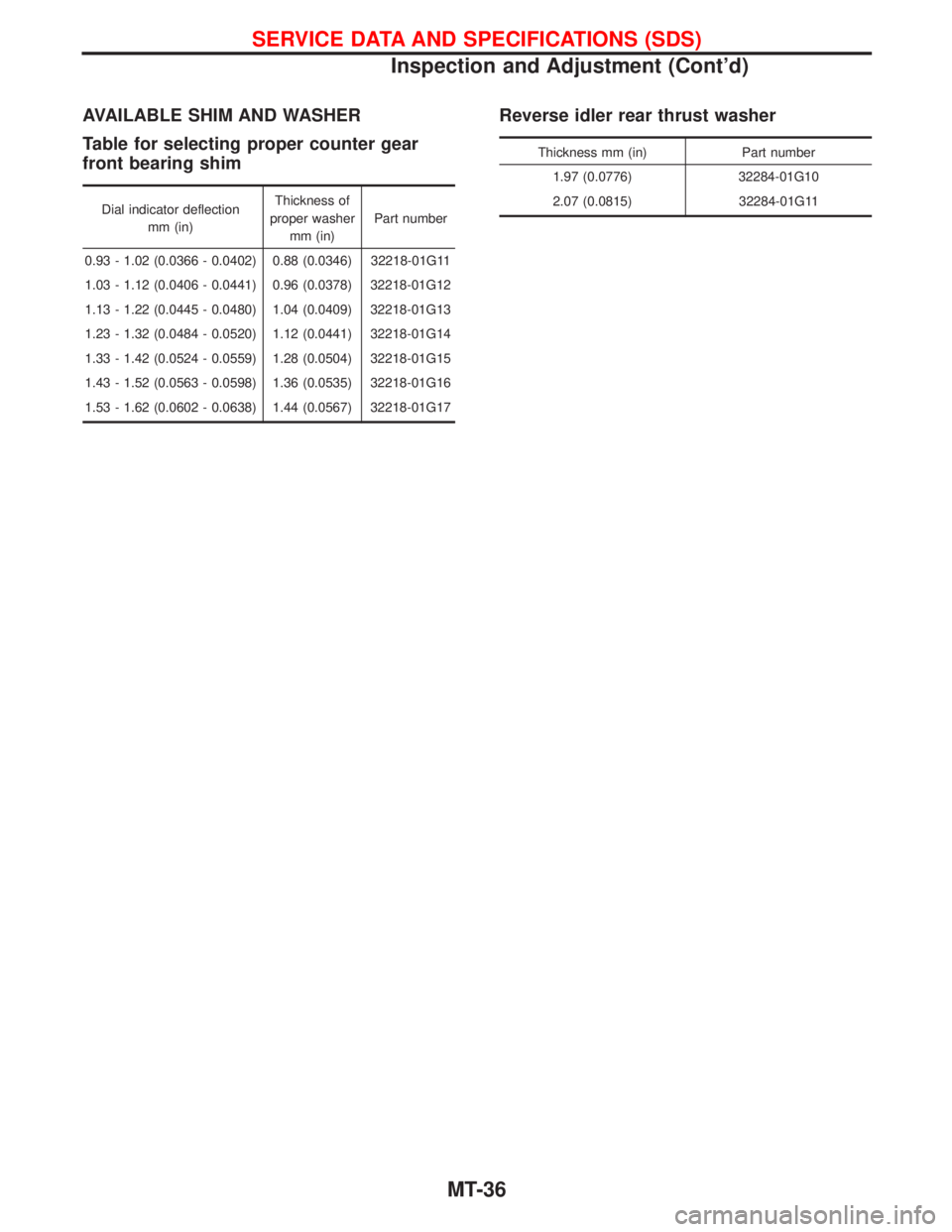

AVAILABLE SHIM AND WASHER

Table for selecting proper counter gear

front bearing shim

Dial indicator deflection

mm (in)Thickness of

proper washer

mm (in)Part number

0.93 - 1.02 (0.0366 - 0.0402) 0.88 (0.0346) 32218-01G11

1.03 - 1.12 (0.0406 - 0.0441) 0.96 (0.0378) 32218-01G12

1.13 - 1.22 (0.0445 - 0.0480) 1.04 (0.0409) 32218-01G13

1.23 - 1.32 (0.0484 - 0.0520) 1.12 (0.0441) 32218-01G14

1.33 - 1.42 (0.0524 - 0.0559) 1.28 (0.0504) 32218-01G15

1.43 - 1.52 (0.0563 - 0.0598) 1.36 (0.0535) 32218-01G16

1.53 - 1.62 (0.0602 - 0.0638) 1.44 (0.0567) 32218-01G17

Reverse idler rear thrust washer

Thickness mm (in) Part number

1.97 (0.0776) 32284-01G10

2.07 (0.0815) 32284-01G11

SERVICE DATA AND SPECIFICATIONS (SDS)

Inspection and Adjustment (Cont'd)

MT-36

Page 1546 of 1767

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

CONTENTS

PREPARATION................................................................2

PROPELLER SHAFT......................................................5

On-Vehicle Service ......................................................6

Removal and Installation .............................................7

Inspection.....................................................................7

Disassembly.................................................................7

Assembly .....................................................................8

ON-VEHICLE SERVICE................................................10

Front Oil Seal Replacement

(Front final drive: R180A) ..........................................10

Front Oil Seal Replacement

(Rear final drive: H233B) ...........................................10

REMOVAL AND INSTALLATION (Front final drive

- R180A).........................................................................12

Removal .....................................................................12

Installation ..................................................................12

REMOVAL AND INSTALLATION (Rear final drive

- H233B).........................................................................13

Removal .....................................................................13

Installation ..................................................................13

FRONT FINAL DRIVE (R180A)....................................14

DISASSEMBLY (R180A)...............................................15

Pre-inspection ............................................................15

Final Drive Housing ...................................................15

Differential Case ........................................................18

Extension Tube and Differential Side Shaft ..............19

INSPECTION (R180A)...................................................20

Ring Gear and Drive Pinion ......................................20

Differential Case Assembly........................................20

Bearing.......................................................................20

ADJUSTMENT (R180A)................................................21

Drive Pinion Height ....................................................21Side Bearing Preload.................................................24

Tooth Contact.............................................................27

ASSEMBLY (R180A).....................................................28

Extension Tube and Differential Side Shaft ..............28

Differential Case ........................................................29

Final Drive Housing ...................................................30

REAR FINAL DRIVE (H233B).......................................35

Air Breather................................................................36

DISASSEMBLY (H233B)...............................................37

Pre-inspection ............................................................37

Differential Carrier......................................................38

Differential Case ........................................................40

INSPECTION (H233B)...................................................42

Ring Gear and Drive Pinion ......................................42

Differential Case Assembly........................................42

Bearing.......................................................................42

LIMITED SLIP DIFFERENTIAL (H233B)......................43

Preparation for Disassembly .....................................43

Disassembly...............................................................44

Inspection...................................................................44

Adjustment .................................................................45

Assembly ...................................................................47

ADJUSTMENT (H233B)................................................49

Drive Pinion Height ....................................................49

Tooth Contact.............................................................52

ASSEMBLY (H233B).....................................................53

Differential Carrier......................................................53

SERVICE DATA AND SPECIFICATIONS (SDS)..........57

Propeller Shaft ...........................................................57

Final Drive..................................................................58

Page 1547 of 1767

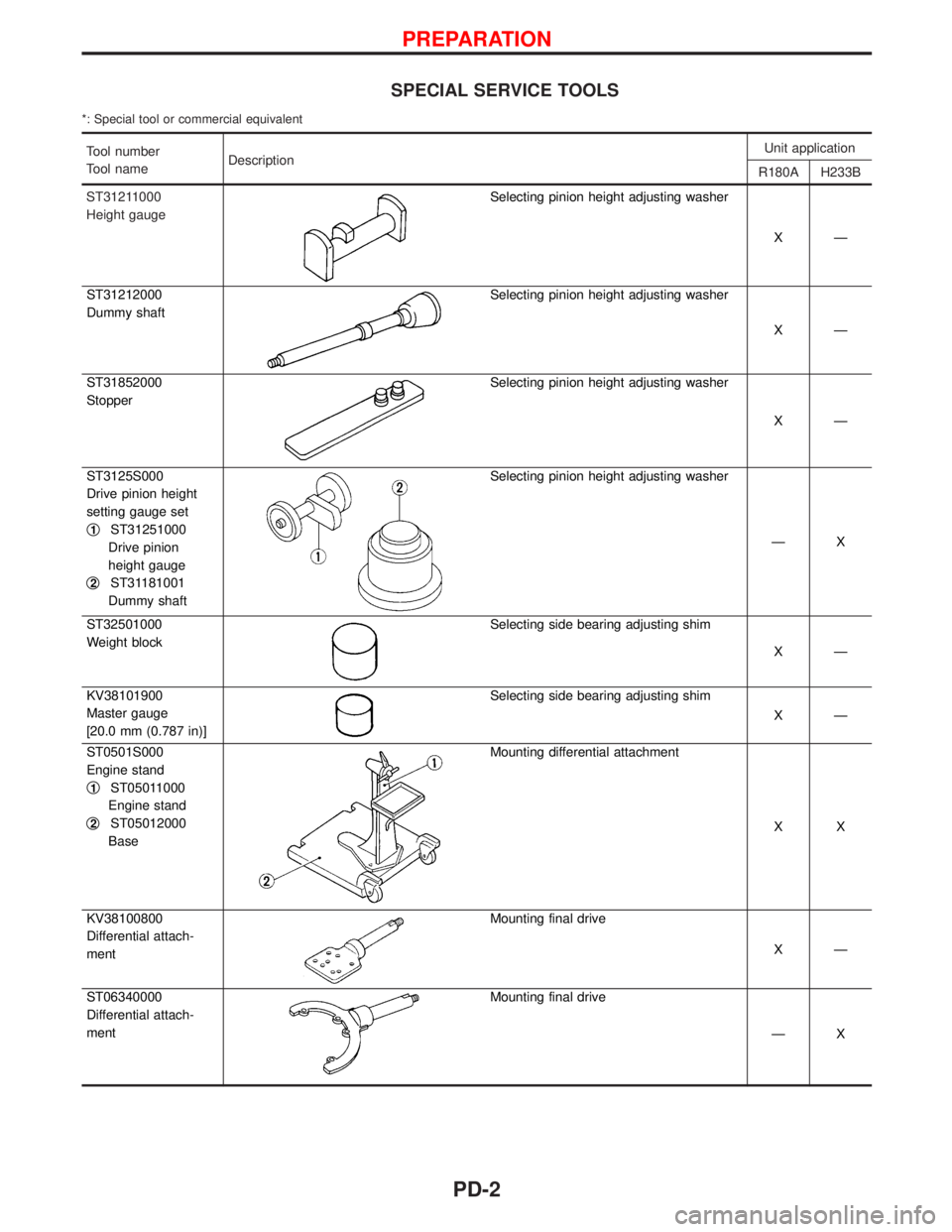

SPECIAL SERVICE TOOLS

*: Special tool or commercial equivalent

Tool number

Tool nameDescriptionUnit application

R180A H233B

ST31211000

Height gauge

Selecting pinion height adjusting washer

XÐ

ST31212000

Dummy shaft

Selecting pinion height adjusting washer

XÐ

ST31852000

Stopper

Selecting pinion height adjusting washer

XÐ

ST3125S000

Drive pinion height

setting gauge set

q

1ST31251000

Drive pinion

height gauge

q

2ST31181001

Dummy shaft

Selecting pinion height adjusting washer

ÐX

ST32501000

Weight block

Selecting side bearing adjusting shim

XÐ

KV38101900

Master gauge

[20.0 mm (0.787 in)]

Selecting side bearing adjusting shim

XÐ

ST0501S000

Engine stand

q

1ST05011000

Engine stand

q

2ST05012000

Base

Mounting differential attachment

XX

KV38100800

Differential attach-

ment

Mounting final drive

XÐ

ST06340000

Differential attach-

ment

Mounting final drive

ÐX

PREPARATION

PD-2

Page 1548 of 1767

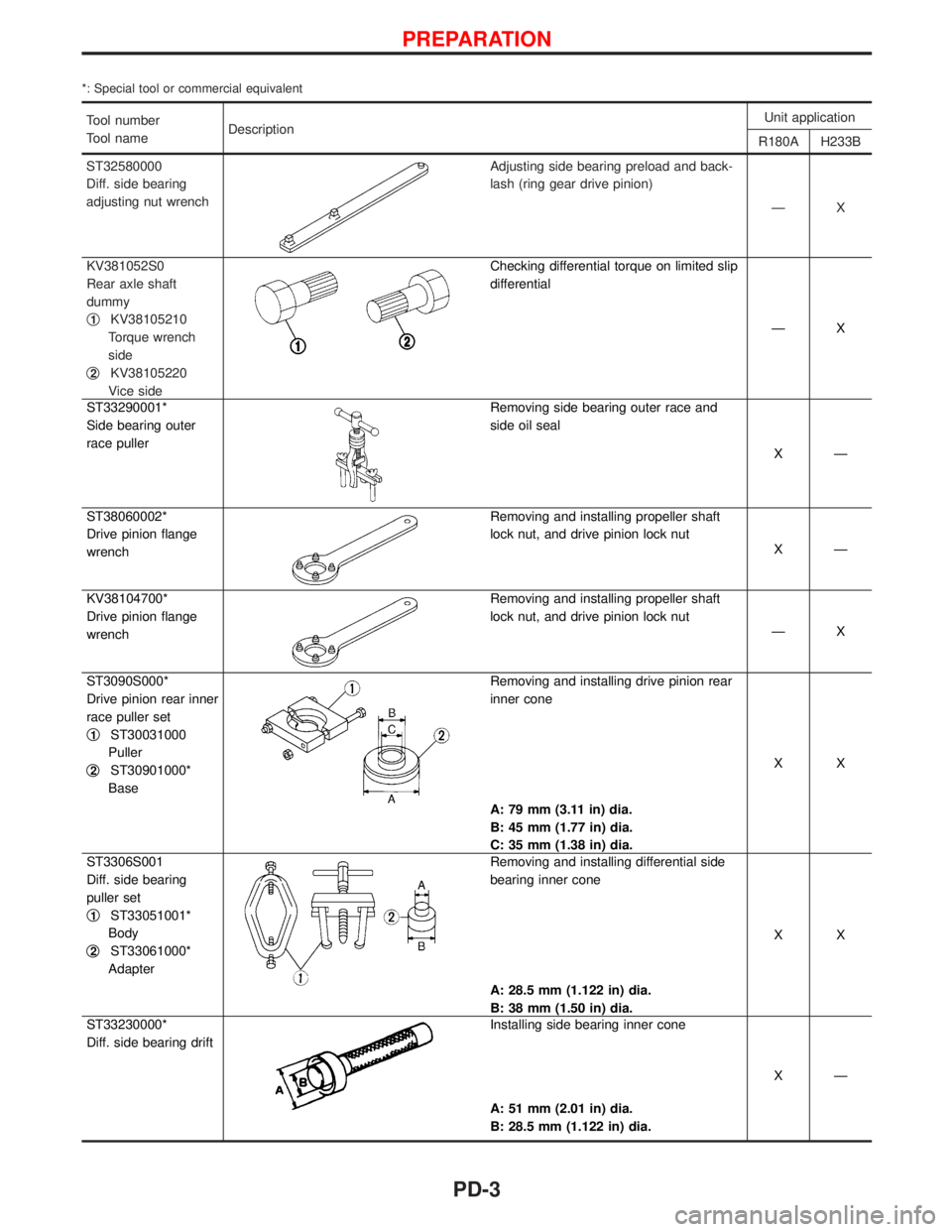

*: Special tool or commercial equivalent

Tool number

Tool nameDescriptionUnit application

R180A H233B

ST32580000

Diff. side bearing

adjusting nut wrench

Adjusting side bearing preload and back-

lash (ring gear drive pinion)

ÐX

KV381052S0

Rear axle shaft

dummy

q

1KV38105210

Torque wrench

side

q

2KV38105220

Vice side

Checking differential torque on limited slip

differential

ÐX

ST33290001*

Side bearing outer

race puller

Removing side bearing outer race and

side oil seal

XÐ

ST38060002*

Drive pinion flange

wrench

Removing and installing propeller shaft

lock nut, and drive pinion lock nut

XÐ

KV38104700*

Drive pinion flange

wrench

Removing and installing propeller shaft

lock nut, and drive pinion lock nut

ÐX

ST3090S000*

Drive pinion rear inner

race puller set

q

1ST30031000

Puller

q

2ST30901000*

Base

Removing and installing drive pinion rear

inner cone

A: 79 mm (3.11 in) dia.

B: 45 mm (1.77 in) dia.

C: 35 mm (1.38 in) dia.XX

ST3306S001

Diff. side bearing

puller set

q

1ST33051001*

Body

q

2ST33061000*

Adapter

Removing and installing differential side

bearing inner cone

A: 28.5 mm (1.122 in) dia.

B: 38 mm (1.50 in) dia.XX

ST33230000*

Diff. side bearing drift

Installing side bearing inner cone

A: 51 mm (2.01 in) dia.

B: 28.5 mm (1.122 in) dia.XÐ

PREPARATION

PD-3

Page 1549 of 1767

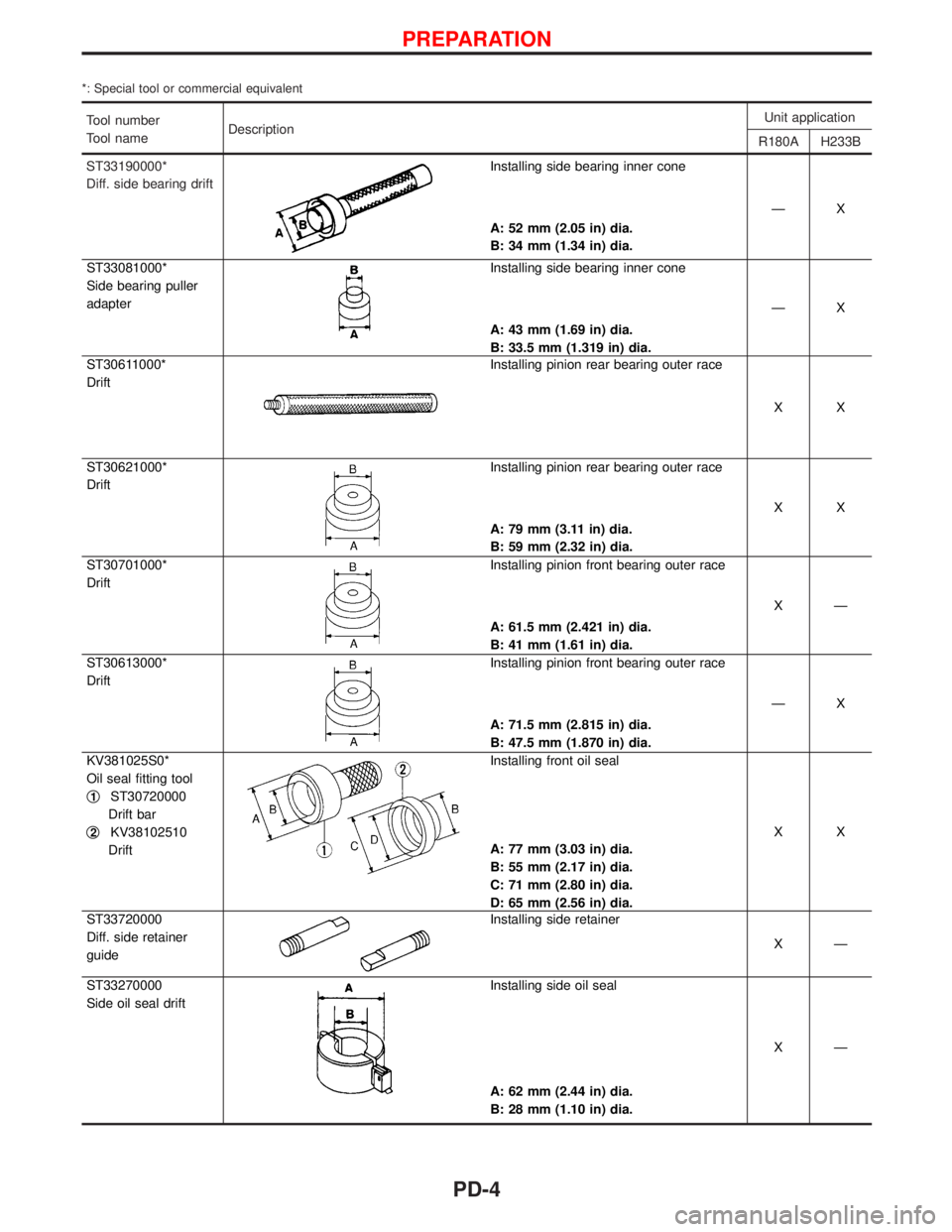

*: Special tool or commercial equivalent

Tool number

Tool nameDescriptionUnit application

R180A H233B

ST33190000*

Diff. side bearing drift

Installing side bearing inner cone

A: 52 mm (2.05 in) dia.

B: 34 mm (1.34 in) dia.ÐX

ST33081000*

Side bearing puller

adapter

Installing side bearing inner cone

A: 43 mm (1.69 in) dia.

B: 33.5 mm (1.319 in) dia.ÐX

ST30611000*

Drift

Installing pinion rear bearing outer race

XX

ST30621000*

Drift

Installing pinion rear bearing outer race

A: 79 mm (3.11 in) dia.

B: 59 mm (2.32 in) dia.XX

ST30701000*

Drift

Installing pinion front bearing outer race

A: 61.5 mm (2.421 in) dia.

B: 41 mm (1.61 in) dia.XÐ

ST30613000*

Drift

Installing pinion front bearing outer race

A: 71.5 mm (2.815 in) dia.

B: 47.5 mm (1.870 in) dia.ÐX

KV381025S0*

Oil seal fitting tool

q

1ST30720000

Drift bar

q

2KV38102510

Drift

Installing front oil seal

A: 77 mm (3.03 in) dia.

B: 55 mm (2.17 in) dia.

C: 71 mm (2.80 in) dia.

D: 65 mm (2.56 in) dia.XX

ST33720000

Diff. side retainer

guide

Installing side retainer

XÐ

ST33270000

Side oil seal drift

Installing side oil seal

A: 62 mm (2.44 in) dia.

B: 28 mm (1.10 in) dia.XÐ

PREPARATION

PD-4

Page 1550 of 1767

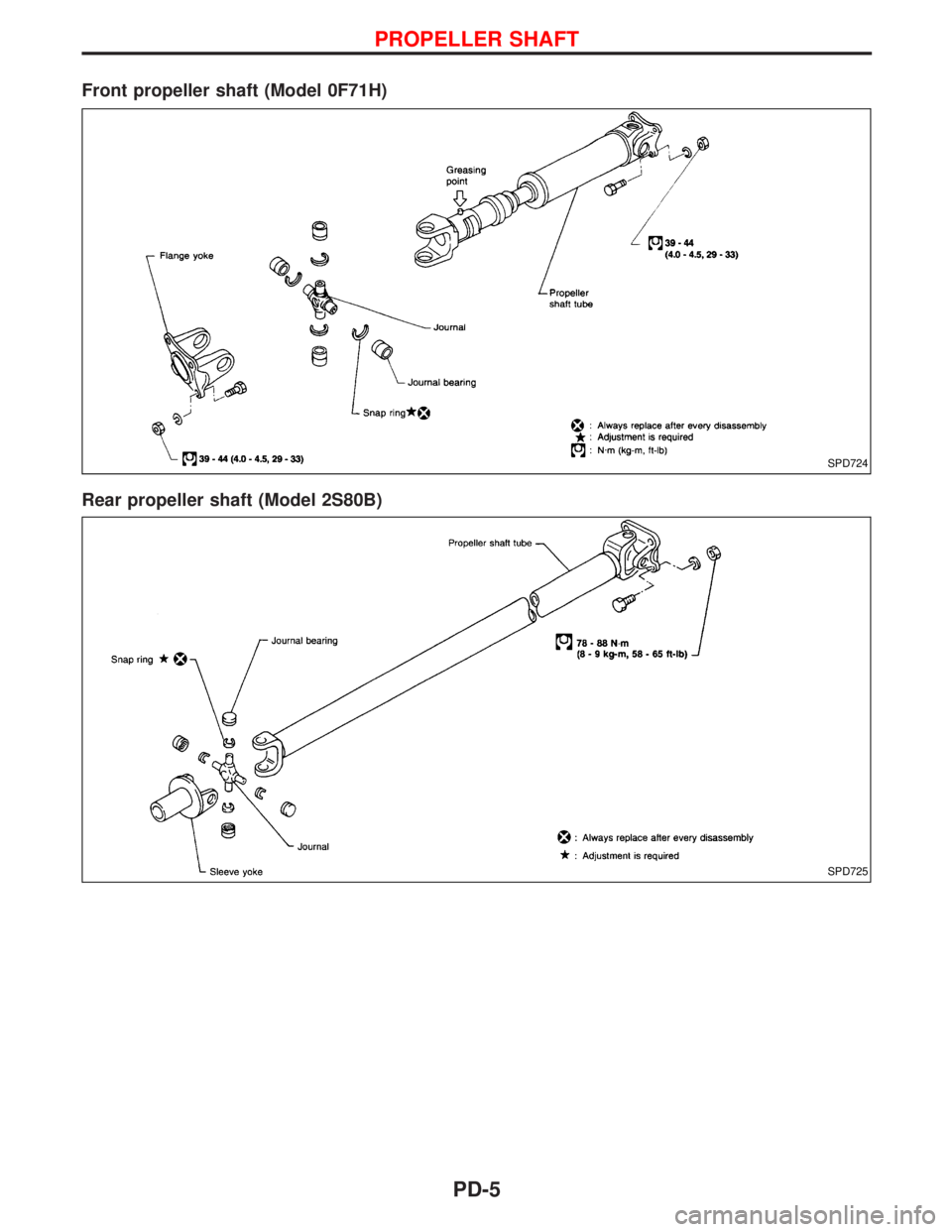

Front propeller shaft (Model 0F71H)

Rear propeller shaft (Model 2S80B)

SPD724

SPD725

PROPELLER SHAFT

PD-5