NISSAN TERRANO 2004 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 1141 of 1833

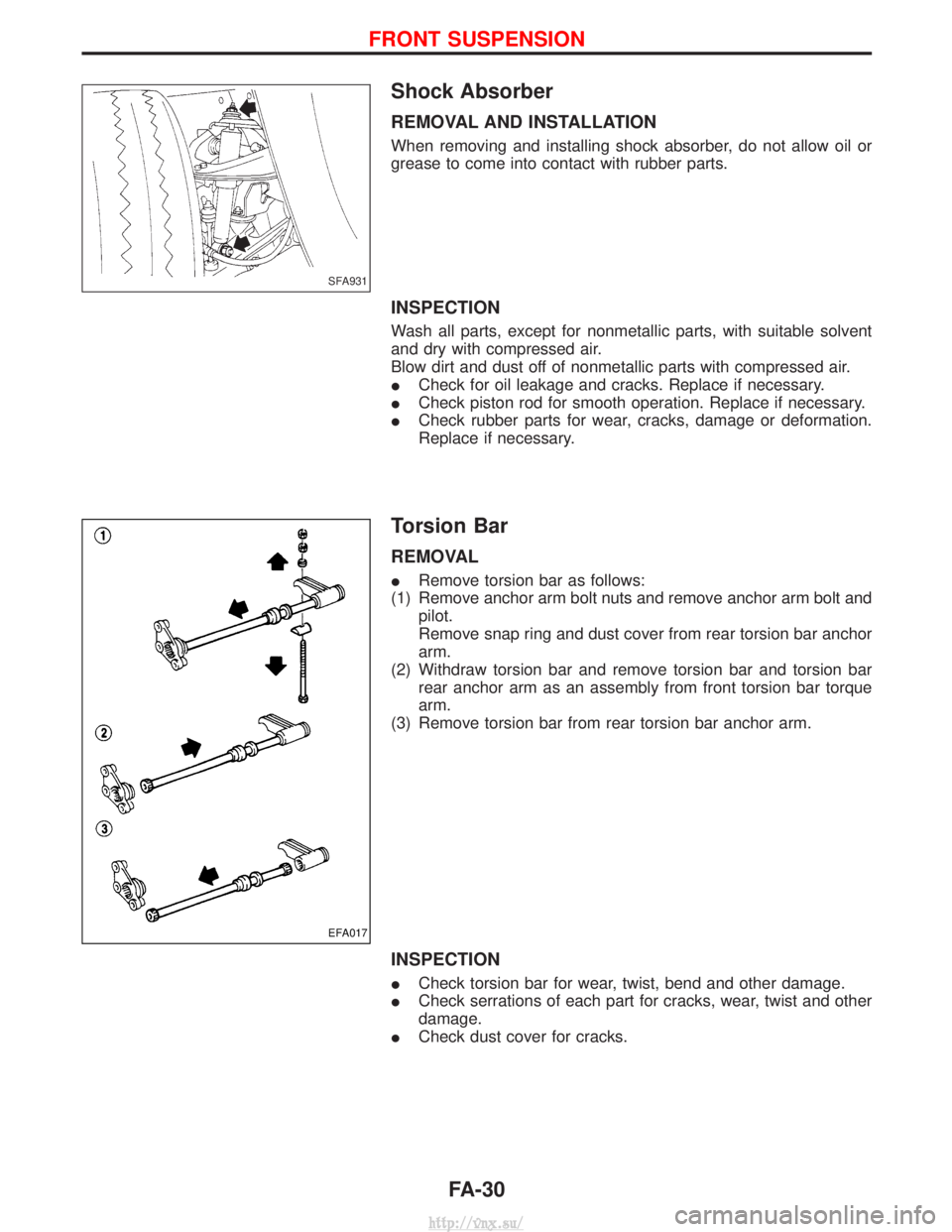

Shock Absorber

REMOVAL AND INSTALLATION

When removing and installing shock absorber, do not allow oil or

grease to come into contact with rubber parts.

INSPECTION

Wash all parts, except for nonmetallic parts, with suitable solvent

and dry with compressed air.

Blow dirt and dust off of nonmetallic parts with compressed air.

ICheck for oil leakage and cracks. Replace if necessary.

I Check piston rod for smooth operation. Replace if necessary.

I Check rubber parts for wear, cracks, damage or deformation.

Replace if necessary.

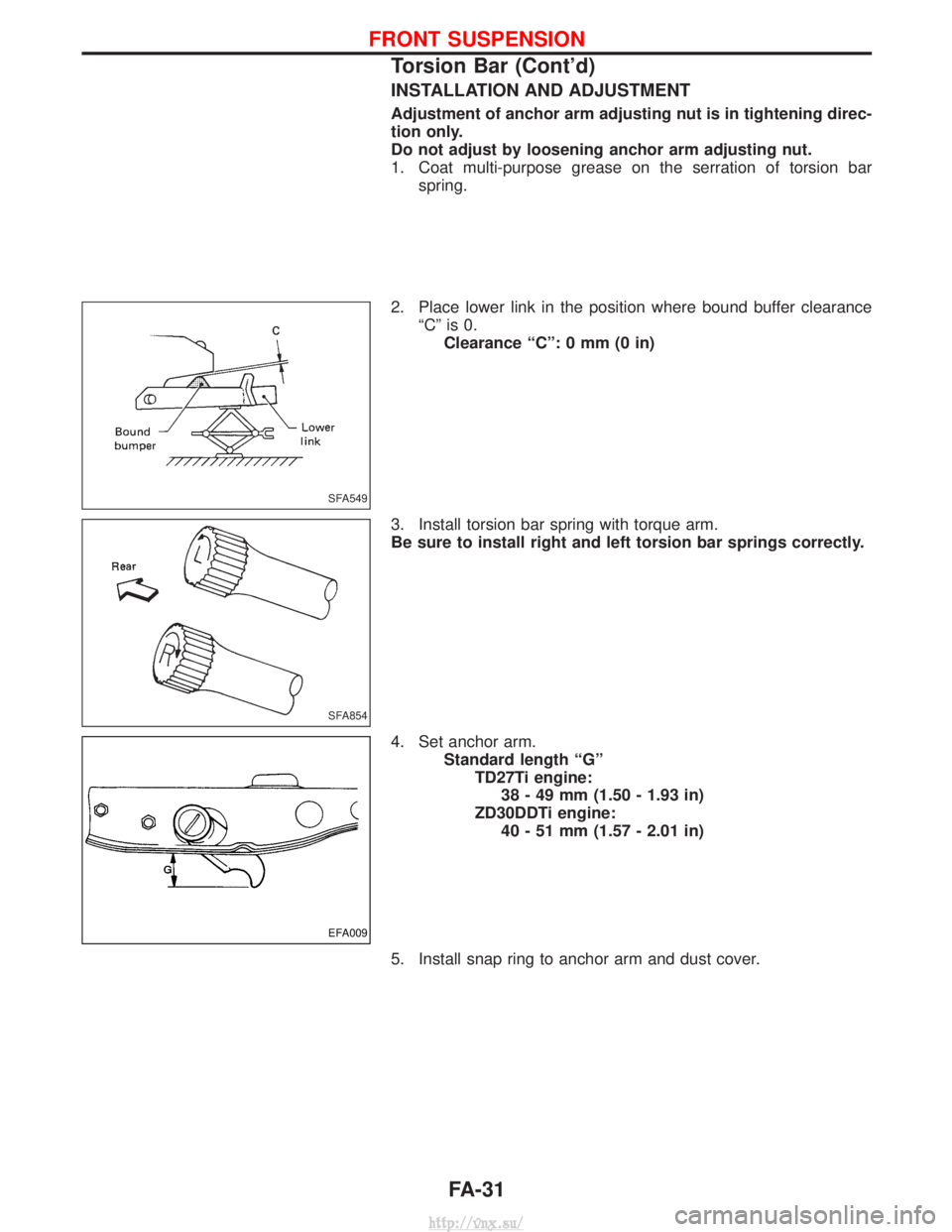

Torsion Bar

REMOVAL

IRemove torsion bar as follows:

(1) Remove anchor arm bolt nuts and remove anchor arm bolt and pilot.

Remove snap ring and dust cover from rear torsion bar anchor

arm.

(2) Withdraw torsion bar and remove torsion bar and torsion bar rear anchor arm as an assembly from front torsion bar torque

arm.

(3) Remove torsion bar from rear torsion bar anchor arm.

INSPECTION

I Check torsion bar for wear, twist, bend and other damage.

I Check serrations of each part for cracks, wear, twist and other

damage.

I Check dust cover for cracks.

SFA931

EFA017

FRONT SUSPENSION

FA-30

http://vnx.su/

Page 1142 of 1833

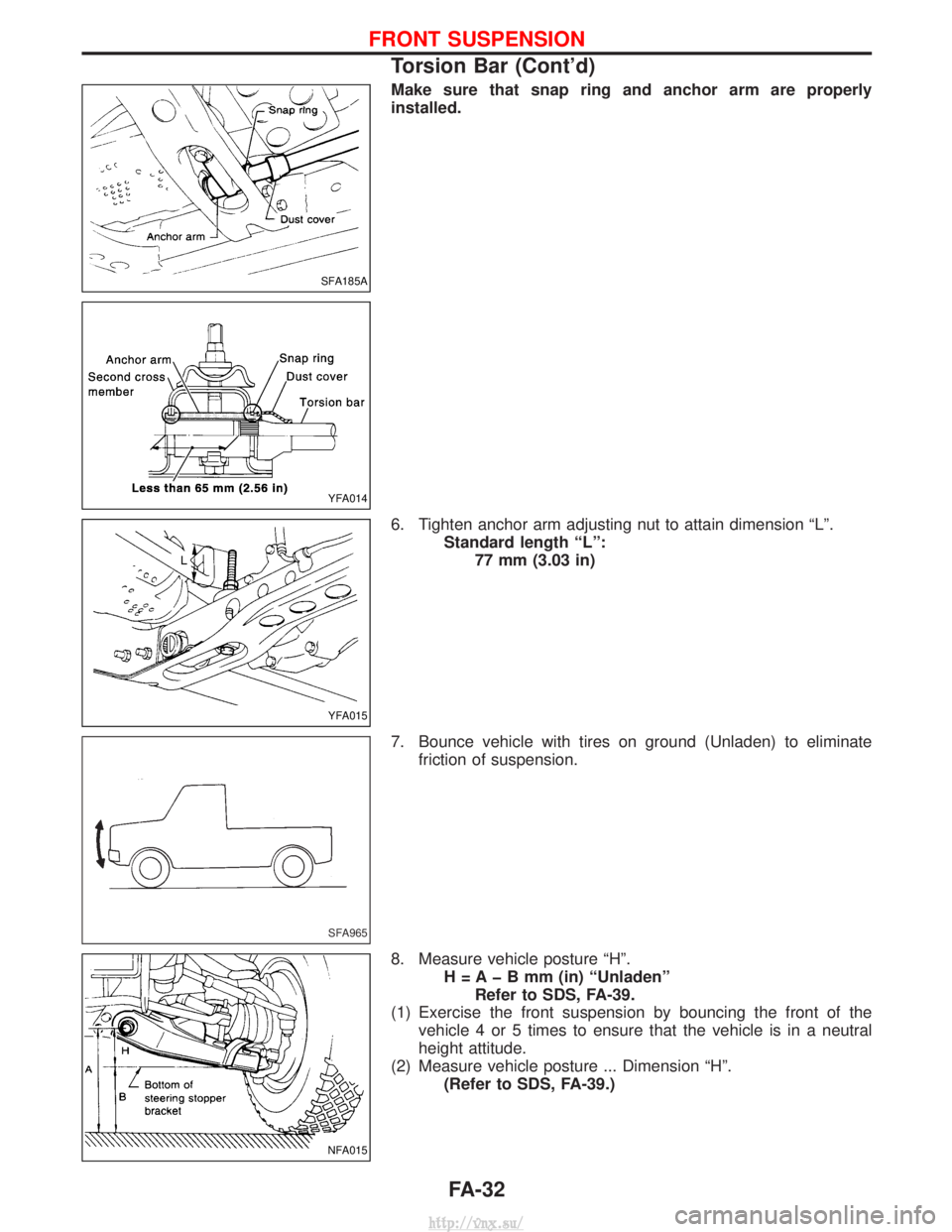

INSTALLATION AND ADJUSTMENT

Adjustment of anchor arm adjusting nut is in tightening direc-

tion only.

Do not adjust by loosening anchor arm adjusting nut.

1. Coat multi-purpose grease on the serration of torsion barspring.

2. Place lower link in the position where bound buffer clearance ªCº is 0.Clearance ªCº: 0 mm (0 in)

3. Install torsion bar spring with torque arm.

Be sure to install right and left torsion bar springs correctly.

4. Set anchor arm. Standard length ªGºTD27Ti engine:38 - 49 mm (1.50 - 1.93 in)

ZD30DDTi engine: 40 - 51 mm (1.57 - 2.01 in)

5. Install snap ring to anchor arm and dust cover.

SFA549

SFA854

EFA009

FRONT SUSPENSION

Torsion Bar (Cont'd)

FA-31

http://vnx.su/

Page 1143 of 1833

Make sure that snap ring and anchor arm are properly

installed.

6. Tighten anchor arm adjusting nut to attain dimension ªLº.Standard length ªLº:77 mm (3.03 in)

7. Bounce vehicle with tires on ground (Unladen) to eliminate friction of suspension.

8. Measure vehicle posture ªHº. H = A þ B mm (in) ªUnladenºRefer to SDS, FA-39.

(1) Exercise the front suspension by bouncing the front of the vehicle 4 or 5 times to ensure that the vehicle is in a neutral

height attitude.

(2) Measure vehicle posture ... Dimension ªHº. (Refer to SDS, FA-39.)

SFA185A

YFA014

YFA015

SFA965

NFA015

FRONT SUSPENSION

Torsion Bar (Cont'd)

FA-32

http://vnx.su/

Page 1144 of 1833

(3) If height of the vehicle is not as specified, adjust vehicle pos-ture.(Refer to SDS, FA-39.)

(4) Check wheel alignment if necessary. (Refer to SDS, FA-39.)

9. If ªHº dimension is not within the specified value, readjust vehicle posture using anchor arm adjusting nut.

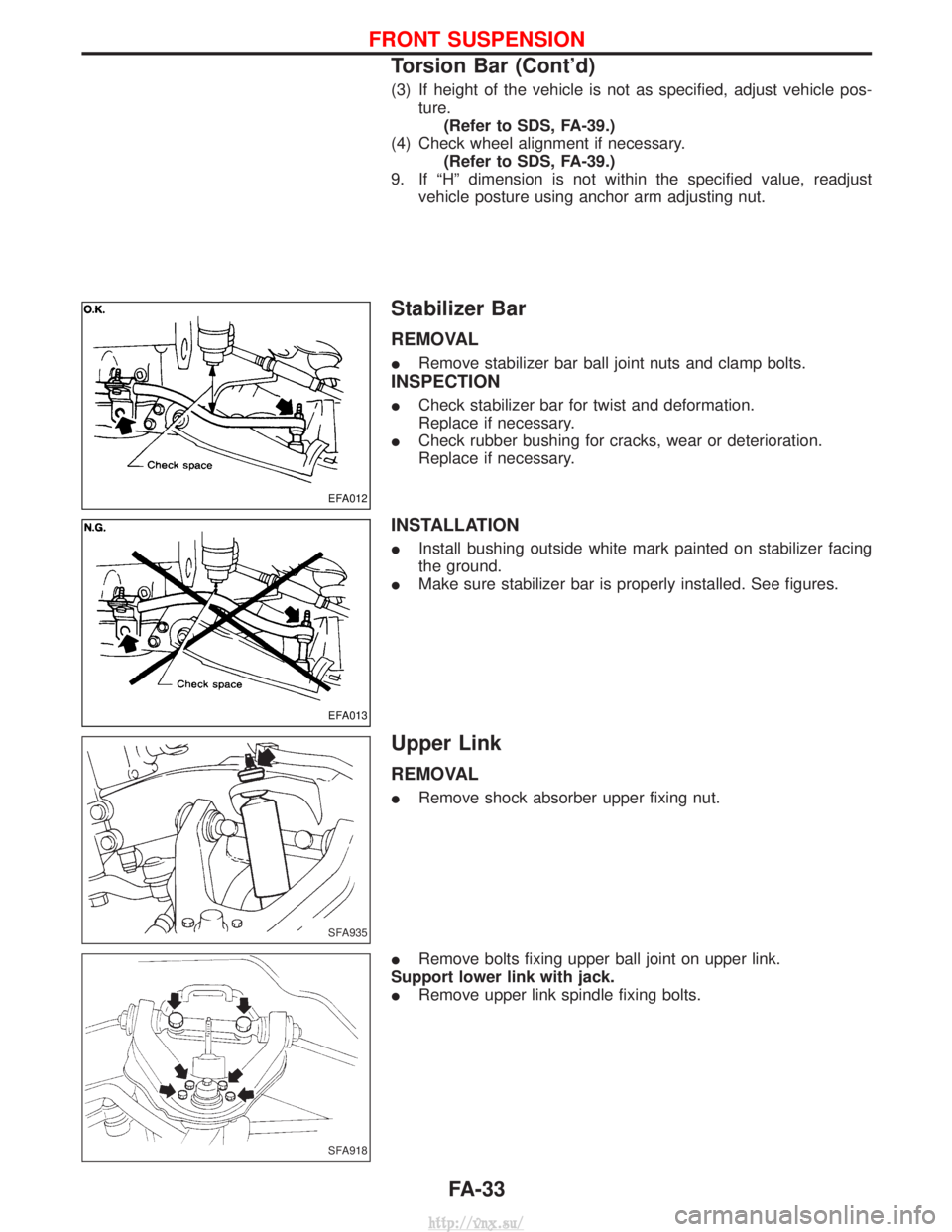

Stabilizer Bar

REMOVAL

IRemove stabilizer bar ball joint nuts and clamp bolts.

INSPECTION

ICheck stabilizer bar for twist and deformation.

Replace if necessary.

I Check rubber bushing for cracks, wear or deterioration.

Replace if necessary.

INSTALLATION

IInstall bushing outside white mark painted on stabilizer facing

the ground.

I Make sure stabilizer bar is properly installed. See figures.

Upper Link

REMOVAL

IRemove shock absorber upper fixing nut.

I Remove bolts fixing upper ball joint on upper link.

Support lower link with jack.

I Remove upper link spindle fixing bolts.

EFA012

EFA013

SFA935

SFA918

FRONT SUSPENSION

Torsion Bar (Cont'd)

FA-33

http://vnx.su/

Page 1145 of 1833

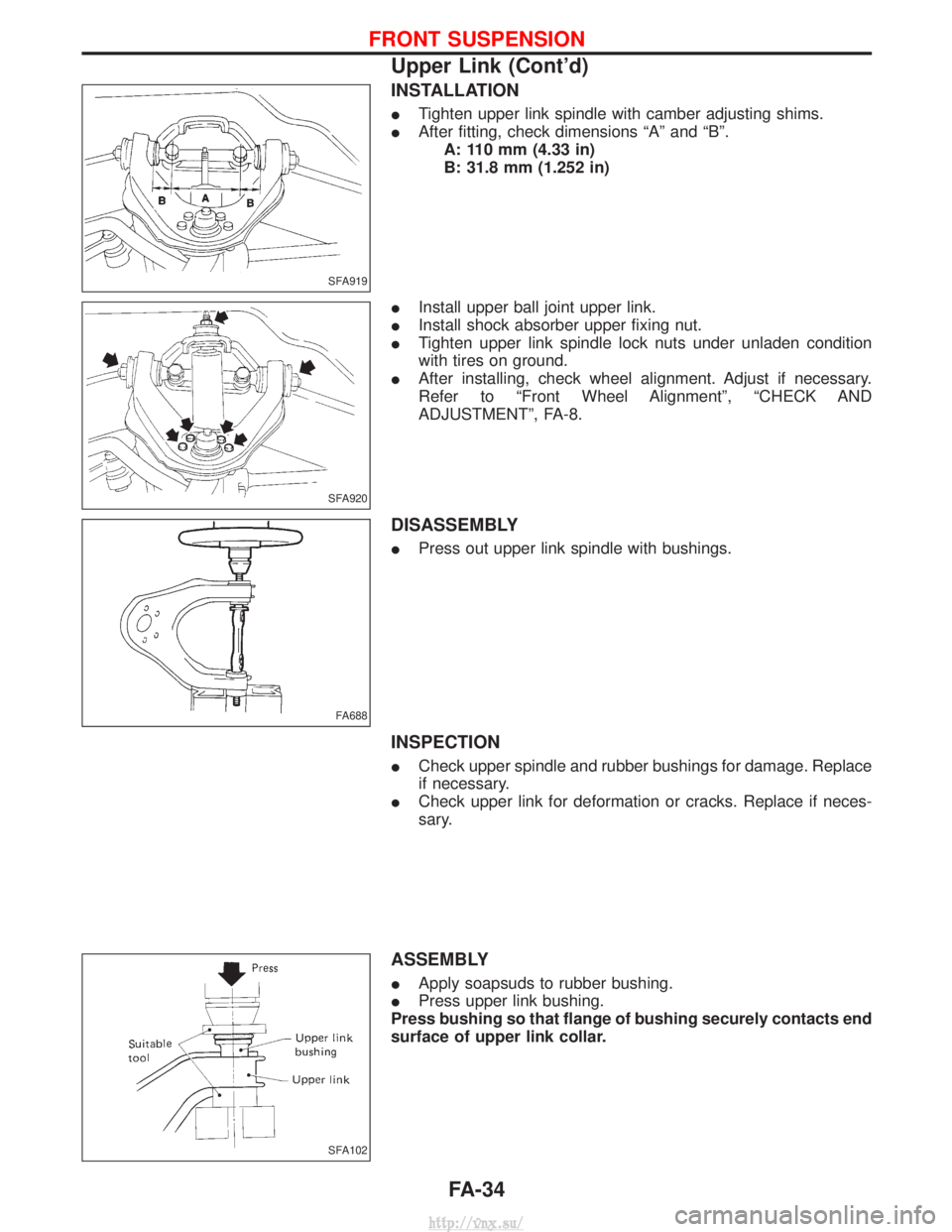

INSTALLATION

ITighten upper link spindle with camber adjusting shims.

I After fitting, check dimensions ªAº and ªBº.

A: 110 mm (4.33 in)

B: 31.8 mm (1.252 in)

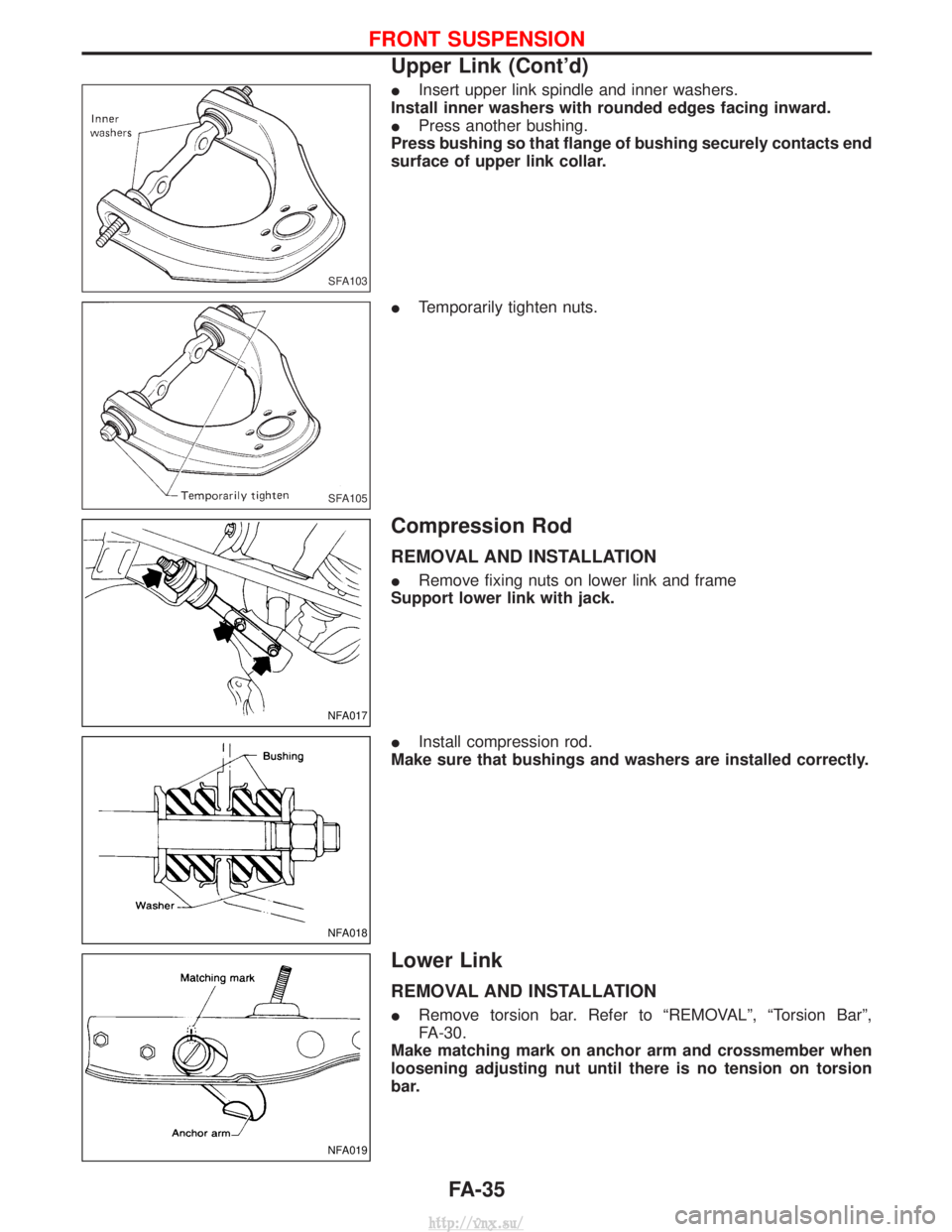

I Install upper ball joint upper link.

I Install shock absorber upper fixing nut.

I Tighten upper link spindle lock nuts under unladen condition

with tires on ground.

I After installing, check wheel alignment. Adjust if necessary.

Refer to ªFront Wheel Alignmentº, ªCHECK AND

ADJUSTMENTº, FA-8.

DISASSEMBLY

IPress out upper link spindle with bushings.

INSPECTION

ICheck upper spindle and rubber bushings for damage. Replace

if necessary.

I Check upper link for deformation or cracks. Replace if neces-

sary.

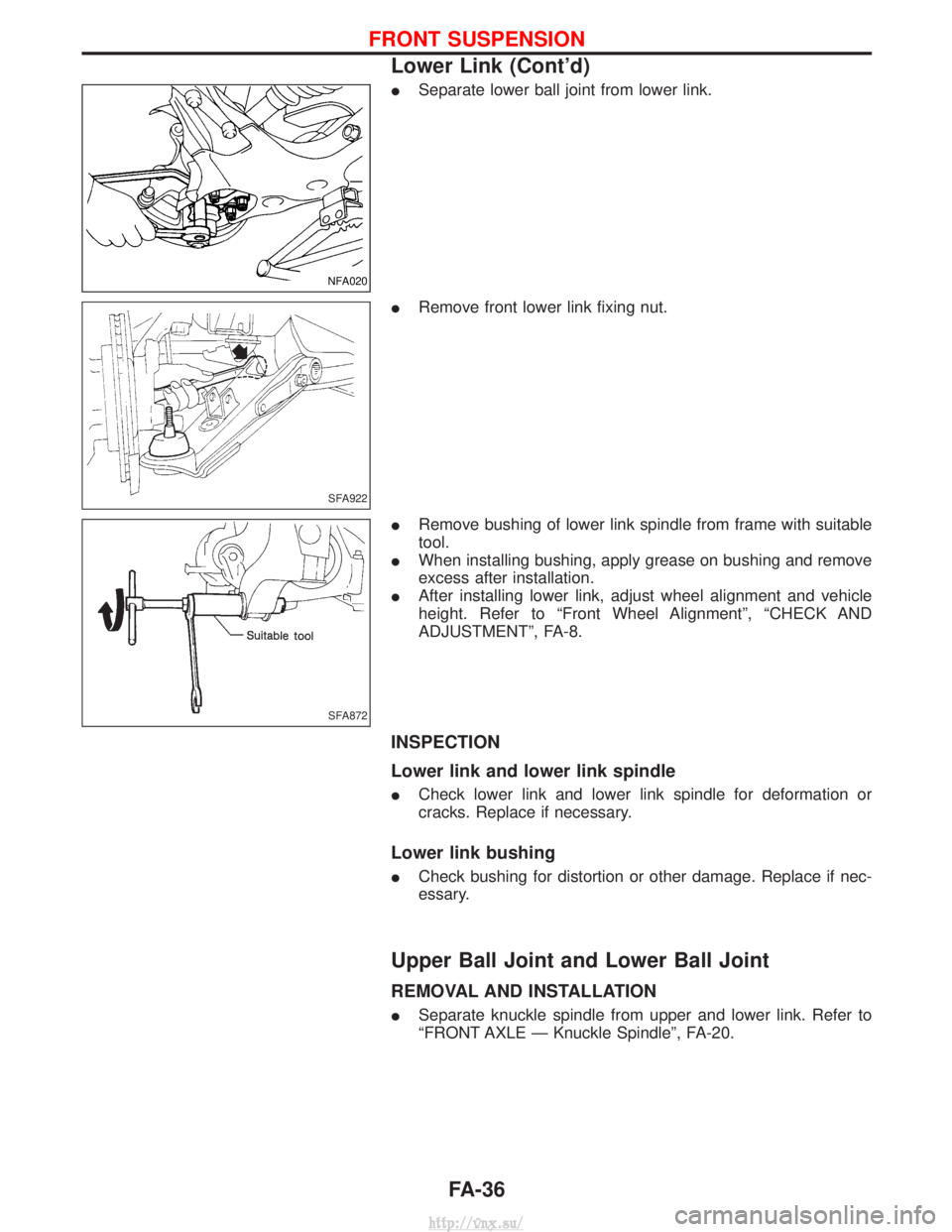

ASSEMBLY

IApply soapsuds to rubber bushing.

I Press upper link bushing.

Press bushing so that flange of bushing securely contacts end

surface of upper link collar.

SFA919

SFA920

FA688

SFA102

FRONT SUSPENSION

Upper Link (Cont'd)

FA-34

http://vnx.su/

Page 1146 of 1833

IInsert upper link spindle and inner washers.

Install inner washers with rounded edges facing inward.

I Press another bushing.

Press bushing so that flange of bushing securely contacts end

surface of upper link collar.

I Temporarily tighten nuts.

Compression Rod

REMOVAL AND INSTALLATION

IRemove fixing nuts on lower link and frame

Support lower link with jack.

I Install compression rod.

Make sure that bushings and washers are installed correctly.

Lower Link

REMOVAL AND INSTALLATION

I Remove torsion bar. Refer to ªREMOVALº, ªTorsion Barº,

FA-30.

Make matching mark on anchor arm and crossmember when

loosening adjusting nut until there is no tension on torsion

bar.

SFA103

SFA105

NFA017

NFA018

NFA019

FRONT SUSPENSION

Upper Link (Cont'd)

FA-35

http://vnx.su/

Page 1147 of 1833

ISeparate lower ball joint from lower link.

I Remove front lower link fixing nut.

I Remove bushing of lower link spindle from frame with suitable

tool.

I When installing bushing, apply grease on bushing and remove

excess after installation.

I After installing lower link, adjust wheel alignment and vehicle

height. Refer to ªFront Wheel Alignmentº, ªCHECK AND

ADJUSTMENTº, FA-8.

INSPECTION

Lower link and lower link spindle

ICheck lower link and lower link spindle for deformation or

cracks. Replace if necessary.

Lower link bushing

ICheck bushing for distortion or other damage. Replace if nec-

essary.

Upper Ball Joint and Lower Ball Joint

REMOVAL AND INSTALLATION

ISeparate knuckle spindle from upper and lower link. Refer to

ªFRONT AXLE Ð Knuckle Spindleº, FA-20.

NFA020

SFA922

SFA872

FRONT SUSPENSION

Lower Link (Cont'd)

FA-36

http://vnx.su/

Page 1148 of 1833

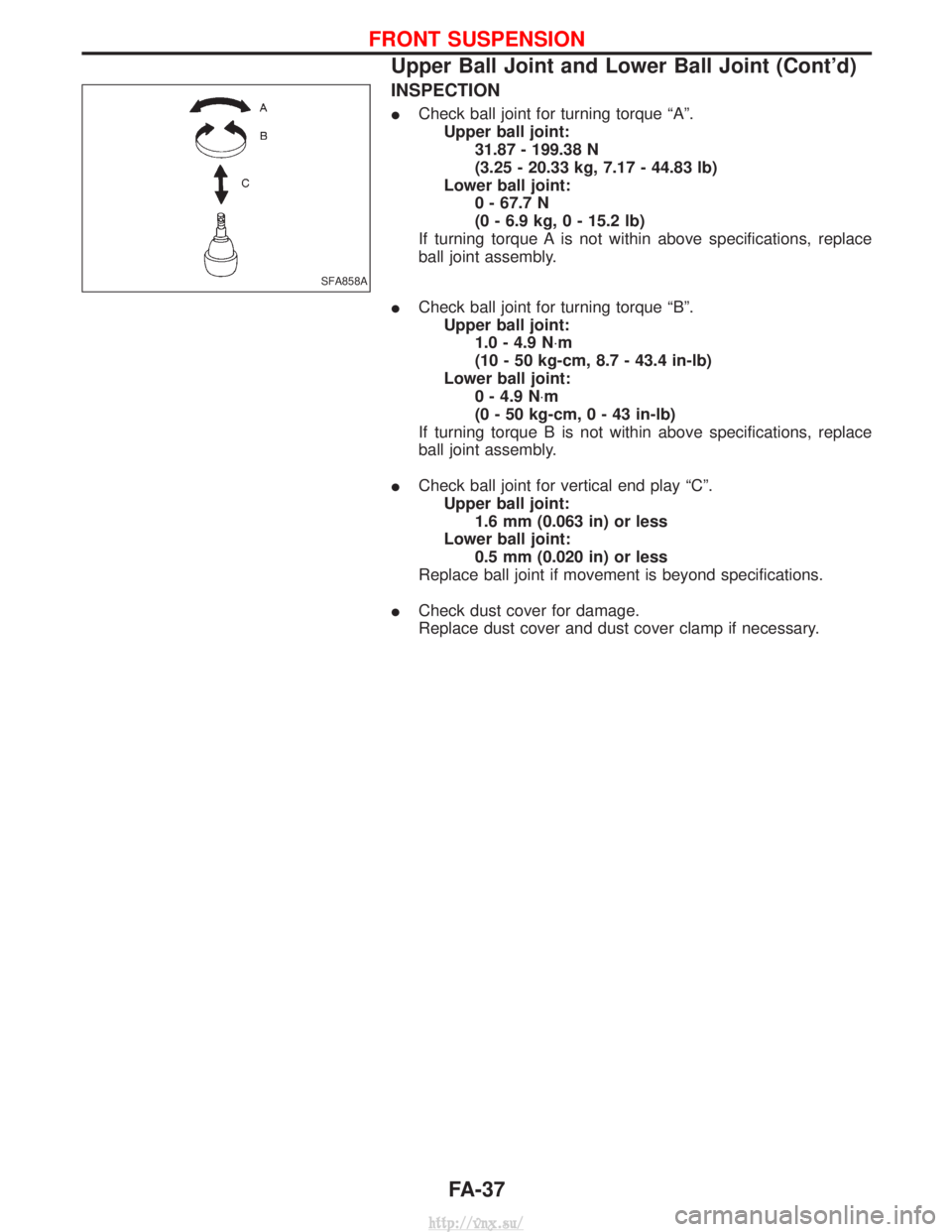

INSPECTION

ICheck ball joint for turning torque ªAº.

Upper ball joint: 31.87 - 199.38 N

(3.25 - 20.33 kg, 7.17 - 44.83 lb)

Lower ball joint: 0 - 67.7 N

(0 - 6.9 kg, 0 - 15.2 lb)

If turning torque A is not within above specifications, replace

ball joint assembly.

I Check ball joint for turning torque ªBº.

Upper ball joint: 1.0 - 4.9 N ×m

(10 - 50 kg-cm, 8.7 - 43.4 in-lb)

Lower ball joint: 0 - 4.9 N ×m

(0 - 50 kg-cm,0-43 in-lb)

If turning torque B is not within above specifications, replace

ball joint assembly.

I Check ball joint for vertical end play ªCº.

Upper ball joint: 1.6 mm (0.063 in) or less

Lower ball joint: 0.5 mm (0.020 in) or less

Replace ball joint if movement is beyond specifications.

I Check dust cover for damage.

Replace dust cover and dust cover clamp if necessary.

SFA858A

FRONT SUSPENSION

Upper Ball Joint and Lower Ball Joint (Cont'd)

FA-37

http://vnx.su/

Page 1149 of 1833

General Specifications

TORSION BAR SPRING

Applied modelHardtop Wagon

Spring diameter x length mm (in)26.0 x 1,230 (1.024 x 48.43)

Spring constant N/mm (kg/mm, lb/in) 25.3 (2.58, 144.5)

SHOCK ABSORBER

Applied model

ABS models

Shock absorber type Non-adjustable (hydraulic)

Damping force N (kg, lb)

[at 0.3 m (1.0 ft)/sec.]

Extension 2,265 314

(231.0 32.0, 509.2 70.6)

Compression 653 124

(66.6 12.6,

146.8 27.9)

STABILIZER BAR

Applied model All

Stabilizer bar diameter mm (in) 29 (1.14)

COMPRESSION ROD

Applied model Hardtop Wagon

Rod diameter mm (in) 23.5 (0.925)

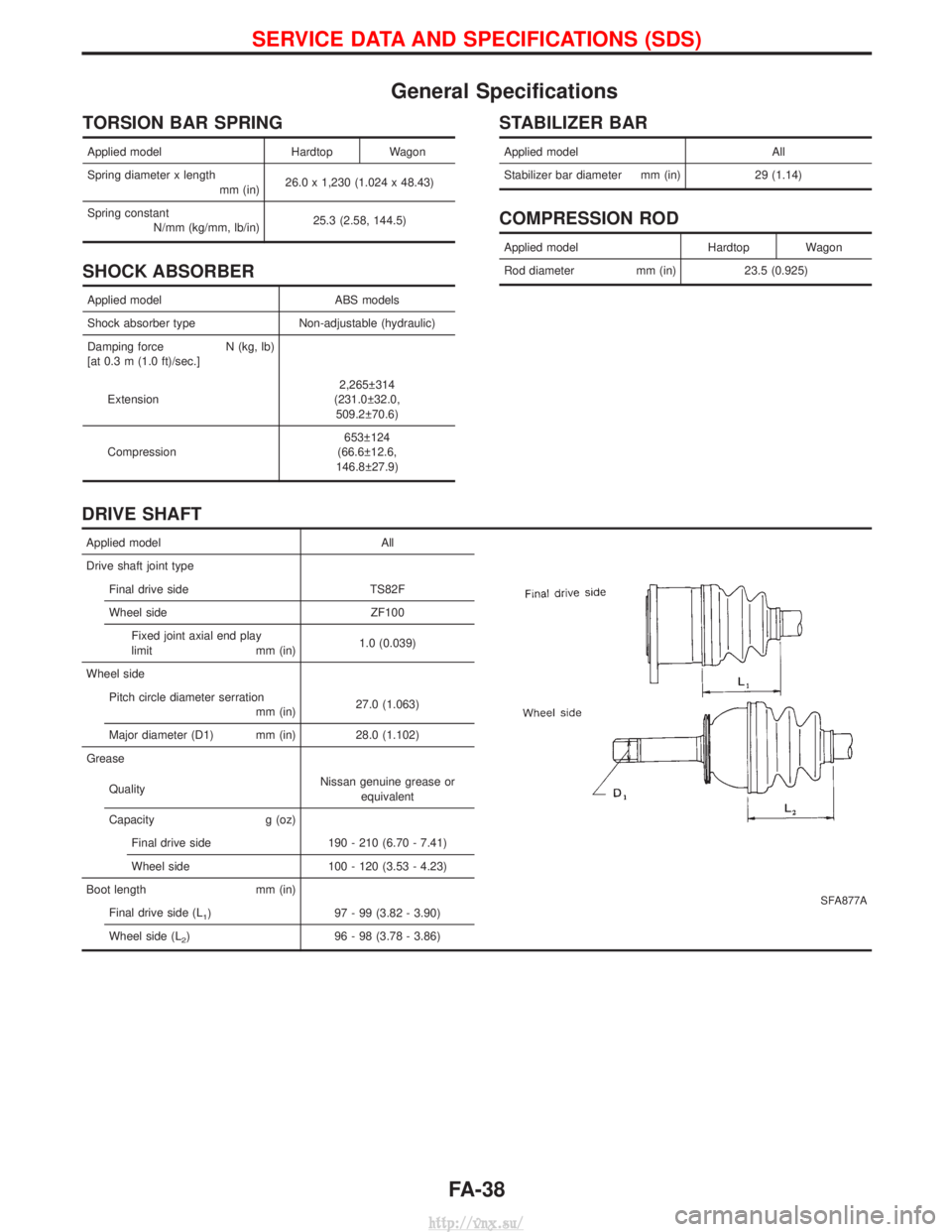

DRIVE SHAFT

Applied model All

SFA877A

Drive shaft joint type

Final drive side TS82F

Wheel side ZF100Fixed joint axial end play

limit mm (in) 1.0 (0.039)

Wheel side Pitch circle diameter serration mm (in)27.0 (1.063)

Major diameter (D1) mm (in) 28.0 (1.102)

Grease

Quality Nissan genuine grease or

equivalent

Capacity g (oz) Final drive side 190 - 210 (6.70 - 7.41)

Wheel side 100 - 120 (3.53 - 4.23)

Boot length mm (in) Final drive side (L

1) 97 - 99 (3.82 - 3.90)

Wheel side (L

2) 96 - 98 (3.78 - 3.86)

SERVICE DATA AND SPECIFICATIONS (SDS)

FA-38

http://vnx.su/

Page 1150 of 1833

Inspection and Adjustment

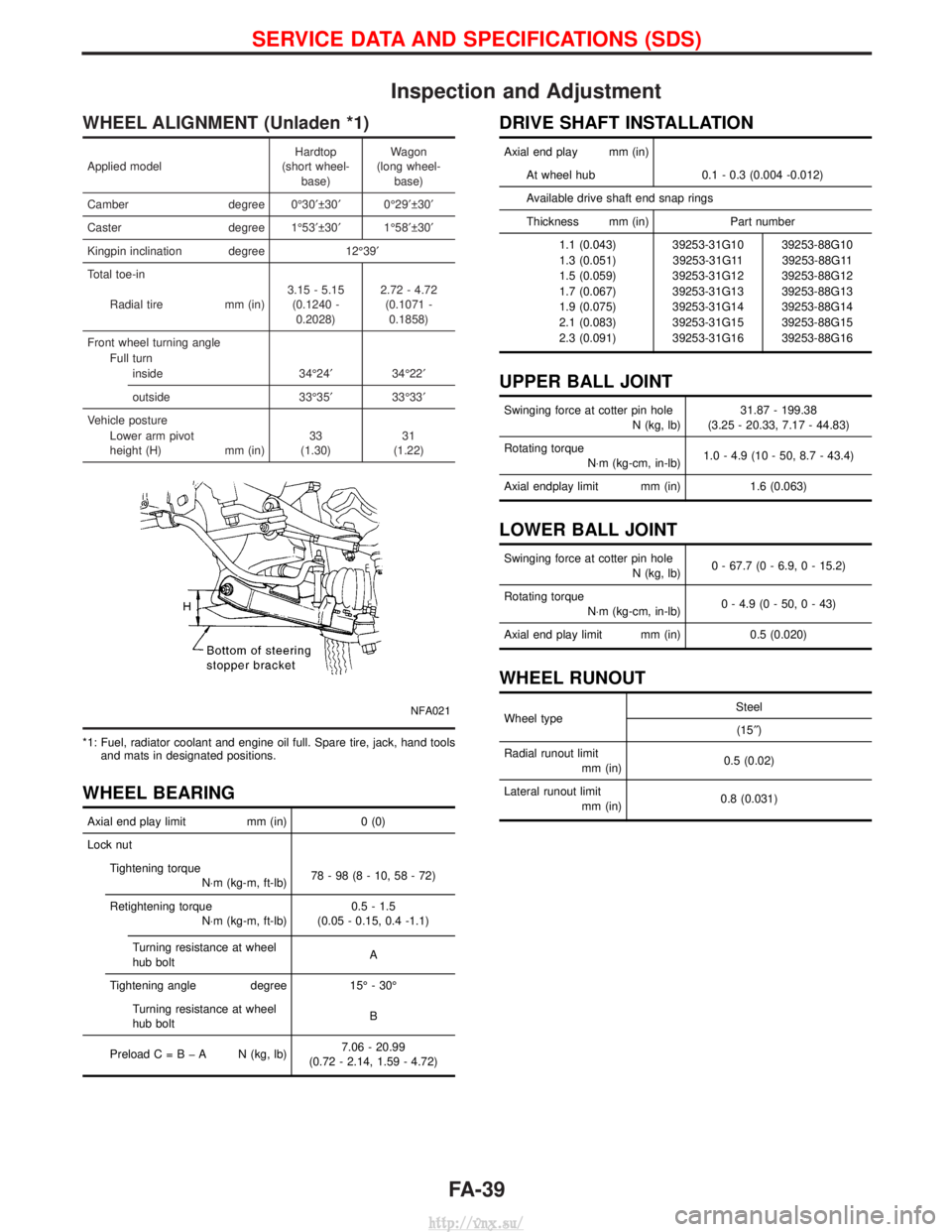

WHEEL ALIGNMENT (Unladen *1)

Applied modelHardtop

(short wheel- base) Wagon

(long wheel- base)

Camber degree 0É30¢ 30¢0É29¢ 30¢

Caster degree 1É53¢ 30¢1É58¢ 30¢

Kingpin inclination degree 12É39¢

Total toe-in

Radial tire mm (in)3.15 - 5.15

(0.1240 -0.2028) 2.72 - 4.72

(0.1071 -0.1858)

Front wheel turning angle Full turninside 34É24¢34É22¢

outside 33É35¢33É33¢

Vehicle posture Lower arm pivot

height (H) mm (in)33

(1.30) 31

(1.22)

NFA021

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

WHEEL BEARING

Axial end play limit mm (in)0 (0)

Lock nut Tightening torque N×m (kg-m, ft-lb) 78-98(8-10,58-72)

Retightening torque N×m (kg-m, ft-lb) 0.5 - 1.5

(0.05 - 0.15, 0.4 -1.1)

Turning resistance at wheel

hub bolt A

Tightening angle degree 15É - 30É

Turning resistance at wheel

hub bolt B

PreloadC=BþA N(kg, lb) 7.06 - 20.99

(0.72 - 2.14, 1.59 - 4.72)

DRIVE SHAFT INSTALLATION

Axial end play mm (in)

At wheel hub 0.1 - 0.3 (0.004 -0.012)

Available drive shaft end snap rings

Thickness mm (in) Part number 1.1 (0.043) 39253-31G10 39253-88G10

1.3 (0.051) 39253-31G11 39253-88G11

1.5 (0.059) 39253-31G12 39253-88G12

1.7 (0.067) 39253-31G13 39253-88G13

1.9 (0.075) 39253-31G14 39253-88G14

2.1 (0.083) 39253-31G15 39253-88G15

2.3 (0.091) 39253-31G16 39253-88G16

UPPER BALL JOINT

Swinging force at cotter pin hole N (kg, lb)31.87 - 199.38

(3.25 - 20.33, 7.17 - 44.83)

Rotating torque N×m (kg-cm, in-lb) 1.0 - 4.9 (10 - 50, 8.7 - 43.4)

Axial endplay limit mm (in) 1.6 (0.063)

LOWER BALL JOINT

Swinging force at cotter pin hole

N (kg, lb)0 - 67.7 (0 - 6.9, 0 - 15.2)

Rotating torque N×m (kg-cm, in-lb) 0 - 4.9 (0 - 50, 0 - 43)

Axial end play limit mm (in) 0.5 (0.020)

WHEEL RUNOUT

Wheel type Steel

(15² )

Radial runout limit mm (in) 0.5 (0.02)

Lateral runout limit mm (in) 0.8 (0.031)

SERVICE DATA AND SPECIFICATIONS (SDS)

FA-39

http://vnx.su/