NISSAN TERRANO 2004 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 1251 of 1833

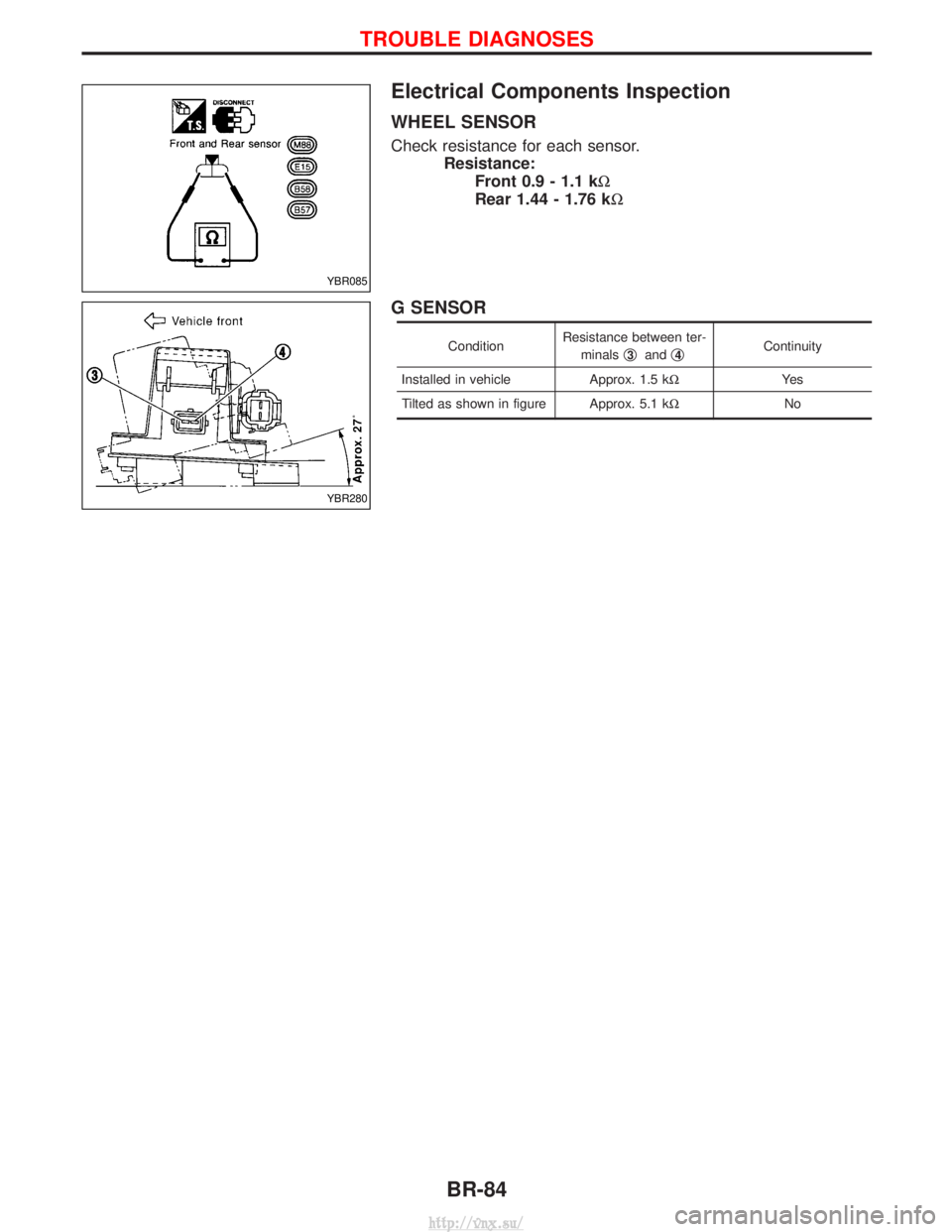

Electrical Components Inspection

WHEEL SENSOR

Check resistance for each sensor.Resistance:Front 0.9 - 1.1 k W

Rear 1.44 - 1.76 k W

G SENSOR

Condition Resistance between ter-

minals q3andq4Continuity

Installed in vehicle Approx. 1.5 kW Ye s

Tilted as shown in figure Approx. 5.1 kW No

YBR085

YBR280

TROUBLE DIAGNOSES

BR-84

http://vnx.su/

Page 1252 of 1833

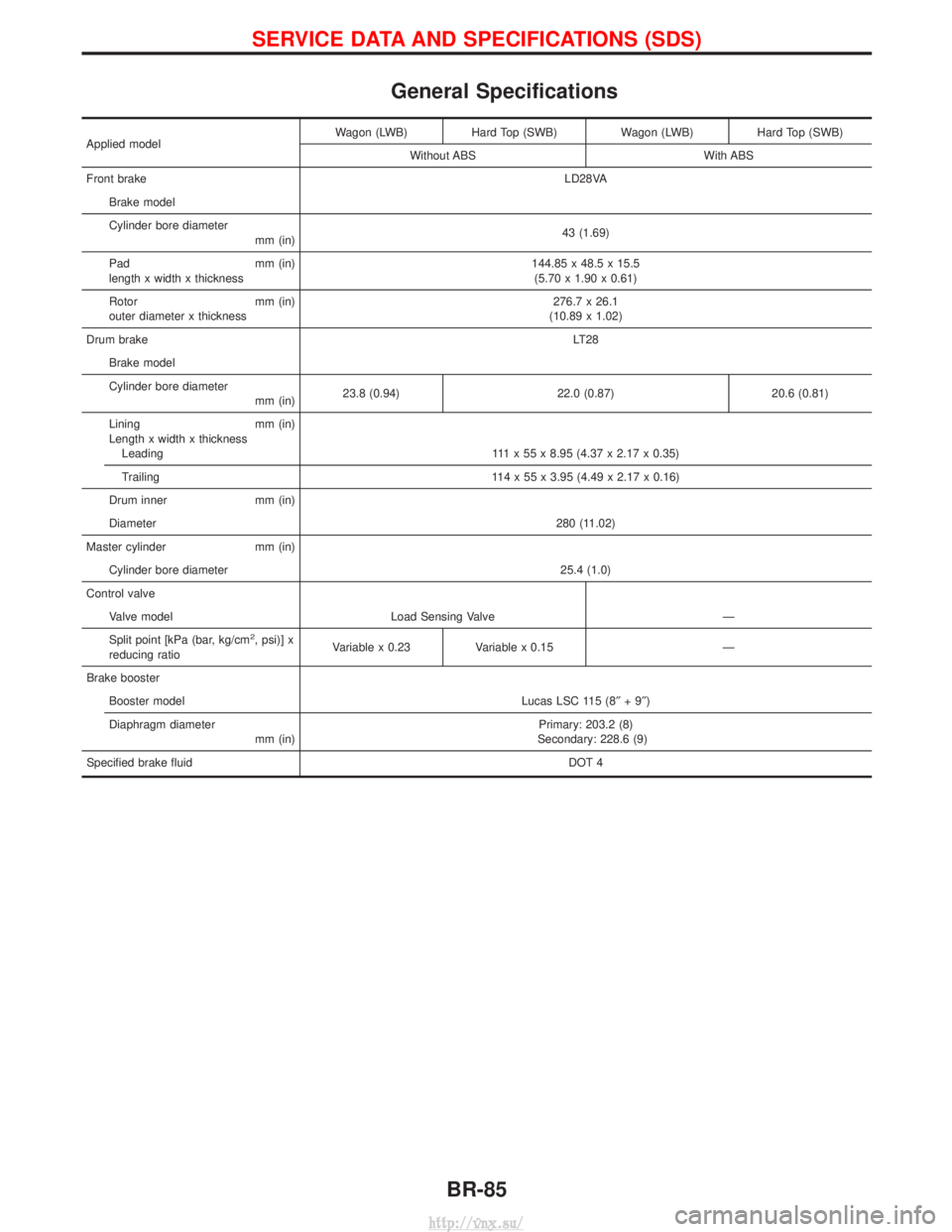

General Specifications

Applied modelWagon (LWB) Hard Top (SWB) Wagon (LWB) Hard Top (SWB)

Without ABS With ABS

Front brake LD28VA

Brake model

Cylinder bore diameter mm (in) 43 (1.69)

Pad mm (in)

length x width x thickness 144.85 x 48.5 x 15.5

(5.70 x 1.90 x 0.61)

Rotor mm (in)

outer diameter x thickness 276.7 x 26.1

(10.89 x 1.02)

Drum brake LT28

Brake model

Cylinder bore diameter mm (in)23.8 (0.94) 22.0 (0.87) 20.6 (0.81)

Lining mm (in)

Length x width x thickness Leading 111 x 55 x 8.95 (4.37 x 2.17 x 0.35)

Trailing 114 x 55 x 3.95 (4.49 x 2.17 x 0.16)

Drum inner mm (in)

Diameter 280 (11.02)

Master cylinder mm (in) Cylinder bore diameter 25.4 (1.0)

Control valve Valve model Load Sensing Valve Ð

Split point [kPa (bar, kg/cm

2, psi)] x

reducing ratio Variable x 0.23 Variable x 0.15 Ð

Brake booster Booster model Lucas LSC 115 (8² +9²)

Diaphragm diameter mm (in) Primary: 203.2 (8)

Secondary: 228.6 (9)

Specified brake fluid DOT 4

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-85

http://vnx.su/

Page 1253 of 1833

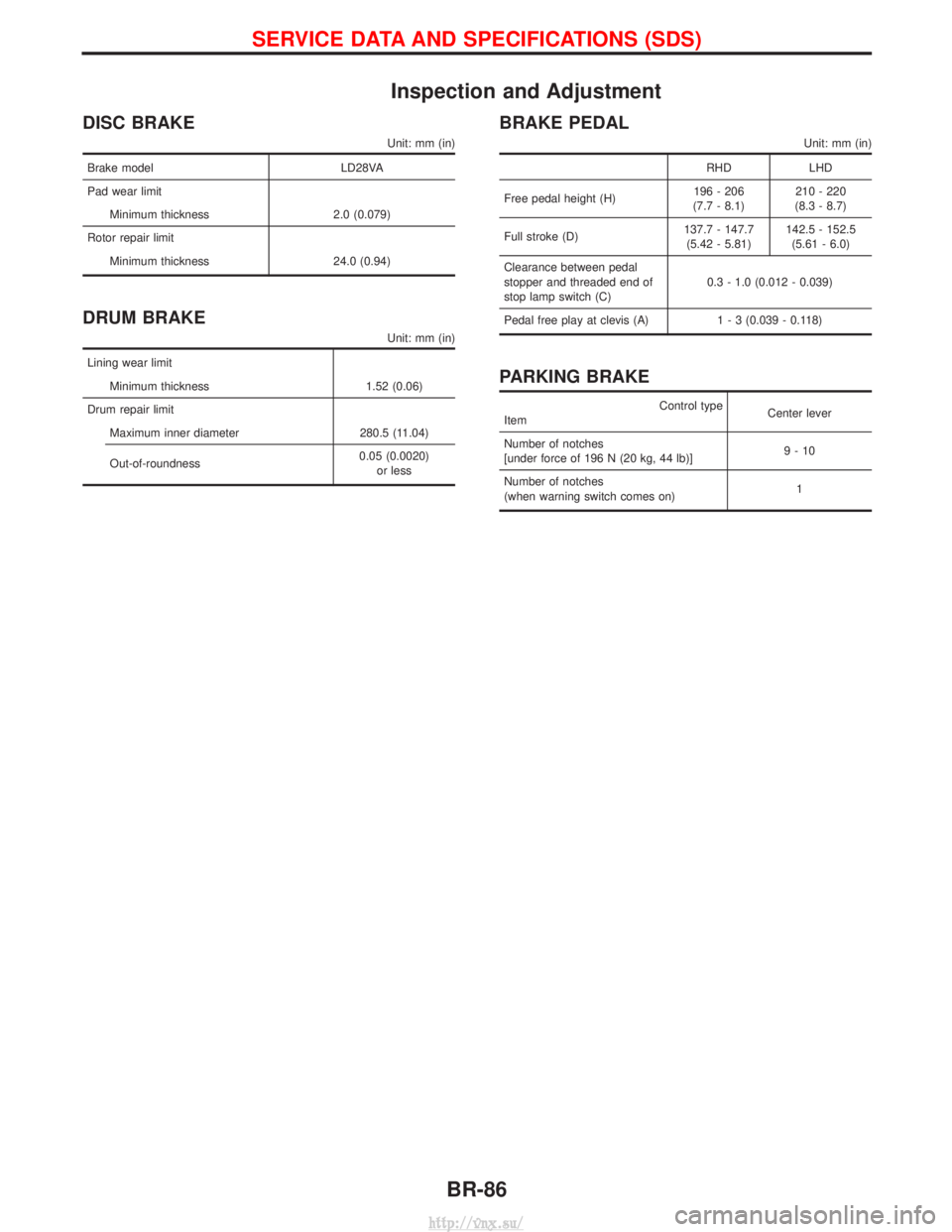

Inspection and Adjustment

DISC BRAKE

Unit: mm (in)

Brake modelLD28VA

Pad wear limit Minimum thickness 2.0 (0.079)

Rotor repair limit Minimum thickness 24.0 (0.94)

DRUM BRAKE

Unit: mm (in)

Lining wear limit

Minimum thickness 1.52 (0.06)

Drum repair limit Maximum inner diameter 280.5 (11.04)

Out-of-roundness 0.05 (0.0020)

or less

BRAKE PEDAL

Unit: mm (in)

RHD LHD

Free pedal height (H) 196 - 206

(7.7 - 8.1) 210 - 220

(8.3 - 8.7)

Full stroke (D) 137.7 - 147.7

(5.42 - 5.81) 142.5 - 152.5

(5.61 - 6.0)

Clearance between pedal

stopper and threaded end of

stop lamp switch (C) 0.3 - 1.0 (0.012 - 0.039)

Pedal free play at clevis (A) 1 - 3 (0.039 - 0.118)

PARKING BRAKE

Control type

Item Center lever

Number of notches

[under force of 196 N (20 kg, 44 lb)] 9-10

Number of notches

(when warning switch comes on) 1

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-86

http://vnx.su/

Page 1254 of 1833

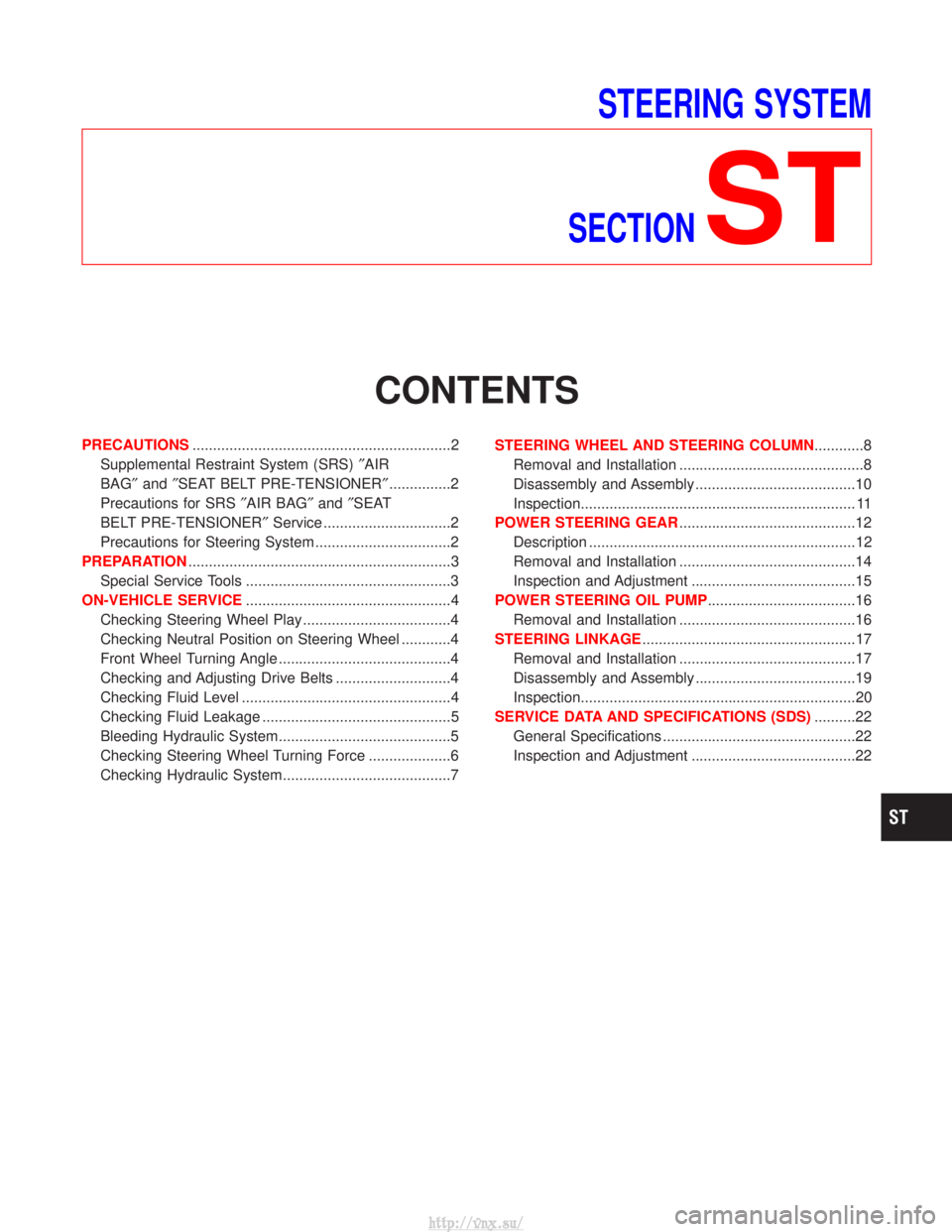

STEERING SYSTEM

SECTION

ST

CONTENTS

PRECAUTIONS ...............................................................2

Supplemental Restraint System (SRS) ²AIR

BAG² and²SEAT BELT PRE-TENSIONER² ...............2

Precautions for SRS ²AIR BAG² and²SEAT

BELT PRE-TENSIONER² Service ...............................2

Precautions for Steering System .................................2

PREPARATION ................................................................3

Special Service Tools ..................................................3

ON-VEHICLE SERVICE ..................................................4

Checking Steering Wheel Play ....................................4

Checking Neutral Position on Steering Wheel ............4

Front Wheel Turning Angle ..........................................4

Checking and Adjusting Drive Belts ............................4

Checking Fluid Level ...................................................4

Checking Fluid Leakage ..............................................5

Bleeding Hydraulic System..........................................5

Checking Steering Wheel Turning Force ....................6

Checking Hydraulic System.........................................7 STEERING WHEEL AND STEERING COLUMN

............8

Removal and Installation .............................................8

Disassembly and Assembly .......................................10

Inspection................................................................... 11

POWER STEERING GEAR ...........................................12

Description .................................................................12

Removal and Installation ...........................................14

Inspection and Adjustment ........................................15

POWER STEERING OIL PUMP ....................................16

Removal and Installation ...........................................16

STEERING LINKAGE ....................................................17

Removal and Installation ...........................................17

Disassembly and Assembly .......................................19

Inspection...................................................................20

SERVICE DATA AND SPECIFICATIONS (SDS) ..........22

General Specifications ...............................................22

Inspection and Adjustment ........................................22

http://vnx.su/

Page 1255 of 1833

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL R20 is as follows (The composition

varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for SRS ªAIR BAGº and ªSEAT

BELT PRE-TENSIONERº Service

IDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

I Before servicing the SRS, turn ignition switch ªOFFº, disconnect both battery cables and wait at least 3

minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

I Diagnosis sensor unit must always be installed with their arrow marks ª +º pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

I The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

I Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and place front side air bag module (built-in type) standing with stud bolt side setting

bottom.

I Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

I After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Precautions for Steering System

IBefore disassembly, thoroughly clean the outside of the unit.

I Disassembly should be done in a clean work area. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

I When disassembling parts, be sure to place them in order on a part rack so they can be reinstalled

in their proper positions.

I Use nylon cloths or paper towels to clean the parts; common shop rags can leave lint that might

interfere with their operation.

I Before inspection or reassembly, carefully clean all parts with a general purpose, non-flammable

solvent.

I Before assembly, apply a coat of recommended ATF* to hydraulic parts. Vaseline may be applied

to O-rings and seals. Do not use any grease.

I Replace all gaskets, seals and O-rings. Avoid damaging O-rings, seals and gaskets during instal-

lation. Perform functional tests whenever designated.

*: Automatic transmission fluid

PRECAUTIONS

ST-2

http://vnx.su/

Page 1256 of 1833

Special Service Tools

*: Special tool or commercial equivalent

Tool number

Tool nameDescription

KV48100700

Torque adapter

Measuring pinion rotating torque

ST27180001*

Steering wheel puller

Removing and installing steering wheel

ST27850000

Ball joint remover

Removing ball joint

ST29020001*

Steering gear arm puller

Removing and installing pitman arm

ST3127S000*

q

1GG91030000

Torque wrench

q

2HT62940000

Socket adapter

q

3HT62900000

Socket adapter

Measuring turning torque

KV48100301*

Strut & steering gearbox

attachment

Steering gear is installed

KV48103500-A

Pressure gauge

Measuring oil pressure

KV48102500

Pressure gauge adapter

Measuring oil pressure

KV481009S0

Oil seal drift set

q

1KV48100910

Drift

q

2KV48100920

Adapter

q

3KV48100930

Adapter

Installing oil seal

PREPARATION

ST-3

http://vnx.su/

Page 1257 of 1833

Checking Steering Wheel Play

1. With wheels in a straight-ahead position, check steering wheelplay.Steering wheel play: 35 mm (1.38 in) or less

2. If it is not within specification, check steering gear assembly when front suspension and axle, steering gear assembly and

steering column are mounted correctly.

Checking Neutral Position on Steering Wheel

CHECKING

1. Check that the steering wheel is in the neutral position whendriving straight ahead.

2. If it is not in the neutral position, remove the steering wheel and reinstall it correctly.

3. If the neutral position is between two serrated teeth, loosen tie-rod lock nut and move tie-rod in the opposite direction by the

same amount on both left and right sides to compensate for

error in the neutral position.

Front Wheel Turning Angle

Rotate steering wheel all the way right and left; measure turning

angle. Turning angle of full turns:Refer to section FA for SDS.

Checking and Adjusting Drive Belts

Refer to section MA for Drive Belt Inspection.

Checking Fluid Level

Check the fluid level in the reservoir when the engine is cold. If the

fluid level is below the MIN line, and fluid up to the MAX line.

CAUTION:

IDo not overfill the MAX level.

I Do not reuse any used power steering fluid.

I Use only ªDEXRON

TMº or equivalent.

SST103B

SST900A

SMA127

NST030

ON-VEHICLE SERVICE

ST-4

http://vnx.su/

Page 1258 of 1833

Checking Fluid Leakage

Check the lines for improper attachment and for leaks, cracks,

damage, loose connections, chafing or deterioration.

1. Run engine between idle speed and 1,000 rpm.

Make sure temperature of fluid in oil tank rises to 50 to 80ÉC

(122 to 176ÉF).

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each ªlockº position for five seconds andcarefully check for fluid leakage.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 10 seconds (There is possibility that oil pump may be

damaged.).

4. If fluid leakage at connectors is noticed, loosen flare nut and then retighten.

Do not overtighten connector as this can damage O-ring,

washer and connector.

5. If fluid leakage at the connectors are noticed, then loosen the flare nut and retighten it.

Bleeding Hydraulic System

1. Raise front end of vehicle until wheels are clear of the ground.

2. Add fluid into oil tank to specified level. Meanwhile quickly turnsteering wheel fully to right and left and lightly touch steering

stoppers.

Repeat steering wheel operation until fluid level no longer

decreases.

3. Start engine. Repeat step 2 above.

I Incomplete air bleeding will cause the following to occur. When

this happens, bleed air again.

a. Generation of air bubbles in reservoir tank

b. Generation of clicking noise in oil pump

c. Excessive buzzing in oil pump

While the vehicle is stationary or while moving the steering wheel

slowly, fluid noise may occur in the valve or oil pump. This noise is

inherent in this steering system, and it will not affect performance

or durability of the system.

SST621A

ON-VEHICLE SERVICE

ST-5

http://vnx.su/

Page 1259 of 1833

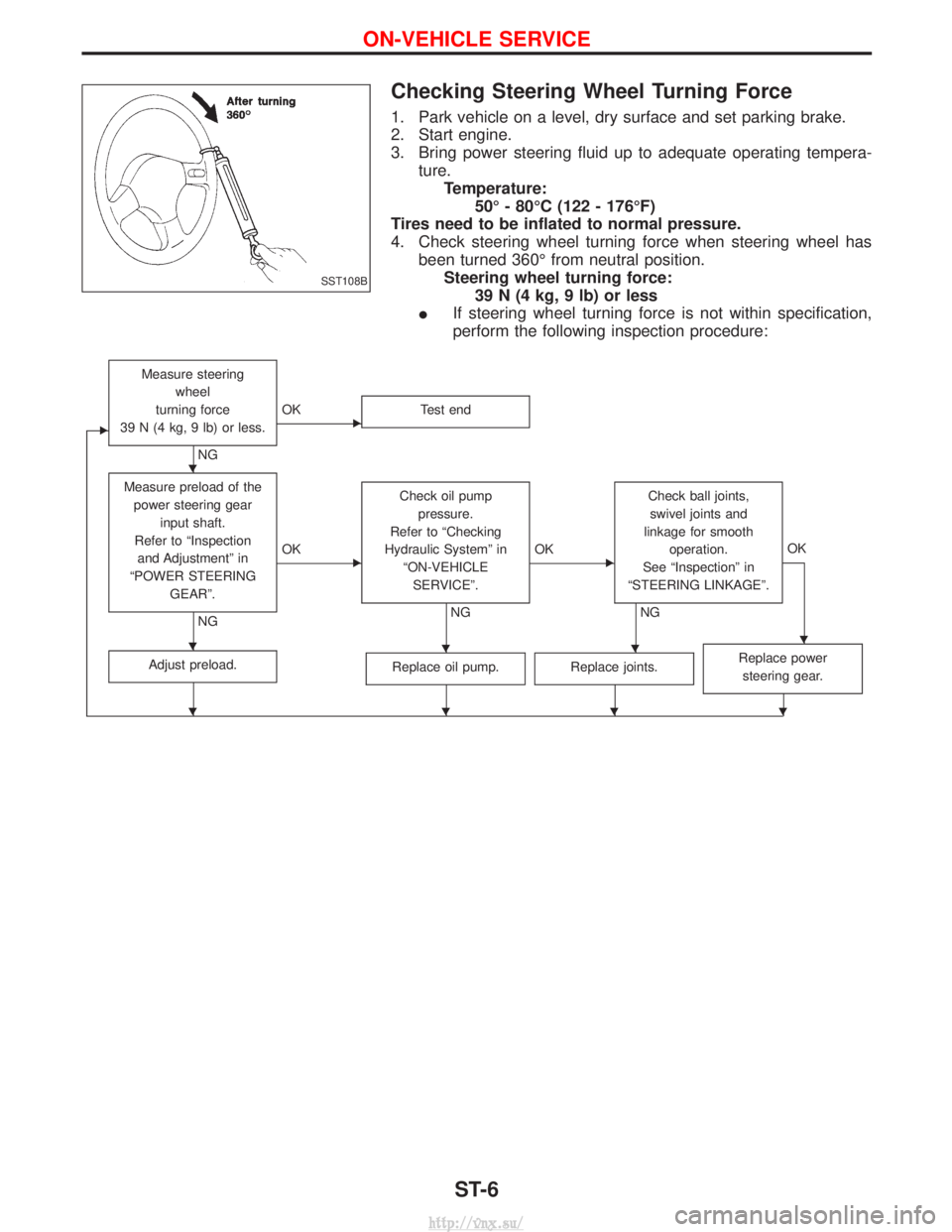

Checking Steering Wheel Turning Force

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating tempera-ture.Temperature: 50É - 80ÉC (122 - 176ÉF)

Tires need to be inflated to normal pressure.

4. Check steering wheel turning force when steering wheel has been turned 360É from neutral position.Steering wheel turning force: 39 N (4 kg, 9 lb) or less

I If steering wheel turning force is not within specification,

perform the following inspection procedure:

E

Measure steering

wheel

turning force

39 N (4 kg, 9 lb) or less.

NG

EOK Test end

Measure preload of the

power steering gear input shaft.

Refer to ªInspection and Adjustmentº in

ªPOWER STEERING GEARº.

NG

EOK Check oil pump

pressure.

Refer to ªChecking

Hydraulic Systemº in ªON-VEHICLESERVICEº.

NG

EOK Check ball joints,

swivel joints and

linkage for smooth operation.

See ªInspectionº in

ªSTEERING LINKAGEº.

NG OK

Adjust preload.Replace oil pump.Replace joints.Replace power

steering gear.

SST108B

H

HHHH

HHHH

ON-VEHICLE SERVICE

ST-6

http://vnx.su/

Page 1260 of 1833

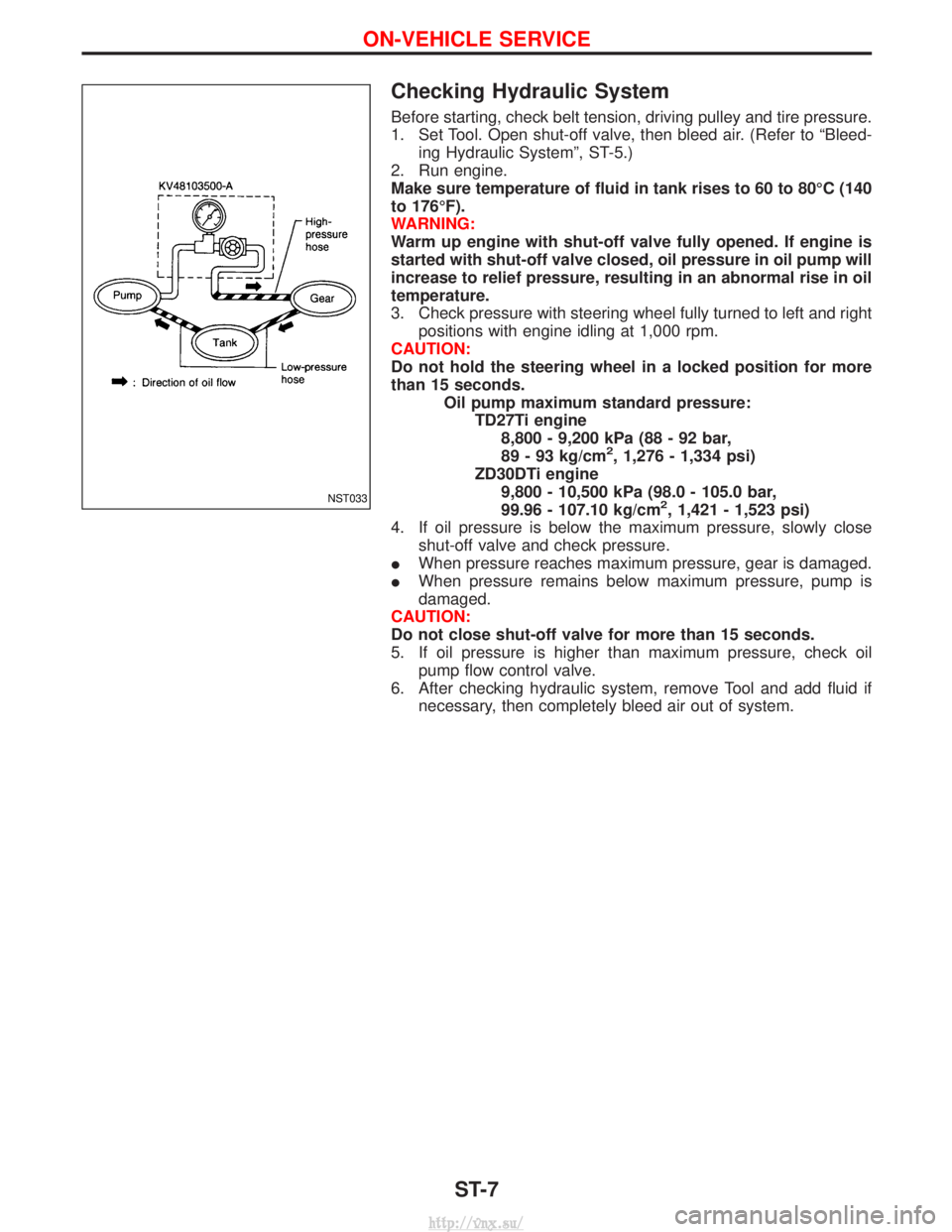

Checking Hydraulic System

Before starting, check belt tension, driving pulley and tire pressure.

1. Set Tool. Open shut-off valve, then bleed air. (Refer to ªBleed-ing Hydraulic Systemº, ST-5.)

2. Run engine.

Make sure temperature of fluid in tank rises to 60 to 80ÉC (140

to 176ÉF).

WARNING:

Warm up engine with shut-off valve fully opened. If engine is

started with shut-off valve closed, oil pressure in oil pump will

increase to relief pressure, resulting in an abnormal rise in oil

temperature.

3. Check pressure with steering wheel fully turned to left and right positions with engine idling at 1,000 rpm.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds. Oil pump maximum standard pressure:TD27Ti engine8,800 - 9,200 kPa (88 - 92 bar,

89 - 93 kg/cm

2, 1,276 - 1,334 psi)

ZD30DTi engine 9,800 - 10,500 kPa (98.0 - 105.0 bar,

99.96 - 107.10 kg/cm

2, 1,421 - 1,523 psi)

4. If oil pressure is below the maximum pressure, slowly close shut-off valve and check pressure.

I When pressure reaches maximum pressure, gear is damaged.

I When pressure remains below maximum pressure, pump is

damaged.

CAUTION:

Do not close shut-off valve for more than 15 seconds.

5. If oil pressure is higher than maximum pressure, check oil pump flow control valve.

6. After checking hydraulic system, remove Tool and add fluid if necessary, then completely bleed air out of system.NST033

ON-VEHICLE SERVICE

ST-7

http://vnx.su/