Ignition NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 622 of 1833

DIAGNOSTIC TEST MODE IÐBULB CHECK

In this mode, the MALFUNCTION INDICATOR on the instrument panel should stay ON. If it remains OFF,

check the bulb. Refer to EL section (ªWARNING LAMPS/WIRING DIAGRAMº) or see EC-475.

DIAGNOSTIC TEST MODE IÐMALFUNCTION WARNING

MICondition

ON When a malfunction is detected or the ECM's CPU is malfunctioning.

OFF No malfunction.

I These Diagnostic Trouble Code Numbers are clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC

RESULTS).

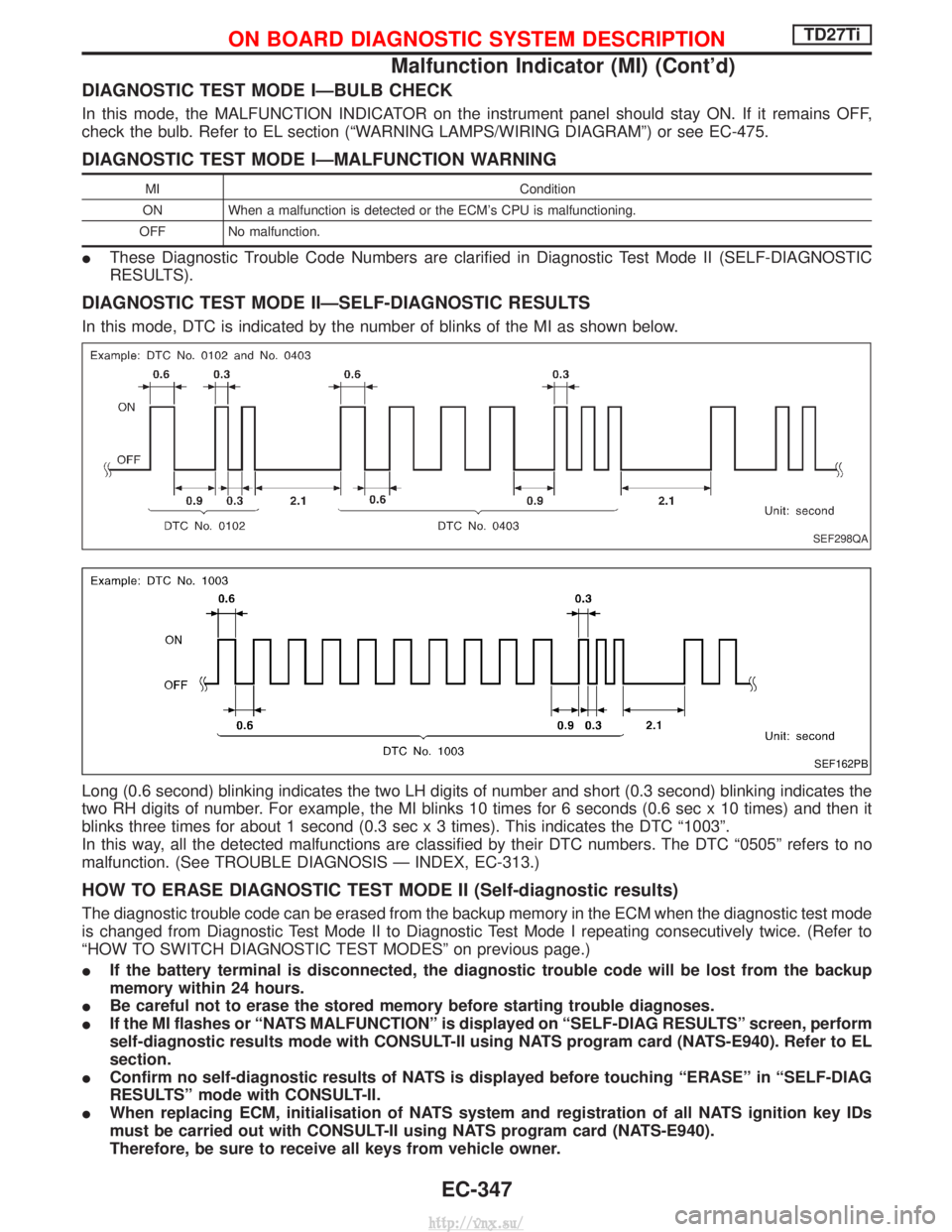

DIAGNOSTIC TEST MODE IIÐSELF-DIAGNOSTIC RESULTS

In this mode, DTC is indicated by the number of blinks of the MI as shown below.

Long (0.6 second) blinking indicates the two LH digits of number and short (0.3 second) blinking indicates the

two RH digits of number. For example, the MI blinks 10 times for 6 seconds (0.6 sec x 10 times) and then it

blinks three times for about 1 second (0.3 sec x 3 times). This indicates the DTC ª1003º.

In this way, all the detected malfunctions are classified by their DTC numbers. The DTC ª0505º refers to no

malfunction. (See TROUBLE DIAGNOSIS Ð INDEX, EC-313.)

HOW TO ERASE DIAGNOSTIC TEST MODE II (Self-diagnostic results)

The diagnostic trouble code can be erased from the backup memory in the ECM when the diagnostic test mode

is changed from Diagnostic Test Mode II to Diagnostic Test Mode I repeating consecutively twice. (Refer to

ªHOW TO SWITCH DIAGNOSTIC TEST MODESº on previous page.)

IIf the battery terminal is disconnected, the diagnostic trouble code will be lost from the backup

memory within 24 hours.

I Be careful not to erase the stored memory before starting trouble diagnoses.

I If the MI flashes or ªNATS MALFUNCTIONº is displayed on ªSELF-DIAG RESULTSº screen, perform

self-diagnostic results mode with CONSULT-II using NATS program card (NATS-E940). Refer to EL

section.

I Confirm no self-diagnostic results of NATS is displayed before touching ªERASEº in ªSELF-DIAG

RESULTSº mode with CONSULT-II.

I When replacing ECM, initialisation of NATS system and registration of all NATS ignition key IDs

must be carried out with CONSULT-II using NATS program card (NATS-E940).

Therefore, be sure to receive all keys from vehicle owner.

SEF298QA

SEF162PB

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

Malfunction Indicator (MI) (Cont'd)

EC-347

http://vnx.su/

Page 623 of 1833

Regarding the procedures of NATS initialisation and NATS ignition key ID registration, refer to

CONSULT-II operation manual, NATS.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

Malfunction Indicator (MI) (Cont'd)EC-348

http://vnx.su/

Page 625 of 1833

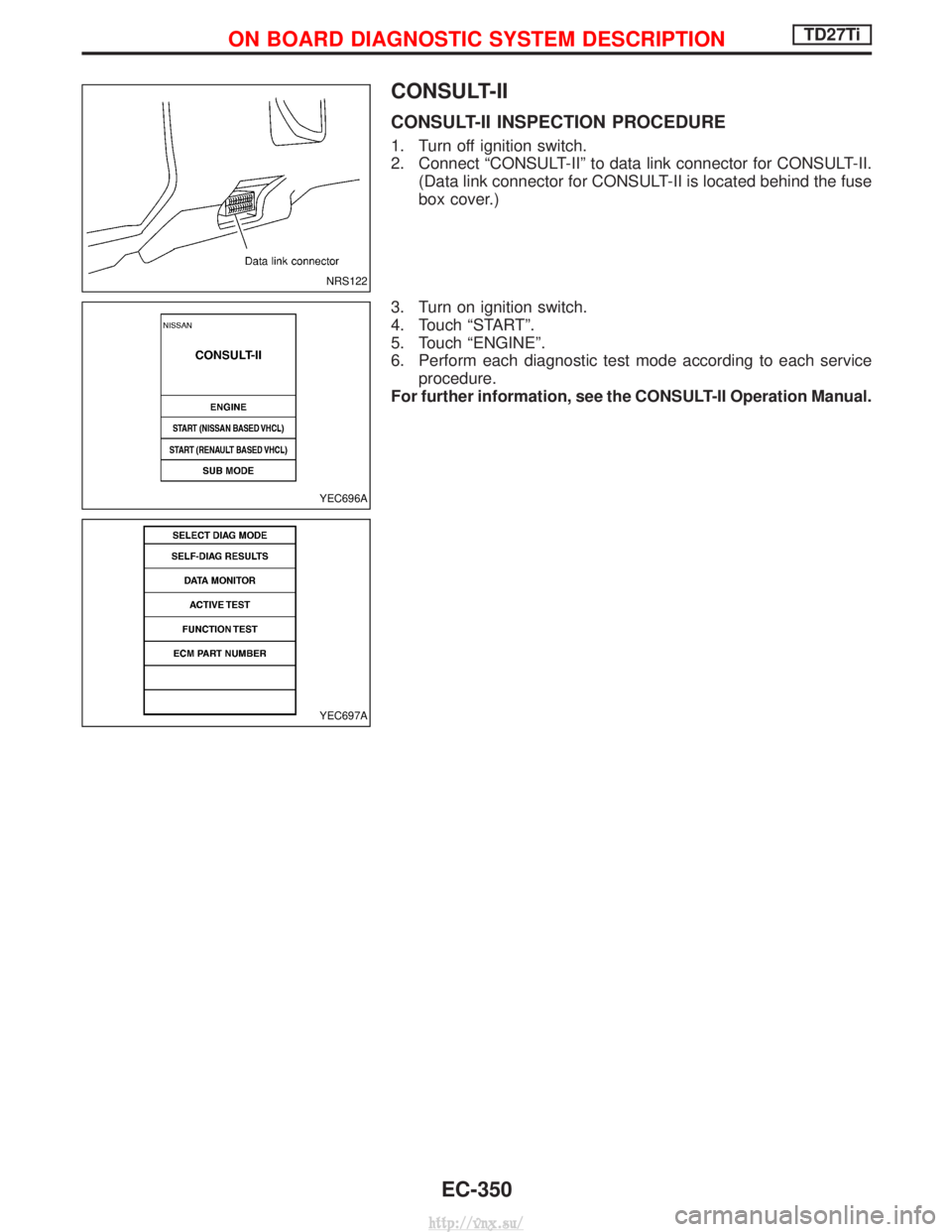

CONSULT-II

CONSULT-II INSPECTION PROCEDURE

1. Turn off ignition switch.

2. Connect ªCONSULT-IIº to data link connector for CONSULT-II.(Data link connector for CONSULT-II is located behind the fuse

box cover.)

3. Turn on ignition switch.

4. Touch ªSTARTº.

5. Touch ªENGINEº.

6. Perform each diagnostic test mode according to each service procedure.

For further information, see the CONSULT-II Operation Manual.

NRS122

YEC696A

YEC697A

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

EC-350

http://vnx.su/

Page 626 of 1833

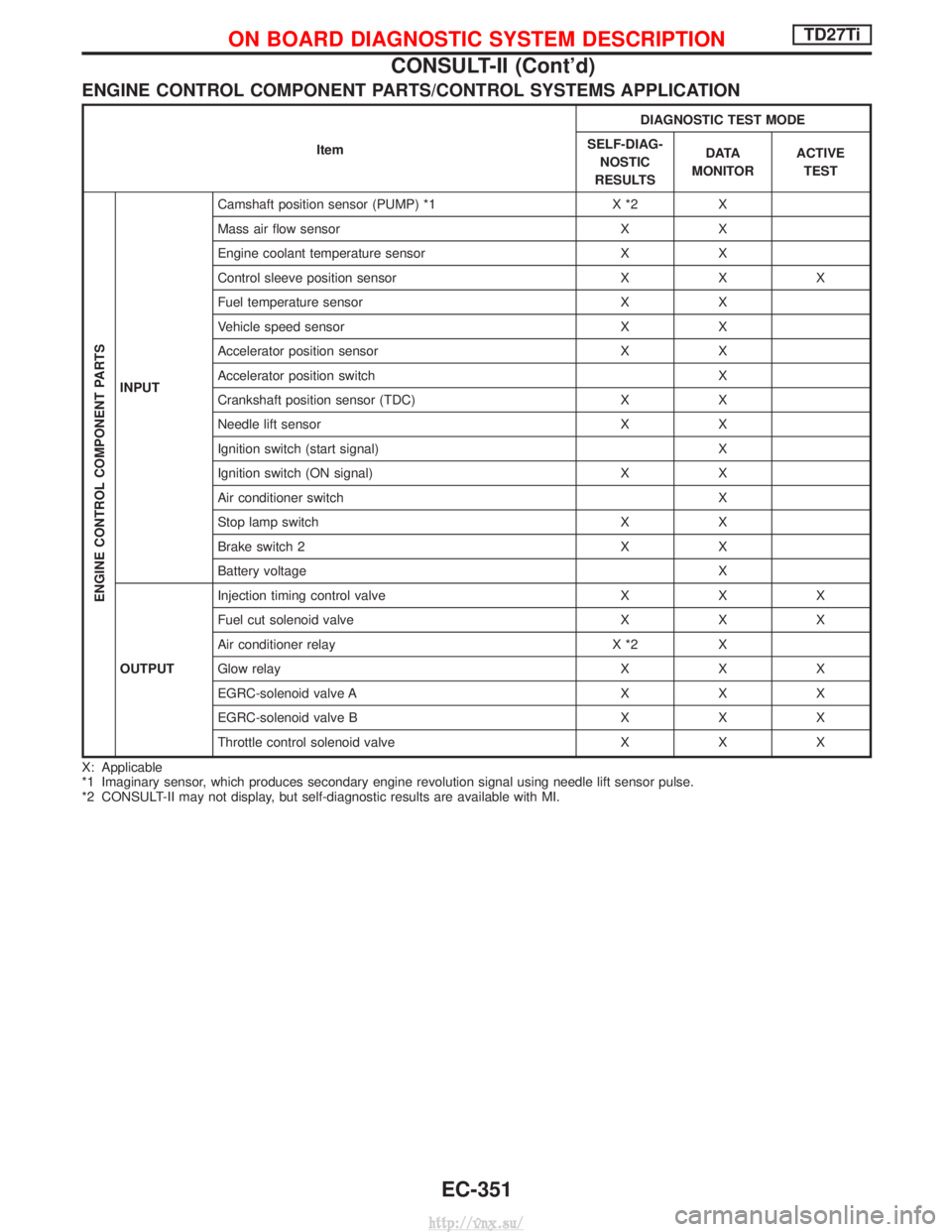

ENGINE CONTROL COMPONENT PARTS/CONTROL SYSTEMS APPLICATION

ItemDIAGNOSTIC TEST MODE

SELF-DIAG- NOSTIC

RESULTS D ATA

MONITOR ACTIVE

TEST

ENGINE CONTROL COMPONENT PARTS

INPUT Camshaft position sensor (PUMP) *1 X *2 X

Mass air flow sensor X X

Engine coolant temperature sensor X X

Control sleeve position sensor X X X

Fuel temperature sensor X X

Vehicle speed sensor X X

Accelerator position sensor X X

Accelerator position switch X

Crankshaft position sensor (TDC) X X

Needle lift sensor X X

Ignition switch (start signal) X

Ignition switch (ON signal) X X

Air conditioner switch X

Stop lamp switch X X

Brake switch 2 X X

Battery voltage X

OUTPUT Injection timing control valve X X X

Fuel cut solenoid valve X X X

Air conditioner relay X *2 X

Glow relay X X X

EGRC-solenoid valve A X X X

EGRC-solenoid valve B X X X

Throttle control solenoid valve X X X

X: Applicable

*1 Imaginary sensor, which produces secondary engine revolution signal using needle lift sensor pulse.

*2 CONSULT-II may not display, but self-diagnostic results are available with MI.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

CONSULT-II (Cont'd)

EC-351

http://vnx.su/

Page 629 of 1833

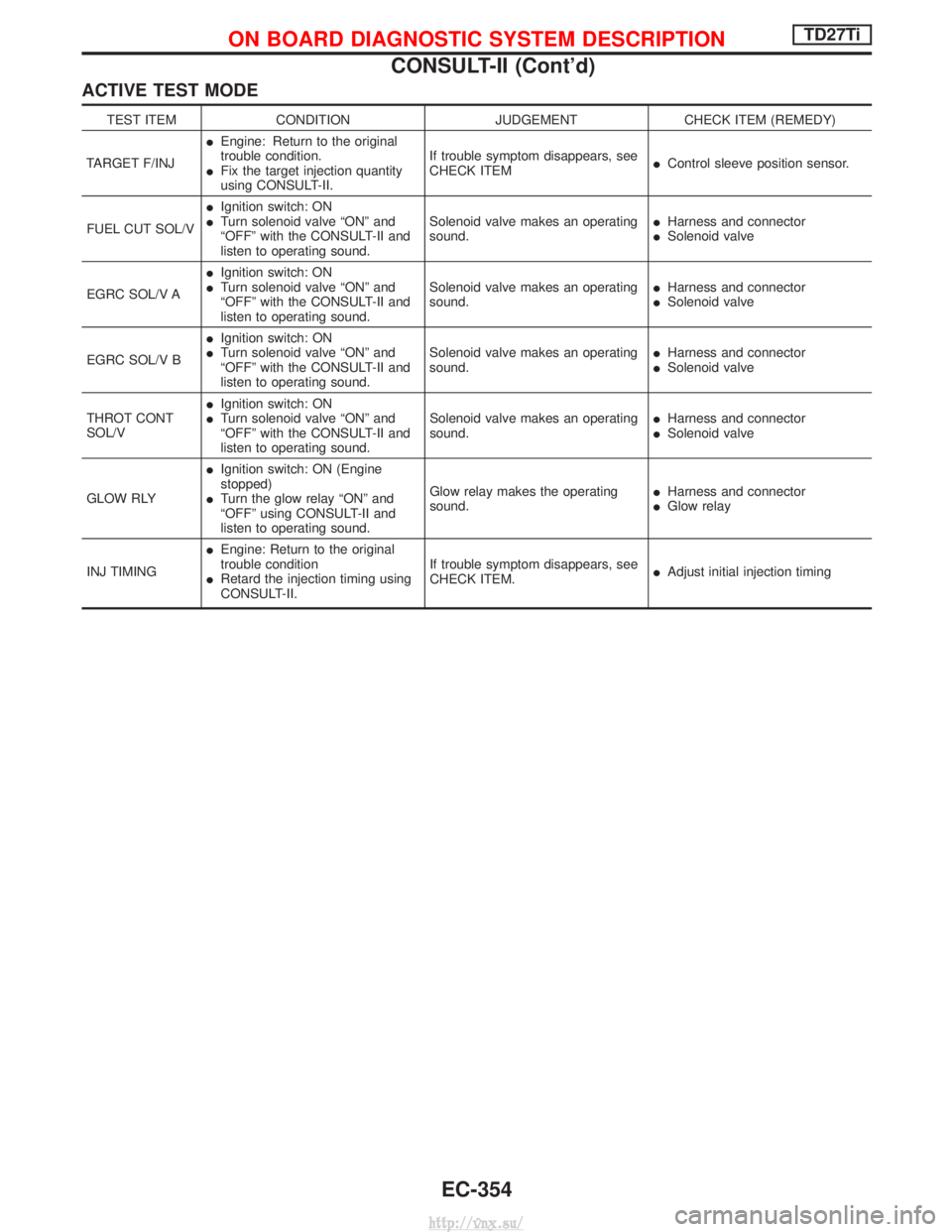

ACTIVE TEST MODE

TEST ITEMCONDITION JUDGEMENTCHECK ITEM (REMEDY)

TARGET F/INJ I

Engine: Return to the original

trouble condition.

I Fix the target injection quantity

using CONSULT-II. If trouble symptom disappears, see

CHECK ITEM

I

Control sleeve position sensor.

FUEL CUT SOL/V I

Ignition switch: ON

I Turn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound. Solenoid valve makes an operating

sound.

I

Harness and connector

I Solenoid valve

EGRC SOL/V A I

Ignition switch: ON

I Turn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound. Solenoid valve makes an operating

sound.

I

Harness and connector

I Solenoid valve

EGRC SOL/V B I

Ignition switch: ON

I Turn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound. Solenoid valve makes an operating

sound.

I

Harness and connector

I Solenoid valve

THROT CONT

SOL/V I

Ignition switch: ON

I Turn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound. Solenoid valve makes an operating

sound.

I

Harness and connector

I Solenoid valve

GLOW RLY I

Ignition switch: ON (Engine

stopped)

I Turn the glow relay ªONº and

ªOFFº using CONSULT-II and

listen to operating sound. Glow relay makes the operating

sound.

I

Harness and connector

I Glow relay

INJ TIMING I

Engine: Return to the original

trouble condition

I Retard the injection timing using

CONSULT-II. If trouble symptom disappears, see

CHECK ITEM.

I

Adjust initial injection timing

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

CONSULT-II (Cont'd)

EC-354

http://vnx.su/

Page 636 of 1833

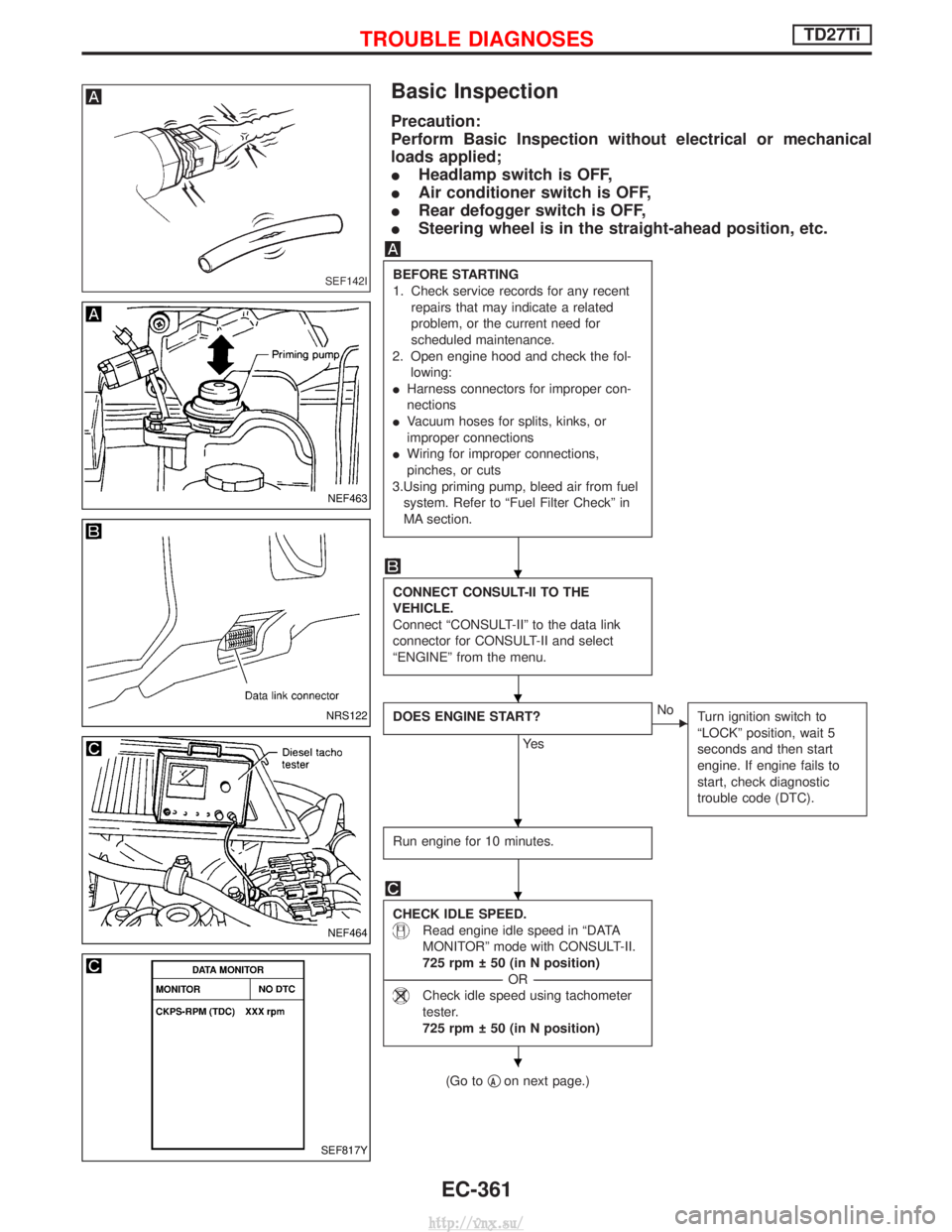

Basic Inspection

Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

IHeadlamp switch is OFF,

I Air conditioner switch is OFF,

I Rear defogger switch is OFF,

I Steering wheel is in the straight-ahead position, etc.

BEFORE STARTING

1. Check service records for any recent

repairs that may indicate a related

problem, or the current need for

scheduled maintenance.

2. Open engine hood and check the fol- lowing:

I Harness connectors for improper con-

nections

I Vacuum hoses for splits, kinks, or

improper connections

I Wiring for improper connections,

pinches, or cuts

3.Using priming pump, bleed air from fuel system. Refer to ªFuel Filter Checkº in

MA section.

CONNECT CONSULT-II TO THE

VEHICLE.

Connect ªCONSULT-IIº to the data link

connector for CONSULT-II and select

ªENGINEº from the menu.

DOES ENGINE START?

Ye s

ENo Turn ignition switch to

ªLOCKº position, wait 5

seconds and then start

engine. If engine fails to

start, check diagnostic

trouble code (DTC).

Run engine for 10 minutes.

CHECK IDLE SPEED.

Read engine idle speed in ªDATA

MONITORº mode with CONSULT-II.

725 rpm 50 (in N position)

----------------------------------------------------------------------------------------------------------------------------------- -OR------------------------------------------------------------------------------------------------------------------------------------

Check idle speed using tachometer

tester.

725 rpm 50 (in N position)

(Go to qAon next page.)

SEF142I

NEF463

NRS122

NEF464

SEF817Y

H

H

H

H

H

TROUBLE DIAGNOSESTD27Ti

EC-361

http://vnx.su/

Page 640 of 1833

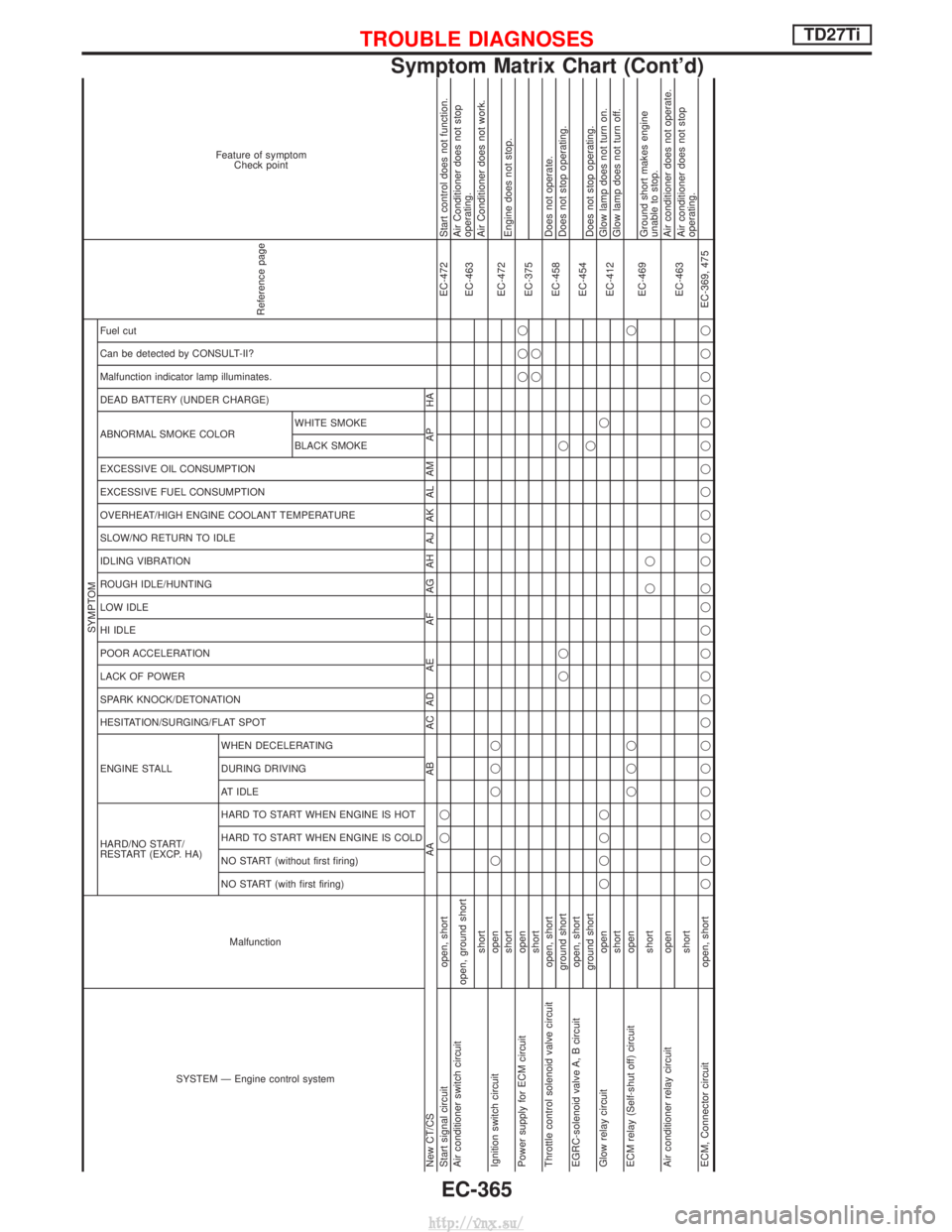

SYSTEM Ð Engine control systemMalfunction

SYMPTOM

Reference page

Feature of symptomCheck point

HARD/NO START/

RESTART (EXCP. HA) ENGINE STALL HESITATION/SURGING/FLAT SPOT SPARK KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE) Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cut NO START (with first firing)

NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATINGBLACK SMOKE

WHITE SMOKE

New CT/CS

AAAB AC AD AE AF AG AH AJ AK AL AM AP HA

Start signal circuit open, shortqq EC-472 Start control does not function.

Air conditioner switch circuit open, ground short

EC-463Air Conditioner does not stop

operating.

short Air Conditioner does not work.

Ignition switch circuit open q qqq

EC-472

short Engine does not stop.

Power supply for ECM circuit open qqq

EC-375

short qq

Throttle control solenoid valve circuit open, short EC-458Does not operate.

ground short qq q Does not stop operating.

EGRC-solenoid valve A, B circuit open, short EC-454

ground short qDoes not stop operating.

Glow relay circuit open qqqq q

EC-412Glow lamp does not turn on.

short Glow lamp does not turn off.

ECM relay (Self-shut off) circuit open qqq q

EC-469

short qqGround short makes engine

unable to stop.

Air conditioner relay circuit open EC-463Air conditioner does not operate.

short Air conditioner does not stop

operating.

ECM, Connector circuit open, short qqqqqqqqqqqqqq qqqqqqqqqqq EC-369, 475

TROUBLE DIAGNOSESTD27Ti

Symptom Matrix Chart (Cont'd)

EC-365

http://vnx.su/

Page 641 of 1833

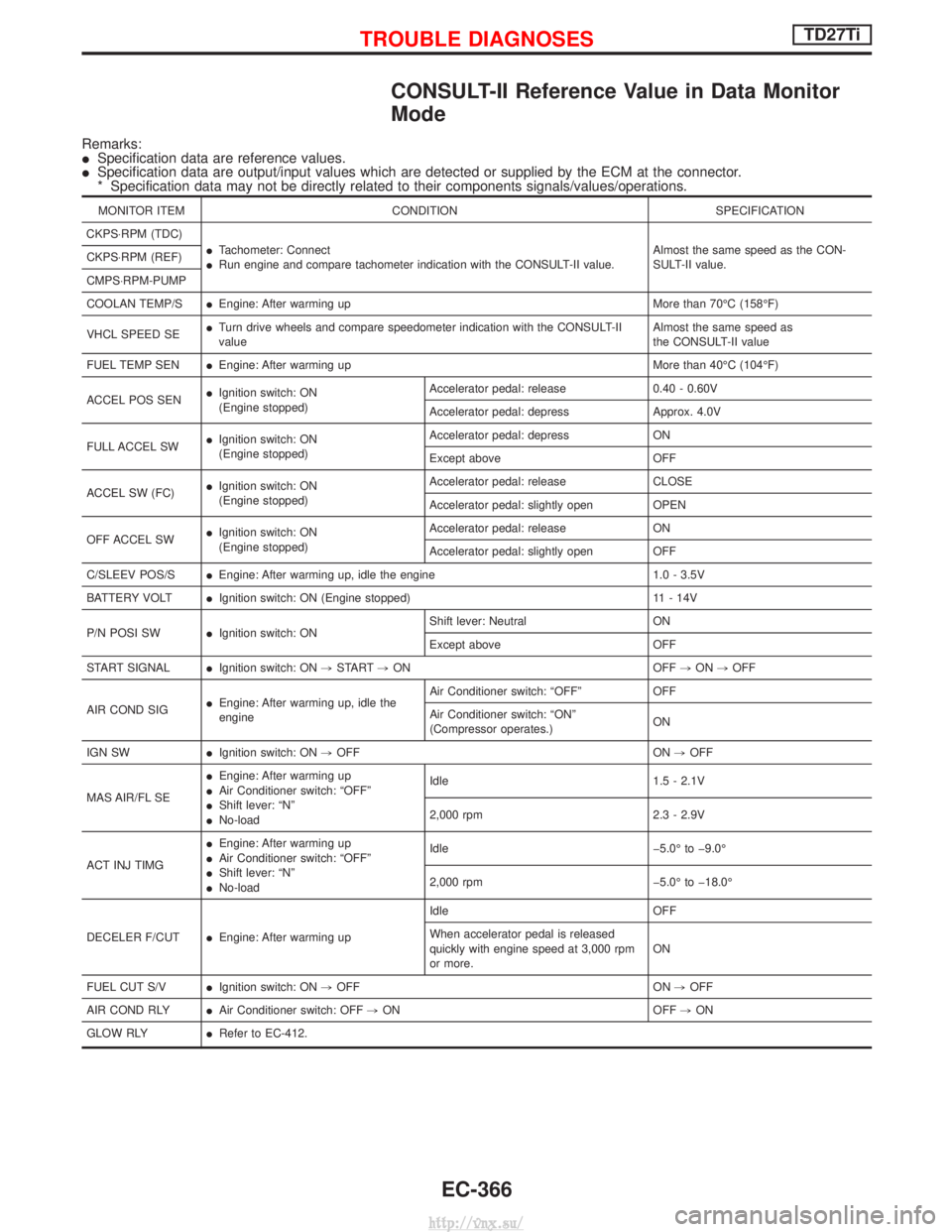

CONSULT-II Reference Value in Data Monitor

Mode

Remarks:

ISpecification data are reference values.

I Specification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

MONITOR ITEM CONDITION SPECIFICATION

CKPS×RPM (TDC) ITachometer: Connect

I Run engine and compare tachometer indication with the CONSULT-II value. Almost the same speed as the CON-

SULT-II value.

CKPS×RPM (REF)

CMPS×RPM-PUMP

COOLAN TEMP/S

IEngine: After warming up More than 70ÉC (158ÉF)

VHCL SPEED SE I

Turn drive wheels and compare speedometer indication with the CONSULT-II

value Almost the same speed as

the CONSULT-II value

FUEL TEMP SEN IEngine: After warming up More than 40ÉC (104ÉF)

ACCEL POS SEN I

Ignition switch: ON

(Engine stopped) Accelerator pedal: release 0.40 - 0.60V

Accelerator pedal: depress Approx. 4.0V

FULL ACCEL SW I

Ignition switch: ON

(Engine stopped) Accelerator pedal: depress ON

Except above OFF

ACCEL SW (FC) I

Ignition switch: ON

(Engine stopped) Accelerator pedal: release CLOSE

Accelerator pedal: slightly open OPEN

OFF ACCEL SW I

Ignition switch: ON

(Engine stopped) Accelerator pedal: release ON

Accelerator pedal: slightly open OFF

C/SLEEV POS/S IEngine: After warming up, idle the engine 1.0 - 3.5V

BATTERY VOLT IIgnition switch: ON (Engine stopped) 11 - 14V

P/N POSI SW IIgnition switch: ON Shift lever: Neutral ON

Except above OFF

START SIGNAL IIgnition switch: ON ,START ,ON OFF ,ON ,OFF

AIR COND SIG I

Engine: After warming up, idle the

engine Air Conditioner switch: ªOFFº OFF

Air Conditioner switch: ªONº

(Compressor operates.)

ON

IGN SW IIgnition switch: ON ,OFF ON ,OFF

MAS AIR/FL SE I

Engine: After warming up

I Air Conditioner switch: ªOFFº

I Shift lever: ªNº

I No-load Idle 1.5 - 2.1V

2,000 rpm 2.3 - 2.9V

ACT INJ TIMG I

Engine: After warming up

I Air Conditioner switch: ªOFFº

I Shift lever: ªNº

I No-load Idle þ5.0É to þ9.0É

2,000 rpm þ5.0É to þ18.0É

DECELER F/CUT IEngine: After warming up Idle OFF

When accelerator pedal is released

quickly with engine speed at 3,000 rpm

or more.

ON

FUEL CUT S/V IIgnition switch: ON ,OFF ON ,OFF

AIR COND RLY IAir Conditioner switch: OFF ,ON OFF ,ON

GLOW RLY IRefer to EC-412.

TROUBLE DIAGNOSESTD27Ti

EC-366

http://vnx.su/

Page 645 of 1833

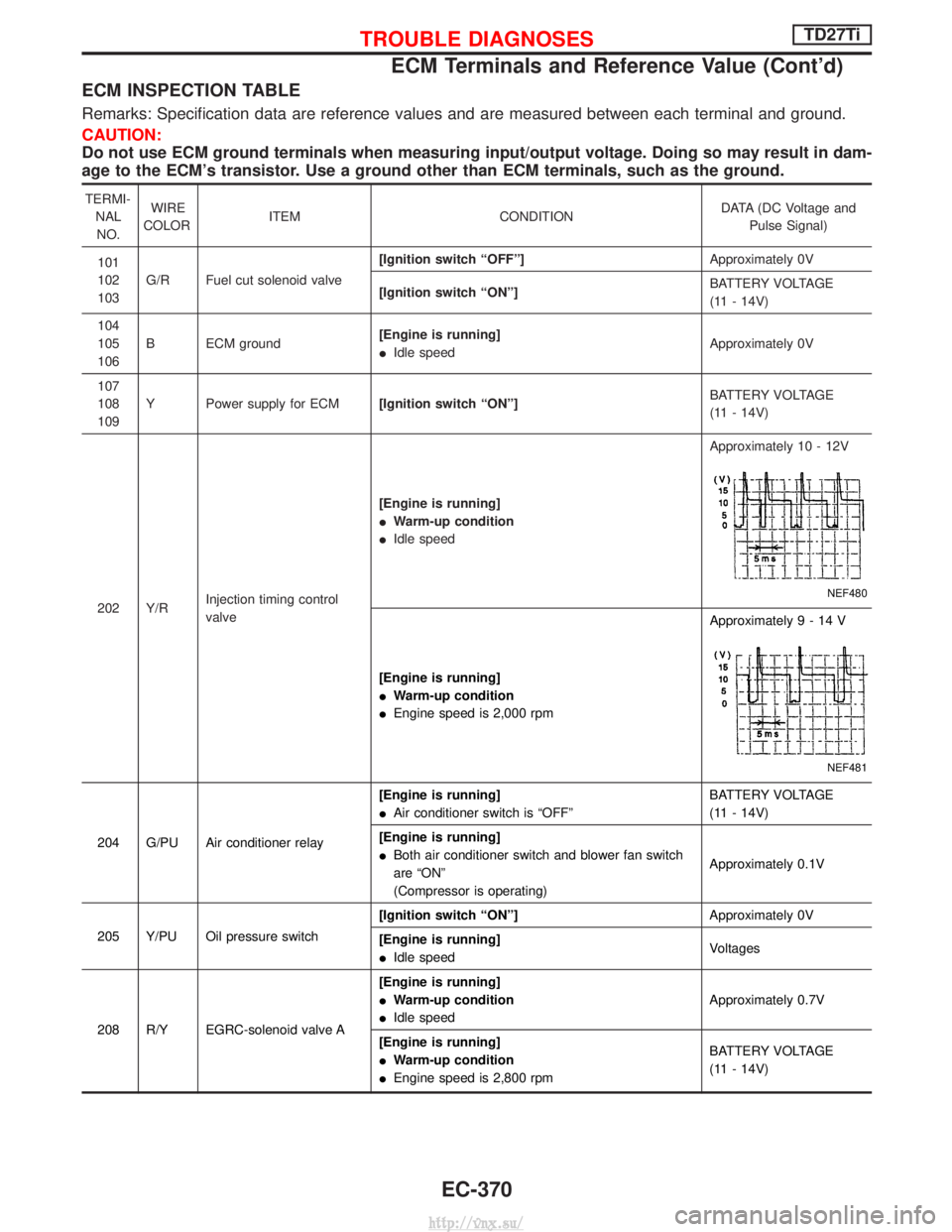

ECM INSPECTION TABLE

Remarks: Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-NALNO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and

Pulse Signal)

101

102

103 G/R Fuel cut solenoid valve [Ignition switch ªOFFº]

Approximately 0V

[Ignition switch ªONº] BATTERY VOLTAGE

(11 - 14V)

104

105

106 B ECM ground

[Engine is running]

I

Idle speed Approximately 0V

107

108

109 Y Power supply for ECM

[Ignition switch ªONº] BATTERY VOLTAGE

(11 - 14V)

202 Y/R Injection timing control

valve [Engine is running]

I

Warm-up condition

I Idle speed Approximately 10 - 12V

NEF480

[Engine is running]

I

Warm-up condition

I Engine speed is 2,000 rpm Approximately9-14V

NEF481

204 G/PU Air conditioner relay

[Engine is running]

I

Air conditioner switch is ªOFFº BATTERY VOLTAGE

(11 - 14V)

[Engine is running]

I Both air conditioner switch and blower fan switch

are ªONº

(Compressor is operating) Approximately 0.1V

205 Y/PU Oil pressure switch [Ignition switch ªONº]

Approximately 0V

[Engine is running]

I Idle speed Voltages

208 R/Y EGRC-solenoid valve A [Engine is running]

I

Warm-up condition

I Idle speed Approximately 0.7V

[Engine is running]

I Warm-up condition

I Engine speed is 2,800 rpm BATTERY VOLTAGE

(11 - 14V)

TROUBLE DIAGNOSESTD27Ti

ECM Terminals and Reference Value (Cont'd)

EC-370

http://vnx.su/

Page 646 of 1833

![NISSAN TERRANO 2004 Service Repair Manual TERMI-NALNO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and

Pulse Signal)

210 Y/B EGRC-solenoid valve B [Engine is running]

I

Warm-up condition

I Idle speed Approximately 0.4V

[Engine is running]

I Wa NISSAN TERRANO 2004 Service Repair Manual TERMI-NALNO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and

Pulse Signal)

210 Y/B EGRC-solenoid valve B [Engine is running]

I

Warm-up condition

I Idle speed Approximately 0.4V

[Engine is running]

I Wa](/img/5/57394/w960_57394-645.png)

TERMI-NALNO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and

Pulse Signal)

210 Y/B EGRC-solenoid valve B [Engine is running]

I

Warm-up condition

I Idle speed Approximately 0.4V

[Engine is running]

I Warm-up condition

I Engine speed is 2,500 rpm BATTERY VOLTAGE

(11 - 14V)

213 G/Y Throttle control solenoid

valve [Engine is running]

I

Warm-up condition

I Low load Approximately 0V

Except above condition Battery voltage (12 - 14V)

214 LG Glow relay Refer to ªGlow Control Systemº, EC-412.

215 L Malfunction indicator (MI) [Ignition switch ªONº]

Approximately 1.0V

[Engine is running]

I Idle speed BATTERY VOLTAGE

(11 - 14V)

218 G/R Sensors' ground [Engine is running]

I

Warm-up condition

I Idle speed Approximately 0V

219 LG/R Cooling fan relay [Engine is running]

I

Cooling fan is not operating BATTERY VOLTAGE

(11 - 14V)

[Engine is running]

I Cooling fan is operating Approximately 0.1V

221 G/W Glow lamp [Ignition switch ªONº]

I

Glow lamp is ªONº Approximately 1V

[Ignition switch ªONº]

I Glow lamp is ªOFFº BATTERY VOLTAGE

(11 - 14V)

223 R/L Mass air flow sensor

power supply [Ignition switch ªONº]

Approximately 5V

224 L/W Mass air flow sensor [Engine is running]

I

Warm-up condition

I Idle speed 1.5 - 2.0V

320 W Control sleeve position

sensor [Engine is running]

I

Idle speed Approximately 2.6V

NEF477

321 R

Control sleeve position

sensor power supply [Engine is running]

I

Idle speed Approximately 2.6V

NEF476

TROUBLE DIAGNOSESTD27Ti

ECM Terminals and Reference Value (Cont'd)

EC-371

http://vnx.su/