NISSAN TERRANO 2004 Service Repair Manual

TERRANO 2004

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57394/w960_57394-0.png

NISSAN TERRANO 2004 Service Repair Manual

Trending: bolt pattern, Rocker, ad blue, cooling, speedometer, parking brake, fuse chart

Page 371 of 1833

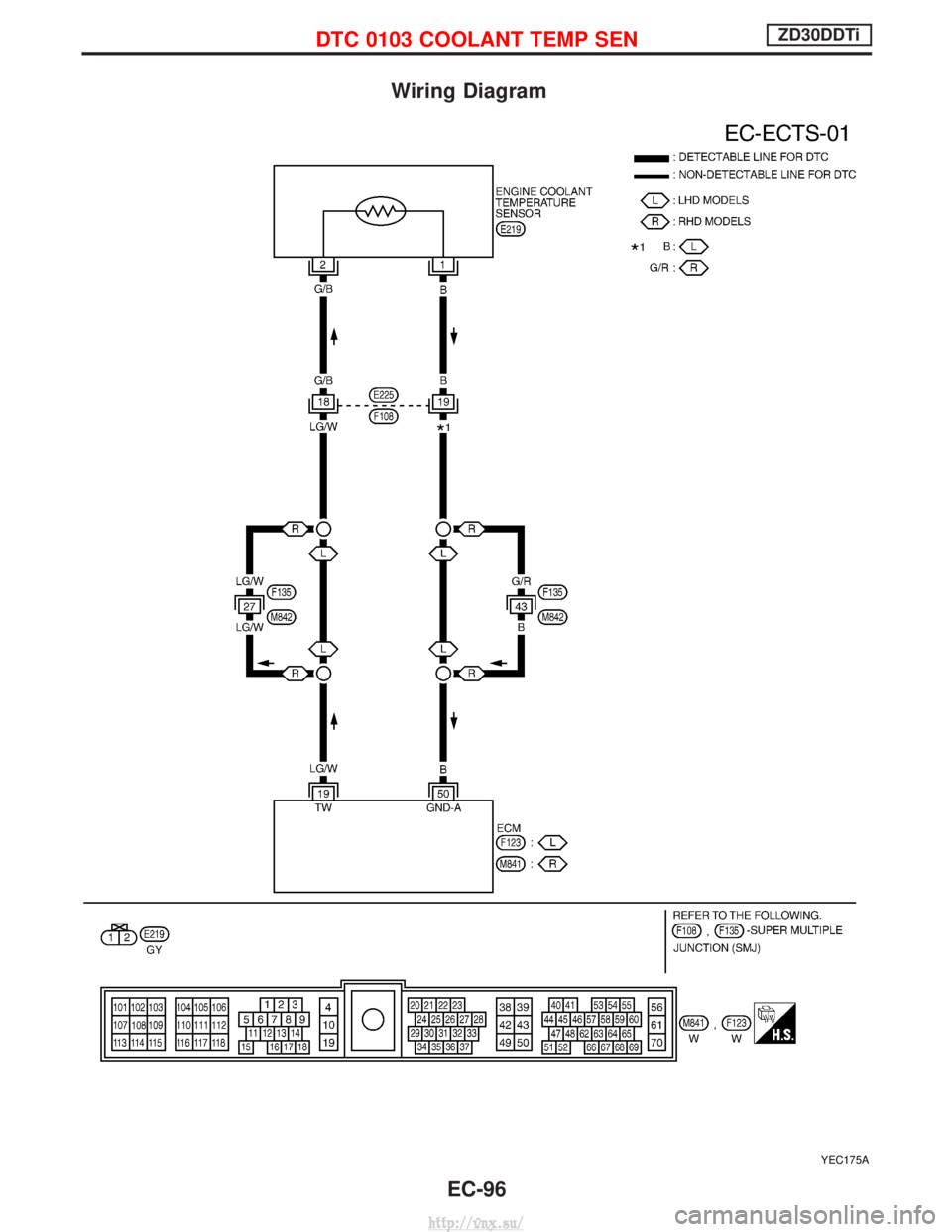

Wiring Diagram

YEC175A

DTC 0103 COOLANT TEMP SENZD30DDTi

EC-96

http://vnx.su/

Page 372 of 1833

Diagnostic Procedure

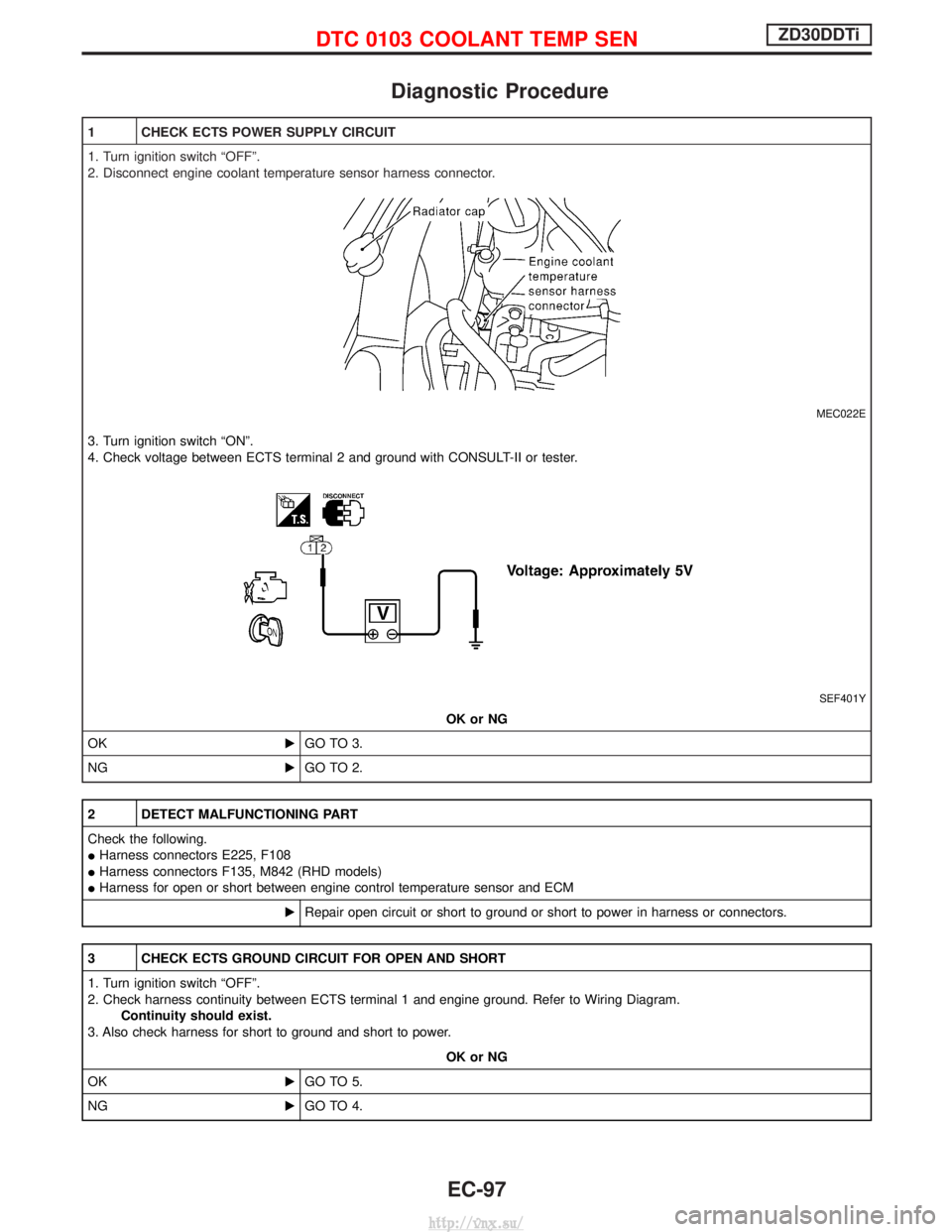

1 CHECK ECTS POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect engine coolant temperature sensor harness connector.

MEC022E

3. Turn ignition switch ªONº.

4. Check voltage between ECTS terminal 2 and ground with CONSULT-II or tester.

SEF401Y

OK or NG

OK EGO TO 3.

NG EGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

I Harness connectors F135, M842 (RHD models)

I Harness for open or short between engine control temperature sensor and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ECTS GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between ECTS terminal 1 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 5.

NG EGO TO 4.

DTC 0103 COOLANT TEMP SENZD30DDTi

EC-97

http://vnx.su/

Page 373 of 1833

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

I Harness connectors F135, M842 (RHD models)

I Harness for open or short between engine coolant temperature sensor and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

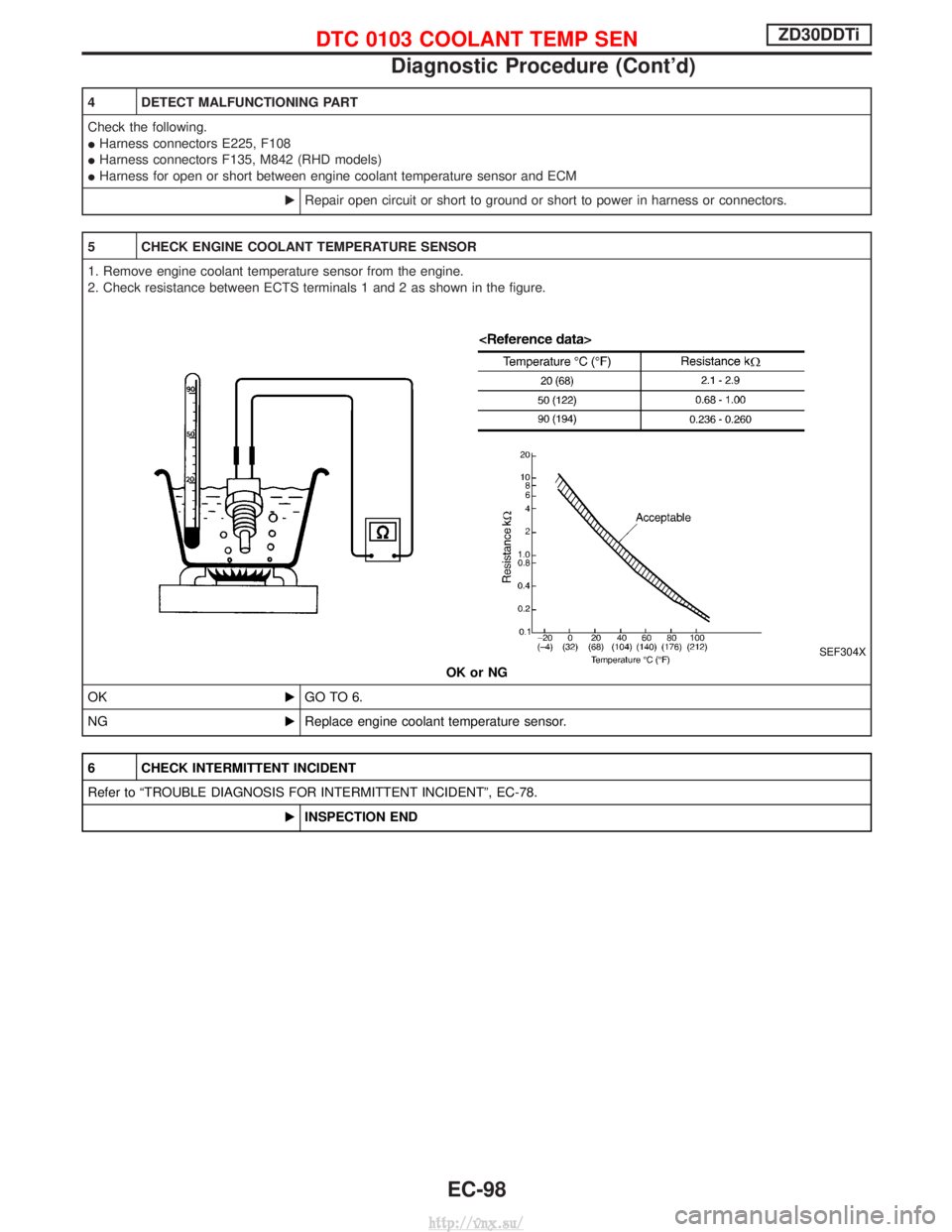

5 CHECK ENGINE COOLANT TEMPERATURE SENSOR

1. Remove engine coolant temperature sensor from the engine.

2. Check resistance between ECTS terminals 1 and 2 as shown in the figure.

SEF304X

OK or NG

OK EGO TO 6.

NG EReplace engine coolant temperature sensor.

6 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

DTC 0103 COOLANT TEMP SENZD30DDTi

Diagnostic Procedure (Cont'd)

EC-98

http://vnx.su/

Page 374 of 1833

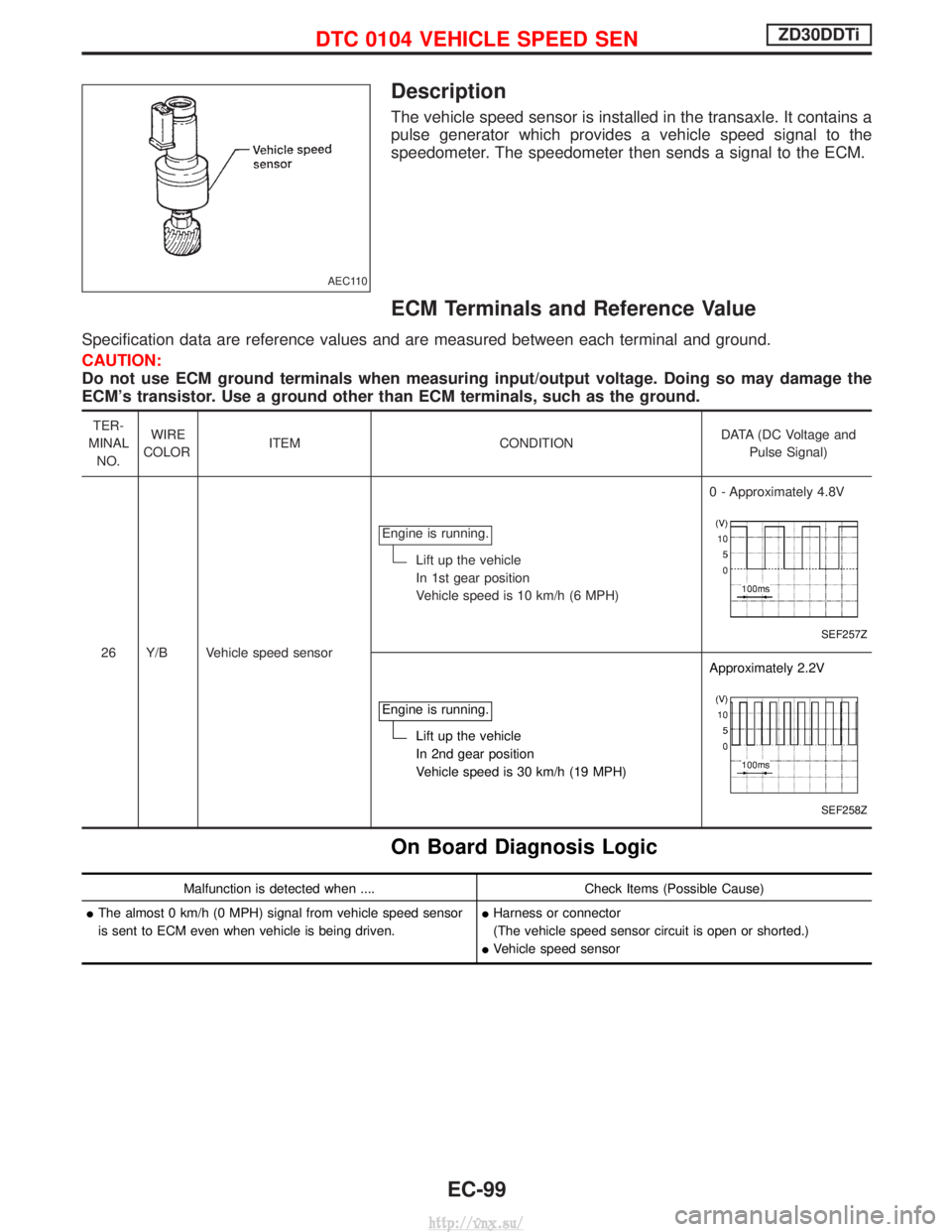

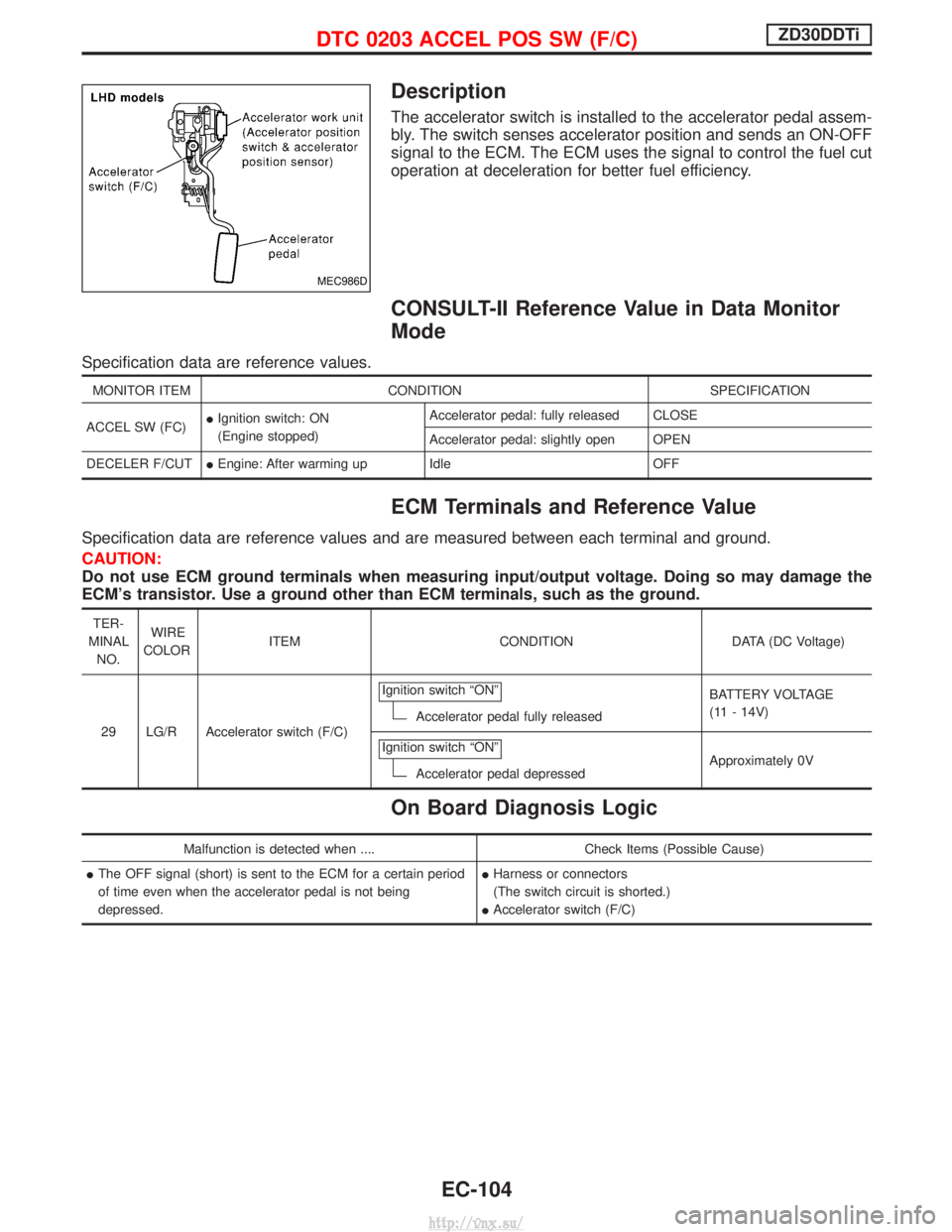

Description

The vehicle speed sensor is installed in the transaxle. It contains a

pulse generator which provides a vehicle speed signal to the

speedometer. The speedometer then sends a signal to the ECM.

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and

Pulse Signal)

26 Y/B Vehicle speed sensor Engine is running.

Lift up the vehicle

In 1st gear position

Vehicle speed is 10 km/h (6 MPH)

0 - Approximately 4.8V

SEF257Z

Engine is running.

Lift up the vehicle

In 2nd gear position

Vehicle speed is 30 km/h (19 MPH)Approximately 2.2V

SEF258Z

On Board Diagnosis Logic

Malfunction is detected when ....

Check Items (Possible Cause)

I The almost 0 km/h (0 MPH) signal from vehicle speed sensor

is sent to ECM even when vehicle is being driven. I

Harness or connector

(The vehicle speed sensor circuit is open or shorted.)

I Vehicle speed sensor

AEC110

DTC 0104 VEHICLE SPEED SENZD30DDTi

EC-99

http://vnx.su/

Page 375 of 1833

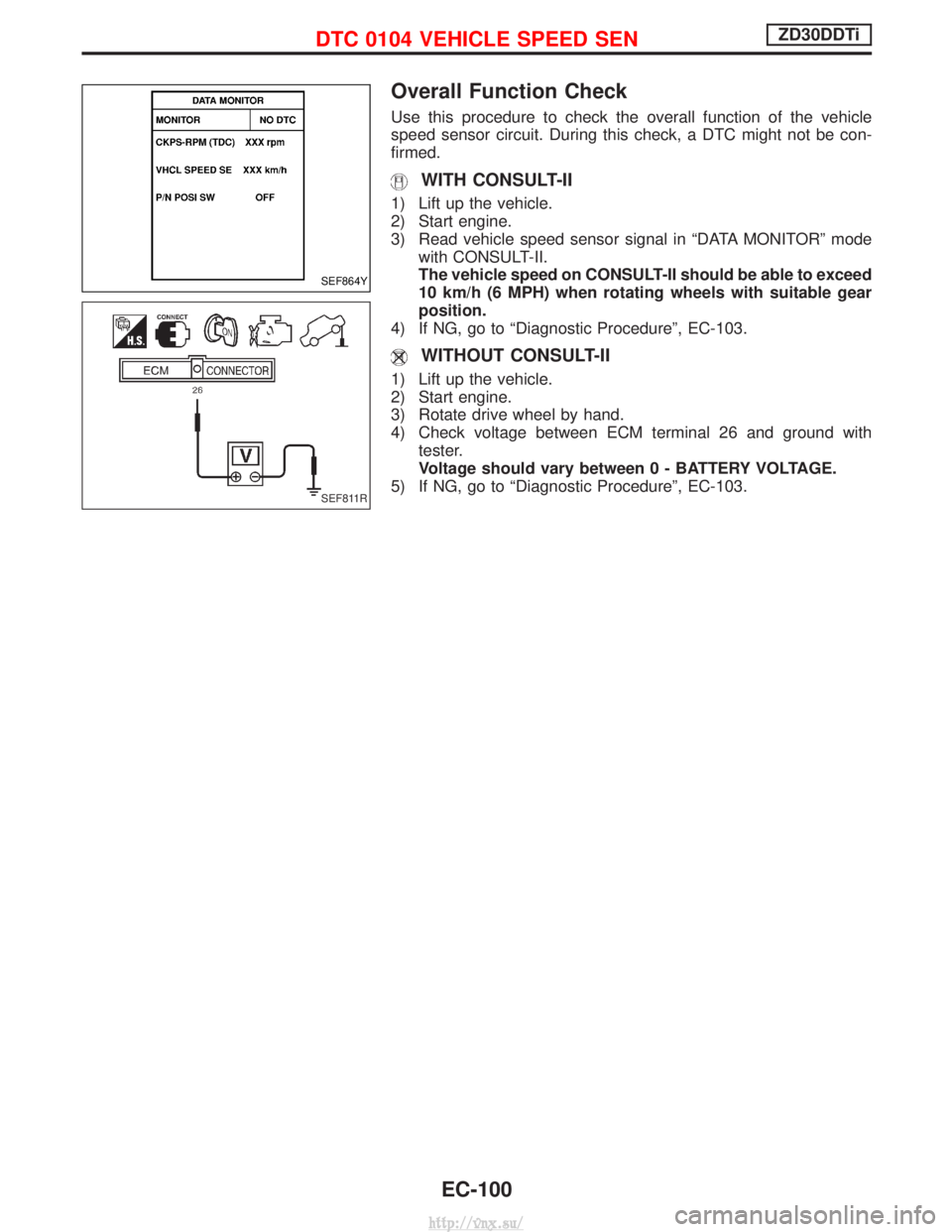

Overall Function Check

Use this procedure to check the overall function of the vehicle

speed sensor circuit. During this check, a DTC might not be con-

firmed.

WITH CONSULT-II

1) Lift up the vehicle.

2) Start engine.

3) Read vehicle speed sensor signal in ªDATA MONITORº modewith CONSULT-II.

The vehicle speed on CONSULT-II should be able to exceed

10 km/h (6 MPH) when rotating wheels with suitable gear

position.

4) If NG, go to ªDiagnostic Procedureº, EC-103.

WITHOUT CONSULT-II

1) Lift up the vehicle.

2) Start engine.

3) Rotate drive wheel by hand.

4) Check voltage between ECM terminal 26 and ground with tester.

Voltage should vary between0-BA TTERY VOLTAGE.

5) If NG, go to ªDiagnostic Procedureº, EC-103.

SEF864Y

SEF811R

DTC 0104 VEHICLE SPEED SENZD30DDTi

EC-100

http://vnx.su/

Page 376 of 1833

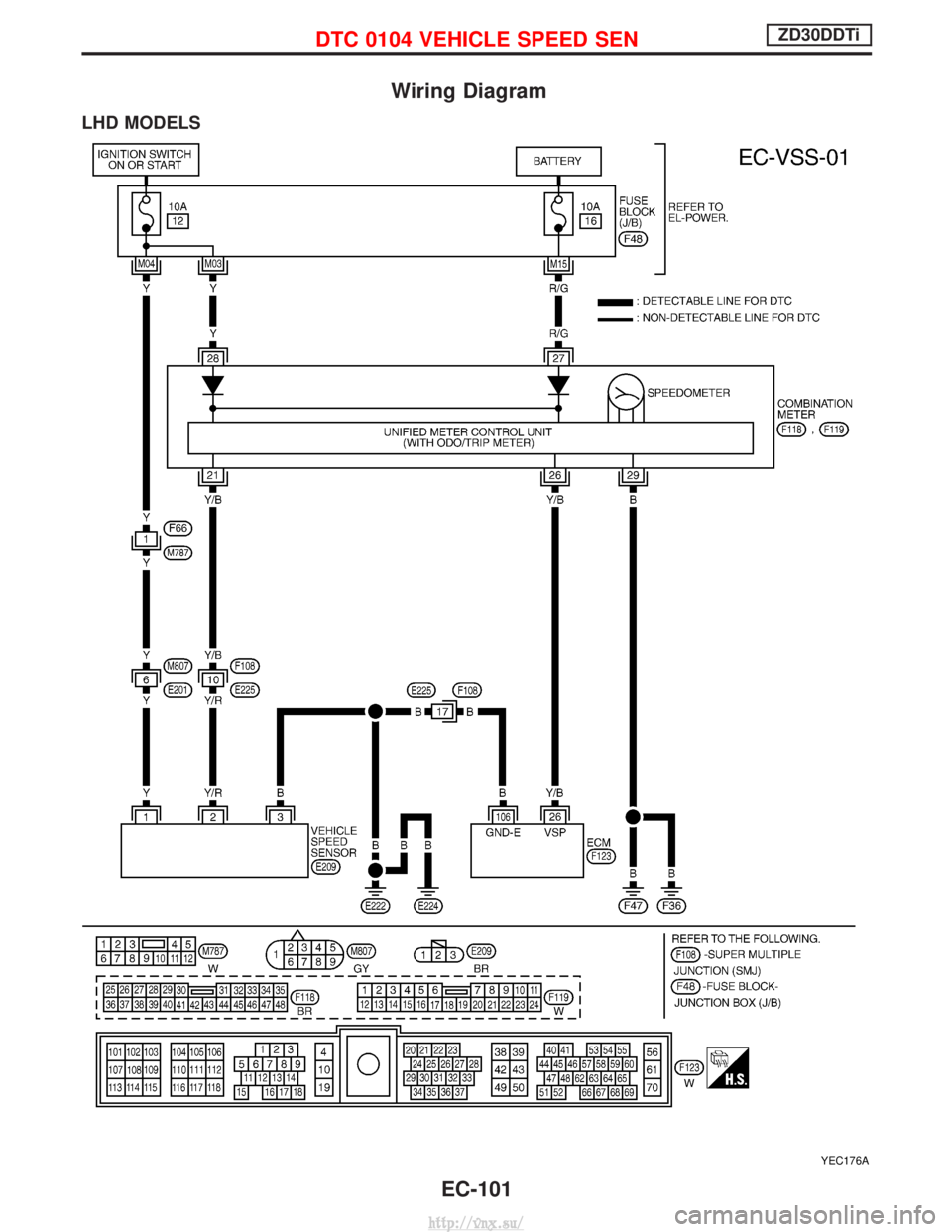

Wiring Diagram

LHD MODELS

YEC176A

DTC 0104 VEHICLE SPEED SENZD30DDTi

EC-101

http://vnx.su/

Page 377 of 1833

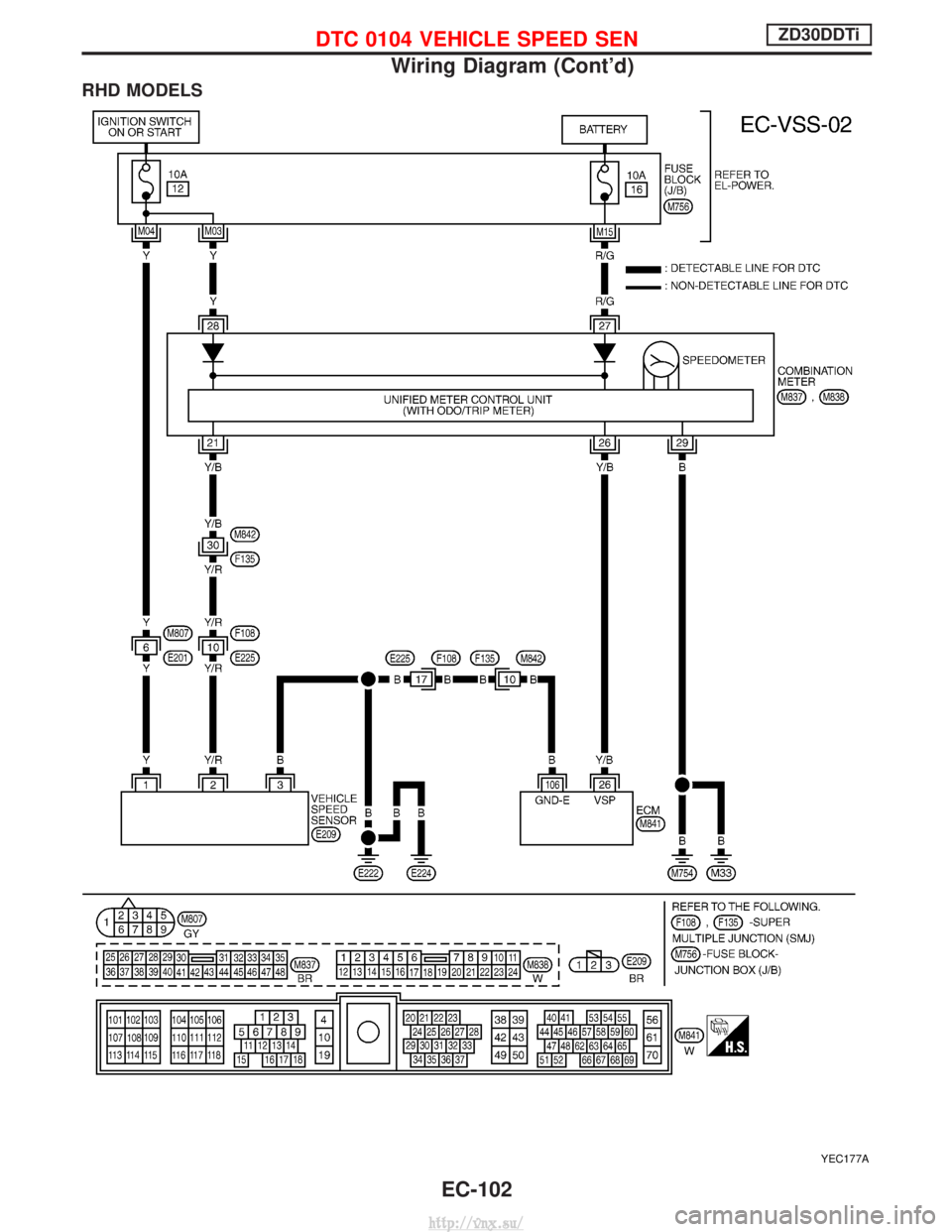

RHD MODELS

YEC177A

DTC 0104 VEHICLE SPEED SENZD30DDTi

Wiring Diagram (Cont'd)EC-102

http://vnx.su/

Page 378 of 1833

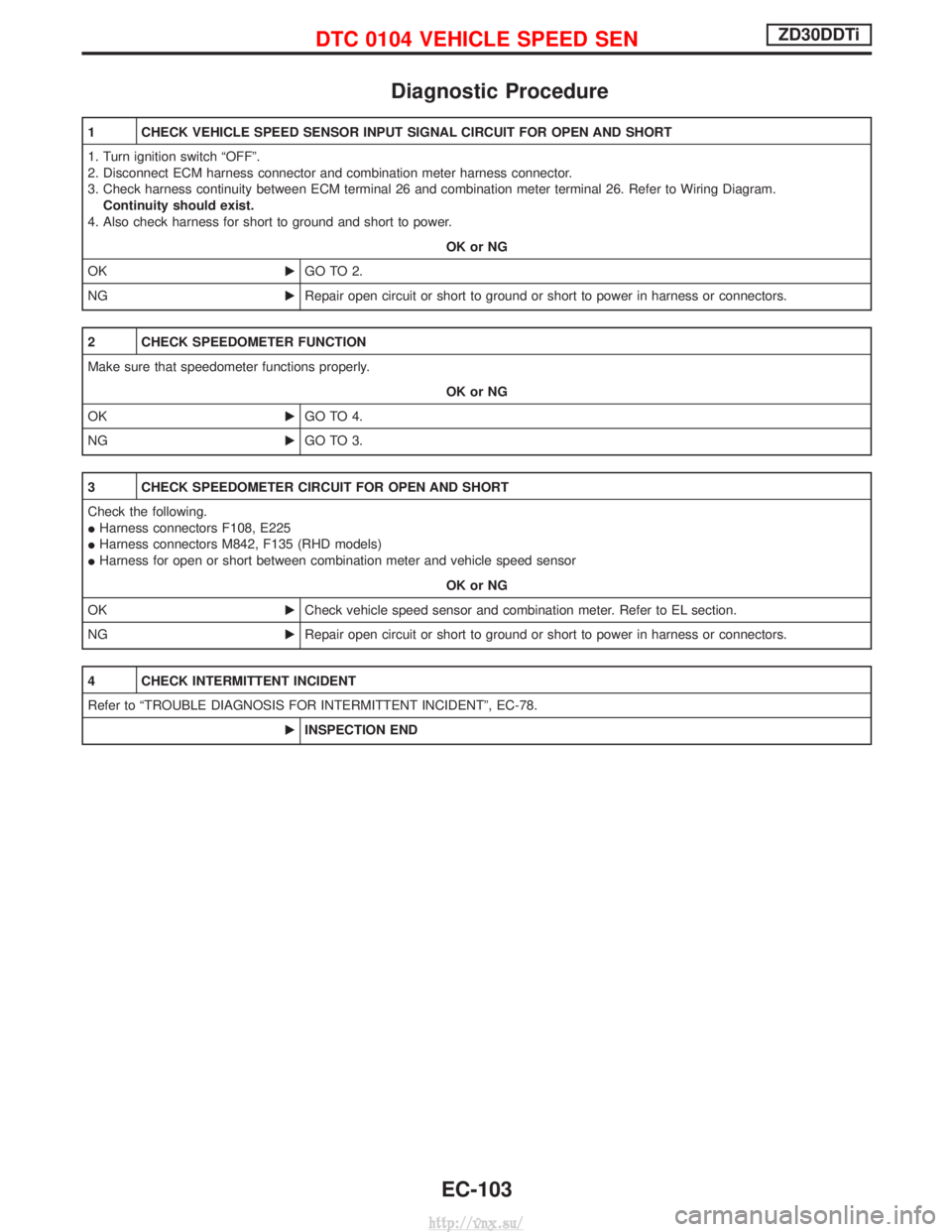

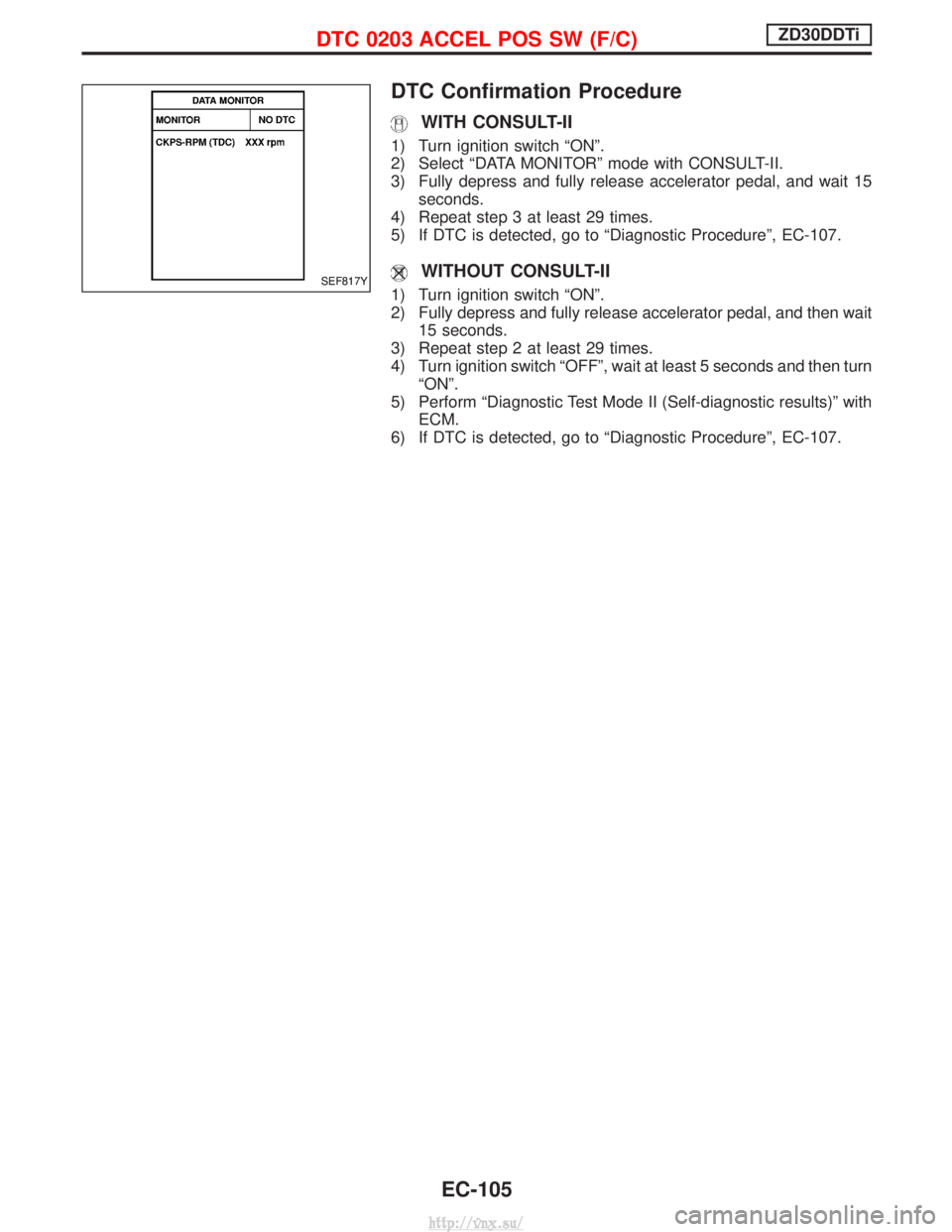

Diagnostic Procedure

1 CHECK VEHICLE SPEED SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector and combination meter harness connector.

3. Check harness continuity between ECM terminal 26 and combination meter terminal 26. Refer to Wiring Diagram.Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 2.

NG ERepair open circuit or short to ground or short to power in harness or connectors.

2 CHECK SPEEDOMETER FUNCTION

Make sure that speedometer functions properly.

OK or NG

OK EGO TO 4.

NG EGO TO 3.

3 CHECK SPEEDOMETER CIRCUIT FOR OPEN AND SHORT

Check the following.

IHarness connectors F108, E225

I Harness connectors M842, F135 (RHD models)

I Harness for open or short between combination meter and vehicle speed sensor

OK or NG

OK ECheck vehicle speed sensor and combination meter. Refer to EL section.

NG ERepair open circuit or short to ground or short to power in harness or connectors.

4 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

DTC 0104 VEHICLE SPEED SENZD30DDTi

EC-103

http://vnx.su/

Page 379 of 1833

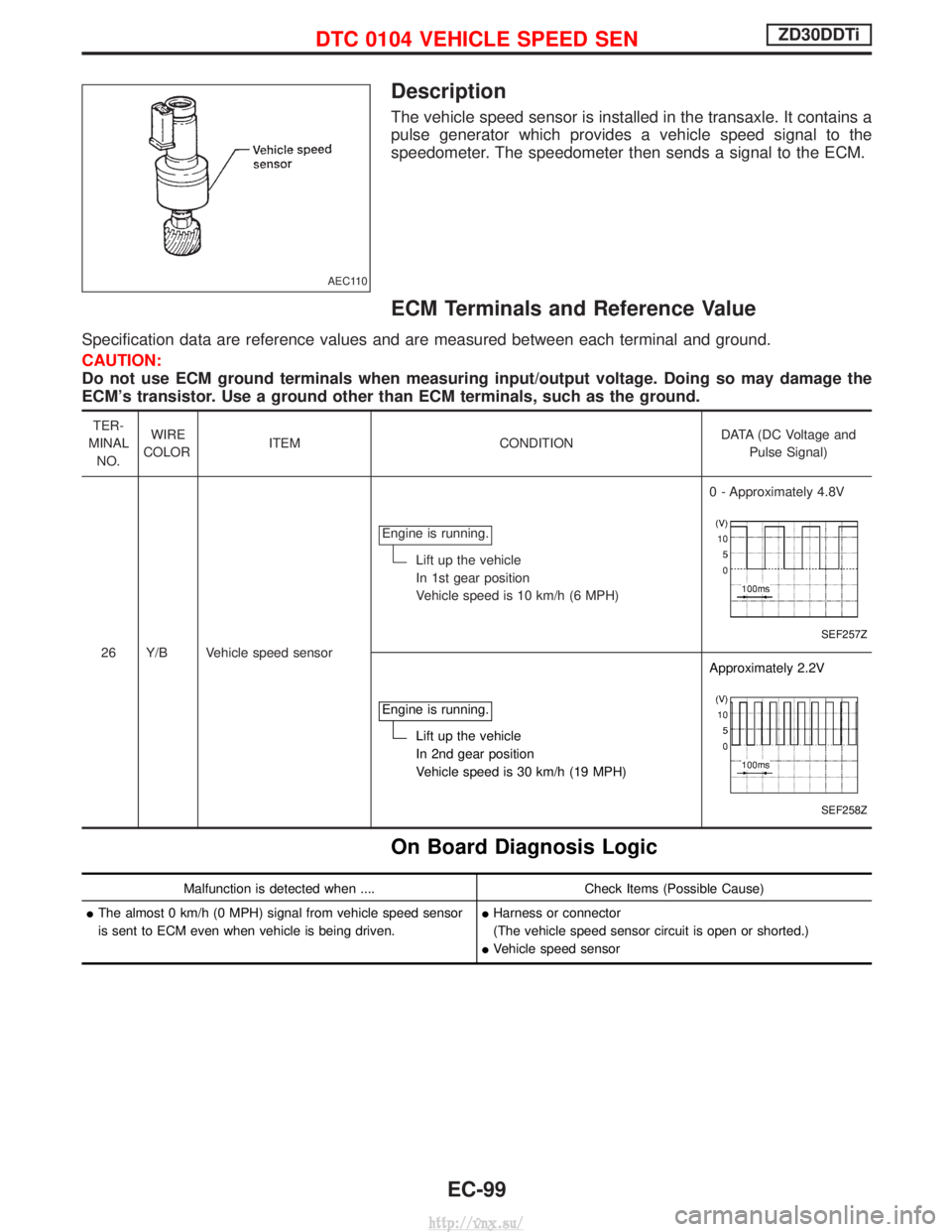

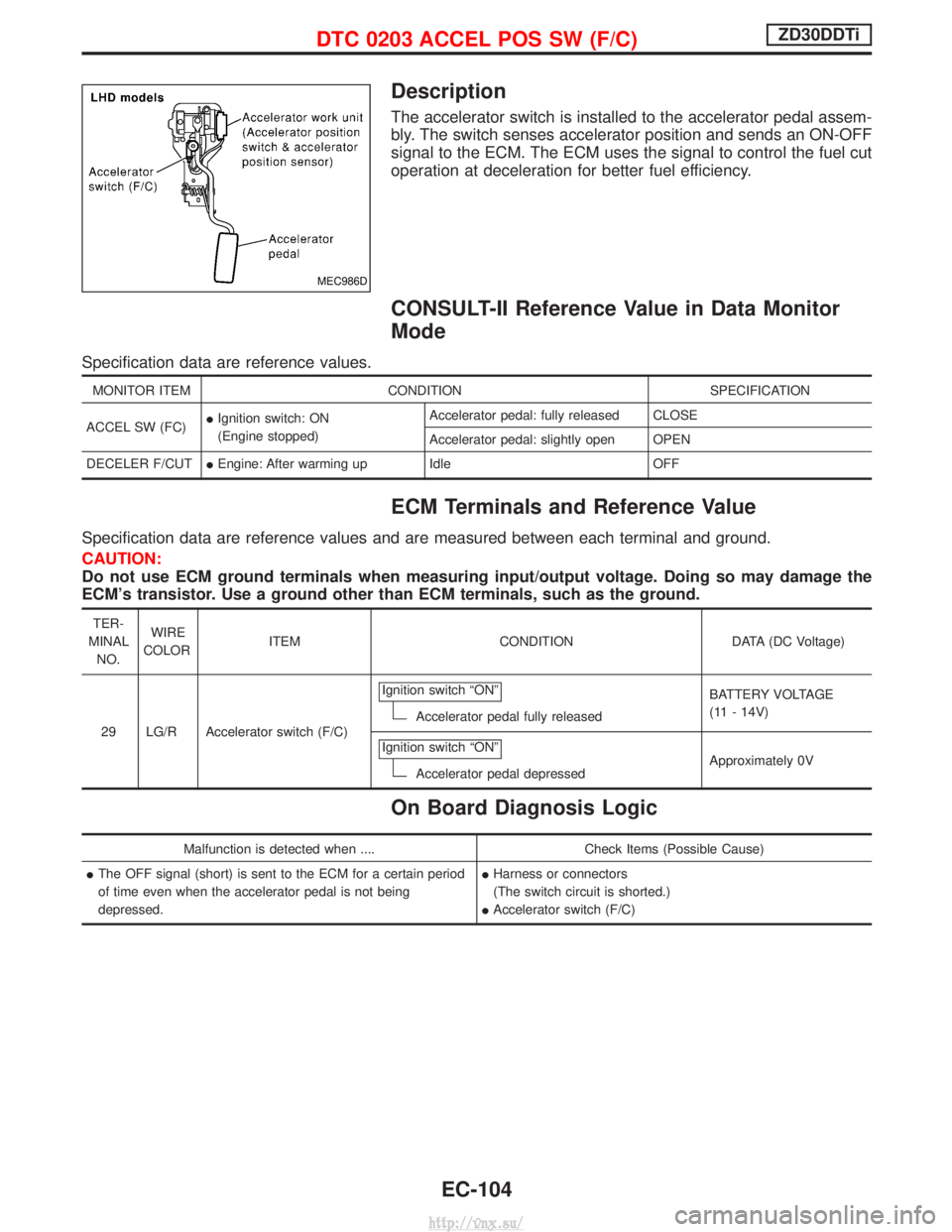

Description

The accelerator switch is installed to the accelerator pedal assem-

bly. The switch senses accelerator position and sends an ON-OFF

signal to the ECM. The ECM uses the signal to control the fuel cut

operation at deceleration for better fuel efficiency.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEMCONDITION SPECIFICATION

ACCEL SW (FC) I

Ignition switch: ON

(Engine stopped) Accelerator pedal: fully released CLOSE

Accelerator pedal: slightly open OPEN

DECELER F/CUT IEngine: After warming up Idle OFF

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

29 LG/R Accelerator switch (F/C) Ignition switch ªONº

Accelerator pedal fully released

BATTERY VOLTAGE

(11 - 14V)

Ignition switch ªONº

Accelerator pedal depressed Approximately 0V

On Board Diagnosis Logic

Malfunction is detected when ....

Check Items (Possible Cause)

I The OFF signal (short) is sent to the ECM for a certain period

of time even when the accelerator pedal is not being

depressed. I

Harness or connectors

(The switch circuit is shorted.)

I Accelerator switch (F/C)

MEC986D

DTC 0203 ACCEL POS SW (F/C)ZD30DDTi

EC-104

http://vnx.su/

Page 380 of 1833

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Fully depress and fully release accelerator pedal, and wait 15seconds.

4) Repeat step 3 at least 29 times.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-107.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº.

2) Fully depress and fully release accelerator pedal, and then wait 15 seconds.

3) Repeat step 2 at least 29 times.

4) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn ªONº.

5) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

6) If DTC is detected, go to ªDiagnostic Procedureº, EC-107.SEF817Y

DTC 0203 ACCEL POS SW (F/C)ZD30DDTi

EC-105

http://vnx.su/

Trending: wheel size, transmission, diagnostic menu, maintenance, buttons, window, four wheel drive