compressor NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3632 of 5883

![NISSAN TIIDA 2007 Service Repair Manual INSUFFICIENT COOLING

HAC-299

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT COOLING

Component Function CheckINFOID:0000000001547374

SYMPTOM: Insuffi NISSAN TIIDA 2007 Service Repair Manual INSUFFICIENT COOLING

HAC-299

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT COOLING

Component Function CheckINFOID:0000000001547374

SYMPTOM: Insuffi](/img/5/57395/w960_57395-3631.png)

INSUFFICIENT COOLING

HAC-299

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT COOLING

Component Function CheckINFOID:0000000001547374

SYMPTOM: Insufficient cooling

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - TEMPERATURE DECREASE

1. Press the AUTO switch.

2. Turn temperature control dial counterclockwise until 18° C (60° F) is displayed.

3. Check for cold air at discharge air outlets.

Can the symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to HAC-202, "

Operational Check".

Does another symptom exist?

YES >> Refer to HAC-298, "SymptomMatrixChart".

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 3.

4.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis Refer to HAC-213, "

Front Air Control Self-Diagnosis".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Refer to HAC-218, "

Front Air Control Self-Diagnosis Code Chart".

5.CHECK DRIVE BELTS

Check compressor belt tension. Refer to EM-15, "

Checking" HR16DE EM-142, "Checking Drive Belts" or

HR18DE or EM-263, "

Inspection and Adjustment" K9K.

Is the inspection result normal?

OK >> GO TO 6.

NG >> Adjust or replace compressor belt. Refer to XX-XX, "*****"

.

6.CHECK AIR MIX DOOR OPERATION

Check and verify air mix door mechanism for smooth operation. Refer to HAC-225, "

Air Mix Door Motor Com-

ponent Function Check"

Does air mix door operate correctly?

YES >> GO TO 7.

NO >> Check air mix door motor circuit. Refer to HAC-226, "

Air Mix Door Motor Diagnosis Procedure".

7.CHECK COOLING FAN MOTOR OPERATION

Check and verify cooling fan motor for smooth operation.

Does cooling fan motor operate correctly?

YES >> GO TO 8.

NO >> Check cooling fan motor. Refer to CO-18, "

Component (Models with A/C)".

8.CHECK RECOVERY/RECYCLING EQUIPMENT BEFORE USAGE

Check recovery/recycling equipment before connecting to vehicle. Verify there is no pressure in the recovery/

recycling equipment by checking the gauges. If pressure exists, recover refrigerant from equipment lines.

Page 3635 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-302

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Performance Chart

INFOID:0000000001547376

PERFORMANCE CHART

Test Condition

*1HA-32, "Removal and Installation of

Comp NISSAN TIIDA 2007 Service Repair Manual HAC-302

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Performance Chart

INFOID:0000000001547376

PERFORMANCE CHART

Test Condition

*1HA-32, "Removal and Installation of

Comp](/img/5/57395/w960_57395-3634.png)

HAC-302

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Performance Chart

INFOID:0000000001547376

PERFORMANCE CHART

Test Condition

*1HA-32, "Removal and Installation of

Compressor - MR18DE" or HA-34,

"Removal and Installation of Com-

pressor - HR16DE" or HA-35, "Re-

moval and Installation of Compressor

- K9K"

*2HAC-233, "Front Blower Motor Com-

ponent Function Check"

*3EM-15, "Checking" (HR16DE) or EM-

142, "Checking Drive Belts"

(MR18DE) or EM-263, "

Inspection

and Adjustment" (K9K)

RJIA3107E

Page 3637 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-304

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Whenever system’s high and/or low side pressure(s) is/are unusual, diagnose using a manifold gauge. The

marker above NISSAN TIIDA 2007 Service Repair Manual HAC-304

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Whenever system’s high and/or low side pressure(s) is/are unusual, diagnose using a manifold gauge. The

marker above](/img/5/57395/w960_57395-3636.png)

HAC-304

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Whenever system’s high and/or low side pressure(s) is/are unusual, diagnose using a manifold gauge. The

marker above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the

standard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air tempera-

ture-to-operating pressure table).

Both High- and Low-pressure Sides are Too High

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too High

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too high.Pressure is reduced soon af-

ter water is splashed on con-

denser.Excessive refrigerant charge in refrig-

eration cycle.Reduce refrigerant until

specified pressure is ob-

tained.

Air suction by cooling fan is in-

sufficient.Insufficient condenser cooling perfor-

mance.

↓

1. Condenser fins are clogged.

2. Improper fan rotation of cooling

fan. Clean condenser.

Check and repair cooling

fan if necessary.

Low-pressure pipe is not

cold.

When compressor is

stopped high-pressure val-

ue quickly drops by approx-

imately 196 kPa (1.96 bar, 2

kg/cm

2, 28 psi). It then de-

creases gradually thereaf-

ter.Poor heat exchange in condenser

(After compressor operation stops,

high-pressure decreases too slowly.).

↓

Air in refrigeration cycle.Evacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems malfunction.Check and repair each en-

gine cooling system.

An area of the low-pressure

pipe is colder than areas

near the evaporator outlet.

Plates are sometimes cov-

ered with frost. Excessive liquid refrigerant on low-

pressure side.

Excessive refrigerant discharge

flow.

Expansion valve is open a little

compared with the specification.

↓

Improper expansion valve adjust-

ment.Replace expansion valve.

AC359A

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too high

and low-pressure side is too low.

Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts located

between compressor and condenser

are clogged or crushed. Check and repair or re-

place malfunctioning

parts.

Check oil for contami-

nation.

AC360A

Page 3638 of 5883

![NISSAN TIIDA 2007 Service Repair Manual INSUFFICIENT COOLING

HAC-305

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Neg NISSAN TIIDA 2007 Service Repair Manual INSUFFICIENT COOLING

HAC-305

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Neg](/img/5/57395/w960_57395-3637.png)

INSUFFICIENT COOLING

HAC-305

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Negative

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too low

and low-pressure side is too

high.High- and low-pressure sides

become equal soon after com-

pressor operation stops.Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides.Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.Replace compressor.

AC356A

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too low. There is a big temperature dif-

ference between liquid tank

outlet and inlet. Outlet tem-

perature is extremely low.

Liquid tank inlet and expan-

sion valve are frosted.Liquid tank inside is slightly

clogged. Replace liquid tank.

Check oil for contamination.

Temperature of expansion

valve inlet is extremely low as

compared with areas near liq-

uid tank.

Expansion valve inlet may be

frosted.

Temperature difference oc-

curs somewhere in high-pres-

sure side.High-pressure pipe located be-

tween liquid tank and expansion

valve is clogged. Check and repair malfunc-

tioning parts.

Check oil for contamination.

Expansion valve and liquid tank

are warm or only cool when

touched.Low refrigerant charge.

↓

Leaking fittings or componentsCheck refrigerant for leaks.

Refer to HA-22, "

Checking of

Refrigerant Leaks".

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted.Expansion valve closes a little

compared with the specification.

↓

1. Improper expansion valve

adjustment.

2. Malfunctioning expansion

valve.

3. Outlet and inlet may be

clogged. Remove foreign particles by

using compressed air.

Replace expansion valve.

Check oil for contamination.

An area of the low-pressure pipe

is colder than areas near the

evaporator outlet.Low-pressure pipe is clogged or

crushed. Check and repair malfunc-

tioning parts.

Check oil for contamination.

Air flow volume is not enough or

is too low.Evaporator is frozen. Check intake sensor circuit.

Refer to HAC-229, "

Intake

Door Motor Component

Function Check".

Replace compressor.

Repair evaporator fins.

Replace evaporator.

Refer to HAC-233, "

Front

Blower Motor Component

Function Check".

AC353A

Page 3639 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-306

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Low-pressure Side Becomes Negative

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure si NISSAN TIIDA 2007 Service Repair Manual HAC-306

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Low-pressure Side Becomes Negative

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure si](/img/5/57395/w960_57395-3638.png)

HAC-306

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Low-pressure Side Becomes Negative

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side sometimes be-

comes negative. Air conditioning system does

not function and does not cy-

clically cool the compart-

ment air.

The system constantly func-

tions for a certain period of

time after compressor is

stopped and restarted.Refrigerant does not discharge

cyclically.

↓

Moisture is frozen at expan-

sion valve outlet and inlet.

↓

Water is mixed with refrigerant. Drain water from refrigerant

or replace refrigerant.

Replace liquid tank.

AC354A

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side becomes nega-

tive.

Liquid tank or front/rear side of

expansion valve’s pipe is frost-

ed or dewed.High-pressure side is closed

and refrigerant does not flow.

↓

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the malfunction is caused by

water or foreign particles.

If water is the cause, initially

cooling is okay. Then the wa-

ter freezes causing a block-

age. Drain water from

refrigerant or replace refrig-

erant.

If due to foreign particles, re-

move expansion valve and

remove the particles with dry

and compressed air (not

shop air).

If either of the above meth-

ods cannot correct the mal-

function, replace expansion

valve.

Replace liquid tank.

Check oil for contamination.

AC362A

Page 3643 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-310

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

NOISE

*1HA-32, "Removal and Installation of

Compressor - MR18DE" or HA-34,

"Removal and Installation of Com-

pressor - HR16DE" or HA-35, NISSAN TIIDA 2007 Service Repair Manual HAC-310

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

NOISE

*1HA-32, "Removal and Installation of

Compressor - MR18DE" or HA-34,

"Removal and Installation of Com-

pressor - HR16DE" or HA-35,](/img/5/57395/w960_57395-3642.png)

HAC-310

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

NOISE

*1HA-32, "Removal and Installation of

Compressor - MR18DE" or HA-34,

"Removal and Installation of Com-

pressor - HR16DE" or HA-35, "Re-

moval and Installation of Compressor

- K9K"

*2HA-32, "Removal and Installation of

Compressor - MR18DE" or HA-34,

"Removal and Installation of Com-

pressor - HR16DE" or HA-35, "Re-

moval and Installation of Compressor

- K9K"

*3HA-19, "Maintenance of Oil Quantity

in Compressor"

*4HAC-202, "Operational Check"5.EM-15, "Checking" (HR16DE) or EM-

142, "Checking Drive Belts"

(HR18DE) or EM-263, "

Inspection

and Adjustment" (K9K)

Page 3646 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

HAC-313

< PRECAUTION >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

P NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

HAC-313

< PRECAUTION >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

P](/img/5/57395/w960_57395-3645.png)

PRECAUTIONS

HAC-313

< PRECAUTION >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001548120

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Procedures Without Cowl Top CoverINFOID:0000000001548121

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Working with HFC-134a (R-134a)INFOID:0000000001547383

WARNING:

CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. If the refrigerants

are mixed compressor failure is likely to occur. Refer to XX-XX, "*****"

. To determine the purity of

HFC-134a (R-134a) in the vehicle and recovery tank, use Refrigerant Recovery/Recycling Recharging

equipment and Refrigerant Identifier.

Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If

oil other than that specified is used, compressor failure is likely to occur.

The specified HFC-134a (R-134a) oil rapidly absorbs moisture from the atmosphere. The following

handling precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

- When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as possible

to minimize the entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately reseal containers of oil. Without

proper sealing, oil will become moisture saturated and should not be used.

- Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Remove HFC-134a (R-134a) from the A/C system using certified service equipment meeting require-

ments of SAE J2210 [HFC-134a (R-134a) recycling equipment], or J2209 [HFC-134a (R-134a) recy-

cling equipment], If accidental system discharge occurs, ventilate work area before resuming

service. Additional health and safety information may be obtained from refrigerant and oil manufac-

turers.

PIIB3706J

Page 3773 of 5883

![NISSAN TIIDA 2007 Service Repair Manual LAN

CAN COMMUNICATION SYSTEM

LAN-33

< FUNCTION DIAGNOSIS >[CAN]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Check CAN system type from the vehicle shape and equipment.

CAN Communication Signal ChartINFOID:000000000 NISSAN TIIDA 2007 Service Repair Manual LAN

CAN COMMUNICATION SYSTEM

LAN-33

< FUNCTION DIAGNOSIS >[CAN]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Check CAN system type from the vehicle shape and equipment.

CAN Communication Signal ChartINFOID:000000000](/img/5/57395/w960_57395-3772.png)

LAN

CAN COMMUNICATION SYSTEM

LAN-33

< FUNCTION DIAGNOSIS >[CAN]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Check CAN system type from the vehicle shape and equipment.

CAN Communication Signal ChartINFOID:0000000001162801

Refer to LAN-21, "How to Use CAN Communication Signal Chart" for how to use CAN communication signal

chart.

NOTE:

Refer to LAN-27, "

Abbreviation List" for the abbreviations of the connecting units.

T: Transmit R: Receive

ALMIA0068GB

Signal name/Connecting unitECM

BCM

EPS

I-KEY

M&A

STRG

AV

ABS

TCM

IPDM-E

A/C compressor request signal TR

Accelerator pedal position signal T

R

*1R

ASCD CRUISE lamp signal T R

ASCD status signal T R

Closed throttle position signal T R

Cooling fan speed request signal TR

Engine coolant temperature signal T R R

Engine speed signal T R R R

R

*1R

Engine status signal T R R R

Fuel consumption monitor signal T R R

Glow indicator signal

*2TR

Malfunctioning indicator lamp signal (×2

*2)TR

Wide open throttle signal T R

A/C switch signal R T

Blower fan motor switch signal

*3RT

Page 4237 of 5883

![NISSAN TIIDA 2007 Service Repair Manual LU-30

< ON-VEHICLE REPAIR >[K9K]

OIL COOLER

OIL COOLER

Exploded ViewINFOID:0000000001381543

Removal and InstallationINFOID:0000000001381544

CAUTION:

Be careful not to get burned when the engine and NISSAN TIIDA 2007 Service Repair Manual LU-30

< ON-VEHICLE REPAIR >[K9K]

OIL COOLER

OIL COOLER

Exploded ViewINFOID:0000000001381543

Removal and InstallationINFOID:0000000001381544

CAUTION:

Be careful not to get burned when the engine and](/img/5/57395/w960_57395-4236.png)

LU-30

< ON-VEHICLE REPAIR >[K9K]

OIL COOLER

OIL COOLER

Exploded ViewINFOID:0000000001381543

Removal and InstallationINFOID:0000000001381544

CAUTION:

Be careful not to get burned when the engine and engine oil are hot.

When removing, prepare a shop cloth to absorb any oil leakage or spillage.

Completely wipe off any oil that adhere to the engine and the vehicle.

REMOVAL

1. Remove engine undercover using power tool.

2. Drain engine coolant. Refer to CO-58, "

Draining".

CAUTION:

Perform when engine is cold.

3. Remove RH front wheel. Refer to WT-6, "

Rotation".

4. Remove RH fender protector. Refer to EXT-22, "

Removal and Installation".

5. Remove drive belt. Refer to EM-263, "

Removal and Installation".

6. Remove generator and position aside. Refer to CHG-43, "

Removal and Installation".

7. Remove A/C compressor and position aside. Refer to HA-35, "

Removal and Installation of Compressor -

K9K".

8. Remove oil filter and oil filter bracket. Refer to LU-28, "

Replacement".

1. Cylinder block 2. Water pipe 3. O-ring

4. O-ring 5. O-ring 6. Oil cooler

7. Connecting stud 8. O-ring 9. Oil filter bracket

10. Oil pressure switch 11. Oil filter 12. O-ring

13. Connecting bolt

A. To radiator lower hose B. To water pump

E1BIA0011GB

Page 4262 of 5883

MA-22

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE (HR16DE)

ENGINE MAINTENANCE (HR16DE)

DRIVE BELTS

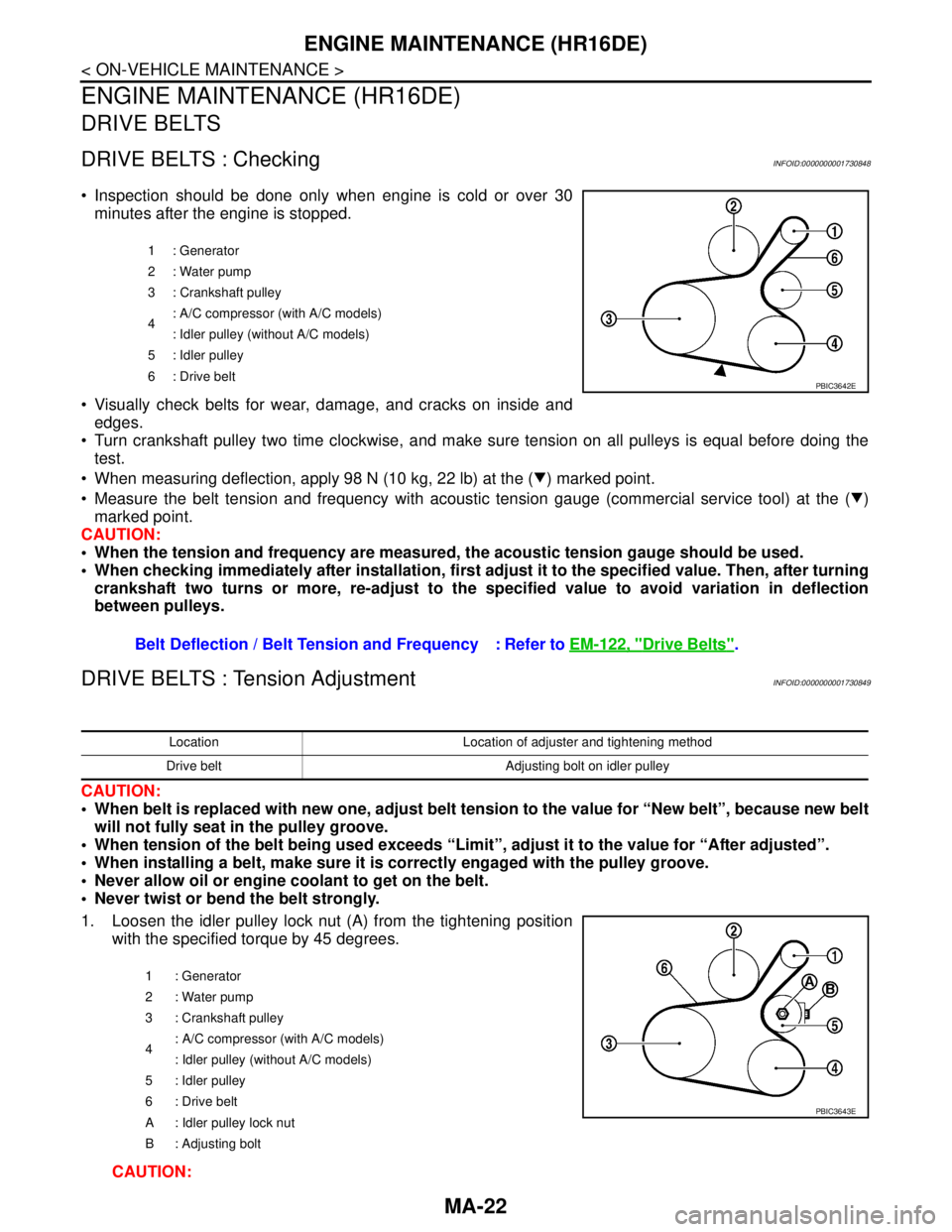

DRIVE BELTS : CheckingINFOID:0000000001730848

Inspection should be done only when engine is cold or over 30

minutes after the engine is stopped.

Visually check belts for wear, damage, and cracks on inside and

edges.

Turn crankshaft pulley two time clockwise, and make sure tension on all pulleys is equal before doing the

test.

When measuring deflection, apply 98 N (10 kg, 22 lb) at the ( ) marked point.

Measure the belt tension and frequency with acoustic tension gauge (commercial service tool) at the ( )

marked point.

CAUTION:

When the tension and frequency are measured, the acoustic tension gauge should be used.

When checking immediately after installation, first adjust it to the specified value. Then, after turning

crankshaft two turns or more, re-adjust to the specified value to avoid variation in deflection

between pulleys.

DRIVE BELTS : Tension AdjustmentINFOID:0000000001730849

CAUTION:

When belt is replaced with new one, adjust belt tension to the value for “New belt”, because new belt

will not fully seat in the pulley groove.

When tension of the belt being used exceeds “Limit”, adjust it to the value for “After adjusted”.

When installing a belt, make sure it is correctly engaged with the pulley groove.

Never allow oil or engine coolant to get on the belt.

Never twist or bend the belt strongly.

1. Loosen the idler pulley lock nut (A) from the tightening position

with the specified torque by 45 degrees.

CAUTION:

1 : Generator

2: Water pump

3 : Crankshaft pulley

4: A/C compressor (with A/C models)

: Idler pulley (without A/C models)

5 : Idler pulley

6: Drive belt

Belt Deflection / Belt Tension and Frequency : Refer to EM-122, "Drive Belts".

PBIC3642E

Location Location of adjuster and tightening method

Drive belt Adjusting bolt on idler pulley

1 : Generator

2: Water pump

3 : Crankshaft pulley

4: A/C compressor (with A/C models)

: Idler pulley (without A/C models)

5 : Idler pulley

6 : Drive belt

A : Idler pulley lock nut

B : Adjusting bolt

PBIC3643E