warning NISSAN TIIDA 2007 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 151 of 5883

BCS-16

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000001451463

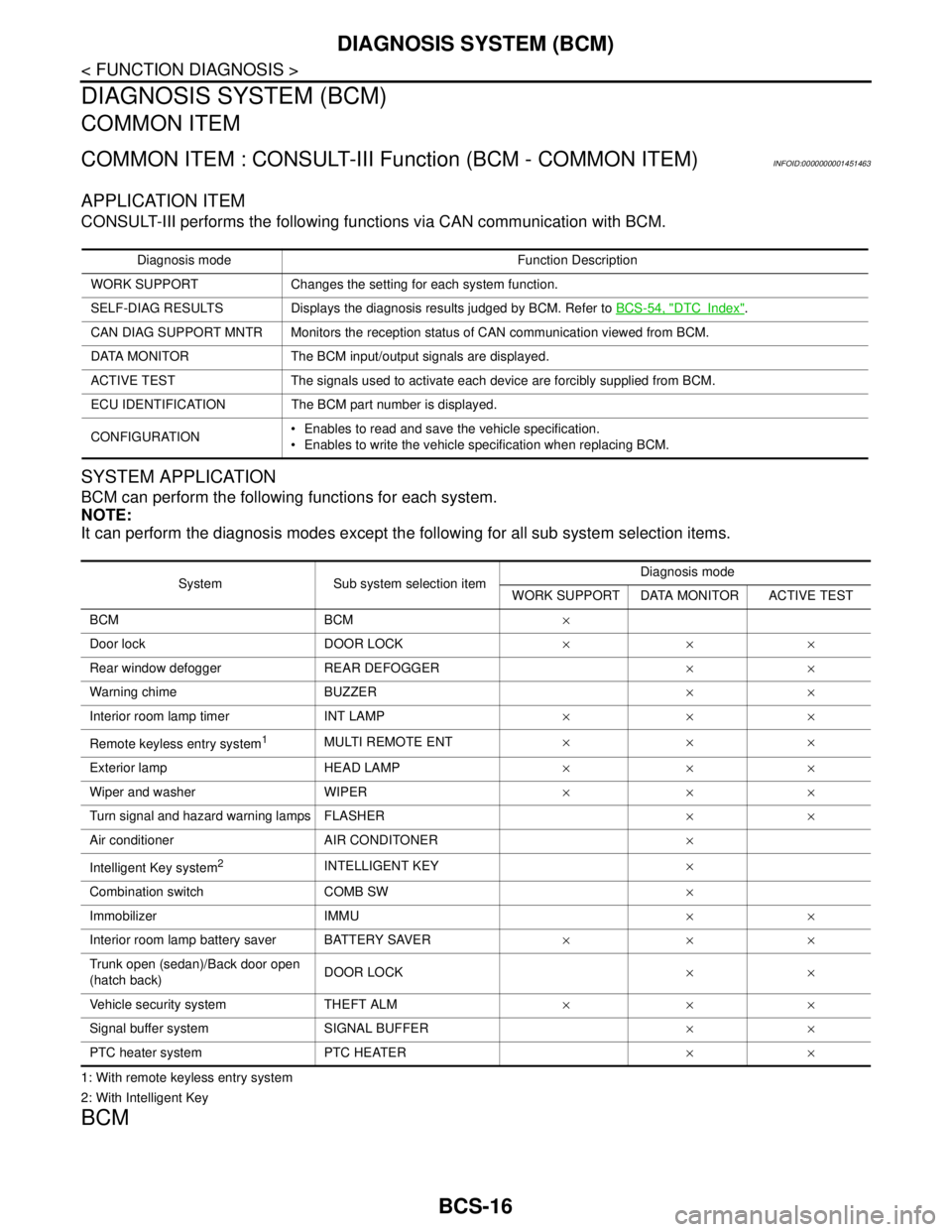

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

1: With remote keyless entry system

2: With Intelligent Key

BCM

Diagnosis mode Function Description

WORK SUPPORT Changes the setting for each system function.

SELF-DIAG RESULTS Displays the diagnosis results judged by BCM. Refer to BCS-54, "

DTCIndex".

CAN DIAG SUPPORT MNTR Monitors the reception status of CAN communication viewed from BCM.

DATA MONITOR The BCM input/output signals are displayed.

ACTIVE TEST The signals used to activate each device are forcibly supplied from BCM.

ECU IDENTIFICATION The BCM part number is displayed.

CONFIGURATION Enables to read and save the vehicle specification.

Enables to write the vehicle specification when replacing BCM.

System Sub system selection itemDiagnosis mode

WORK SUPPORT DATA MONITOR ACTIVE TEST

BCM BCM×

Door lock DOOR LOCK×××

Rear window defogger REAR DEFOGGER××

Warning chime BUZZER××

Interior room lamp timer INT LAMP×××

Remote keyless entry system

1MULTI REMOTE ENT×××

Exterior lamp HEAD LAMP×××

Wiper and washer WIPER×××

Turn signal and hazard warning lamps FLASHER××

Air conditioner AIR CONDITONER×

Intelligent Key system

2INTELLIGENT KEY×

Combination switch COMB SW×

Immobilizer IMMU××

Interior room lamp battery saver BATTERY SAVER×××

Trunk open (sedan)/Back door open

(hatch back)DOOR LOCK××

Vehicle security system THEFT ALM×××

Signal buffer system SIGNAL BUFFER××

PTC heater system PTC HEATER××

Page 153 of 5883

BCS-18

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

*: With super lock

REAR WINDOW DEFOGGER

REAR WINDOW DEFOGGER : CONSULT-III Function (BCM - REAR DEFOGGER)

INFOID:0000000001451466

DATA MONITOR

ACTIVE TEST

BUZZER

BUZZER : CONSULT-III Function (BCM - BUZZER)INFOID:0000000001451467

DATA MONITOR

ACTIVE TEST

DOOR LOCK INDThis test is able to check door lock indicator (built in door lock and unlock switch on center

console) operation [ON/OFF].

TRUNK/BACK DOOR This test is able to check trunk/back door lock operation [LOCK (SET)/UNLOCK (RE-

LEASE)]. Test item Description

Monitor Item

[Unit]Description

ENGINE STATUS [RUN/

STOP]Indicates engine running status.

IGN ON SW [ON/OFF] Indicates condition of ignition switch in ON position.

REAR DEF SW [ON/OFF] Displays “Press (ON)/other (OFF)” status determined with the rear window defogger switch.

Test Item Description

REAR DEFOGGER Give a drive signal to the rear window defogger relay to activate it.

Monitor Item

[Unit]Description

IGN ON SW [ON/OFF] Ignition switch (ON) status judged by ignition power supply input.

PUSH SW

1 [ON/OFF]Ignition knob status.

KEY SW

2 [ON/OFF]Key switch status.

DOOR SW -DR [ON/OFF] Front door switch (driver side) status judged by BCM.

DOOR SW -AS [ON/OFF] Front door switch (passenger side) status judged by BCM.

DOOR SW -RR [ON/OFF] Rear door switch RH status judged by BCM.

DOOR SW -RL [ON/OFF] Rear door switch LH status judged by BCM.

BACK DOOR SW [ON/OFF] Back door switch status judged by BCM.

CDL LOCK SW [ON/OFF] Door lock/unlock switch status.

CDL UNLOCK SW [ON/OFF] Door lock/unlock switch status.

LIGHTING SW [ON/OFF]Lighting switch status judged by the lighting switch signal read with combination switch reading func-

tion.

TRNK OPNR SW [ON/OFF] Trunk switch status.

Test Item Description

LIGHT WARN ALM The light reminder warning operation can be checked by operating the relevant function (On/Off).

KEY REMINDER WARN The key reminder warning operation can be checked by operating the relevant function (On/Off).

Page 154 of 5883

BCS

DIAGNOSIS SYSTEM (BCM)

BCS-19

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

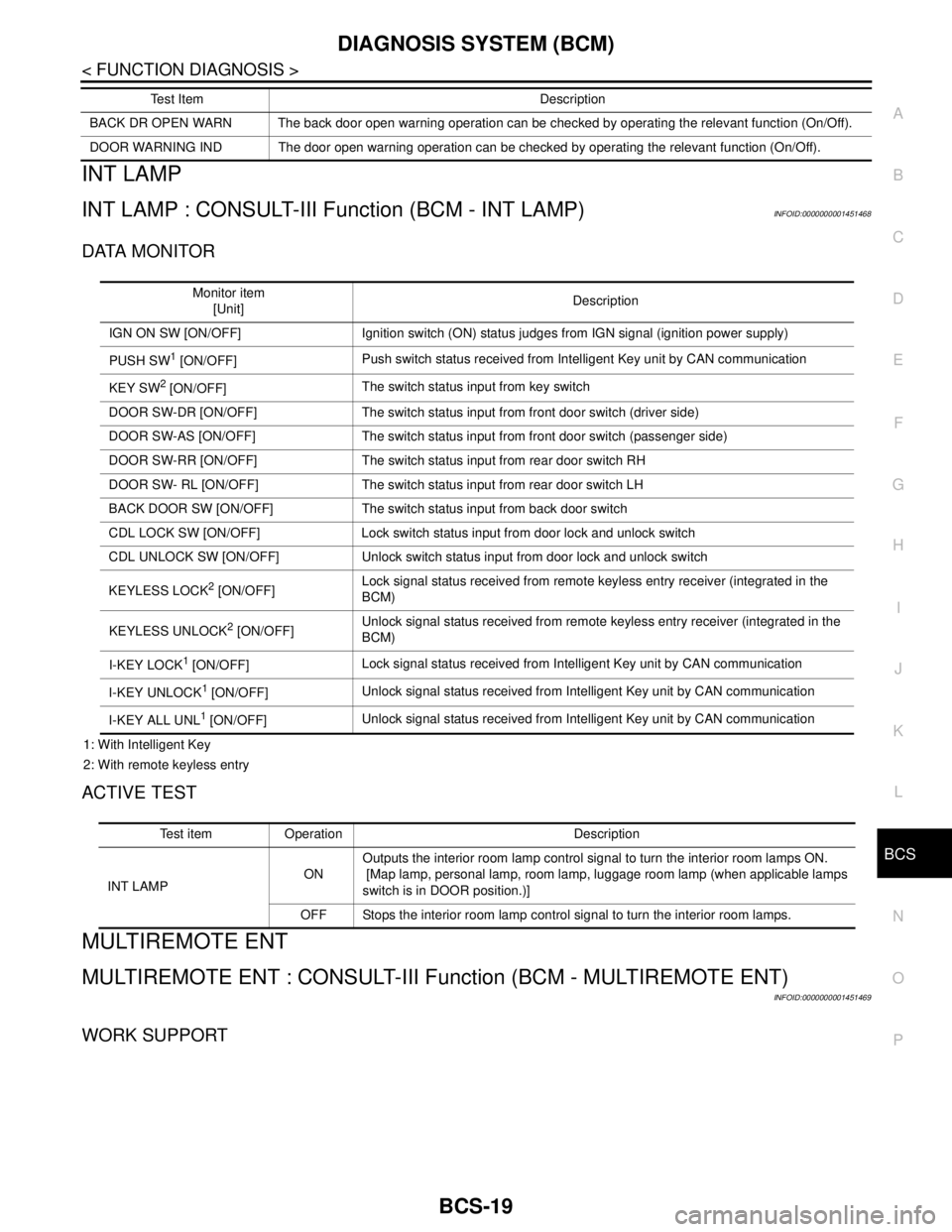

INT LAMP

INT LAMP : CONSULT-III Function (BCM - INT LAMP)INFOID:0000000001451468

DATA MONITOR

1: With Intelligent Key

2: With remote keyless entry

ACTIVE TEST

MULTIREMOTE ENT

MULTIREMOTE ENT : CONSULT-III Function (BCM - MULTIREMOTE ENT)

INFOID:0000000001451469

WORK SUPPORT

BACK DR OPEN WARN The back door open warning operation can be checked by operating the relevant function (On/Off).

DOOR WARNING IND The door open warning operation can be checked by operating the relevant function (On/Off).Test Item Description

Monitor item

[Unit]Description

IGN ON SW [ON/OFF] Ignition switch (ON) status judges from IGN signal (ignition power supply)

PUSH SW

1 [ON/OFF]Push switch status received from Intelligent Key unit by CAN communication

KEY SW

2 [ON/OFF]The switch status input from key switch

DOOR SW-DR [ON/OFF] The switch status input from front door switch (driver side)

DOOR SW-AS [ON/OFF] The switch status input from front door switch (passenger side)

DOOR SW-RR [ON/OFF] The switch status input from rear door switch RH

DOOR SW- RL [ON/OFF] The switch status input from rear door switch LH

BACK DOOR SW [ON/OFF] The switch status input from back door switch

CDL LOCK SW [ON/OFF] Lock switch status input from door lock and unlock switch

CDL UNLOCK SW [ON/OFF] Unlock switch status input from door lock and unlock switch

KEYLESS LOCK

2 [ON/OFF]Lock signal status received from remote keyless entry receiver (integrated in the

BCM)

KEYLESS UNLOCK

2 [ON/OFF]Unlock signal status received from remote keyless entry receiver (integrated in the

BCM)

I-KEY LOCK

1 [ON/OFF]Lock signal status received from Intelligent Key unit by CAN communication

I-KEY UNLOCK

1 [ON/OFF]Unlock signal status received from Intelligent Key unit by CAN communication

I-KEY ALL UNL

1 [ON/OFF]Unlock signal status received from Intelligent Key unit by CAN communication

Test item Operation Description

INT LAMPONOutputs the interior room lamp control signal to turn the interior room lamps ON.

[Map lamp, personal lamp, room lamp, luggage room lamp (when applicable lamps

switch is in DOOR position.)]

OFF Stops the interior room lamp control signal to turn the interior room lamps.

Page 155 of 5883

BCS-20

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

DATA MONITOR

ACTIVE TEST

HEADLAMP

HEADLAMP : CONSULT-III Function (BCM - HEAD LAMP)INFOID:0000000001451470

WORK SUPPORT

*: Initial setting

DATA MONITOR

Work Item Description

HAZARD LAMP SETAnswer back function (hazard) mode can be changed in this mode.

For the detail of the setting, refer to DLK-617, "

REMOTE KEYLESS ENTRY : System Descrip-

tion".

AUTO LOCK SETAuto door lock time can be changed in this mode.

MODE 1: 1 minute

MODE 2: 2 minutes

MODE 3: 3 minutes

MODE 4: 4 minutes

MODE 5: 5 minutes

Monitor Item

[Unit}Condition

IGN ON SW [ON/OFF] Indicates condition of ignition switch in ON position.

KEY SW [ON/OFF] Indicates condition of key switch.

KEYLESS LOCK [ON/OFF] Indicates condition of lock signal from keyfob.

KEYLESS UNLOCK [ON/OFF] Indicates condition of unlock signal from keyfob.

DOOR SW-DR [ON/OFF] Indicates condition of front door switch (driver side).

DOOR SW-AS [ON/OFF] Indicates condition of front door switch (passenger side).

DOOR SW-RR [ON/OFF] Indicates condition of rear door switch RH.

DOOR SW-RL [ON/OFF] Indicates condition of rear door switch LH.

BACK DOOR SW [ON/OFF] Indicates condition of back door switch.

CDL LOCK SW [ON/OFF] Indicates condition of door lock and unlock switch.

CDL UNLOCK SW [ON/OFF] Indicates condition of door lock and unlock switch.

RKE LOCK AND UNLOCK This item is indicated, but not monitored.

Test Item Description

DOOR LOCKThis test is able to check warning chime in combination meter operation. [ALL LOCK/ALL UN-

LOCK/DR UNLOCK/OTHER UNLOCK]

INT LAMP This test is able to check interior lamp operation [ON/OFF].

FLASHER This test is able to check flasher operation [LH/RH/OFF].

Work item Setting Description

BATTERY SAVER SETON*

Battery saver mode can be changed.

OFF

Monitor item

[Unit]Description

IGN ON SW [ON/OFF] Ignition switch (ON) status judged from IGN signal (ignition power supply)

Page 161 of 5883

BCS-26

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

*: Each lamp switch is in ON position.

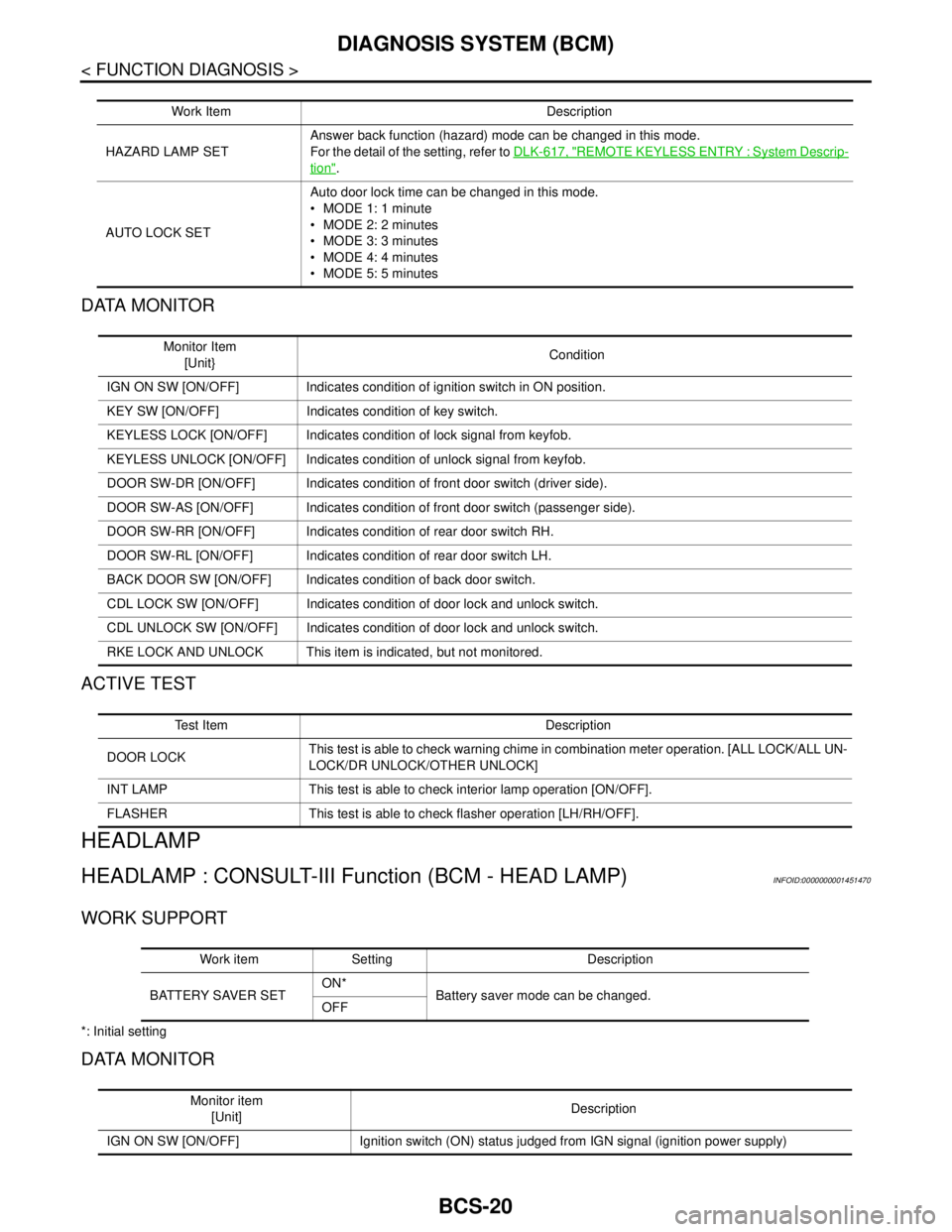

THEFT ALM

THEFT ALM : CONSULT-III Function (BCM - THEFT ALM)INFOID:0000000001451479

WORK SUPPORT

SIGNAL BUFFER

SIGNAL BUFFER : CONSULT-III Function (BCM - SIGNAL BUFFER)INFOID:0000000001451480

DATA MONITOR

ACTIVE TEST

PTC HEATER

PTC HEATER : CONSULT-III Function (BCM - PTC HEATER)INFOID:0000000001451481

DATA MONITOR

ACTIVE TEST

Work Item Description

SECURITY ALARM SETVehicle security function mode can be changed in this mode.

ON: Vehicle security function is ON.

OFF: Vehicle security function is OFF.

Monitor Item

[Unit]Description

OIL PRESS SW [ON/OFF] Displays the status of oil pressure switch received from IPDM E/R via CAN communication.

Test Item Operation Description

OIL PRESSURE SWOFF OFF

ONBCM transmits the oil pressure switch signal to the combination meter via CAN communica-

tion, which illuminates the oil pressure warning lamp in the combination meter.

Monitor Item

[Unit]Description

ELEC PWR CUT

[OFF/FREEZ/INHBT]Indicate [OFF/FREEZ/INHBT] condition of the PTC heater states.

FA N O N S I G

[On/Off]Displays [FAN (ON)/FAN (OFF)] status as judged from blower fan motor signal.

ENGINE STATUS

[STOP/STAL/RUN/CRA]Indicate [STOP/STALL/RUN/CRA] condition of the engine states.

ENG COOLNT T

[°C]The engine coolant temperature (determined by the signal voltage of the engine coolant tem-

perature sensor) is displayed.

BATTERY VOLT

[V]The power supply voltage of BCM is displayed.

ENGINE RPM

[rpm]Indicates the engine speed computed from the signal of the crankshaft position sensor.

OUTSIDE TEMP

[°C]The outside air temperature (determined by the signal voltage of the OAT sensor) is displayed.

Page 171 of 5883

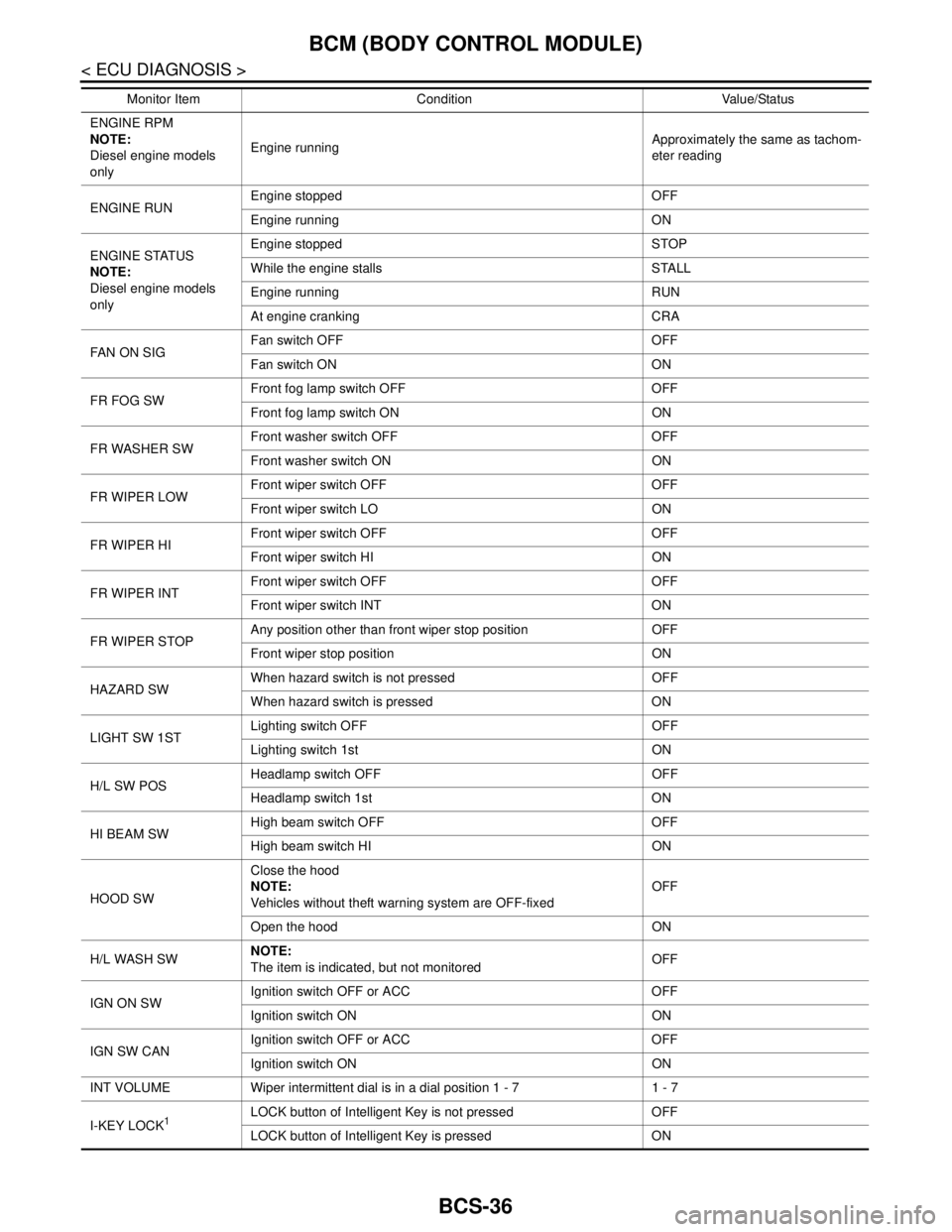

BCS-36

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

ENGINE RPM

NOTE:

Diesel engine models

onlyEngine runningApproximately the same as tachom-

eter reading

ENGINE RUNEngine stopped OFF

Engine running ON

ENGINE STATUS

NOTE:

Diesel engine models

onlyEngine stopped STOP

While the engine stalls STALL

Engine running RUN

At engine cranking CRA

FA N O N S I GFan switch OFF OFF

Fan switch ON ON

FR FOG SWFront fog lamp switch OFF OFF

Front fog lamp switch ON ON

FR WASHER SWFront washer switch OFF OFF

Front washer switch ON ON

FR WIPER LOWFront wiper switch OFF OFF

Front wiper switch LO ON

FR WIPER HIFront wiper switch OFF OFF

Front wiper switch HI ON

FR WIPER INTFront wiper switch OFF OFF

Front wiper switch INT ON

FR WIPER STOPAny position other than front wiper stop position OFF

Front wiper stop position ON

HAZARD SWWhen hazard switch is not pressed OFF

When hazard switch is pressed ON

LIGHT SW 1STLighting switch OFF OFF

Lighting switch 1st ON

H/L SW POSHeadlamp switch OFF OFF

Headlamp switch 1st ON

HI BEAM SWHigh beam switch OFF OFF

High beam switch HI ON

HOOD SWClose the hood

NOTE:

Vehicles without theft warning system are OFF-fixedOFF

Open the hood ON

H/L WASH SWNOTE:

The item is indicated, but not monitoredOFF

IGN ON SWIgnition switch OFF or ACC OFF

Ignition switch ON ON

IGN SW CANIgnition switch OFF or ACC OFF

Ignition switch ON ON

INT VOLUME Wiper intermittent dial is in a dial position 1 - 7 1 - 7

I-KEY LOCK

1LOCK button of Intelligent Key is not pressed OFF

LOCK button of Intelligent Key is pressed ON Monitor Item Condition Value/Status

Page 191 of 5883

BCS-56

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001523305

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Page 195 of 5883

PRECAUTIONS

BR-3

< PRECAUTION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001716907

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Brake SystemINFOID:0000000001716908

Refill using recommended brake fluid. Refer to MA-19, "Fluids and Lubricants".

Never reuse drained brake fluid.

Be careful not to splash brake fluid on painted surface of body. If brake fluid is splashed on painted surfaces

of body immediately wipe it off with cloth and then wash it away with water.

To clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use new brake fluid.

Never use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

Use a flare nut wrench when removing a brake tube and use a

flare nut torque wrench when installing a brake tube.

When installing brake tubes and hoses, be sure to check torque.

Before working, turn ignition switch OFF and disconnect connec-

tors of ABS actuator and electric unit (control unit) or the battery

cable from the negative terminal.

Burnish the new braking surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer toBR-26, "

Brake Burnishing" .

SBR686C

Page 200 of 5883

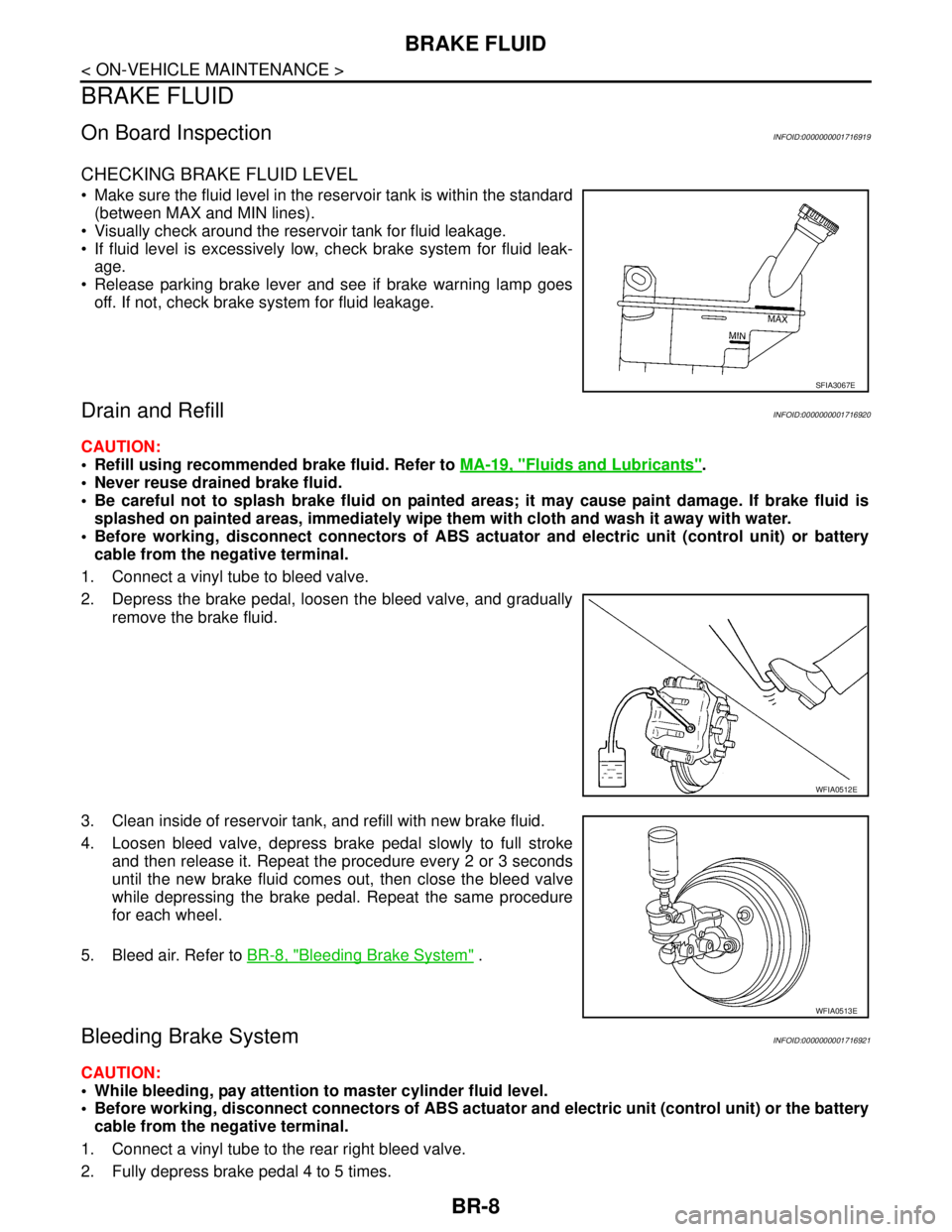

BR-8

< ON-VEHICLE MAINTENANCE >

BRAKE FLUID

BRAKE FLUID

On Board InspectionINFOID:0000000001716919

CHECKING BRAKE FLUID LEVEL

Make sure the fluid level in the reservoir tank is within the standard

(between MAX and MIN lines).

Visually check around the reservoir tank for fluid leakage.

If fluid level is excessively low, check brake system for fluid leak-

age.

Release parking brake lever and see if brake warning lamp goes

off. If not, check brake system for fluid leakage.

Drain and RefillINFOID:0000000001716920

CAUTION:

Refill using recommended brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, immediately wipe them with cloth and wash it away with water.

Before working, disconnect connectors of ABS actuator and electric unit (control unit) or battery

cable from the negative terminal.

1. Connect a vinyl tube to bleed valve.

2. Depress the brake pedal, loosen the bleed valve, and gradually

remove the brake fluid.

3. Clean inside of reservoir tank, and refill with new brake fluid.

4. Loosen bleed valve, depress brake pedal slowly to full stroke

and then release it. Repeat the procedure every 2 or 3 seconds

until the new brake fluid comes out, then close the bleed valve

while depressing the brake pedal. Repeat the same procedure

for each wheel.

5. Bleed air. Refer to BR-8, "

Bleeding Brake System" .

Bleeding Brake SystemINFOID:0000000001716921

CAUTION:

While bleeding, pay attention to master cylinder fluid level.

Before working, disconnect connectors of ABS actuator and electric unit (control unit) or the battery

cable from the negative terminal.

1. Connect a vinyl tube to the rear right bleed valve.

2. Fully depress brake pedal 4 to 5 times.

SFIA3067E

WFIA0512E

WFIA0513E

Page 219 of 5883

REAR DISC BRAKE

BR-27

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

REAR DISC BRAKE

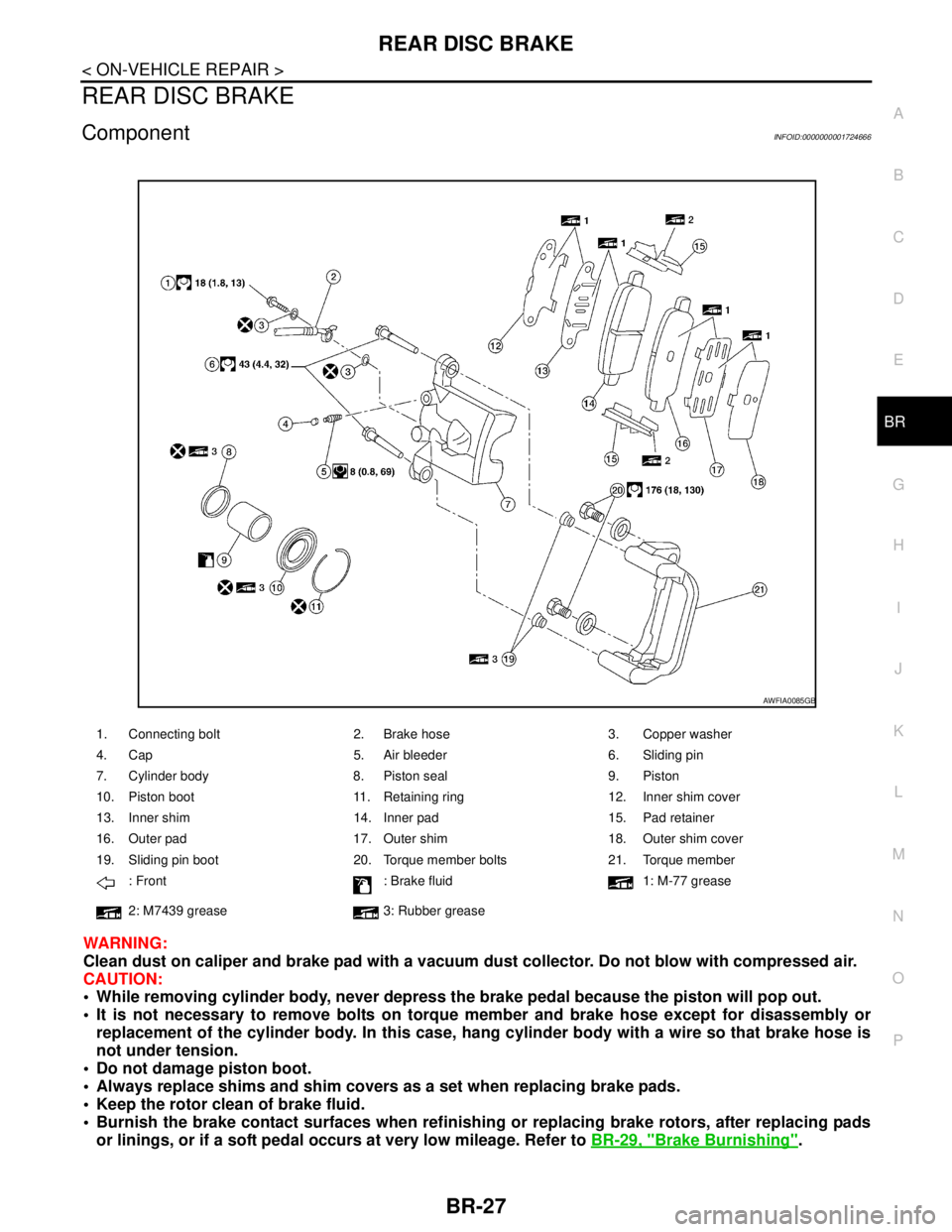

ComponentINFOID:0000000001724666

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector. Do not blow with compressed air.

CAUTION:

While removing cylinder body, never depress the brake pedal because the piston will pop out.

It is not necessary to remove bolts on torque member and brake hose except for disassembly or

replacement of the cylinder body. In this case, hang cylinder body with a wire so that brake hose is

not under tension.

Do not damage piston boot.

Always replace shims and shim covers as a set when replacing brake pads.

Keep the rotor clean of brake fluid.

Burnish the brake contact surfaces when refinishing or replacing brake rotors, after replacing pads

or linings, or if a soft pedal occurs at very low mileage. Refer to BR-29, "

Brake Burnishing".

1. Connecting bolt 2. Brake hose 3. Copper washer

4. Cap 5. Air bleeder 6. Sliding pin

7. Cylinder body 8. Piston seal 9. Piston

10. Piston boot 11. Retaining ring 12. Inner shim cover

13. Inner shim 14. Inner pad 15. Pad retainer

16. Outer pad 17. Outer shim 18. Outer shim cover

19. Sliding pin boot 20. Torque member bolts 21. Torque member

: Front : Brake fluid 1: M-77 grease

2: M7439 grease 3: Rubber grease

AWFIA0085GB