compressor NISSAN TIIDA 2007 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 2950 of 5883

![NISSAN TIIDA 2007 Service Service Manual ENGINE ASSEMBLY

EM-303

< REMOVAL AND INSTALLATION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Remove engine and transaxle assembly from vehicle down ward. Separate engine and transaxle.

Preparation

Remove NISSAN TIIDA 2007 Service Service Manual ENGINE ASSEMBLY

EM-303

< REMOVAL AND INSTALLATION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Remove engine and transaxle assembly from vehicle down ward. Separate engine and transaxle.

Preparation

Remove](/img/5/57395/w960_57395-2949.png)

ENGINE ASSEMBLY

EM-303

< REMOVAL AND INSTALLATION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Remove engine and transaxle assembly from vehicle down ward. Separate engine and transaxle.

Preparation

Remove the following parts.

Battery ground cable.

Engine undercover.

LH and RH front wheels. Refer to WT-6, "

Rotation".

LH and RH fender protectors. Refer to EXT-22, "

Removal and Installation".

Engine Room

1. Drain engine coolant. Refer to CO-58, "Draining".

CAUTION:

Perform when engine is cold.

2. Remove lower radiator hose. Refer to CO-62, "

Exploded View".

3. Drain transaxle fluid. Refer to TM-672, "

Draining".

4. Disconnect clutch tube at clutch housing and drain clutch fluid.

NOTE:

Cover clutch tube ends to prevent contamination.

5. Remove hood. Refer to DLK-214, "

Removal and Installation".

6. Remove cowl top cover and cowl top extension assembly. Refer to EXT-20, "

Removal and Installation".

7. Remove battery and battery trap. Refer to PG-6, "

Removal and Installation".

8. Disconnect engine room harness from the engine side and position aside.

9. Remove the air duct (inlet). Refer to EM-269, "

Exploded View".

10. Remove engine cover.

11. Remove blow-by hose.

12. Remove air cleaner case and air duct (suction). Refer to EM-269, "

Removal and Installation".

13. Remove reservoir tank and hoses. Refer to CO-62, "

Exploded View".

14. Remove charge air cooler hoses and tubes. Refer to EM-270, "

Exploded View".

15. Remove vacuum hose. Refer to EM-280, "

Removal and Installation".

16. Disconnect fuel feed and return hoses, and plug it to prevent fuel from draining.

17. Remove radiator upper hose. Refer to CO-62, "

Exploded View".

18. Disconnect heater hoses.

19. Disconnect transaxle side harness.

20. Disconnect breather hose transaxle side.

21. Disconnect shift cable and select cable. Refer to TM-674, "

Exploded View".

22. Remove cooling fan. Refer to CO-64, "

Removal and Installation".

23. Remove radiator. Refer to CO-62, "

Exploded View".

24. Disconnect all the body-side vacuum hoses and air hoses at engine side.

Vehicle Underbody

1. Remove drive shaft assembly RH and LH. Refer to Removal and Installation.

2. Remove exhaust front tube. Refer to EX-14, "

Component".

3. Remove drive belt. Refer to EM-263, "

Removal and Installation".

4. Remove A/C compressor and position aside.

NOTE:

Secure it to body with a rope to avoid putting load on A/C lines.

5. Remove lower torque rod. Refer to EM-302, "

Exploded View".

Removal

Page 3180 of 5883

FSU-4

< PREPARATION >

PREPARATION

Commercial Service Tool

INFOID:0000000001716879

Tool nameDescription

Spring compressor Removing and installing coil spring

Spring gaugeInspecting tranverse link ball joint

Power tool Removing wheel nuts

Removing front suspension component

parts

S-NT717

LST025

PBIC0190E

Page 3191 of 5883

COIL SPRING AND STRUT

FSU-15

< DISASSEMBLY AND ASSEMBLY >

C

D

F

G

H

I

J

K

L

MA

B

FSU

N

O

P

DISASSEMBLY AND ASSEMBLY

COIL SPRING AND STRUT

Disassembly and AssemblyINFOID:0000000001716887

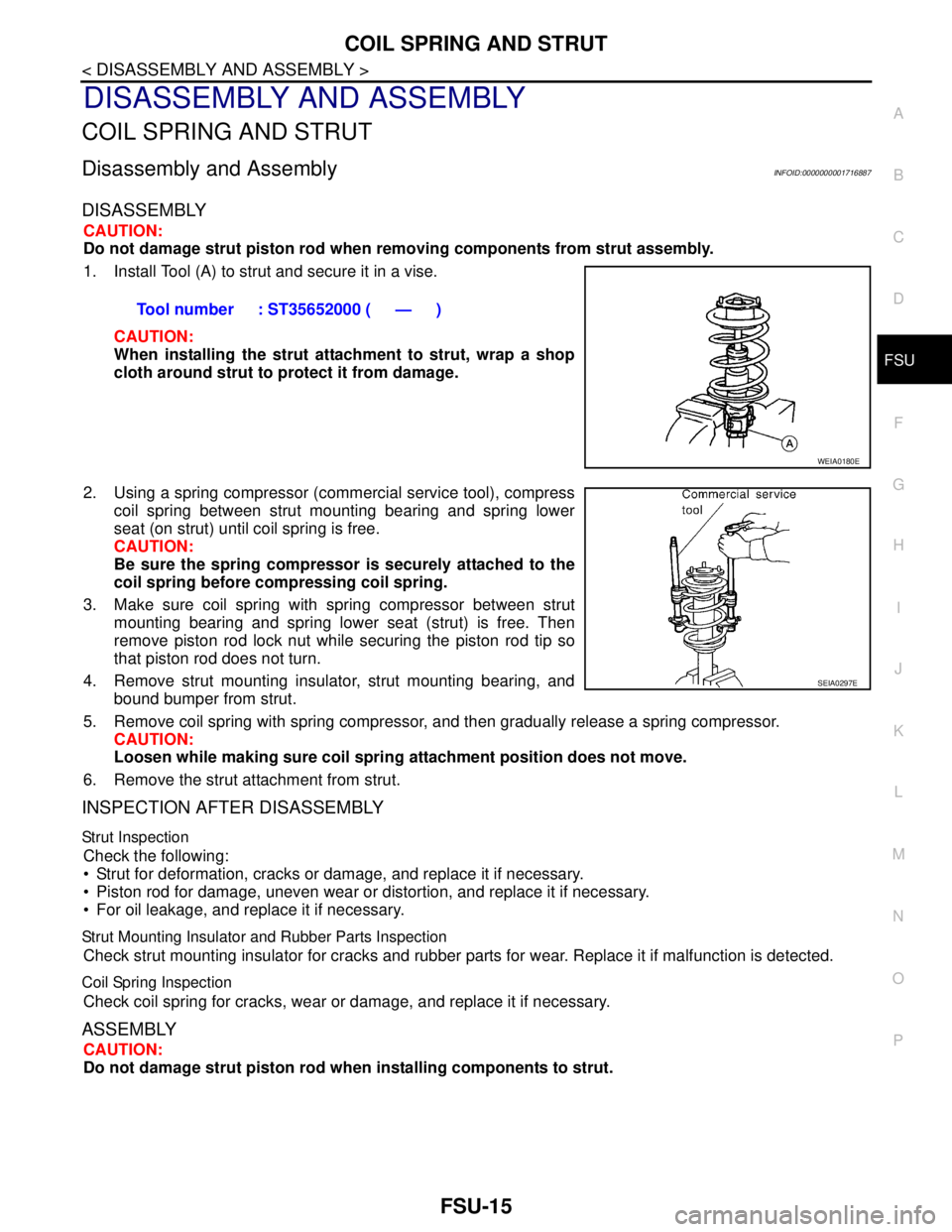

DISASSEMBLY

CAUTION:

Do not damage strut piston rod when removing components from strut assembly.

1. Install Tool (A) to strut and secure it in a vise.

CAUTION:

When installing the strut attachment to strut, wrap a shop

cloth around strut to protect it from damage.

2. Using a spring compressor (commercial service tool), compress

coil spring between strut mounting bearing and spring lower

seat (on strut) until coil spring is free.

CAUTION:

Be sure the spring compressor is securely attached to the

coil spring before compressing coil spring.

3. Make sure coil spring with spring compressor between strut

mounting bearing and spring lower seat (strut) is free. Then

remove piston rod lock nut while securing the piston rod tip so

that piston rod does not turn.

4. Remove strut mounting insulator, strut mounting bearing, and

bound bumper from strut.

5. Remove coil spring with spring compressor, and then gradually release a spring compressor.

CAUTION:

Loosen while making sure coil spring attachment position does not move.

6. Remove the strut attachment from strut.

INSPECTION AFTER DISASSEMBLY

Strut Inspection

Check the following:

Strut for deformation, cracks or damage, and replace it if necessary.

Piston rod for damage, uneven wear or distortion, and replace it if necessary.

For oil leakage, and replace it if necessary.

Strut Mounting Insulator and Rubber Parts Inspection

Check strut mounting insulator for cracks and rubber parts for wear. Replace it if malfunction is detected.

Coil Spring Inspection

Check coil spring for cracks, wear or damage, and replace it if necessary.

ASSEMBLY

CAUTION:

Do not damage strut piston rod when installing components to strut. Tool number : ST35652000 ( — )

WEIA0180E

SEIA0297E

Page 3192 of 5883

FSU-16

< DISASSEMBLY AND ASSEMBLY >

COIL SPRING AND STRUT

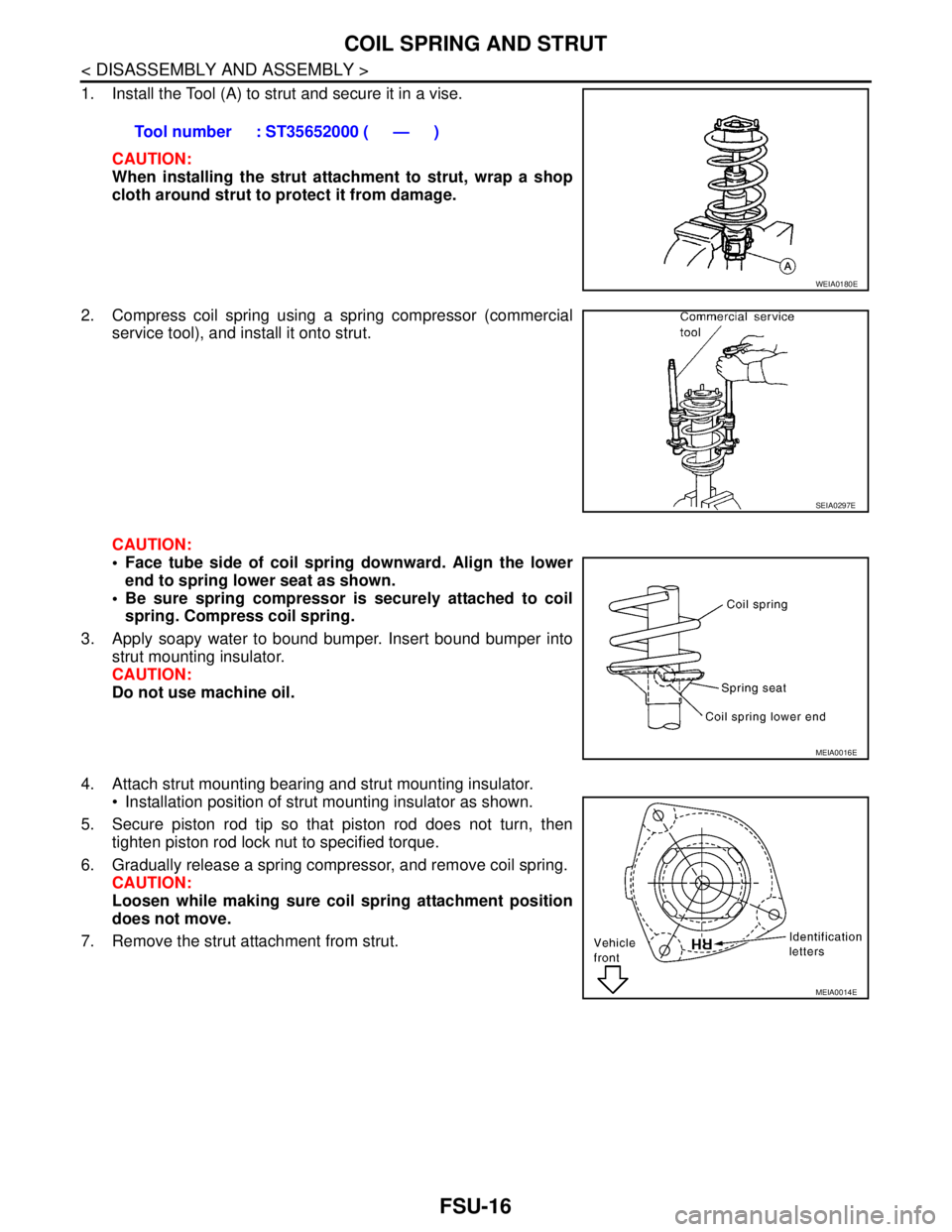

1. Install the Tool (A) to strut and secure it in a vise.

CAUTION:

When installing the strut attachment to strut, wrap a shop

cloth around strut to protect it from damage.

2. Compress coil spring using a spring compressor (commercial

service tool), and install it onto strut.

CAUTION:

Face tube side of coil spring downward. Align the lower

end to spring lower seat as shown.

Be sure spring compressor is securely attached to coil

spring. Compress coil spring.

3. Apply soapy water to bound bumper. Insert bound bumper into

strut mounting insulator.

CAUTION:

Do not use machine oil.

4. Attach strut mounting bearing and strut mounting insulator.

Installation position of strut mounting insulator as shown.

5. Secure piston rod tip so that piston rod does not turn, then

tighten piston rod lock nut to specified torque.

6. Gradually release a spring compressor, and remove coil spring.

CAUTION:

Loosen while making sure coil spring attachment position

does not move.

7. Remove the strut attachment from strut.Tool number : ST35652000 ( — )

WEIA0180E

SEIA0297E

MEIA0016E

MEIA0014E

Page 3283 of 5883

HA-1

VENTILATION, HEATER & AIR CONDITIONER

C

D

E

F

G

H

J

K

L

M

SECTION HA

A

B

HA

N

O

P

CONTENTS

HEATER & AIR CONDITIONING SYSTEM

PRECAUTION ...............................................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for Procedure without Cowl Top Cover ......3

Precaution for Working with HFC-134a (R-134a) ......3

General Refrigerant Precaution ................................4

Oil Precaution ............................................................4

Precaution for Refrigerant Connection ......................4

Precaution for Service of Compressor ......................8

Precaution for Service Equipment .............................9

Precaution for Leak Detection Dye .........................10

PREPARATION ...........................................12

PREPARATION ..................................................12

HFC-134a (R-134a) Service Tool and Equipment ....12

Commercial Service Tool ........................................14

FUNCTION DIAGNOSIS ..............................16

REFRIGERATION SYSTEM ..............................16

Refrigerant Cycle ....................................................16

Refrigerant System Protection ................................16

OIL ......................................................................18

Maintenance of Oil Quantity in Compressor ...........18

ON-VEHICLE MAINTENANCE ....................19

OIL ......................................................................19

Maintenance of Oil Quantity in Compressor ...........19

REFRIGERATION SYSTEM ..............................21

HFC-134a (R-134a) Service Procedure ..................21

Checking of Refrigerant Leaks ................................22

FLUORESCENT LEAK DETECTOR .................24

Checking System for Leaks Using the Fluorescent

Leak Detector ..........................................................

24

Dye Injection ............................................................24

ELECTRICAL LEAK DETECTOR ....................25

Electronic Refrigerant Leak Detector .......................25

ON-VEHICLE REPAIR .................................27

REFRIGERATION SYSTEM .............................27

Component ..............................................................27

HFC-134a (R-134a) Service Procedure ..................29

COMPRESSOR .................................................32

Removal and Installation of Compressor -

MR18DE ..................................................................

32

Removal and Installation of Compressor -

HR16DE ..................................................................

34

Removal and Installation of Compressor - K9K .......35

LOW-PRESSURE FLEXIBLE HOSE ................38

Removal and Installation of Low-Pressure Flexi-

ble Hose - MR18DE, HR16DE ................................

38

Removal and Installation of Low-Pressure Flexi-

ble Hose - K9K ........................................................

38

LOW-PRESSURE PIPE ....................................40

Removal and Installation of Low-Pressure Pipe -

K9K ..........................................................................

40

HIGH-PRESSURE FLEXIBLE HOSE ...............41

Removal and Installation of High-Pressure Flexi-

ble Hose - MR18DE, HR16DE ................................

41

Removal and Installation of High-Pressure Flexi-

ble Hose - K9K ........................................................

41

HIGH-PRESSURE PIPE ....................................43

Removal and Installation of High-Pressure Pipe -

MR18DE, HR16DE ..................................................

43

Removal and Installation of High-Pressure Pipe -

K9K ..........................................................................

43

CONDENSER ....................................................45

Removal and Installation of Condenser -

MR18DE, HR16DE ..................................................

45

Page 3285 of 5883

PRECAUTIONS

HA-3

< PRECAUTION >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001396449

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Procedure without Cowl Top CoverINFOID:0000000001396428

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Working with HFC-134a (R-134a)INFOID:0000000001396429

WARNING:

CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. These refrigerants

must never be mixed, even in the smallest amounts. If the refrigerants are mixed a compressor mal-

function is likely to occur.

Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If

oil other than that specified is used, compressor malfunction is likely to occur.

The specified HFC-134a (R-134a) oil rapidly absorbs moisture from the atmosphere. The following

handling precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

- When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as possible

to minimize the entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately reseal containers of oil. Without

proper sealing, oil will become moisture saturated and should not be used.

- Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant. If acci-

dental system discharge occurs, ventilate work area before resuming service. Additional health and

safety information may be obtained from refrigerant and oil manufacturers.

- Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

PIIB3706J

Page 3286 of 5883

HA-4

< PRECAUTION >

PRECAUTIONS

General Refrigerant Precaution

INFOID:0000000001396430

WARNING:

Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant. If acci-

dental system discharge occurs, ventilate work area before resuming service. Additional health and

safety information may be obtained from refrigerant and oil manufacturers.

Do not release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

Do not store or heat refrigerant containers above 52°C (126° F).

Do not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

Do not intentionally drop, puncture, or incinerate refrigerant containers.

Keep refrigerant away from open flames: poisonous gas will be produced if refrigerant burns.

Refrigerant will displace oxygen, therefore be certain to work in well ventilated areas to prevent suf-

focation.

Do not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condition-

ing systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a) have

been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury or

property damage. Additional health and safety information may be obtained from refrigerant manu-

facturers.

Oil PrecautionINFOID:0000000001396431

Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If oil

other than that specified is used, compressor malfunction is likely to occur.

The specified HFC-134a (R-134a) oil rapidly absorbs moisture from the atmosphere. The following handling

precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to minimize

the entry of moisture from the atmosphere.

- When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just before con-

necting the components. Connect all refrigerant loop components as quickly as possible to minimize the

entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately reseal containers of oil. Without proper seal-

ing, oil will become moisture saturated and should not be used.

Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant. If accidental

system discharge occurs, ventilate work area before resuming service. Additional health and safety informa-

tion may be obtained from refrigerant and oil manufacturers.

Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

Precaution for Refrigerant ConnectionINFOID:0000000001396432

A new type refrigerant connection has been introduced to all refrigerant lines except the following location.

Expansion valve to evaporator

Refrigerant pressure sensor to condenser

Page 3290 of 5883

HA-8

< PRECAUTION >

PRECAUTIONS

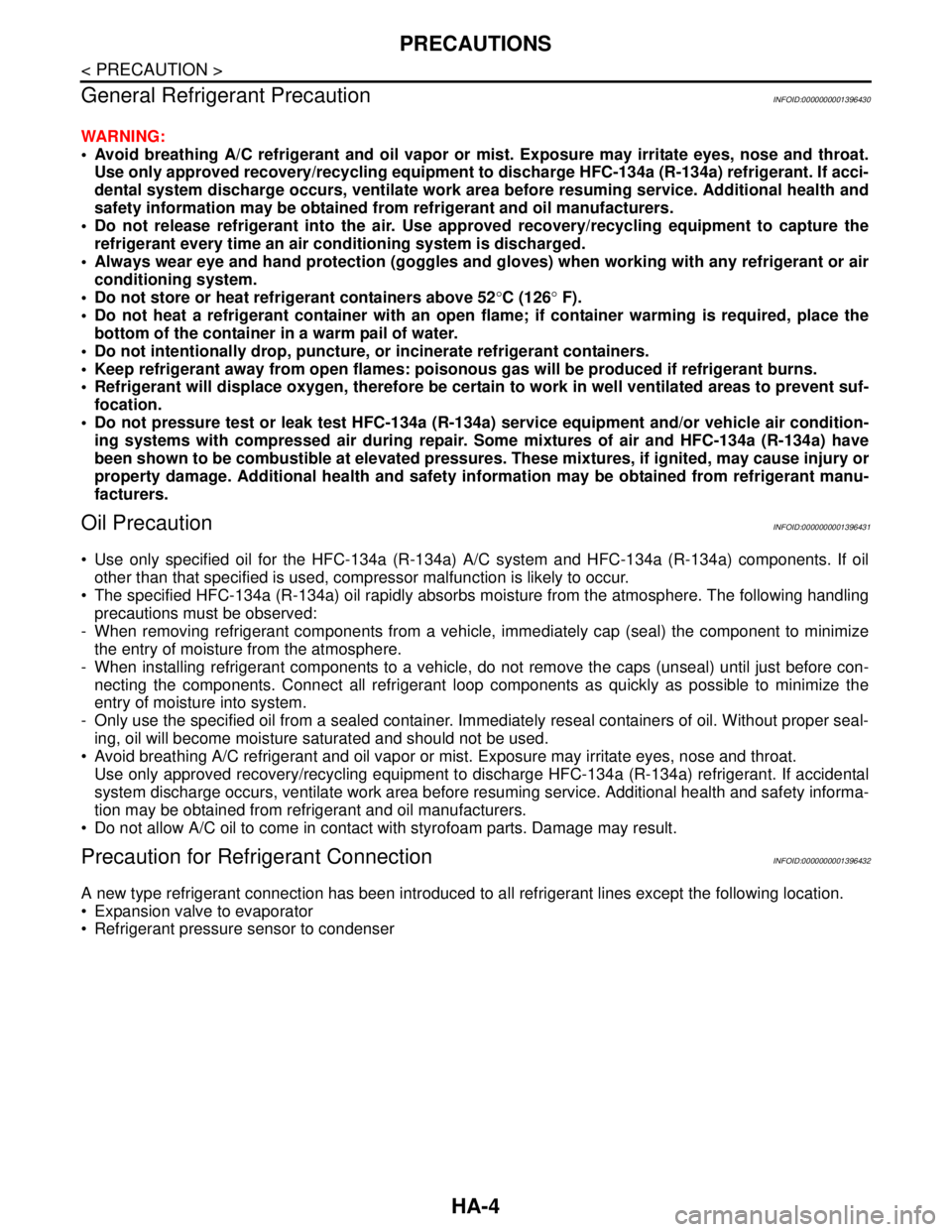

O-Ring Part Numbers and Specifications

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

When the compressor is removed, store it in the same position as it is when mounted on the vehicle.

Doing so will cause oil to enter the low-pressure chamber.

When connecting tubes, always use a torque wrench and a back-up wrench.

After disconnecting tubes, immediately plug all openings to prevent entry of dirt and moisture.

When installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for con-

nection.

Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

Thoroughly remove moisture from the refrigeration system before charging the refrigerant.

Always replace used O-rings.

When connecting tube, apply the specified A/C oil to circle of the O-rings as shown. Be careful not to

apply oil to threaded portion.

O-ring must be closely attached to dented portion of tube.

When replacing the O-ring, be careful not to damage O-ring and tube.

Connect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

After connecting line, perform leak test and make sure that there is no leakage from connections.

When the refrigerant leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

Precaution for Service of CompressorINFOID:0000000001396433

Plug all openings to prevent moisture and foreign matter from entering.

Connection type Piping connection point Part number QTY O-ring size

NewCondenser to high-pressure flexible hose 92472 N8210 1 12

Condenser to high-pressure pipe 92471 N8210 1 8

Low-pressure flexible hose to expansion valve 92473 N8210 1 16

High-pressure pipe to expansion valve 92471 N8210 1 8

Compressor to low-pressure flexible hose 92474 N8210 1 19

Compressor to high-pressure flexible hose 92472 N8210 1 12

Liquid tank to condenser pipeInlet

92471 N82101

8

Outlet 1

FormerRefrigerant pressure sensor to condenser J2476 89956 1 10

Expansion valve to evaporatorInlet 92471 N8200 2 12

Outlet 92473 N8200 2 16

RHA861F

Page 3291 of 5883

PRECAUTIONS

HA-9

< PRECAUTION >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

When the compressor is removed, store it in the same position as it is when mounted on the car.

When replacing or repairing compressor, follow “Maintenance of Oil Quantity in Compressor”

exactly. Refer to HA-19, "

Maintenance of Oil Quantity in Compressor".

Keep friction surfaces between clutch and pulley clean. If the surface is contaminated, with oil, wipe

it off by using a clean waste cloth moistened with thinner.

After compressor service operation, turn the compressor shaft by hand more than five turns in both

directions. This will equally distribute oil inside the compressor. After the compressor is installed,

let the engine idle and operate the compressor for one hour.

After replacing the compressor magnet clutch, apply voltage to the new one and check for usual

operation.

Precaution for Service EquipmentINFOID:0000000001396434

RECOVERY/RECYCLING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Never

introduce any refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Be certain to follow the manufacturer’s instructions for tester operation and tester maintenance.

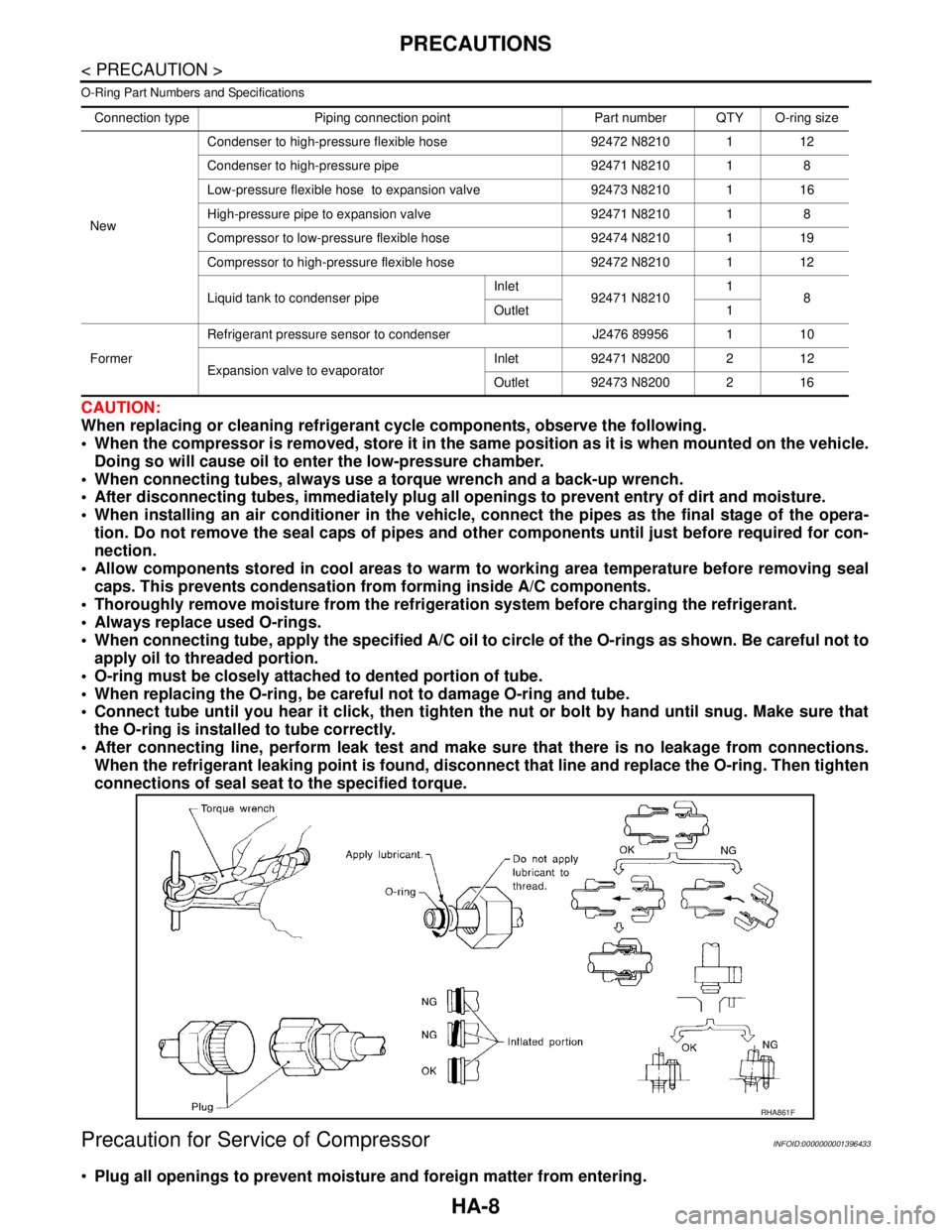

VACUUM PUMP

The oil contained inside the vacuum pump is not compatible with the

specified oil for HFC-134a (R-134a) A/C systems. The vent side of

the vacuum pump is exposed to atmospheric pressure. So the vac-

uum pump oil may migrate out of the pump into the service hose.

This is possible when the pump is switched off after evacuation (vac-

uuming) and hose is connected to it.

To prevent this migration, use a manual valve placed near the hose-

to-pump connection, as follows.

Usually vacuum pumps have a manual isolator valve as part of the

pump. Close this valve to isolate the service hose from the pump.

For pumps without an isolator, use a hose equipped with a manual

shut-off valve near the pump end. Close the valve to isolate the

hose from the pump.

If the hose has an automatic shut-off valve, disconnect the hose

from the pump. As long as the hose is connected, the valve is open

and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under a no vacuum condition. Such valves may restrict the pump’s

ability to pull a deep vacuum and are not recommended.

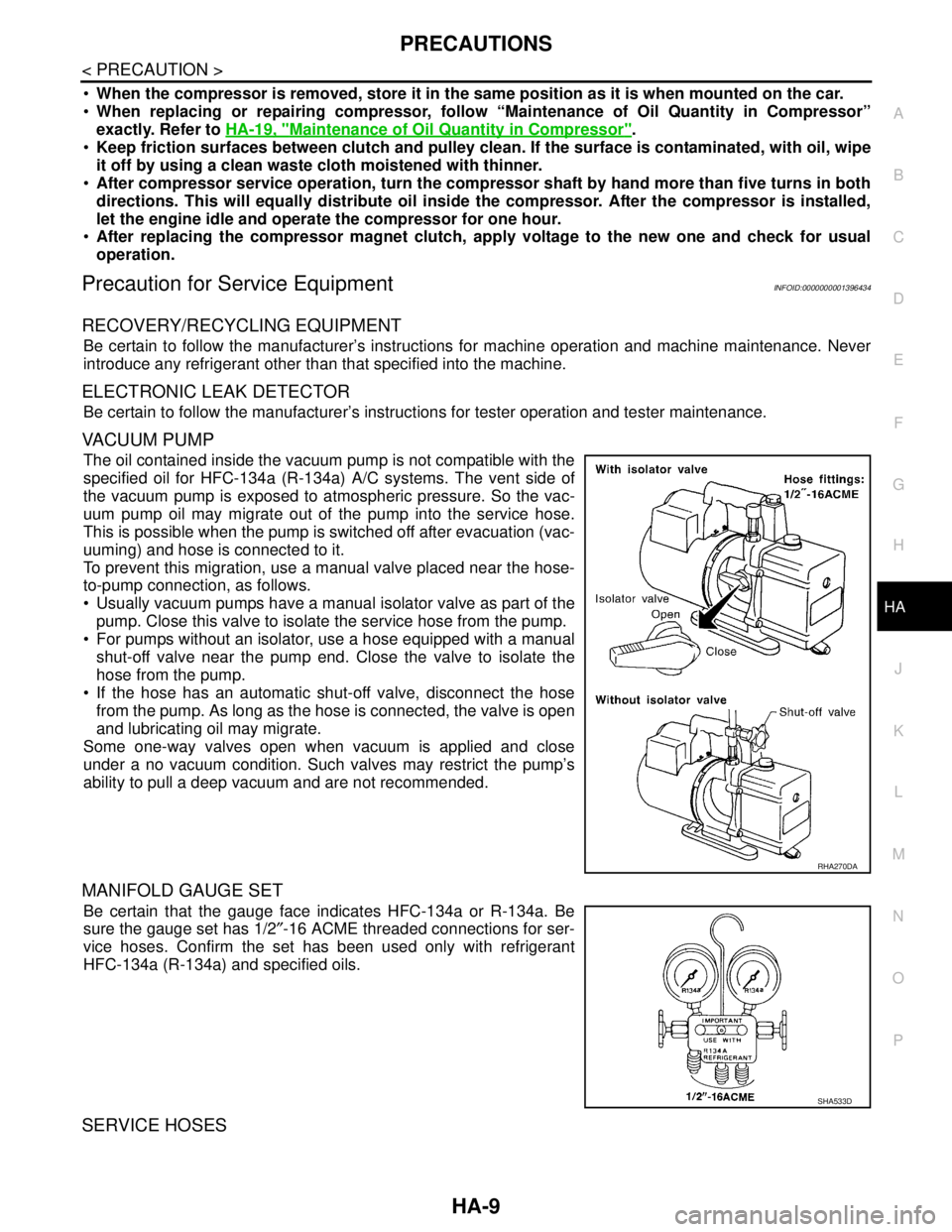

MANIFOLD GAUGE SET

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2″-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified oils.

SERVICE HOSES

RHA270DA

SHA533D

Page 3292 of 5883

HA-10

< PRECAUTION >

PRECAUTIONS

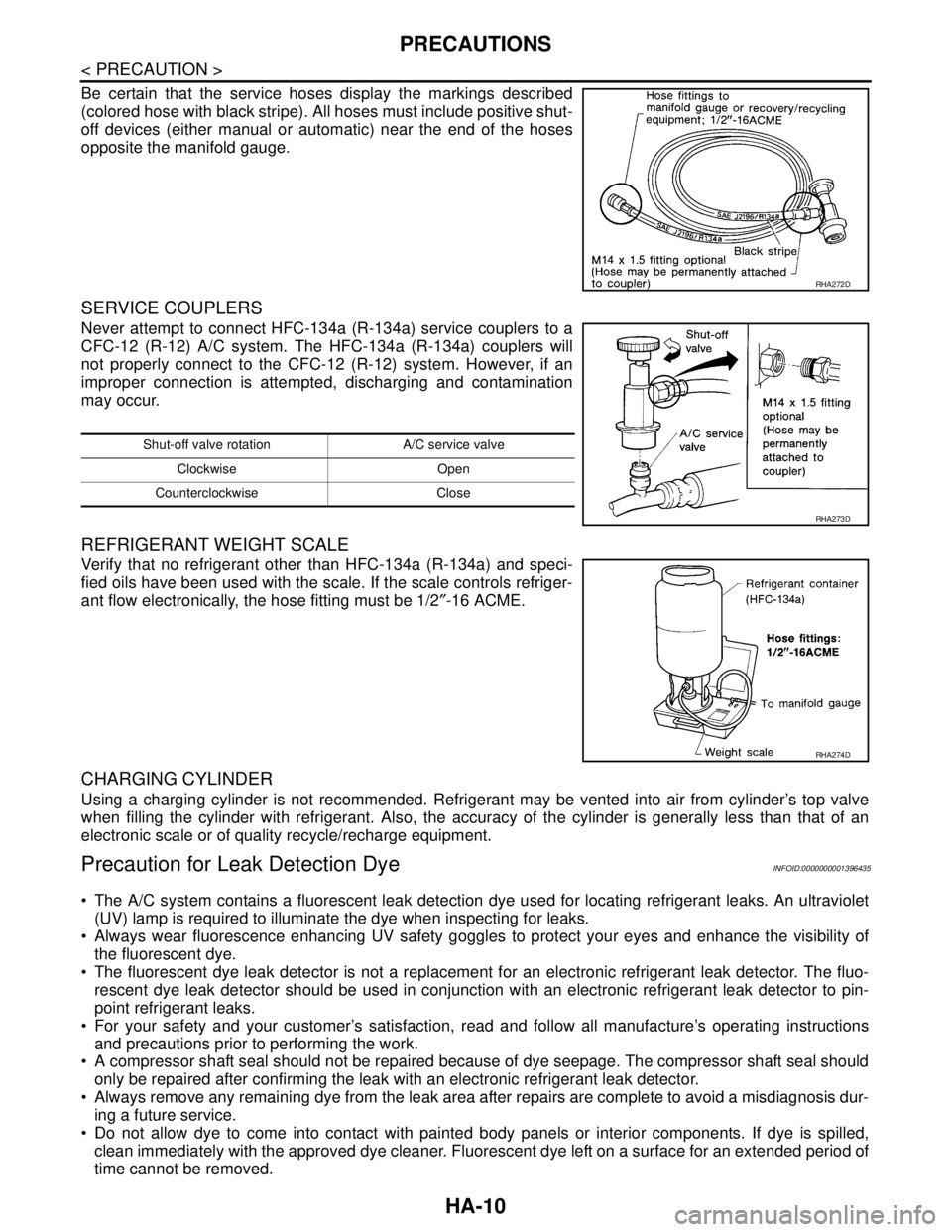

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive shut-

off devices (either manual or automatic) near the end of the hoses

opposite the manifold gauge.

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to a

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied oils have been used with the scale. If the scale controls refriger-

ant flow electronically, the hose fitting must be 1/2″-16 ACME.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accuracy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Precaution for Leak Detection DyeINFOID:0000000001396435

The A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultraviolet

(UV) lamp is required to illuminate the dye when inspecting for leaks.

Always wear fluorescence enhancing UV safety goggles to protect your eyes and enhance the visibility of

the fluorescent dye.

The fluorescent dye leak detector is not a replacement for an electronic refrigerant leak detector. The fluo-

rescent dye leak detector should be used in conjunction with an electronic refrigerant leak detector to pin-

point refrigerant leaks.

For your safety and your customer’s satisfaction, read and follow all manufacture’s operating instructions

and precautions prior to performing the work.

A compressor shaft seal should not be repaired because of dye seepage. The compressor shaft seal should

only be repaired after confirming the leak with an electronic refrigerant leak detector.

Always remove any remaining dye from the leak area after repairs are complete to avoid a misdiagnosis dur-

ing a future service.

Do not allow dye to come into contact with painted body panels or interior components. If dye is spilled,

clean immediately with the approved dye cleaner. Fluorescent dye left on a surface for an extended period of

time cannot be removed.

RHA272D

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D