compressor NISSAN TIIDA 2007 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3324 of 5883

HA-42

< ON-VEHICLE REPAIR >

HIGH-PRESSURE FLEXIBLE HOSE

Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

When recharging refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

Page 3325 of 5883

HIGH-PRESSURE PIPE

HA-43

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

HIGH-PRESSURE PIPE

Removal and Installation of High-Pressure Pipe - MR18DE, HR16DEINFOID:0000000001404219

REMOVAL

1. Remove low-pressure flexible hose. Refer to HA-38, "Removal and Installation of Low-Pressure Flexible

Hose - MR18DE, HR16DE".

2. Remove high-pressure pipe from the clips.

3. Remove high-pressure pipe bolt (A), and then remove high-

pressure pipe (1) from condenser (2).

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace O-rings of high-pressure pipe with a new ones, and apply compressor oil when installing.

When recharging refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

Removal and Installation of High-Pressure Pipe - K9KINFOID:0000000001527625

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove engine cover.

3. Remove cowl top cover. Refer to EXT-20, "

Removal and Installation".

4. Reposition the lower dash insulator out of the way.

5. Remove the front grille. Refer to EXT-19, "

Removal and Installation".

6. Reposition the RH air guide out of the way.

1. High-pressure pipe A. High-pressure pipe clips

SJIA0679E

SJIA0680E

Page 3326 of 5883

HA-44

< ON-VEHICLE REPAIR >

HIGH-PRESSURE PIPE

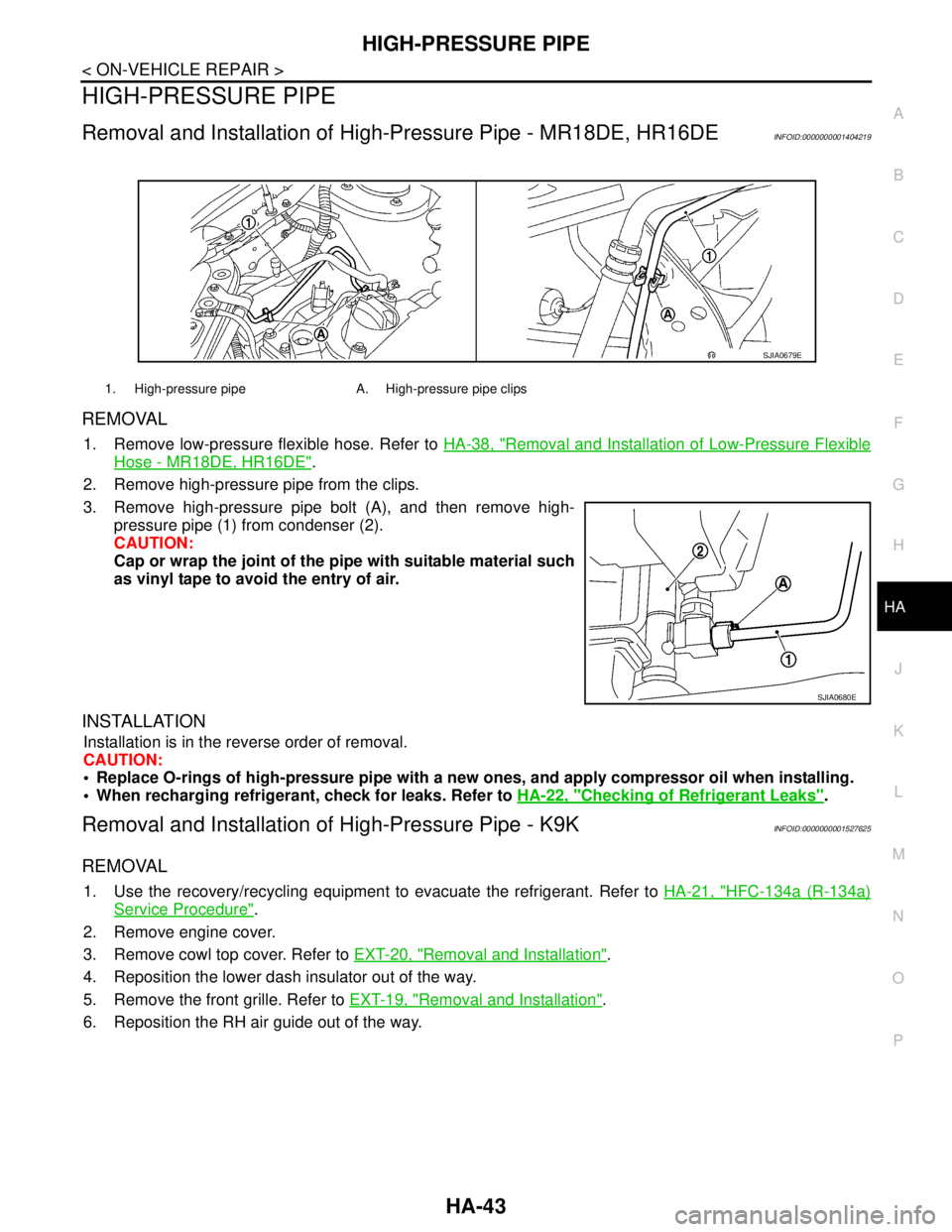

7. Remove bolt (A), and then disconnect the low-pressure pipe (1)

and high-pressure pipe (2) from the expansion valve.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

8. Disconnect the high-pressure pipe from the condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

9. Remove the upper torque rod. Refer to FSU-9, "

Component".

10. Disconnect the high-pressure pipe from the clips.

11. Remove the high-pressure pipe.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

When charging the refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

SJIA0644E

Page 3327 of 5883

CONDENSER

HA-45

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

CONDENSER

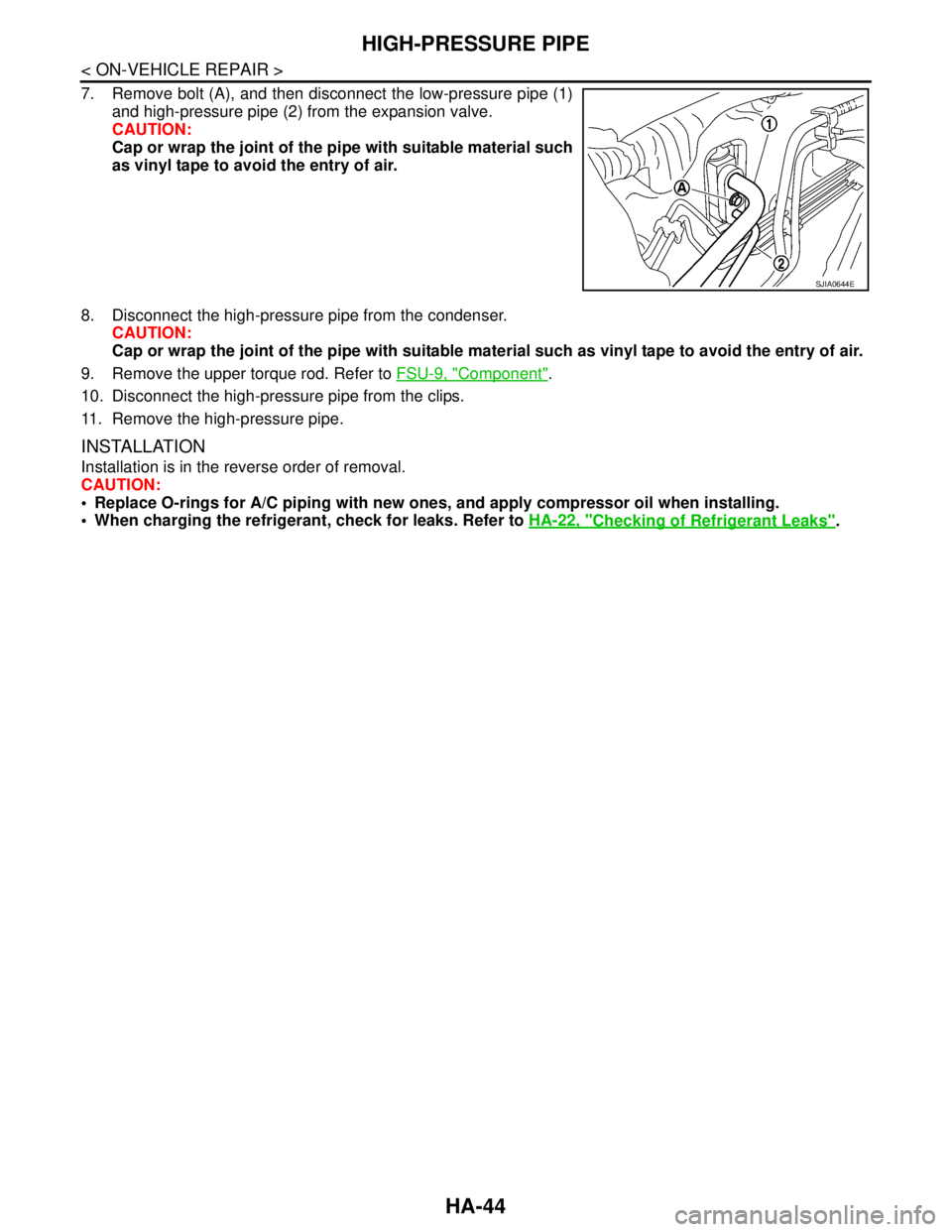

Removal and Installation of Condenser - MR18DE, HR16DEINFOID:0000000001527646

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove the three upper headlamp bolts to reposition the headlamps out of the way

3. Remove the radiator core support upper.

4. Disconnect the high-pressure flexible hose and high-pressure pipe from condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

5. Disconnect refrigerant pressure sensor connector.

6. Tilt radiator toward rear of vehicle, and then remove condenser

(1) from between radiator and radiator core support upper.

CAUTION:

Be careful not to damage the core surface of condenser and

radiator.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

When recharging refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

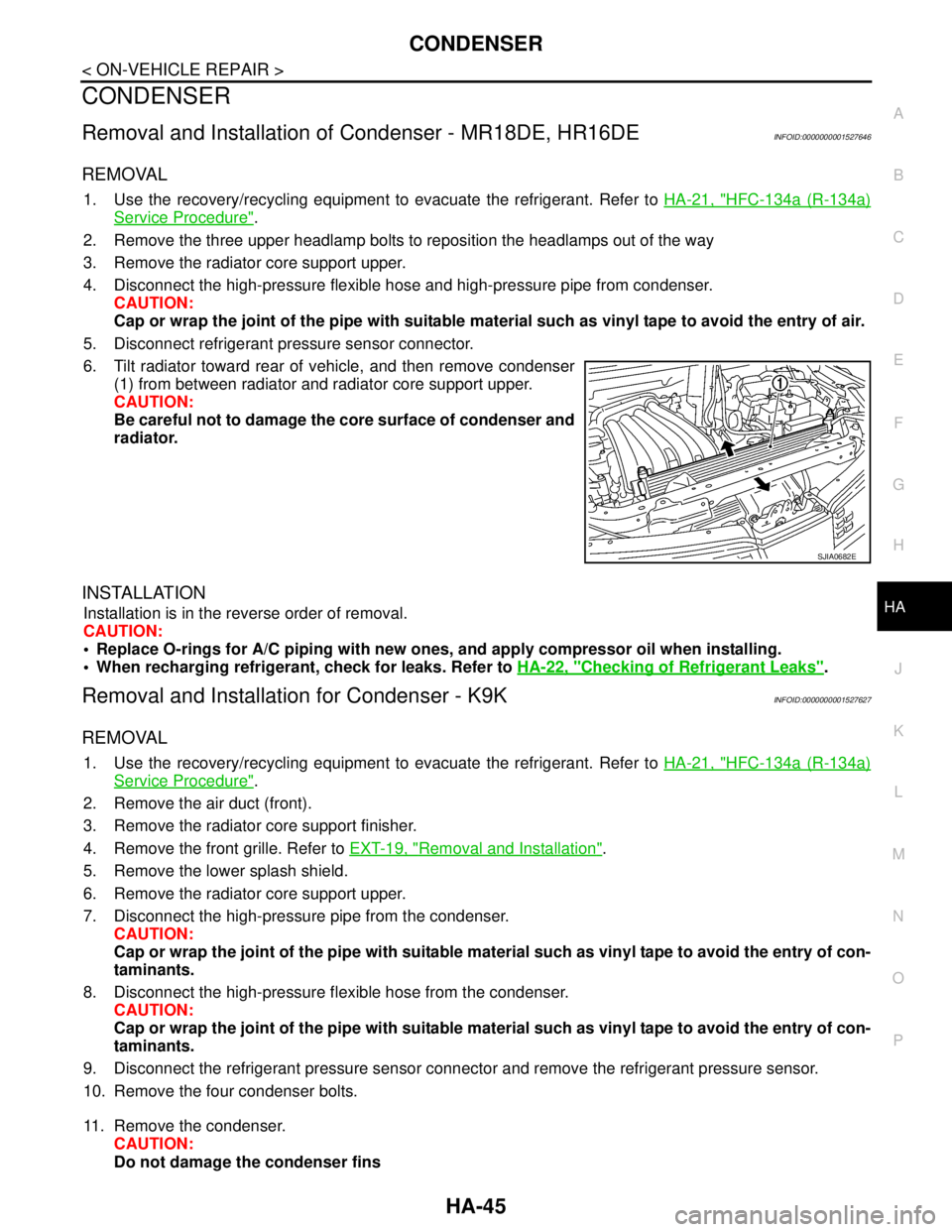

Removal and Installation for Condenser - K9KINFOID:0000000001527627

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove the air duct (front).

3. Remove the radiator core support finisher.

4. Remove the front grille. Refer to EXT-19, "

Removal and Installation".

5. Remove the lower splash shield.

6. Remove the radiator core support upper.

7. Disconnect the high-pressure pipe from the condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of con-

taminants.

8. Disconnect the high-pressure flexible hose from the condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of con-

taminants.

9. Disconnect the refrigerant pressure sensor connector and remove the refrigerant pressure sensor.

10. Remove the four condenser bolts.

11. Remove the condenser.

CAUTION:

Do not damage the condenser fins

SJIA0682E

Page 3328 of 5883

HA-46

< ON-VEHICLE REPAIR >

CONDENSER

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not damage the condenser fins.

Replace O-rings of the high-pressure pipe, high-pressure flexible hose and refrigerant pressure sen-

sor with new ones, and apply compressor oil when installing.

When charging the refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

Page 3330 of 5883

HA-48

< ON-VEHICLE REPAIR >

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR

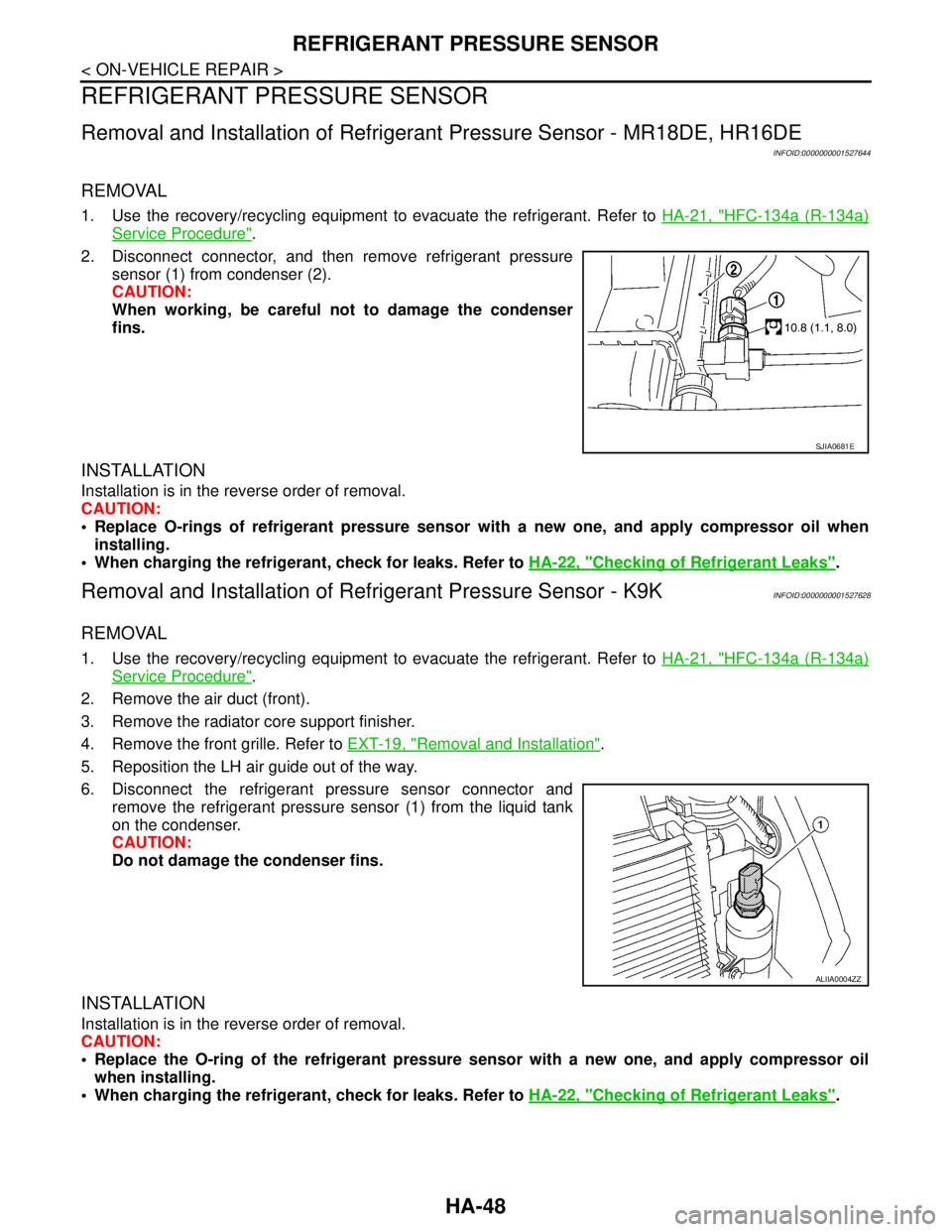

Removal and Installation of Refrigerant Pressure Sensor - MR18DE, HR16DE

INFOID:0000000001527644

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Disconnect connector, and then remove refrigerant pressure

sensor (1) from condenser (2).

CAUTION:

When working, be careful not to damage the condenser

fins.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace O-rings of refrigerant pressure sensor with a new one, and apply compressor oil when

installing.

When charging the refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

Removal and Installation of Refrigerant Pressure Sensor - K9KINFOID:0000000001527628

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove the air duct (front).

3. Remove the radiator core support finisher.

4. Remove the front grille. Refer to EXT-19, "

Removal and Installation".

5. Reposition the LH air guide out of the way.

6. Disconnect the refrigerant pressure sensor connector and

remove the refrigerant pressure sensor (1) from the liquid tank

on the condenser.

CAUTION:

Do not damage the condenser fins.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace the O-ring of the refrigerant pressure sensor with a new one, and apply compressor oil

when installing.

When charging the refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

SJIA0681E

ALIIA0004ZZ

Page 3331 of 5883

EXPANSION VALVE

HA-49

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

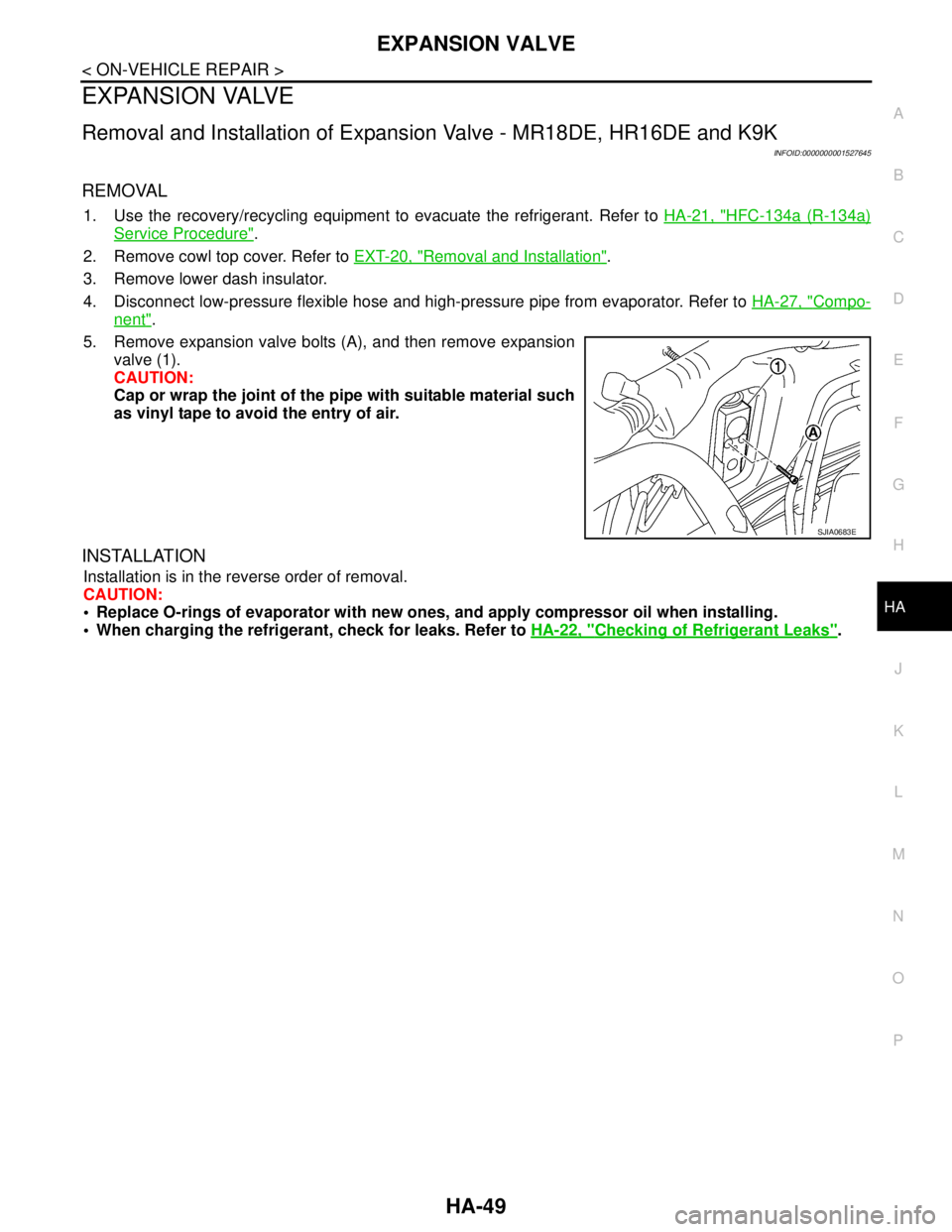

EXPANSION VALVE

Removal and Installation of Expansion Valve - MR18DE, HR16DE and K9K

INFOID:0000000001527645

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove cowl top cover. Refer to EXT-20, "

Removal and Installation".

3. Remove lower dash insulator.

4. Disconnect low-pressure flexible hose and high-pressure pipe from evaporator. Refer to HA-27, "

Compo-

nent".

5. Remove expansion valve bolts (A), and then remove expansion

valve (1).

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace O-rings of evaporator with new ones, and apply compressor oil when installing.

When charging the refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

SJIA0683E

Page 3332 of 5883

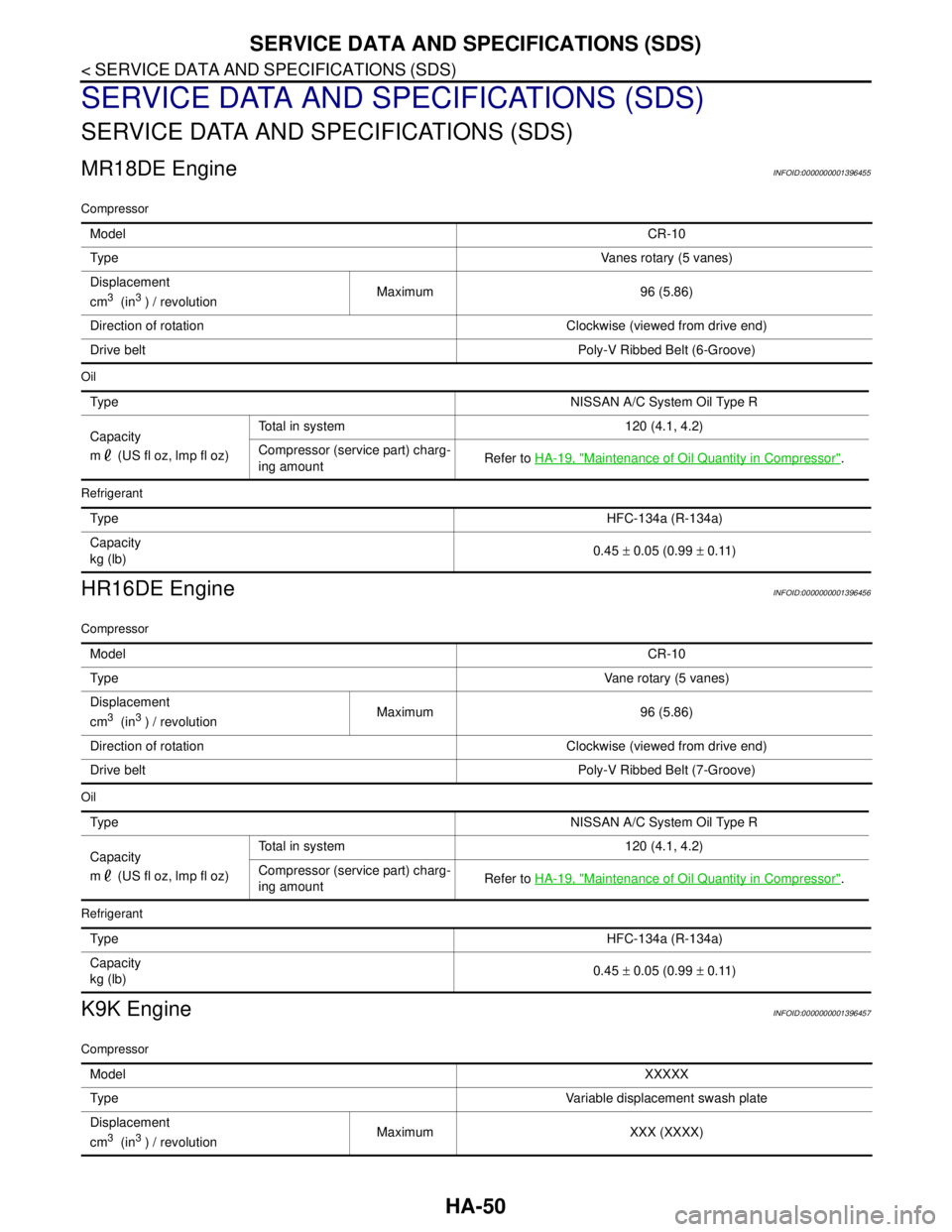

HA-50

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

MR18DE EngineINFOID:0000000001396455

Compressor

Oil

Refrigerant

HR16DE EngineINFOID:0000000001396456

Compressor

Oil

Refrigerant

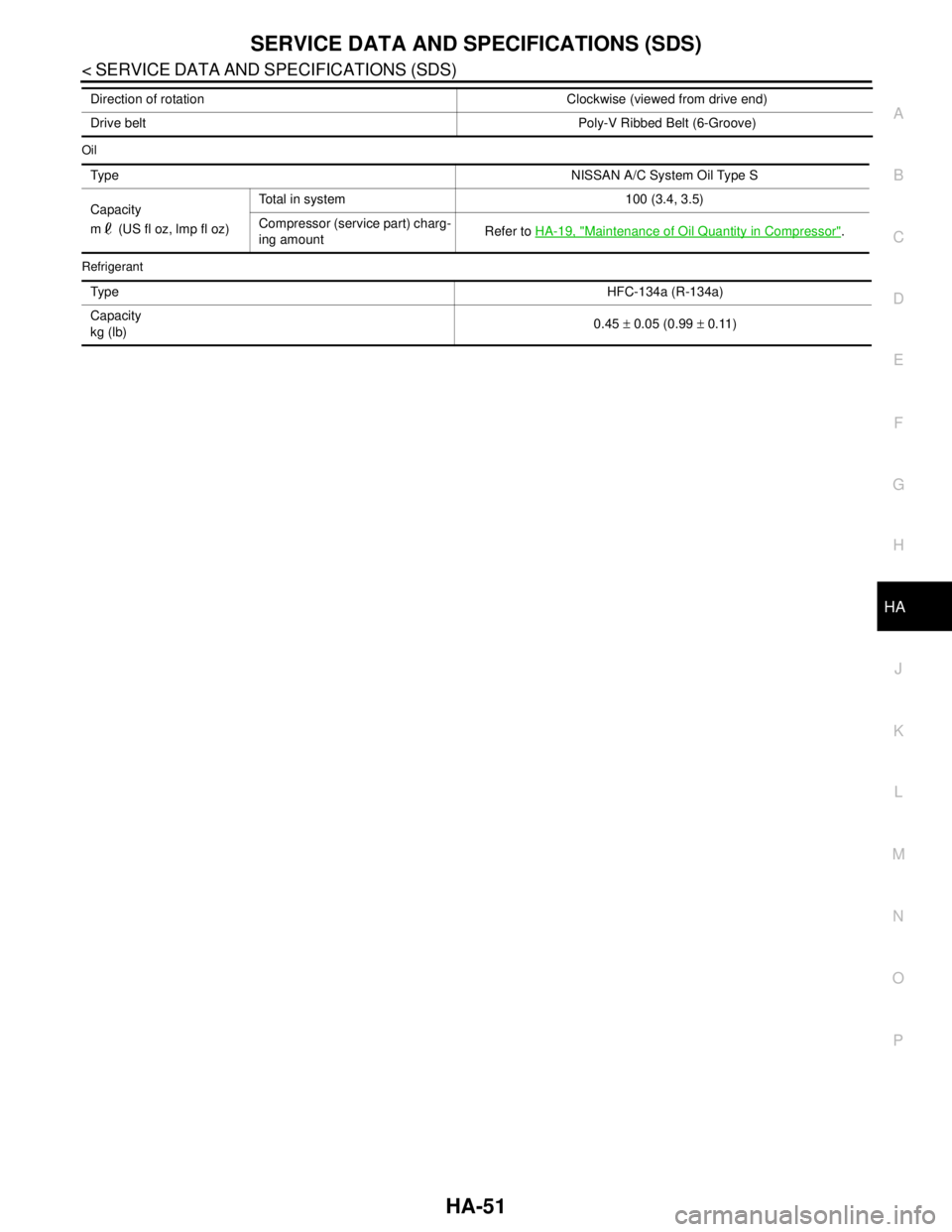

K9K EngineINFOID:0000000001396457

Compressor

ModelCR-10

Ty p eVanes rotary (5 vanes)

Displacement

cm

3 (in3 ) / revolutionMaximum 96 (5.86)

Direction of rotation Clockwise (viewed from drive end)

Drive beltPoly-V Ribbed Belt (6-Groove)

Ty p eNISSAN A/C System Oil Type R

Capacity

m (US fl oz, lmp fl oz)Total in system 120 (4.1, 4.2)

Compressor (service part) charg-

ing amountRefer to HA-19, "

Maintenance of Oil Quantity in Compressor".

Ty p eHFC-134a (R-134a)

Capacity

kg (lb)0.45 ± 0.05 (0.99 ± 0.11)

ModelCR-10

Ty p eVane rotary (5 vanes)

Displacement

cm

3 (in3 ) / revolutionMaximum 96 (5.86)

Direction of rotation Clockwise (viewed from drive end)

Drive beltPoly-V Ribbed Belt (7-Groove)

Ty p eNISSAN A/C System Oil Type R

Capacity

m (US fl oz, lmp fl oz)Total in system 120 (4.1, 4.2)

Compressor (service part) charg-

ing amountRefer to HA-19, "

Maintenance of Oil Quantity in Compressor".

Ty p eHFC-134a (R-134a)

Capacity

kg (lb)0.45 ± 0.05 (0.99 ± 0.11)

ModelXXXXX

Ty p eVariable displacement swash plate

Displacement

cm

3 (in3 ) / revolutionMaximum XXX (XXXX)

Page 3333 of 5883

SERVICE DATA AND SPECIFICATIONS (SDS)

HA-51

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

Oil

Refrigerant

Direction of rotation Clockwise (viewed from drive end)

Drive beltPoly-V Ribbed Belt (6-Groove)

Typ eNISSAN A/C System Oil Type S

Capacity

m (US fl oz, lmp fl oz)Total in system 100 (3.4, 3.5)

Compressor (service part) charg-

ing amountRefer to HA-19, "

Maintenance of Oil Quantity in Compressor".

Typ eHFC-134a (R-134a)

Capacity

kg (lb)0.45 ± 0.05 (0.99 ± 0.11)

Page 3339 of 5883

![NISSAN TIIDA 2007 Service Manual PDF HAC-6

< BASIC INSPECTION >[MANUAL AIR CONDITIONER]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Operational CheckINFOID:0000000001203052

The purpose of the operational check is to confirm that NISSAN TIIDA 2007 Service Manual PDF HAC-6

< BASIC INSPECTION >[MANUAL AIR CONDITIONER]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Operational CheckINFOID:0000000001203052

The purpose of the operational check is to confirm that](/img/5/57395/w960_57395-3338.png)

HAC-6

< BASIC INSPECTION >[MANUAL AIR CONDITIONER]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Operational CheckINFOID:0000000001203052

The purpose of the operational check is to confirm that the system operates properly.

CHECKING BLOWER

1. Turn blower control dial clockwise to "1" position. Blower should operate on low speed.

2. Turn blower control dial clockwise to "2" position, and continue checking blower speed until all speeds are

checked.

3. Leave blower on Maximum speed.

If NG, go to trouble diagnosis procedure for xxx BLOWER MOTOR CIR HAC-19, "

Front Blower Motor Diagno-

sis Procedure".

If OK, continue the check.

CHECKING DISCHARGE AIR

1. Turn mode door control dial to each position.

2. Confirm that discharge air comes out according to the air distribution table. Refer to XXXX DISCHARGE

AIR FLOW.

If NG, go to trouble diagnosis procedure for HAC-16, "

Mode Door Diagnostic Procedure".

If OK, continue the check.

CHECKING RECIRCULATION

1. Set intake door lever to REC position.

2. Operate intake door lever to FRE position.

3. Listen for intake door position change (you should hear blower sound change slightly).

If NG, go to trouble diagnosis procedure for XXXX INTAKE DOOR.

If OK, continue the check.

CHECKING TEMPERATURE DECREASE

1. Turn temperature control dial counterclockwise to full cold position.

2. Check for cold air at discharge air outlets.

If NG, go to trouble diagnosis procedure for XXXX INSUFFICIENT COOLING.

If OK, continue the check.

CHECKING TEMPERATURE INCREASE

1. Turn temperature control dial clockwise to full hot position.

2. Check for hot air at discharge air outlets.

If NG, go to trouble diagnosis procedure for XXXX INSUFFICIENT HEATING.

If OK, continue the check.

CHECKING A/C SWITCH (IF EQUIPPED)

1. Turn fan control dial to the desired (1 to 4 speed) position.

2. Press A/C switch.

3. A/C switch indicator will turn ON.

• Confirm that the compressor clutch engages (sound or visual inspection).

If NG, go to trouble diagnosis procedure for XXXX MAG CLUTCH CIR.

If OK, continue the check.

CHECKING DEFROST A/C SWITCH (IF EQUIPPED)

1. Turn fan control dial to the desired (1 to 4 speed) position.

2. Turn mode dial to ( ) DEF.

3. Confirm that the compressor clutch engages (sound or visual inspection). Conditions : Engine running at normal operating temperature