NISSAN TIIDA 2007 Service Repair Manual

TIIDA 2007

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57395/w960_57395-0.png

NISSAN TIIDA 2007 Service Repair Manual

Trending: Pri pressure, remote start, oil dipstick, glove box, front cowl, Abs CAN line, brake rotor

Page 5741 of 5883

WCS-26

< COMPONENT DIAGNOSIS >

KEY SWITCH SIGNAL CIRCUIT (WITH INTELLIGENT KEY)

KEY SWITCH SIGNAL CIRCUIT (WITH INTELLIGENT KEY)

DescriptionINFOID:0000000001722936

Transmits a key switch signal to the BCM.

Component Function CheckINFOID:0000000001722937

1.CHECK BCM INPUT SIGNAL

Select “DATA MONITOR” for “BCM” and check the “KEY IN SW” monitor value.

>> Inspection End.

Diagnosis ProcedureINFOID:0000000001722938

1.CHECK FUSE

Check if the key switch and ignition knob switch 10A fuse (No. 31, located in the fuse and relay box) is blown.

Is the fuse blown?

YES >> Be sure to repair the cause of malfunction before installing new fuse.

NO >> GO TO 2

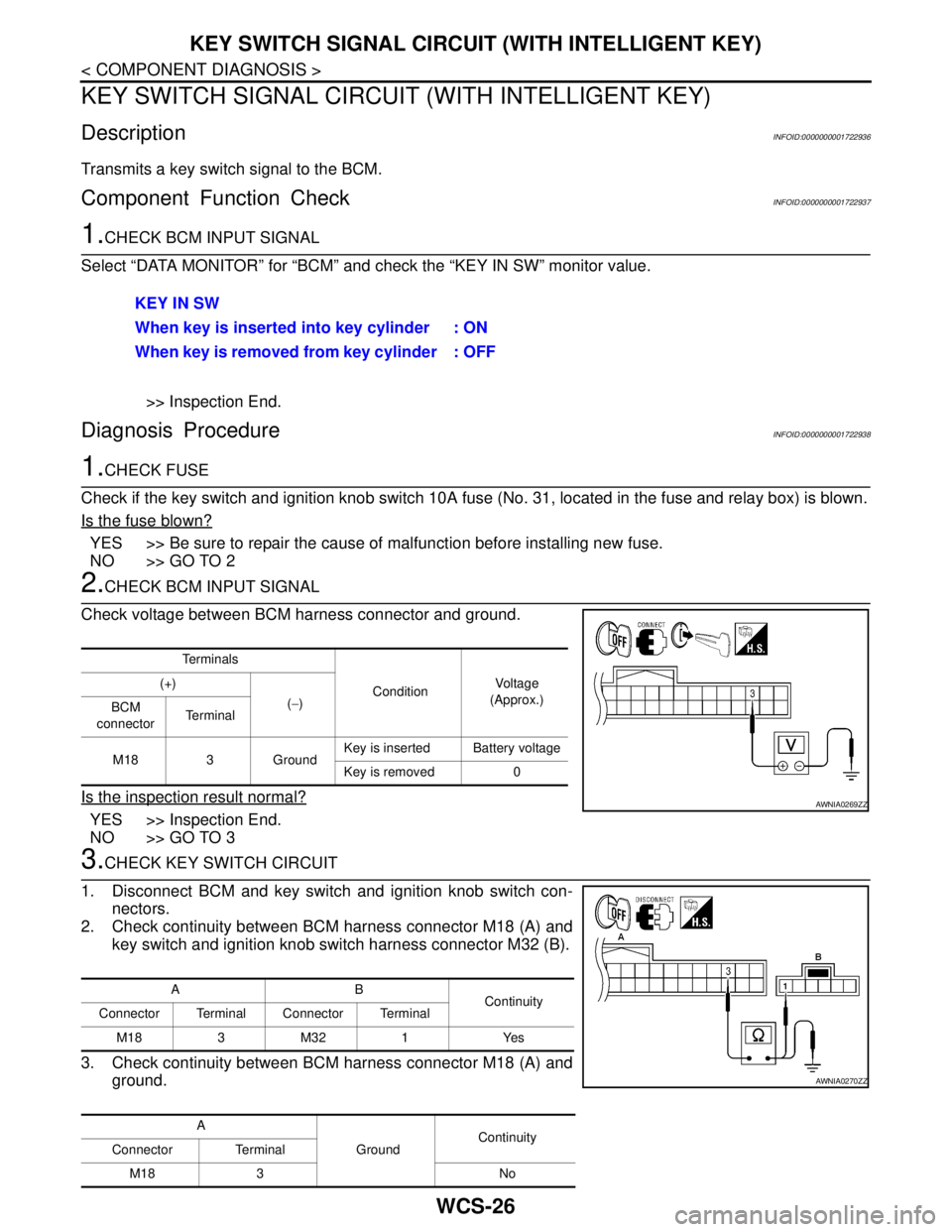

2.CHECK BCM INPUT SIGNAL

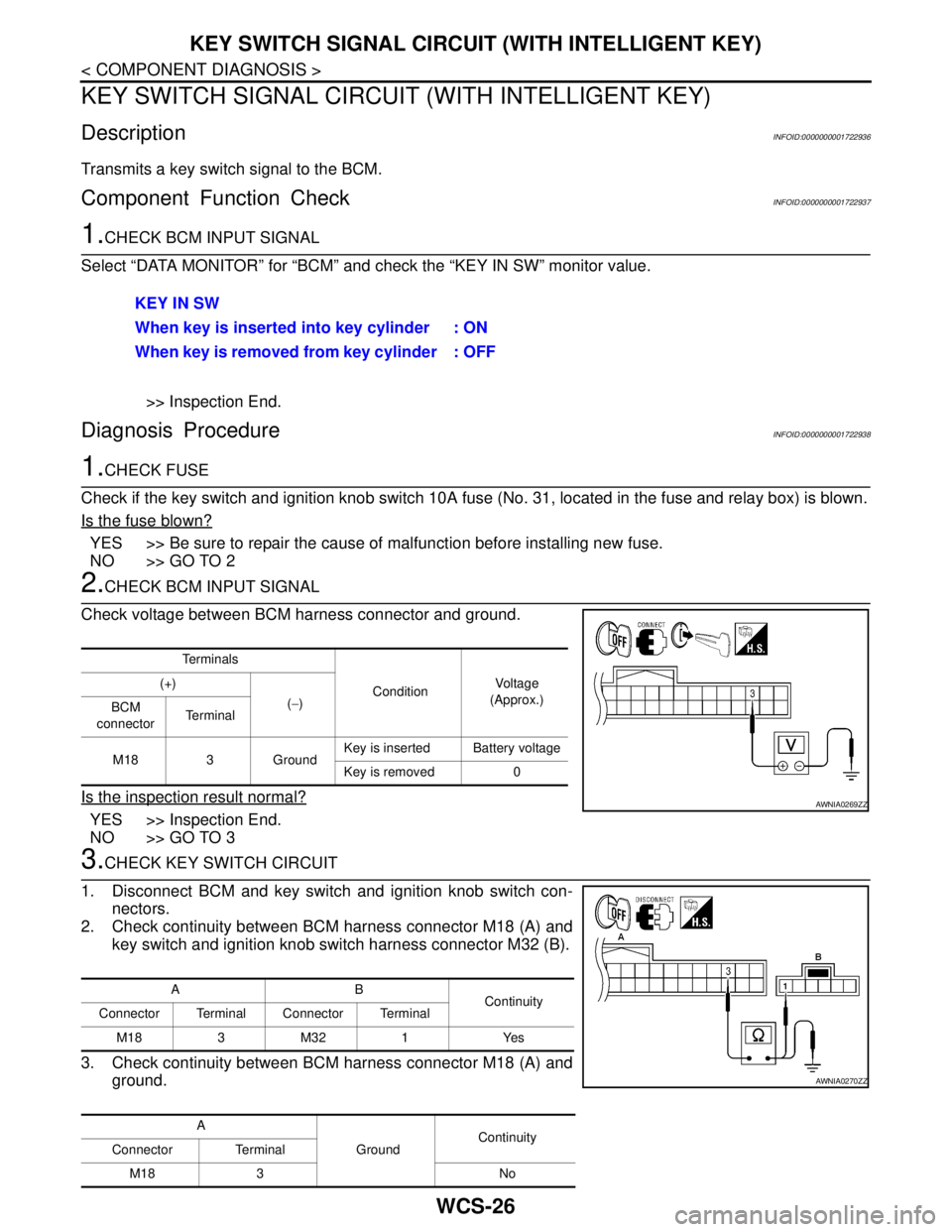

Check voltage between BCM harness connector and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> GO TO 3

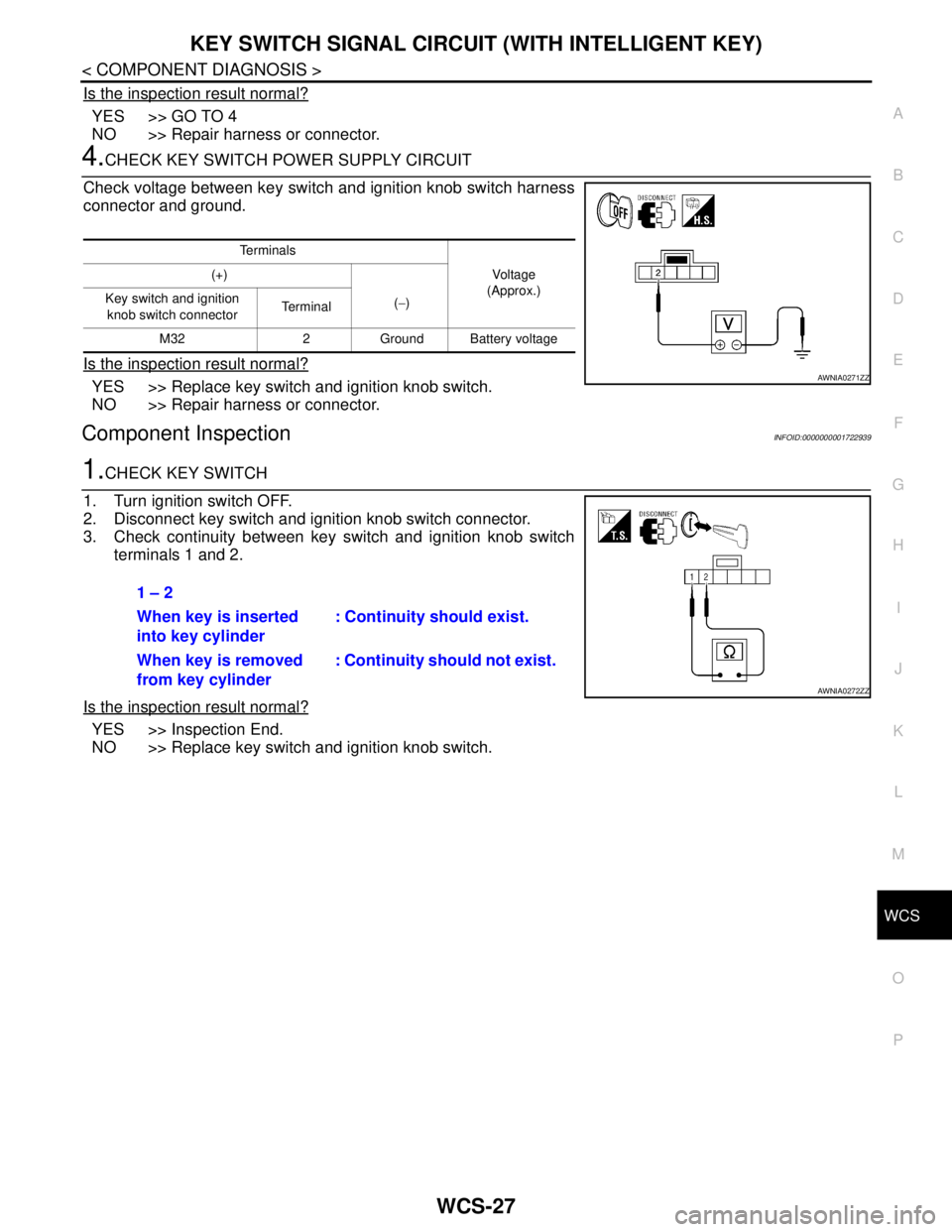

3.CHECK KEY SWITCH CIRCUIT

1. Disconnect BCM and key switch and ignition knob switch con-

nectors.

2. Check continuity between BCM harness connector M18 (A) and

key switch and ignition knob switch harness connector M32 (B).

3. Check continuity between BCM harness connector M18 (A) and

ground.KEY IN SW

When key is inserted into key cylinder : ON

When key is removed from key cylinder : OFF

Te r m i n a l s

ConditionVo l ta g e

(Approx.) (+)

(−)

BCM

connectorTe r m i n a l

M18 3 GroundKey is inserted Battery voltage

Key is removed 0

AWNIA0269ZZ

AB

Continuity

Connector Terminal Connector Terminal

M183M321 Yes

A

GroundContinuity

Connector Terminal

M18 3 No

AWNIA0270ZZ

Page 5742 of 5883

WCS

KEY SWITCH SIGNAL CIRCUIT (WITH INTELLIGENT KEY)

WCS-27

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair harness or connector.

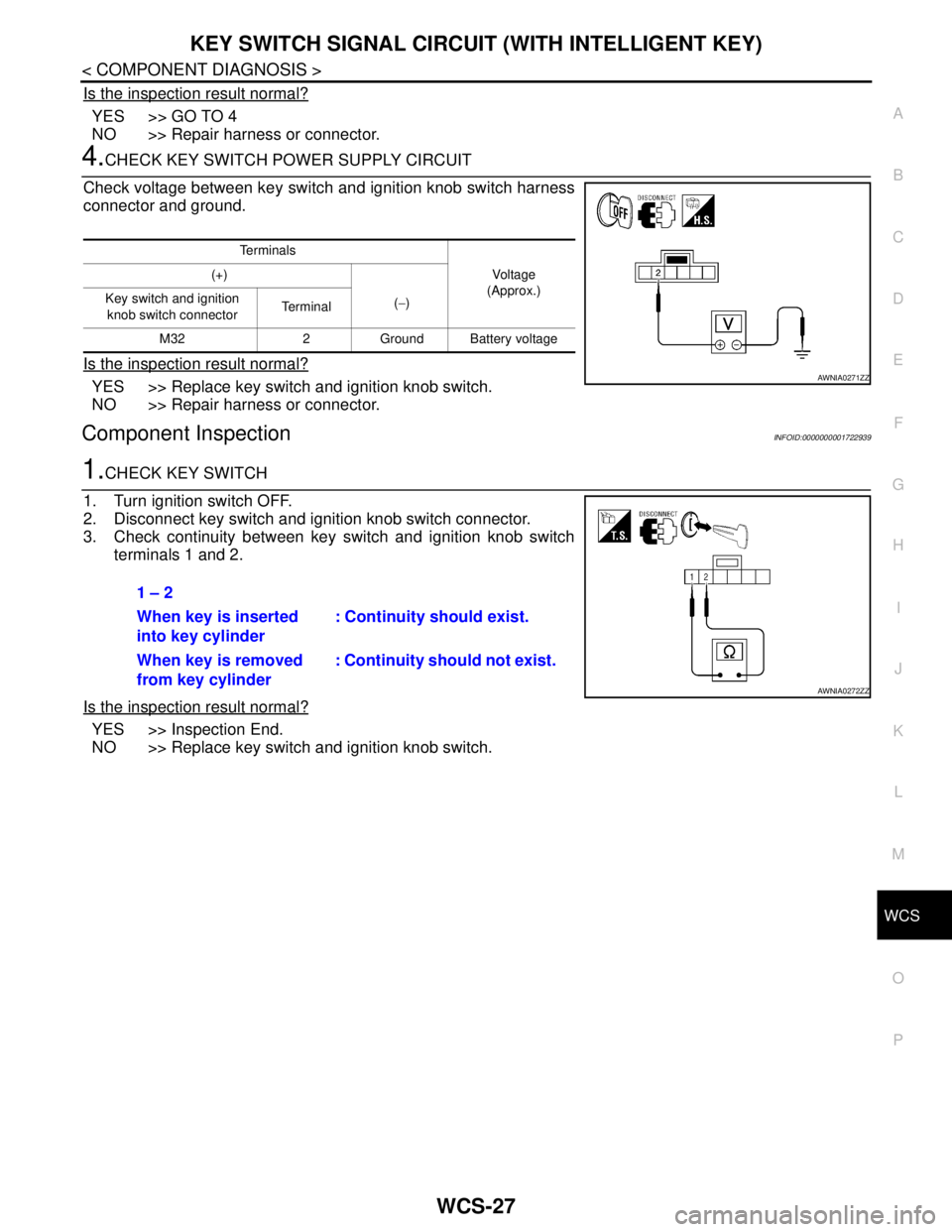

4.CHECK KEY SWITCH POWER SUPPLY CIRCUIT

Check voltage between key switch and ignition knob switch harness

connector and ground.

Is the inspection result normal?

YES >> Replace key switch and ignition knob switch.

NO >> Repair harness or connector.

Component InspectionINFOID:0000000001722939

1.CHECK KEY SWITCH

1. Turn ignition switch OFF.

2. Disconnect key switch and ignition knob switch connector.

3. Check continuity between key switch and ignition knob switch

terminals 1 and 2.

Is the inspection result normal?

YES >> Inspection End.

NO >> Replace key switch and ignition knob switch.

Te r m i n a l s

Vo l ta g e

(Approx.) (+)

(−) Key switch and ignition

knob switch connector Te r m i n a l

M32 2 Ground Battery voltage

AWNIA0271ZZ

1 – 2

When key is inserted

into key cylinder: Continuity should exist.

When key is removed

from key cylinder: Continuity should not exist.

AWNIA0272ZZ

Page 5743 of 5883

WCS-28

< COMPONENT DIAGNOSIS >

KEY SWITCH SIGNAL CIRCUIT (WITHOUT INTELLIGENT KEY)

KEY SWITCH SIGNAL CIRCUIT (WITHOUT INTELLIGENT KEY)

DescriptionINFOID:0000000001722940

Transmits a key switch signal to the BCM.

Component Function CheckINFOID:0000000001722941

1.CHECK BCM INPUT SIGNAL

Select “DATA MONITOR” for “BCM” and check the “KEY IN SW” monitor value.

>> Inspection End.

Diagnosis ProcedureINFOID:0000000001722942

1.CHECK FUSE

Check if the key switch and key lock solenoid 10A fuse [No. 14, located in the fuse block (J/B)] is blown.

Is the fuse blown?

YES >> Be sure to repair the cause of malfunction before installing new fuse.

NO >> GO TO 2

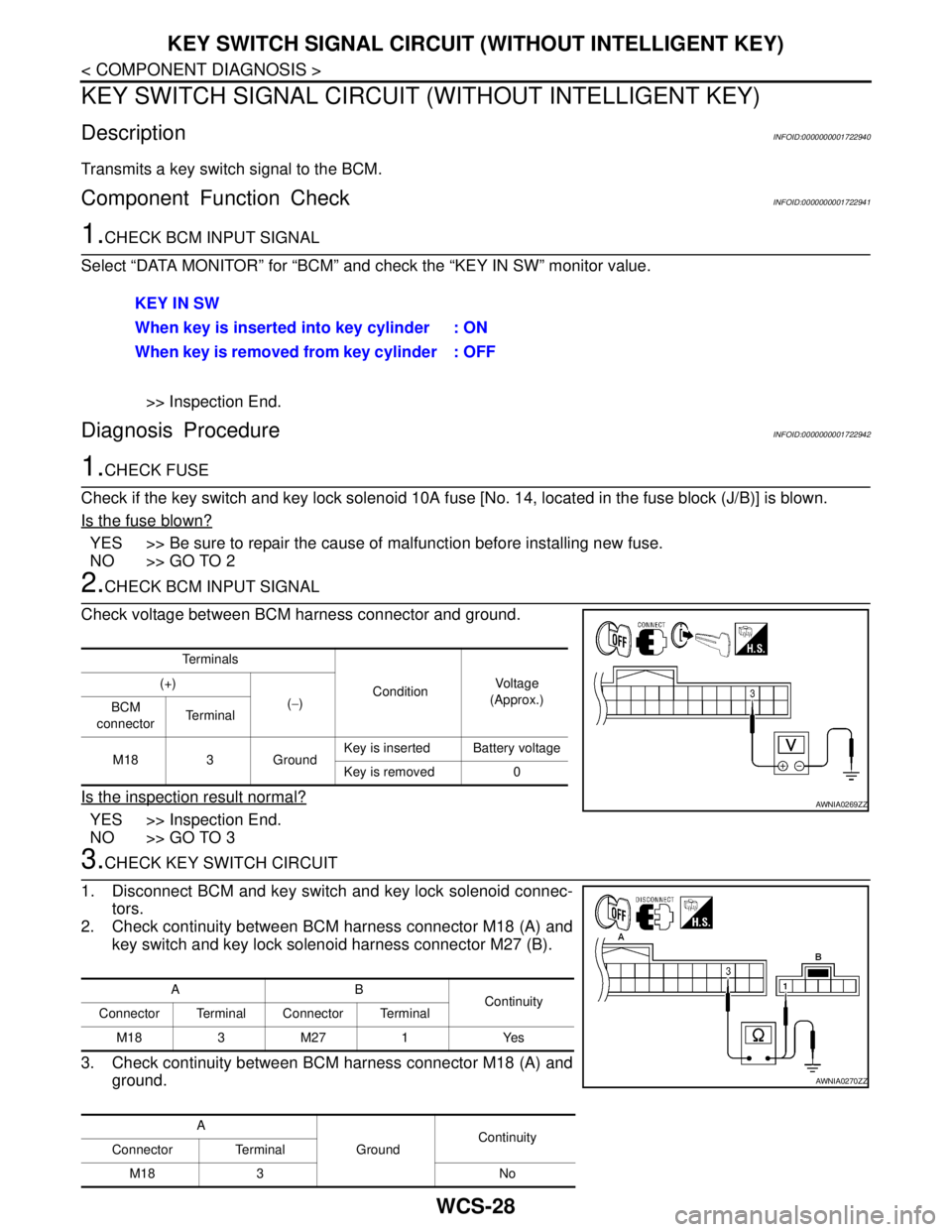

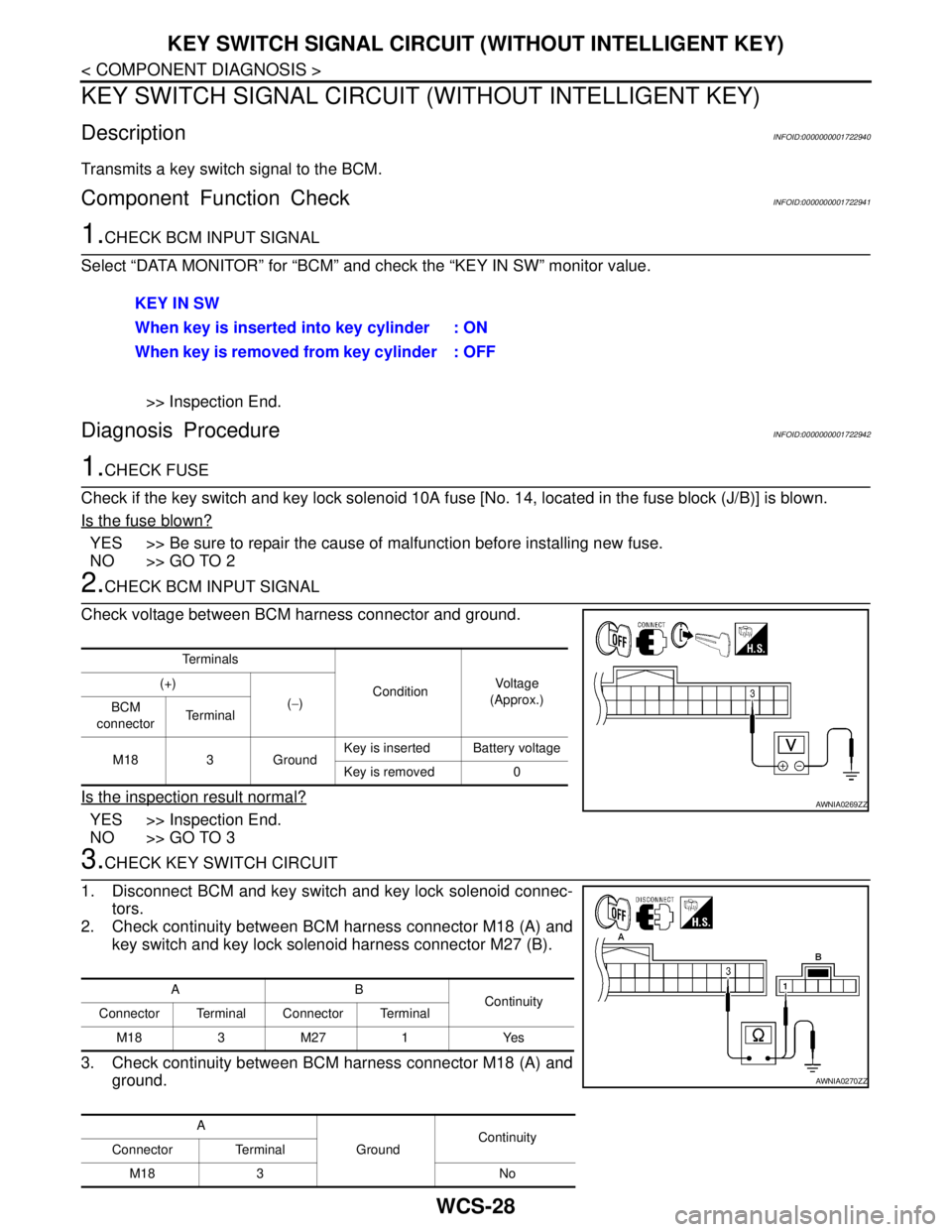

2.CHECK BCM INPUT SIGNAL

Check voltage between BCM harness connector and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> GO TO 3

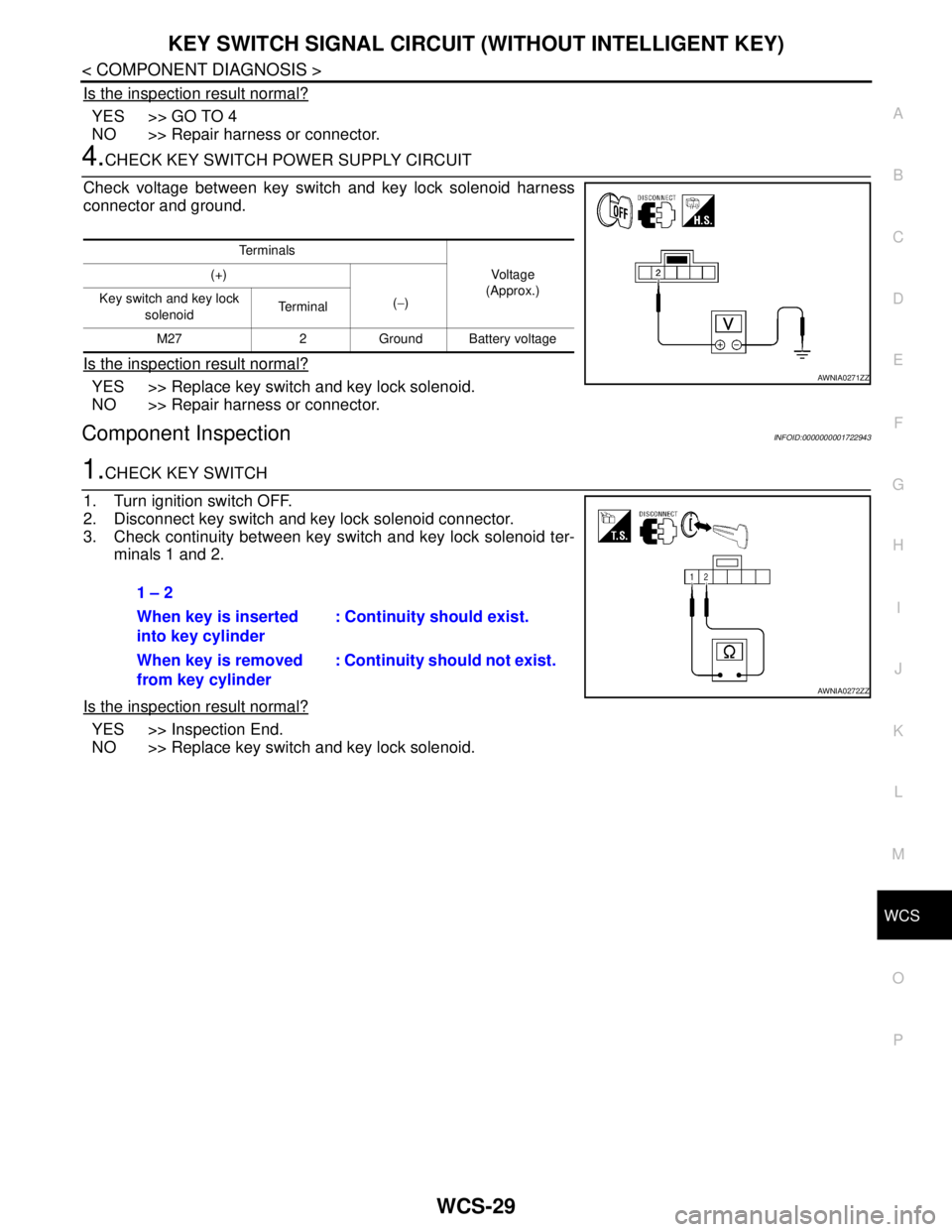

3.CHECK KEY SWITCH CIRCUIT

1. Disconnect BCM and key switch and key lock solenoid connec-

tors.

2. Check continuity between BCM harness connector M18 (A) and

key switch and key lock solenoid harness connector M27 (B).

3. Check continuity between BCM harness connector M18 (A) and

ground.KEY IN SW

When key is inserted into key cylinder : ON

When key is removed from key cylinder : OFF

Te r m i n a l s

ConditionVo l ta g e

(Approx.) (+)

(−)

BCM

connectorTe r m i n a l

M18 3 GroundKey is inserted Battery voltage

Key is removed 0

AWNIA0269ZZ

AB

Continuity

Connector Terminal Connector Terminal

M183M271 Yes

A

GroundContinuity

Connector Terminal

M18 3 No

AWNIA0270ZZ

Page 5744 of 5883

WCS

KEY SWITCH SIGNAL CIRCUIT (WITHOUT INTELLIGENT KEY)

WCS-29

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair harness or connector.

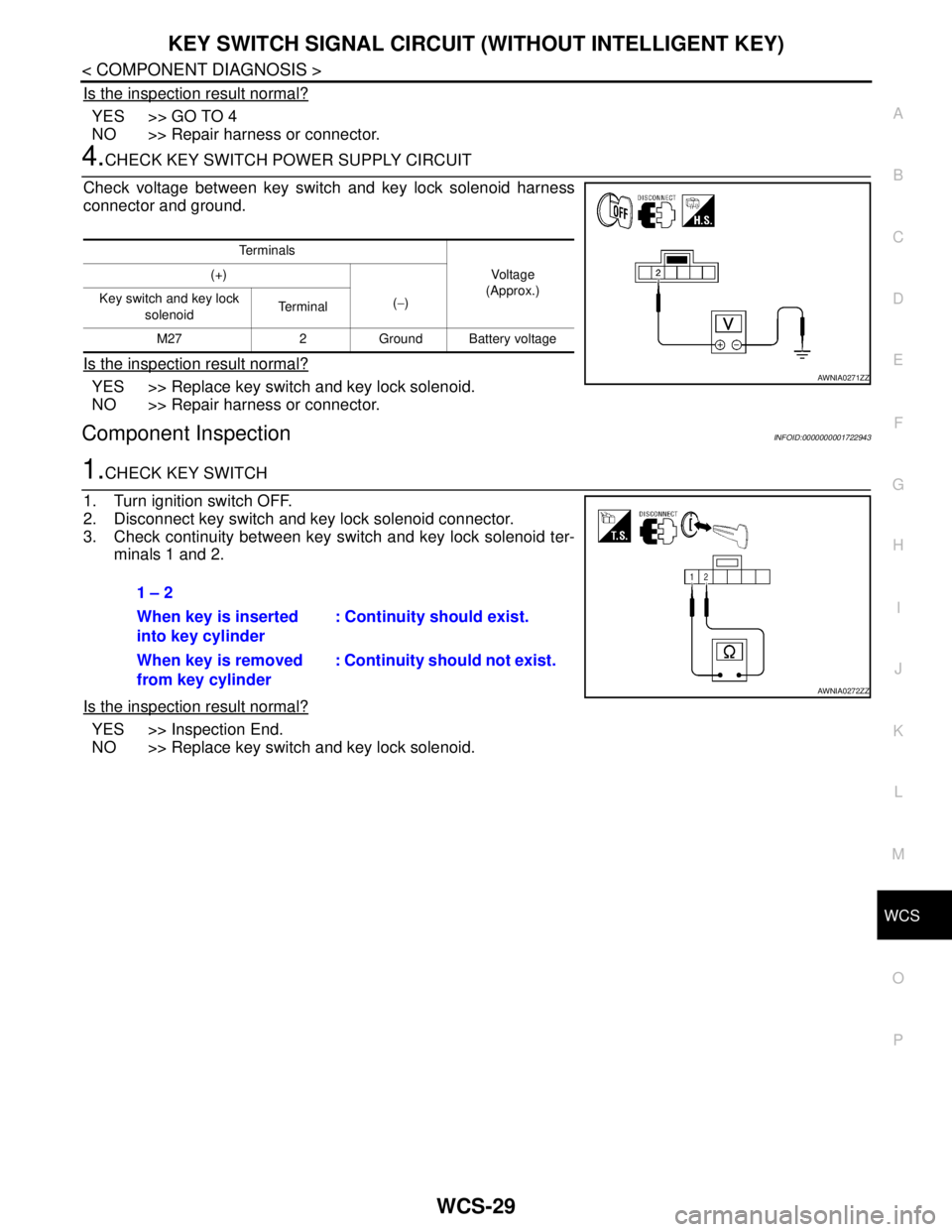

4.CHECK KEY SWITCH POWER SUPPLY CIRCUIT

Check voltage between key switch and key lock solenoid harness

connector and ground.

Is the inspection result normal?

YES >> Replace key switch and key lock solenoid.

NO >> Repair harness or connector.

Component InspectionINFOID:0000000001722943

1.CHECK KEY SWITCH

1. Turn ignition switch OFF.

2. Disconnect key switch and key lock solenoid connector.

3. Check continuity between key switch and key lock solenoid ter-

minals 1 and 2.

Is the inspection result normal?

YES >> Inspection End.

NO >> Replace key switch and key lock solenoid.

Te r m i n a l s

Vo l ta g e

(Approx.) (+)

(−) Key switch and key lock

solenoid Te r m i n a l

M27 2 Ground Battery voltage

AWNIA0271ZZ

1 – 2

When key is inserted

into key cylinder: Continuity should exist.

When key is removed

from key cylinder: Continuity should not exist.

AWNIA0272ZZ

Page 5745 of 5883

WCS-30

< COMPONENT DIAGNOSIS >

PARKING BRAKE SWITCH SIGNAL CIRCUIT

PARKING BRAKE SWITCH SIGNAL CIRCUIT

DescriptionINFOID:0000000001722969

Transmits the parking brake switch signal to the combination meter.

Component Function CheckINFOID:0000000001724686

1.COMBINATION METER INPUT SIGNAL

1. Start engine.

2. Monitor “BRAKE” warning lamp while applying and releasing the parking brake.

>> Inspection End.

Diagnosis ProcedureINFOID:0000000001724687

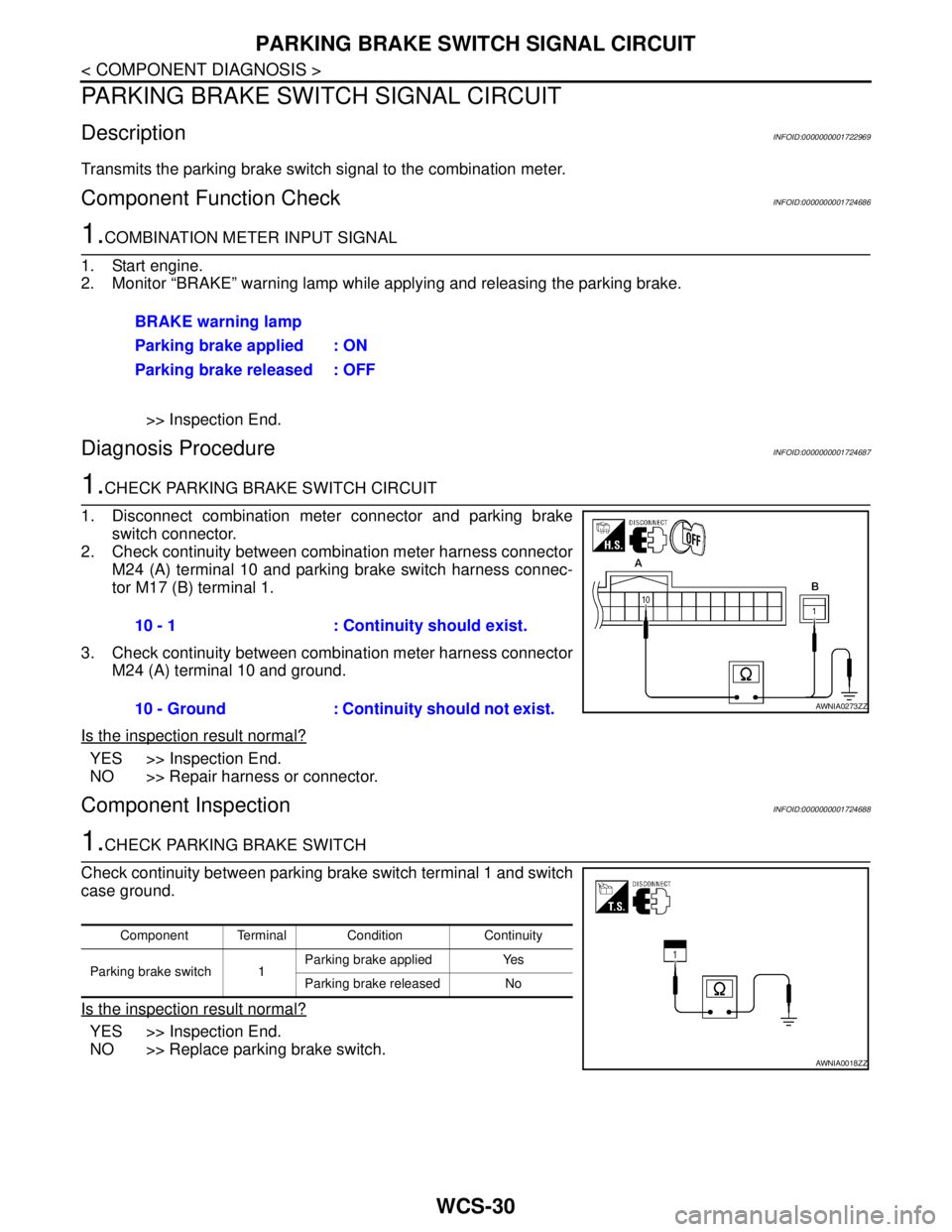

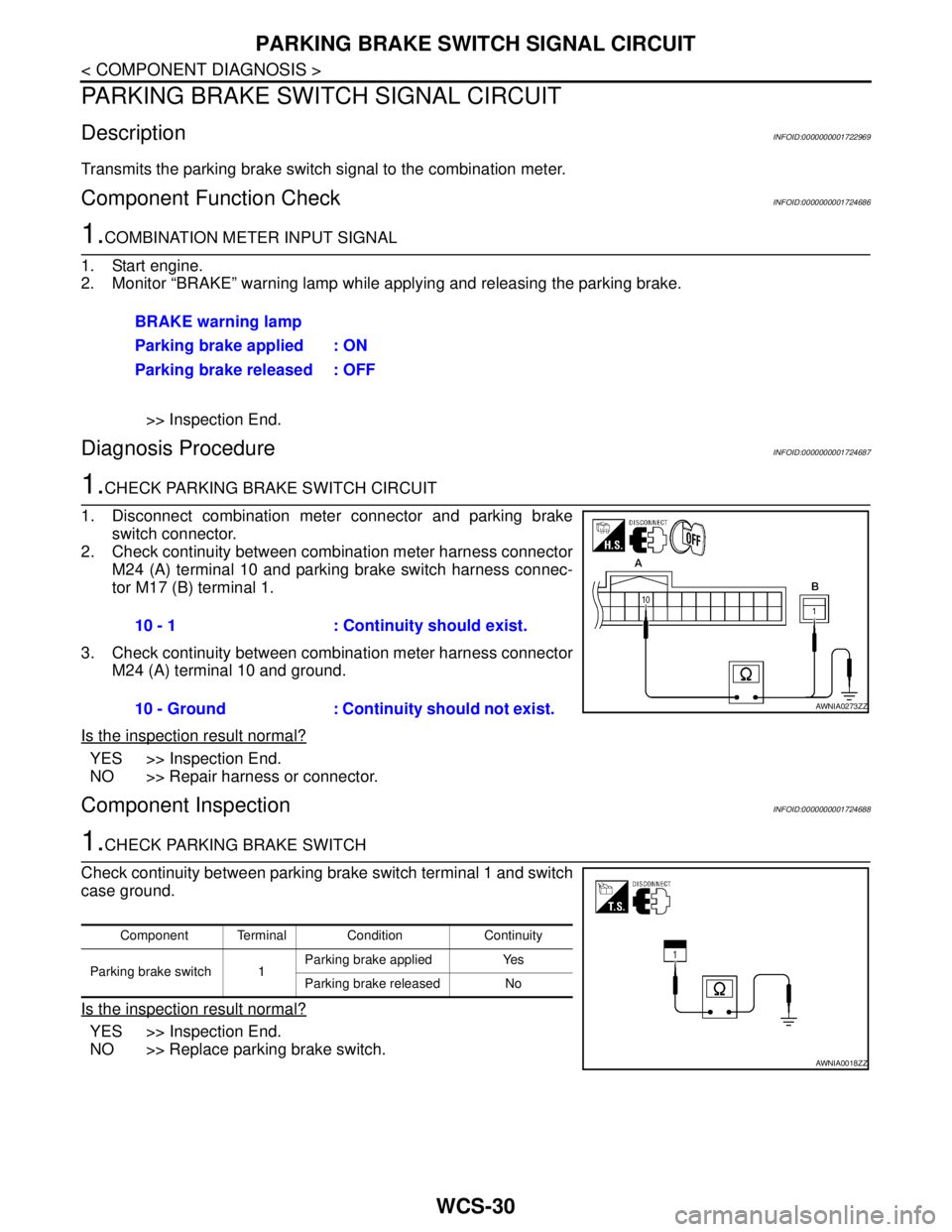

1.CHECK PARKING BRAKE SWITCH CIRCUIT

1. Disconnect combination meter connector and parking brake

switch connector.

2. Check continuity between combination meter harness connector

M24 (A) terminal 10 and parking brake switch harness connec-

tor M17 (B) terminal 1.

3. Check continuity between combination meter harness connector

M24 (A) terminal 10 and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair harness or connector.

Component InspectionINFOID:0000000001724688

1.CHECK PARKING BRAKE SWITCH

Check continuity between parking brake switch terminal 1 and switch

case ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Replace parking brake switch.BRAKE warning lamp

Parking brake applied : ON

Parking brake released : OFF

10 - 1 : Continuity should exist.

10 - Ground : Continuity should not exist.

AWNIA0273ZZ

Component Terminal Condition Continuity

Parking brake switch 1Parking brake applied Yes

Parking brake released No

AWNIA0018ZZ

Page 5746 of 5883

WCS

WARNING CHIME SYSTEM

WCS-31

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

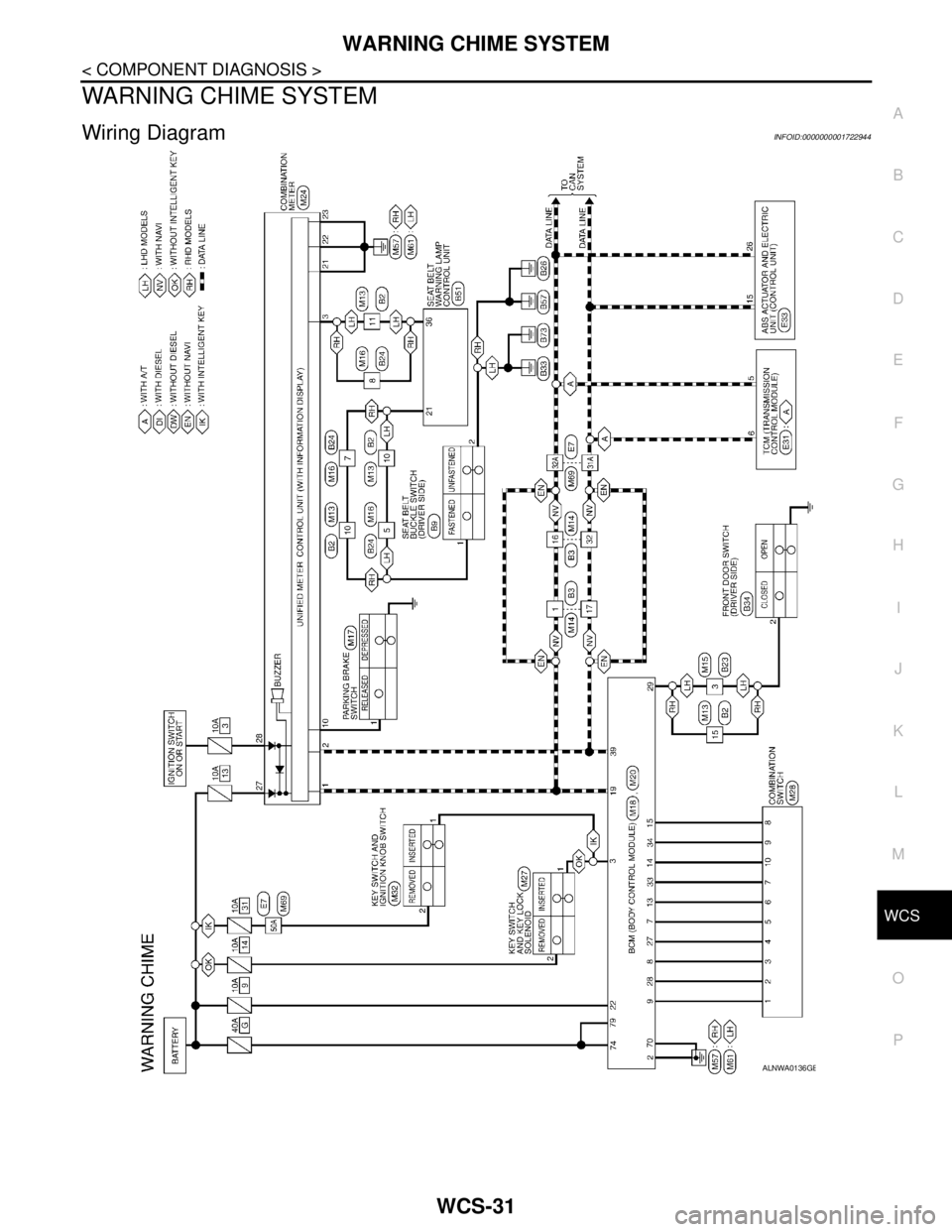

WARNING CHIME SYSTEM

Wiring DiagramINFOID:0000000001722944

ALNWA0136GB

Page 5747 of 5883

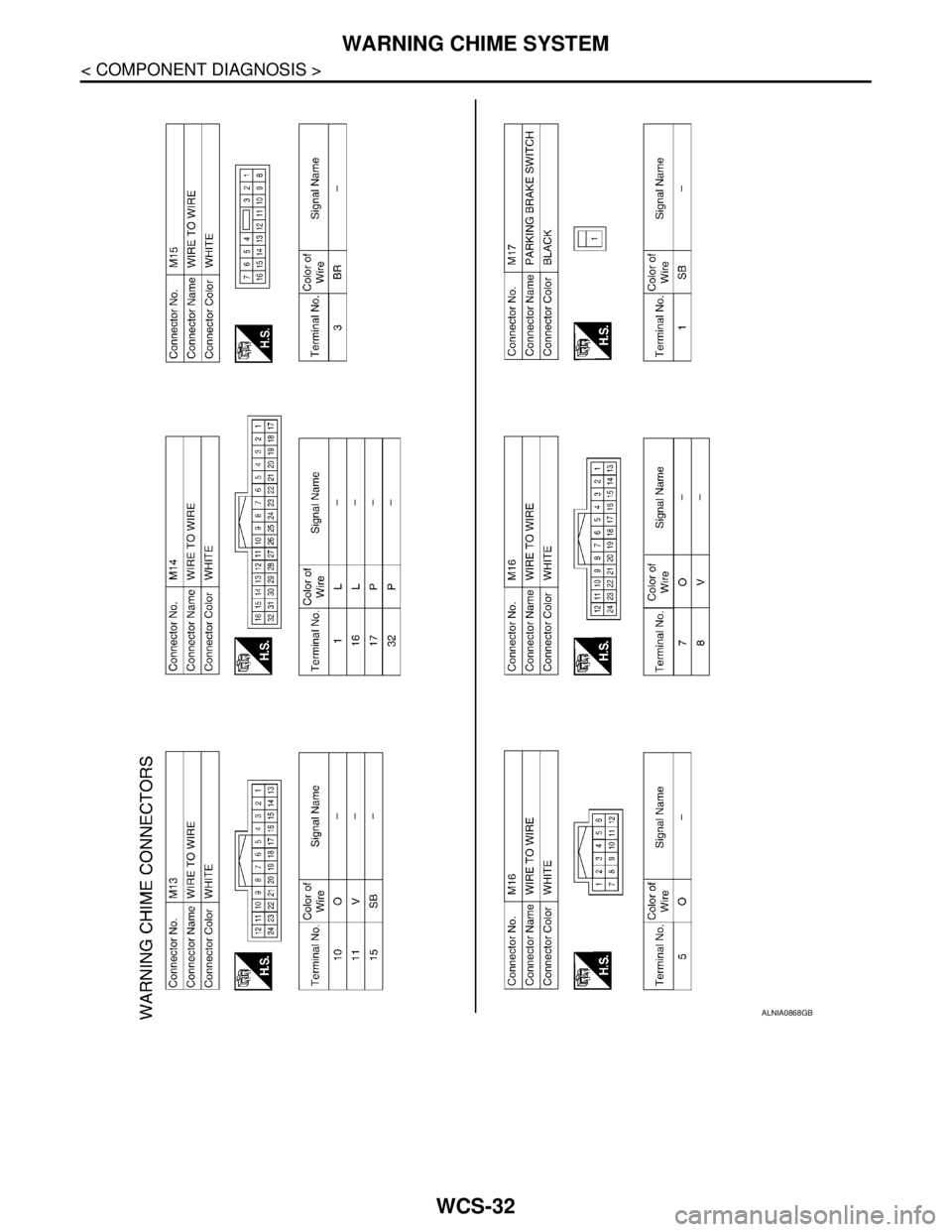

WCS-32

< COMPONENT DIAGNOSIS >

WARNING CHIME SYSTEM

ALNIA0868GB

Page 5748 of 5883

WCS

WARNING CHIME SYSTEM

WCS-33

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

ALNIA0869GB

Page 5749 of 5883

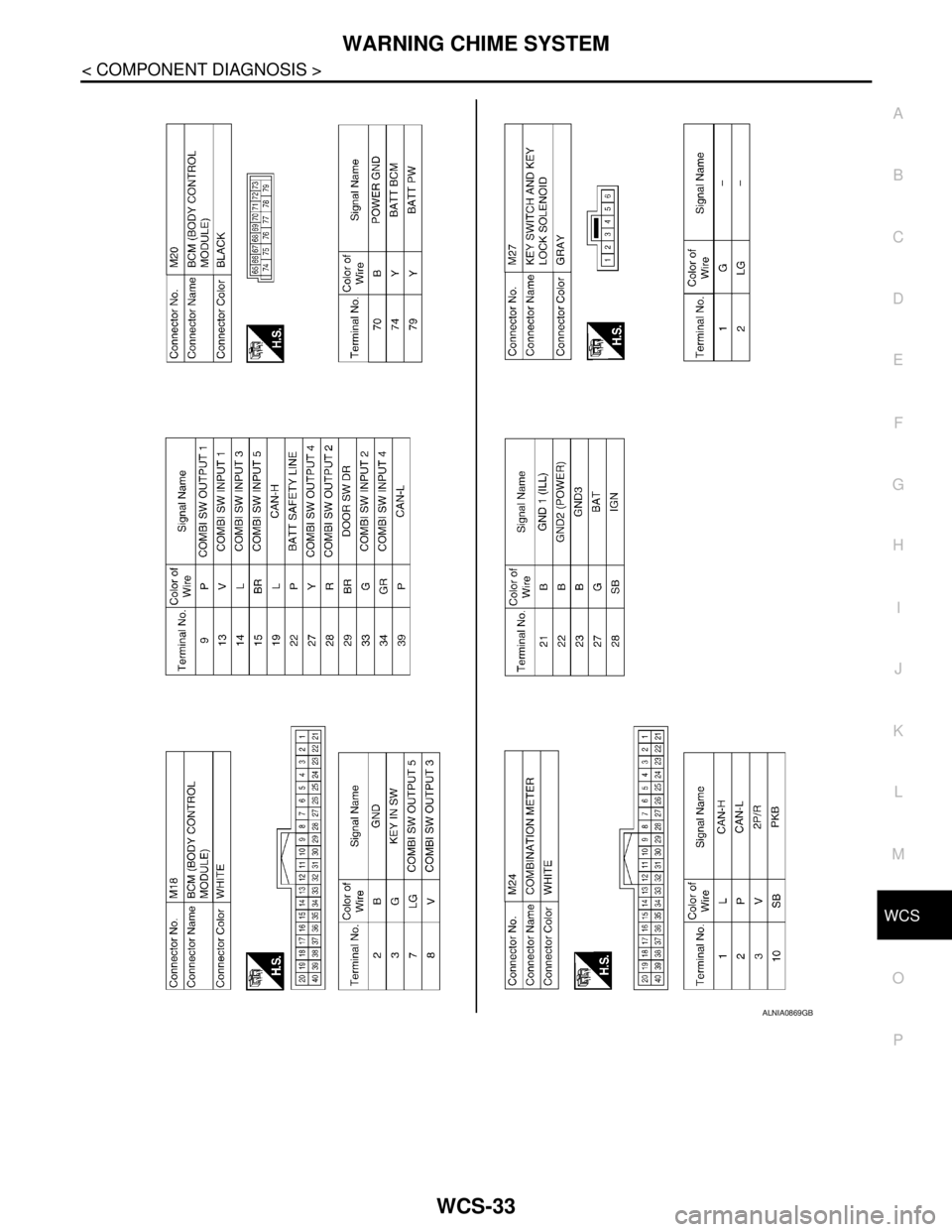

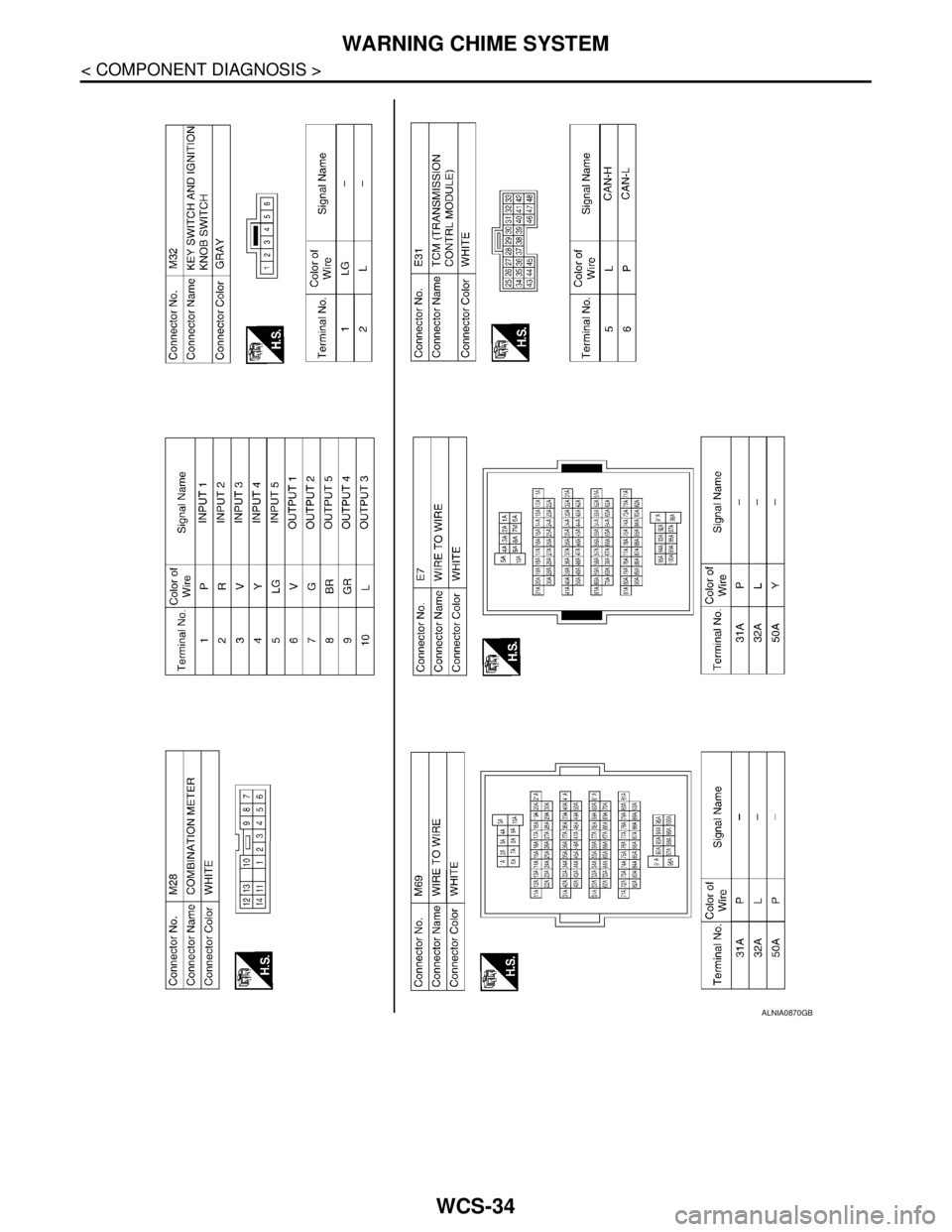

WCS-34

< COMPONENT DIAGNOSIS >

WARNING CHIME SYSTEM

ALNIA0870GB

Page 5750 of 5883

WCS

WARNING CHIME SYSTEM

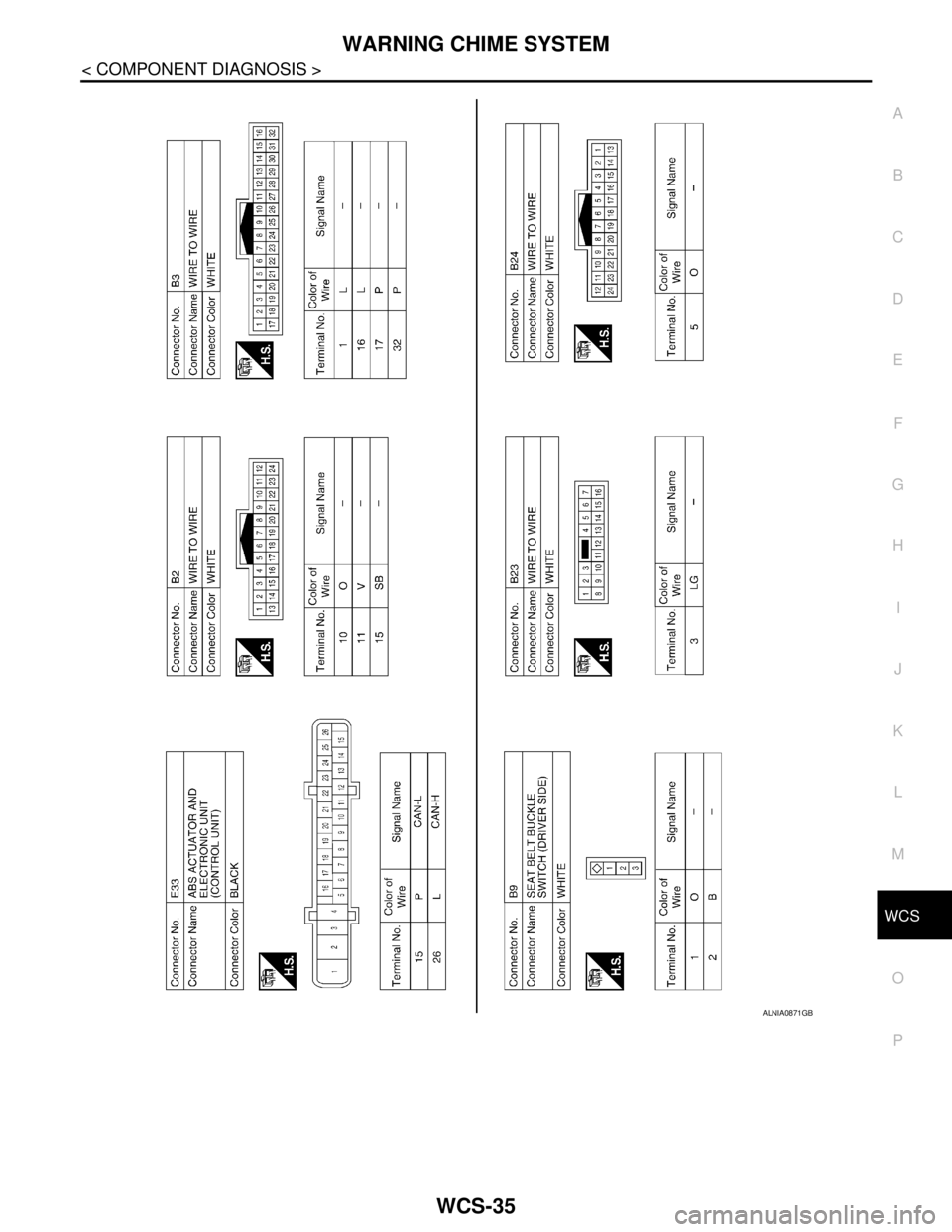

WCS-35

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

ALNIA0871GB

Trending: reset sun roof, engine oil type, Fan system, PWO, fuel tank removal, RECOMMENDED FLUIDS AND LUBRICANTS, gearbox