TCM NISSAN TIIDA 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4949 of 5883

TM-3

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

DTC TURBINE REVOLUTION SENSOR .........104

Description ............................................................104

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

104

On Board Diagnosis Logic ....................................104

Possible Cause .....................................................104

DTC Confirmation Procedure ................................104

Diagnosis Procedure .............................................104

CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ...............................................................

108

Description ............................................................108

On Board Diagnosis Logic ....................................108

Possible Cause .....................................................108

DTC Confirmation Procedure ................................108

Diagnosis Procedure .............................................108

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................

109

Description ............................................................109

On Board Diagnosis Logic ....................................109

Possible Cause .....................................................109

DTC Confirmation Procedure ................................109

Diagnosis Procedure .............................................109

PNP, OD SWITCH AND CLOSED THROT-

TLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUIT .............................................

111

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

111

TCM Terminal and Reference Value .....................111

Diagnosis Procedure .............................................111

Component Inspection ..........................................115

A/T SHIFT LOCK SYSTEM ..............................116

Wiring Diagram - A/T Shift Lock System - .............116

Terminals And Reference Values .........................116

Diagnosis Procedure .............................................117

ECU DIAGNOSIS .......................................119

TCM ..................................................................119

Reference Value ...................................................119

Wiring Diagram - A/T CONTROL SYSTEM - ........123

Fail-Safe ................................................................123

DTC Inspection Priority Chart ...............................125

DTC Index .............................................................125

DTC Alphabetical Index ........................................126

SYMPTOM DIAGNOSIS ............................127

SYSTEM SYMPTOM ........................................127

Symptom Chart .....................................................127

OD OFF Indicator Lamp Does Not Come On .......138

Engine Cannot Be Started in "P" and "N" Position ..140

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ...............................................

140

In "N" Position, Vehicle Moves ..............................141

Large Shock "N" → "R" Position ...........................142

Vehicle Does Not Creep Backward in "R" Position ..142

Vehicle Does Not Creep Forward in "D", "2" or "1"

Position ..................................................................

144

Vehicle Cannot Be Started from D1 .......................145

A/T Does Not Shift: D1→ D2or Does Not Kick-

down: D

4→ D2 .......................................................146

A/T Does Not Shift: D2→ D3 ..................................148

A/T Does Not Shift: D3→ D4 ..................................149

A/T Does Not Perform Lock-up .............................151

A/T Does Not Hold Lock-up Condition ...................151

Lock-up Is Not Released .......................................152

Engine Speed Does Not Return to Idle (Light

Braking D

4→ D3) ...................................................153

A/T Does Not Shift: D4→ D3, When OD OFF ........154

A/T Does Not Shift: D3→ 22, When Selector Lever

"D" → "2" Position .................................................

155

A/T Does Not Shift: 22→ 11, When Selector Lever

"2" → "1" Position ..................................................

156

Vehicle Does Not Decelerate by Engine Brake .....158

TCM Self-Diagnosis Does Not Activate .................161

PRECAUTION ............................................163

PRECAUTIONS ...............................................163

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...............................................................

163

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

163

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine (For Type1 Only) ......................

163

Precaution .............................................................164

Service Notice or Precaution .................................165

Wiring Diagram and Trouble Diagnosis .................165

PREPARATION .........................................166

PREPARATION ...............................................166

Special Service Tool ..............................................166

Commercial Service Tool ......................................169

ON-VEHICLE MAINTENANCE ..................171

A/T FLUID .......................................................171

Checking A/T Fluid ................................................171

Changing A/T Fluid ................................................171

A/T Fluid Cooler Cleaning .....................................172

STALL TEST ...................................................175

Inspection and Judgment ......................................175

LINE PRESSURE TEST ..................................178

Inspection and Judgment ......................................178

ROAD TEST ....................................................180

Description .............................................................180

Check Before Engine Is Started ............................180

Check at Idle ..........................................................181

Cruise Test - Part 1 ...............................................183

Cruise Test - Part 2 ...............................................185

Cruise Test - Part 3 ...............................................186

Vehicle Speed When Shifting Gears .....................188

Page 4951 of 5883

TM-5

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P Cross-Sectional View ............................................

329

Shift Mechanism ....................................................330

TCM Function ........................................................337

CAN Communication .............................................338

Input/Output Signal of TCM ...................................338

Line Pressure Control ...........................................339

Shift Control ..........................................................340

Lock-up Control .....................................................341

Engine Brake Control (Overrun Clutch Control) ....342

Control Valve .........................................................344

Centrifugal Cancel Mechanism .............................344

Component Parts Location ....................................346

A/T SHIFT LOCK SYSTEM ..............................347

System Description ...............................................347

Component Parts Location ....................................347

DIAGNOSIS SYSTEM (TCM) ...........................348

CONSULT-III Function (TRANSMISSION) ...........348

Diagnosis Procedure without CONSULT-III ..........350

COMPONENT DIAGNOSIS .......................355

VEHICLE SPEED SENSOR - A/T (REVOLU-

TION SENSOR) ................................................

355

Description ............................................................355

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

355

On Board Diagnosis Logic ....................................355

Possible Cause .....................................................355

DTC Confirmation Procedure ................................355

Diagnosis Procedure .............................................356

VEHICLE SPEED SENSOR MTR ....................359

Description ............................................................359

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

359

On Board Diagnosis Logic ....................................359

Possible Cause .....................................................359

DTC Confirmation Procedure ................................359

Diagnosis Procedure .............................................359

SHIFT SOLENOID VALVE A ...........................361

Description ............................................................361

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

361

On Board Diagnosis Logic ....................................361

Possible Cause .....................................................361

DTC Confirmation Procedure ................................361

Diagnosis Procedure .............................................361

Component Inspection ..........................................363

SHIFT SOLENOID VALVE B ...........................365

Description ............................................................365

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

365

On Board Diagnosis Logic ....................................365

Possible Cause .....................................................365

DTC Confirmation Procedure ................................365

Diagnosis Procedure .............................................365

Component Inspection ...........................................367

OVERRUN CLUTCH SOLENOID VALVE ......369

Description .............................................................369

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

369

On Board Diagnosis Logic .....................................369

Possible Cause ......................................................369

DTC Confirmation Procedure ................................369

Diagnosis Procedure .............................................369

Component Inspection ...........................................371

TORQUE CONVERTER CLUTCH SOLENOID

VALVE .............................................................

373

Description .............................................................373

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

373

On Board Diagnosis Logic .....................................373

Possible Cause ......................................................373

DTC Confirmation Procedure ................................373

Diagnosis Procedure .............................................373

Component Inspection ...........................................375

BATT/FLUID TEMP SEN (A/T FLUID TEMP

SENSOR CIRCUIT AND TCM POWER

SOURCE) ........................................................

376

Description .............................................................376

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

376

On Board Diagnosis Logic .....................................376

Possible Cause ......................................................376

DTC Confirmation Procedure ................................376

Diagnosis Procedure .............................................376

Component Inspection ...........................................379

ENGINE SPEED SIGNAL ...............................381

Description .............................................................381

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

381

On Board Diagnosis Logic .....................................381

Possible Cause ......................................................381

DTC Confirmation Procedure ................................381

Diagnosis Procedure .............................................381

TURBINE REVOLUTION SENSOR ................383

Description .............................................................383

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

383

On Board Diagnosis Logic .....................................383

Possible Cause ......................................................383

DTC Confirmation Procedure ................................383

Diagnosis Procedure .............................................383

LINE PRESSURE SOLENOID VALVE ...........387

Description .............................................................387

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

387

On Board Diagnosis Logic .....................................387

Possible Cause ......................................................387

DTC Confirmation Procedure ................................387

Page 4952 of 5883

TM-6

Diagnosis Procedure .............................................387

Component Inspection ...........................................390

CAN COMMUNICATION LINE ........................391

Description .............................................................391

On Board Diagnosis Logic .....................................391

Possible Cause ......................................................391

DTC Confirmation Procedure ................................391

Diagnosis Procedure .............................................391

MAIN POWER SUPPLY AND GROUND CIR-

CUIT .................................................................

392

Description .............................................................392

On Board Diagnosis Logic .....................................392

Possible Cause ......................................................392

DTC Confirmation Procedure ................................392

Diagnosis Procedure .............................................392

A/T 1ST GEAR FUNCTION .............................394

Description .............................................................394

On Board Diagnosis Logic .....................................394

Possible Cause ......................................................394

DTC Confirmation Procedure ................................394

Diagnosis Procedure .............................................395

A/T 2ND GEAR FUNCTION ............................397

Description .............................................................397

On Board Diagnosis Logic .....................................397

Possible Cause ......................................................397

DTC Confirmation Procedure ................................397

Diagnosis Procedure .............................................398

A/T 3RD GEAR FUNCTION ............................400

Description .............................................................400

On Board Diagnosis Logic .....................................400

Possible Cause ......................................................400

DTC Confirmation Procedure ................................400

Diagnosis Procedure .............................................401

A/T 4TH GEAR FUNCTION .............................403

Description .............................................................403

On Board Diagnosis Logic .....................................403

Possible Cause ......................................................403

DTC Confirmation Procedure ................................403

Diagnosis Procedure .............................................404

A/T TCC S/V FUNCTION (LOCK-UP) .............408

Description .............................................................408

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

408

On Board Diagnosis Logic .....................................408

Possible Cause ......................................................408

DTC Confirmation Procedure ................................408

Diagnosis Procedure .............................................409

CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ...............................................................

413

Description .............................................................413

On Board Diagnosis Logic .....................................413

Possible Cause ......................................................413

DTC Confirmation Procedure ................................413

Diagnosis Procedure .............................................413

PNP, OD SWITCH AND CLOSED THROT-

TLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUIT .............................................

414

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

414

TCM Terminal and Reference Value ....................414

Diagnosis Procedure .............................................414

Component Inspection ..........................................418

A/T SHIFT LOCK SYSTEM ..............................419

Wiring Diagram - A/T Shift Lock System - ............419

Terminals And Reference Values .........................419

Diagnosis Procedure .............................................420

ECU DIAGNOSIS ......................................422

TCM ..................................................................422

Reference Value ...................................................422

Wiring Diagram - A/T CONTROL SYSTEM - ........426

Fail-Safe ................................................................426

Alphabetical Index .................................................428

SYMPTOM DIAGNOSIS ...........................429

SYSTEM SYMPTOM ........................................429

Symptom Chart .....................................................429

OD OFF Indicator Lamp Does Not Come On .......440

Engine Cannot Be Started in "P" and "N" Position .442

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ...............................................

442

In "N" Position, Vehicle Moves ..............................443

Large Shock "N" → "R" Position ...........................444

Vehicle Does Not Creep Backward in "R" Position .444

Vehicle Does Not Creep Forward in "D", "2" or "1"

Position .................................................................

446

Vehicle Cannot Be Started from D1 ......................447

A/T Does Not Shift: D1→ D2or Does Not Kick-

down: D

4→ D2 ......................................................448

A/T Does Not Shift: D2→ D3 .................................450

A/T Does Not Shift: D3→ D4 .................................451

A/T Does Not Perform Lock-up .............................452

A/T Does Not Hold Lock-up Condition ..................453

Lock-up Is Not Released .......................................454

Engine Speed Does Not Return to Idle (Light

Braking D

4→ D3) ...................................................455

A/T Does Not Shift: D4→ D3, When OD OFF .......456

A/T Does Not Shift: D3→ 22, When Selector Lever

"D" → "2" Position .................................................

456

A/T Does Not Shift: 22→ 11, When Selector Lever

"2" → "1" Position ..................................................

458

Vehicle Does Not Decelerate by Engine Brake ....460

TCM Self-Diagnosis Does Not Activate ................463

PRECAUTION ...........................................465

PRECAUTIONS ................................................465

Page 4956 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual TM-10

< BASIC INSPECTION >[TYPE 1 (4AT: RE4F03B)]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001728290

INTRODUCTION

The TCM receives a signal f NISSAN TIIDA 2007 Service Workshop Manual TM-10

< BASIC INSPECTION >[TYPE 1 (4AT: RE4F03B)]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001728290

INTRODUCTION

The TCM receives a signal f](/img/5/57395/w960_57395-4955.png)

TM-10

< BASIC INSPECTION >[TYPE 1 (4AT: RE4F03B)]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

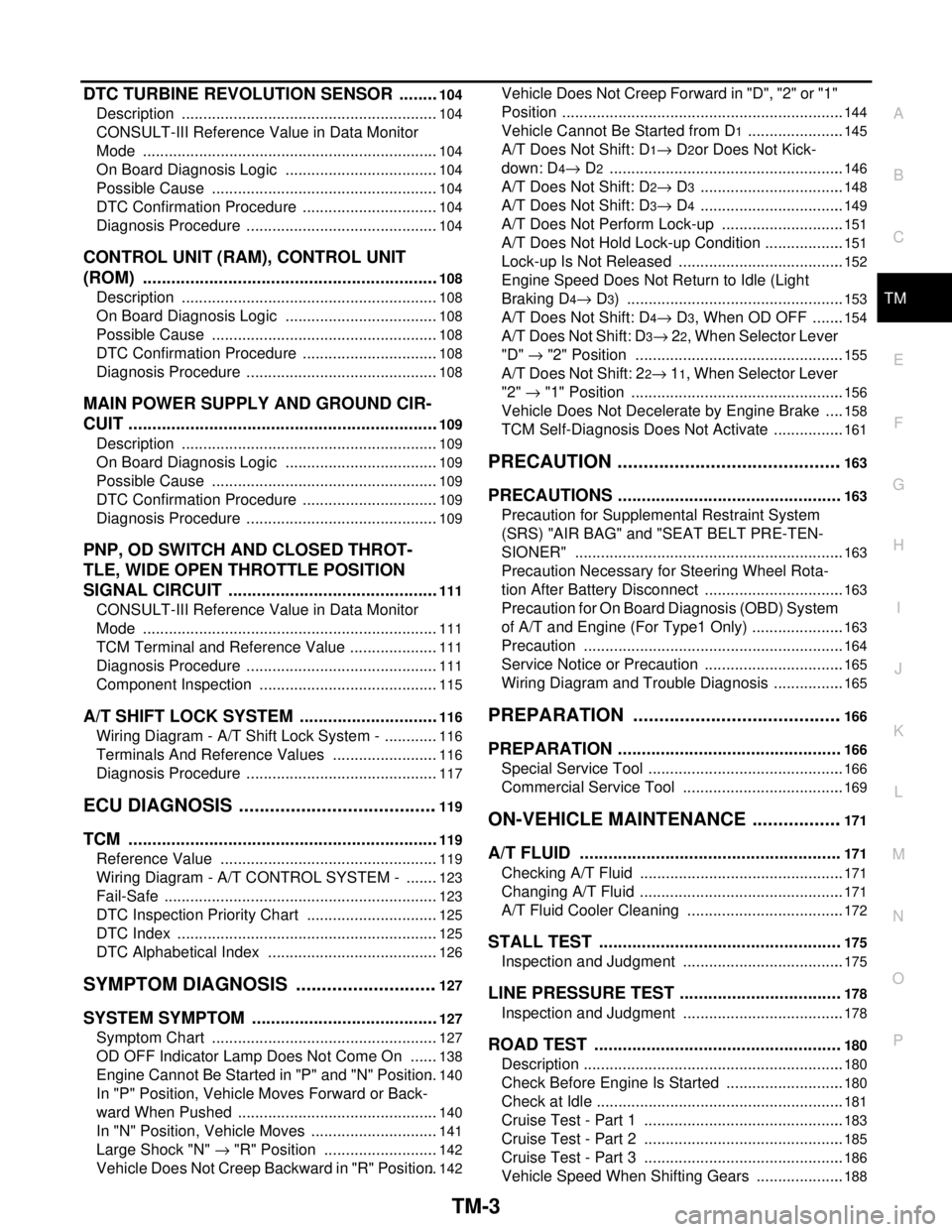

Work FlowINFOID:0000000001728290

INTRODUCTION

The TCM receives a signal from the vehicle speed sensor, accelera-

tor pedal position sensor (throttle position sensor) or PNP switch.

Then provides shift control or lock-up control via A/T solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used with the OBD-related parts of the

A/T system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the A/T system. The A/T system must be in good oper-

ating condition and be free of valve seizure, solenoid valve malfunc-

tion, etc.

It is much more difficult to diagnose an error that occurs intermit-

tently rather than continuously. Most intermittent errors are caused

by poor electric connections or improper wiring. In this case, careful

checking of suspected circuits may help prevent the replacement of

good parts.

A visual check only may not find the cause of the errors. A road test

with CONSULT-III (or GST) or a circuit tester connected should be

performed. Follow the “DETAILED FLOW”.

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such errors, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A “Diagnostic work sheet” as shown on

the example (Refer to TM-11

) should be used.

Start your diagnosis by looking for “conventional” errors first. This will

help troubleshoot driveability errors on an electronically controlled

engine vehicle.

Also check related Service bulletins.

DETAILED FLOW

1.COLLECT THE INFORMATION FROM THE CUSTOMER

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred) using diagnosis worksheet. Refer to TM-11, "

Diagnostic Work Sheet".

>> GO TO 2.

2.CHECK SYMPTOM 1

Check the following items based on the information obtained from the customer.

Fail-safe. Refer to TM-123, "

Fail-Safe".

A/T fluid inspection. Refer to TM-171, "

Checking A/T Fluid".

Stall test. Refer to TM-175, "

Inspection and Judgment".

Line pressure test. Refer to TM-178, "

Inspection and Judgment".

SAT631IB

SAT632I

SEF234G

Page 4958 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual TM-12

< BASIC INSPECTION >[TYPE 1 (4AT: RE4F03B)]

DIAGNOSIS AND REPAIR WORKFLOW

DIAGNOSTIC WORK SHEET

Symptoms❏ Vehicle does not move. (❏ Any position❏ Particular position)

❏ No up-shift (❏ NISSAN TIIDA 2007 Service Workshop Manual TM-12

< BASIC INSPECTION >[TYPE 1 (4AT: RE4F03B)]

DIAGNOSIS AND REPAIR WORKFLOW

DIAGNOSTIC WORK SHEET

Symptoms❏ Vehicle does not move. (❏ Any position❏ Particular position)

❏ No up-shift (❏](/img/5/57395/w960_57395-4957.png)

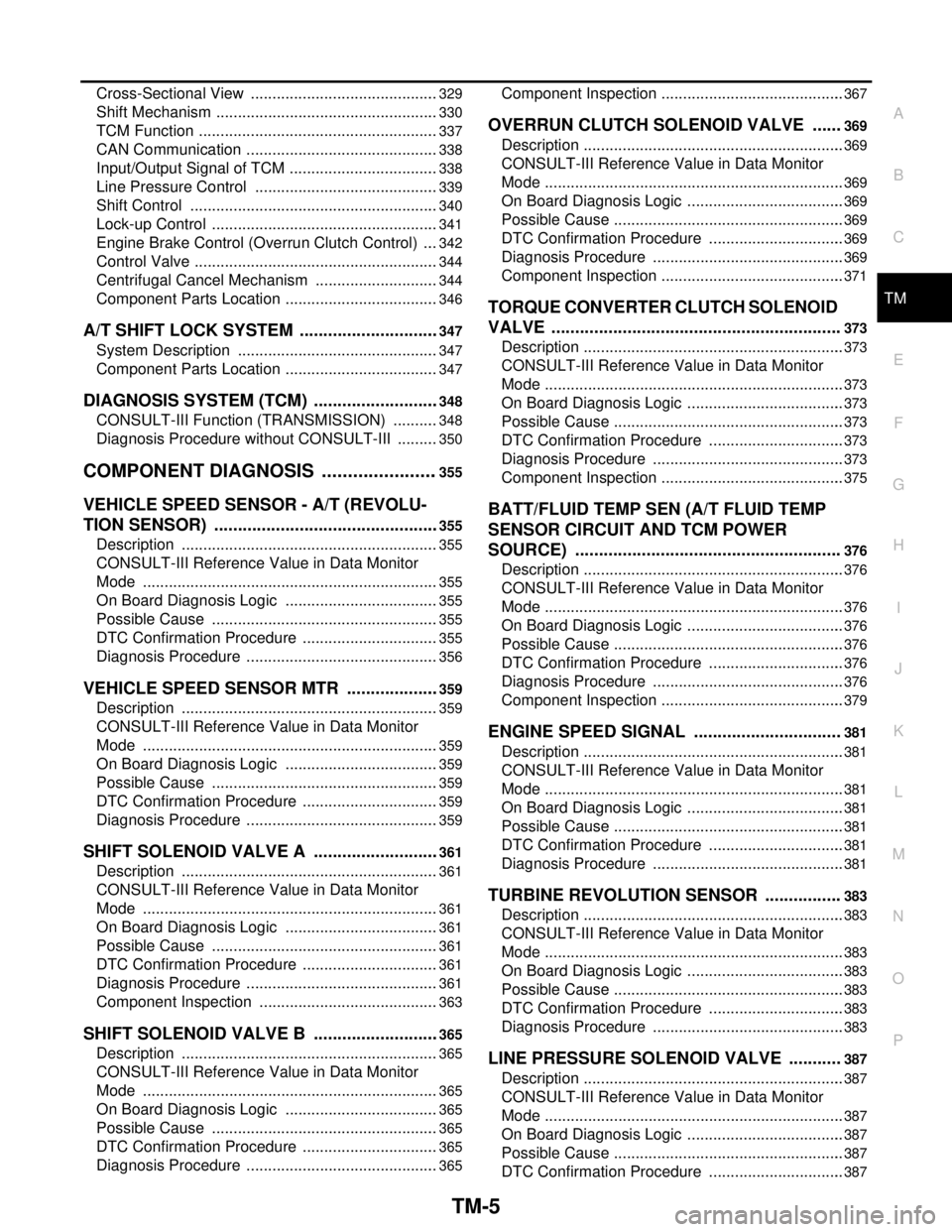

TM-12

< BASIC INSPECTION >[TYPE 1 (4AT: RE4F03B)]

DIAGNOSIS AND REPAIR WORKFLOW

DIAGNOSTIC WORK SHEET

Symptoms❏ Vehicle does not move. (❏ Any position❏ Particular position)

❏ No up-shift (❏ 1st → 2nd❏ 2nd → 3rd❏ 3rd → 4th ❏ 4th → 5th)

❏ No down-shift (❏ 5th → 4th ❏ 4th → 3rd❏ 3rd → 2nd❏ 2nd → 1st)

❏ Lock-up malfunction

❏ Shift point too high or too low.

❏ Shift shock or slip (❏ N → D❏ N → R❏ Lock-up❏ Any drive position)

❏ Noise or vibration

❏ No kick down

❏ No pattern select

❏ Others

()

Malfunction indicator lamp (MIL)❏ Continuously lit❏ Not lit

1❏ Read the item on cautions concerning fail-safe and understand the customer's com-

plaint.TM-123

2❏ A/T fluid inspection, stall test and line pressure test

❏ A/T fluid inspection

TM-171❏ Leak (Repair leak location.)

❏ State

❏ Amount

3❏ Stall test

TM-175

❏ Torque converter one-way clutch

❏ Front brake

❏ High and low reverse clutch

❏ Low coast brake

❏ Forward brake

❏ Reverse brake

❏ Forward one-way clutch❏ 1st one-way

clutch

❏ 3rd one-way

clutch

❏ Engine

❏ Line pressure low

❏ Except for input

clutch and direct

clutch, clutches and

brakes OK

❏ Line pressure test - Suspected part:TM-178

4❏ Perform self-diagnosis. — Check detected items to repair or replace malfunctioning

part.TM-35 or TM-38

5❏ Perform road test.

5-1❏ Check before engine is startedTM-180

5-2❏ Check at idleTM-181

5-3 Cruise test❏ Part 1TM-183❏ Part 2TM-185

❏ Part 3TM-186

❏ Check malfunction phenomena to repair or replace malfunctioning part after completing all road test.

Refer to TM-127

.

5❏ Drive vehicle to check that the malfunction phenomenon has been resolved.

6❏ Erase the results of the self-diagnosis from the TCM and the ECM.TM-35

or TM-38

Page 4967 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual A/T CONTROL SYSTEM

TM-21

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

TCM FunctionINFOID:0000000001694422

The function of the TCM is to:

Receive input signals sent f NISSAN TIIDA 2007 Service Workshop Manual A/T CONTROL SYSTEM

TM-21

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

TCM FunctionINFOID:0000000001694422

The function of the TCM is to:

Receive input signals sent f](/img/5/57395/w960_57395-4966.png)

A/T CONTROL SYSTEM

TM-21

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

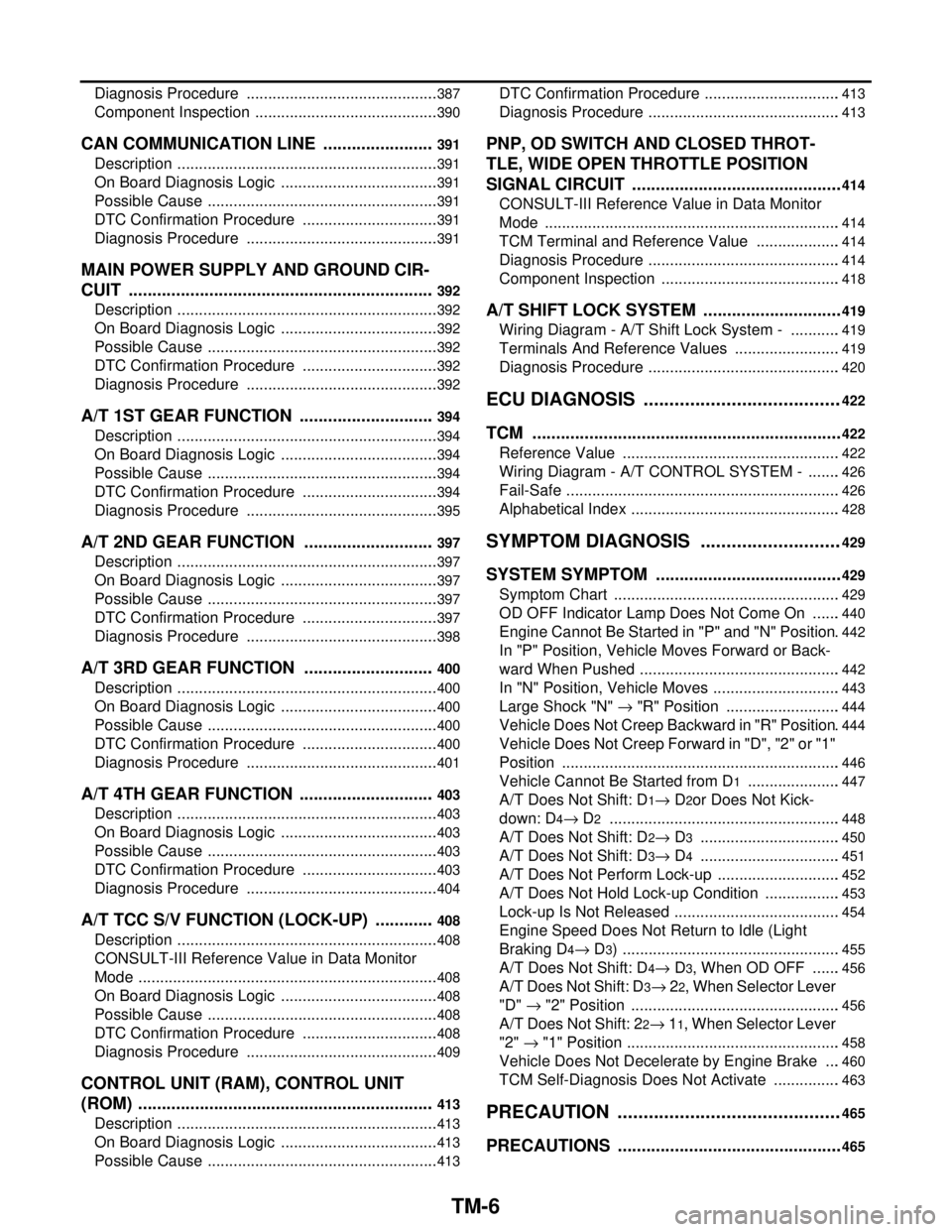

TCM FunctionINFOID:0000000001694422

The function of the TCM is to:

Receive input signals sent from various switches and sensors.

Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

Send required output signals to the respective solenoids.

CONTROL SYSTEM OUTLINE

The automatic transaxle senses vehicle operating conditions through various sensors or signals. It always

controls the optimum shift position and reduces shifting and lock-up shocks.

SAT381J

SWITCHES & SENSORS

⇒TCM

⇒ACTUATORS

PNP switch

Accelerator pedal position signal

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Turbine revolution sensor (Power

train revolution sensor)

Vehicle speed sensor

Overdrive control switch signal

Stop lamp switch signalShift control

Line pressure control

Lock-up control

Overrun clutch control

Fail-safe control

Self-diagnosis

CONSULT-III communication

line controlShift solenoid valve A

Shift solenoid valve B

Overrun clutch solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

OD OFF indicator lamp

Page 4968 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual TM-22

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000001694423

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial comm NISSAN TIIDA 2007 Service Workshop Manual TM-22

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000001694423

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial comm](/img/5/57395/w960_57395-4967.png)

TM-22

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000001694423

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. For details, refer to LAN-13,

"System Description".

Input/Output Signal of TCMINFOID:0000000001694424

SCIA7112E

Control itemLine

pressure

controlVehicle

speed

controlShift

controlLock-up

controlEngine

brake

controlFail-safe

functionSelf-diag-

nostics

function

InputAccelerator pedal position signal

(*5)XXXXX(*3) XX

Vehicle speed sensor·A/T

(Revolution sensor)XXXX (*3) XX

Vehicle speed sensor·MTR (*1) X (*1) X (*1) X (*1) X X

Closed throttle position signal

(*5)(*2) X (*2) X X (*4) X

Wide open throttle position signal

(*5)(*2) X (*2) X (*4) X

Turbine revolution sensor (Power

train revolution sensor)XXXXX

Engine speed signal X X

PNP switch XXXXX(*3) X(*4) X

Stop lamp switch signal

(*5)XXX(*4) X

A/T fluid temperature sensors X X X X

Overdrive control switch signal

(*5)XXX(*4) X

TCM power supply voltage signal XX

Page 4969 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual A/T CONTROL SYSTEM

TM-23

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P*1: Spare for vehicle speed sensor·A/T (revolution sensor)

*2: Spare for accelerator pedal positi NISSAN TIIDA 2007 Service Workshop Manual A/T CONTROL SYSTEM

TM-23

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P*1: Spare for vehicle speed sensor·A/T (revolution sensor)

*2: Spare for accelerator pedal positi](/img/5/57395/w960_57395-4968.png)

A/T CONTROL SYSTEM

TM-23

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P*1: Spare for vehicle speed sensor·A/T (revolution sensor)

*2: Spare for accelerator pedal position signal

*3: If these input and output signals are different, the TCM triggers the fail-safe function.

*4: Used as a condition for starting self-diagnostics; if self-diagnosis are not started, it is judged that there is some kind of error.

*5: Input by CAN communications.

*6: Output by CAN communications.

Line Pressure ControlINFOID:0000000001694425

TCM has various line pressure control characteristics to match the driving conditions.

An ON-OFF duty signal is sent to the line pressure solenoid valve based on TCM characteristics.

Hydraulic pressure on the clutch and brake is electronically controlled through the line pressure solenoid

valve to accommodate engine torque. This results in smooth shift operation.

NORMAL CONTROL

The characteristic of the line pressure to the throttle opening is set

for suitable clutch operation.

BACK-UP CONTROL (ENGINE BRAKE)

If the selector lever is shifted to “2” position while driving in D4 or D3,

great driving force is applied to the clutch inside the transaxle. Clutch

operating pressure (line pressure) must be increased to deal with

this driving force.

DURING SHIFT CHANGE

Out-

putShift solenoid valve A/B X (*3) X X

Line pressure solenoid X (*3) X X

Torque converter clutch solenoid

valveX(*3) XX

Overrun clutch solenoid valve X X (*3) X X

OD OFF indicator lamp

(*6)XX Control itemLine

pressure

controlVeh icl e

speed

controlShift

controlLock-up

controlEngine

brake

controlFail-safe

functionSelf-diag-

nostics

function

SAT003J

SAT004J

Page 4970 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual TM-24

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

The line pressure is temporarily reduced corresponding to a change

in engine torque when shifting gears (that is, when the shift NISSAN TIIDA 2007 Service Workshop Manual TM-24

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

The line pressure is temporarily reduced corresponding to a change

in engine torque when shifting gears (that is, when the shift](/img/5/57395/w960_57395-4969.png)

TM-24

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

The line pressure is temporarily reduced corresponding to a change

in engine torque when shifting gears (that is, when the shift solenoid

valve is switched for clutch operation) to reduce shifting shock.

AT LOW FLUID TEMPERATURE

A/T fluid viscosity and frictional characteristics of the clutch facing change with A/T fluid temperature. Clutch

engaging or band-contacting pressure is compensated for, according to A/T fluid temperature, to stabilize

shifting quality.

The line pressure is reduced below 60°C (140°F) to prevent shift-

ing shock due to high viscosity of A/T fluid when temperature is

low.

Line pressure is increased to a maximum irrespective of the throt-

tle opening when A/T fluid temperature drops to −10°C (14°F). This

pressure rise is adopted to prevent a delay in clutch and brake

operation due to extreme drop of A/T fluid viscosity at low temper-

ature.

Shift ControlINFOID:0000000001694426

The shift is regulated entirely by electronic control to accommodate vehicle speed and varying engine opera-

tions. This is accomplished by electrical signals transmitted by the revolution sensor and the ECM (accelerator

pedal position sensor). This results in improved acceleration performance and fuel economy.

CONTROL OF SHIFT SOLENOID VALVES A AND B

The TCM activates shift solenoid valves A and B according to sig-

nals from the accelerator pedal position sensor and revolution sen-

sor to select the optimum gear position on the basis of the shift

schedule memorized in the TCM.

The shift solenoid valve performs simple ON-OFF operation. When

set to “ON”, the drain circuit closes and pilot pressure is applied to

the shift valve.

RELATION BETWEEN SHIFT SOLENOID VALVES A AND B AND GEAR POSITIONS

SCIA4828E

SCIA4829E

SCIA4830E

SAT008J

Page 4971 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual A/T CONTROL SYSTEM

TM-25

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

CONTROL OF SHIFT VALVES A AND B

Pilot pressure generated by the operation of shift solenoid valve NISSAN TIIDA 2007 Service Workshop Manual A/T CONTROL SYSTEM

TM-25

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

CONTROL OF SHIFT VALVES A AND B

Pilot pressure generated by the operation of shift solenoid valve](/img/5/57395/w960_57395-4970.png)

A/T CONTROL SYSTEM

TM-25

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

CONTROL OF SHIFT VALVES A AND B

Pilot pressure generated by the operation of shift solenoid valves A and B is applied to the end face of shift

valves A and B.

The figure above shows the operation of shift valve B. When the shift solenoid valve is “ON”, pilot pressure

applied to the end face of the shift valve overcomes spring force, moving the valve upward.

Lock-up ControlINFOID:0000000001694427

The torque converter clutch piston in the torque converter is locked to eliminate torque converter slip and to

increase power transmission efficiency. The solenoid valve is controlled by an ON-OFF duty signal sent from

the TCM. The signal is converted to an oil pressure signal which controls the torque converter clutch piston.

CONDITIONS FOR LOCK-UP OPERATION

When vehicle is driven in 3rd and 4th gear positions, vehicle speed and throttle opening are detected. If the

detected values fall within the lock-up zone memorized in the TCM, lock-up is performed.

TORQUE CONVERTER CLUTCH SOLENOID VALVE CONTROL

Gear position 1 2 3 4

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

SAT009J

OD ON OFF

Selector lever “D” position

Gear position D

4D3

Vehicle speed sensor More than set value

Throttle position sensor Less than set opening

Closed throttle position switch OFF

A/T fluid temperature sensor More than 40°C (104°F)