engine control NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4392 of 5883

MWI

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

MWI-85

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation

coil circuit.

If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to

alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

NOTE:

The tail lamp turns OFF when the ignition switch is turned ON.

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop position by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 second activation and 20 second stop five times.

NOTE:

This operation status can be confirmed on the IPDM E/R “DATA MONITOR” that displays “Block” for the item

“WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains

active for 90 seconds.

Control part Fail-safe in operation

Cooling fan Turns ON the cooling fan relay when the ignition switch is turned ON

Turns OFF the cooling fan relay when the ignition switch is turned OFF

Control part Fail-safe in operation

Headlamp Turns ON the headlamp low relay when the ignition switch is turned ON

Turns OFF the headlamp low relay when the ignition switch is turned OFF

Headlamp high relay OFF

Parking lamps

License plate lamps

Tail lamps Turns ON the tail lamp relay when the ignition switch is turned ON

Turns OFF the tail lamp relay when the ignition switch is turned OFF

Front wiper The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

The wiper is operated at LO speed until the ignition switch is turned OFF if the fail-

safe control is activated while the front wiper is set in the INT mode and the front wiper

motor is operating.

Rear window defogger Rear window defogger relay OFF

A/C compressor A/C relay OFF

Front fog lamps Front fog lamp relay OFF

Ignition switch Ignition relay Tail lamp relay

ON ON —

OFF OFF —

Ignition switch Front wiper switch Auto stop signal

ONOFFFront wiper stop position signal cannot be

input 10 seconds.

ON The signal does not change for 10 seconds.

Page 4415 of 5883

PCS

PCS-1

ELECTRICAL & POWER CONTROL

C

D

E

F

G

H

I

J

K

L B

SECTION PCS

A

O

P N

CONTENTS

POWER CONTROL SYSTEM

IPDM E/R

FUNCTION DIAGNOSIS ...............................

3

RELAY CONTROL SYSTEM ..............................3

System Diagram ........................................................3

System Description ...................................................4

Component Parts Location ........................................5

POWER CONTROL SYSTEM .............................6

System Diagram ........................................................6

System Description ...................................................6

SIGNAL BUFFER SYSTEM ................................7

System Diagram ........................................................7

System Description ...................................................7

POWER CONSUMPTION CONTROL SYS-

TEM .....................................................................

8

System Diagram ........................................................8

System Description ...................................................8

Component Parts Location ........................................9

DIAGNOSIS SYSTEM (IPDM E/R) .....................10

Diagnosis Description .............................................10

CONSULT - III Function (IPDM E/R) .......................13

COMPONENT DIAGNOSIS .........................15

U1000 CAN COMM CIRCUIT .............................15

Description ..............................................................15

DTC Logic ...............................................................15

Diagnosis Procedure ...............................................15

POWER SUPPLY AND GROUND CIRCUIT ......16

Diagnosis Procedure ...............................................16

ECU DIAGNOSIS .........................................17

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

17

Reference Value .....................................................17

Terminal Layout ......................................................19

Physical Values .......................................................19

Wiring Diagram ........................................................23

Fail Safe ..................................................................26

DTC Index ...............................................................28

PRECAUTION ..............................................29

PRECAUTIONS .................................................29

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

29

REMOVAL AND INSTALLATION ...............30

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

30

Removal and Installation of IPDM E/R ....................30

POWER DISTRIBUTION SYSTEM

BASIC INSPECTION ...................................

31

DIAGNOSIS AND REPAIR WORKFLOW ........31

Work Flow ................................................................31

FUNCTION DIAGNOSIS ..............................34

POWER DISTRIBUTION SYSTEM ...................34

System Description ..................................................34

Component Parts Location ......................................34

Component Description ..........................................34

DIAGNOSIS SYSTEM (BCM) ...........................35

COMMON ITEM .........................................................35

COMMON ITEM : Diagnosis Description ................35

COMMON ITEM : CONSULT-III Function ...............35

INTELLIGENT KEY ....................................................35

INTELLIGENT KEY : CONSULT-III Function

(BCM - INTELLIGENT KEY) ....................................

35

COMPONENT DIAGNOSIS .........................36

Page 4416 of 5883

PCS-2

U1000 CAN COMM CIRCUIT ............................36

Description ..............................................................36

DTC Logic ...............................................................36

Diagnosis Procedure ..............................................36

POWER SUPPLY AND GROUND CIRCUIT .....37

BCM ...........................................................................37

BCM : Diagnosis Procedure ...................................37

BCM : Special Repair Requirement ........................37

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) .............................

37

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure .....................................................................

37

ECU DIAGNOSIS ........................................38

BCM (BODY CONTROL MODULE) ..................38

Reference Value .....................................................38

Terminal Layout ......................................................38

Physical Values ......................................................38

Wiring Diagram .......................................................38

DTC Inspection Priority Chart ...............................38

DTC Index ..............................................................38

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

39

Reference Value .....................................................39

Terminal Layout ......................................................39

Physical Values .......................................................39

Wiring Diagram .......................................................39

Fail Safe .................................................................39

DTC Index ..............................................................39

ON-VEHICLE MAINTENANCE ..................40

PRE-INSPECTION FOR DIAGNOSTIC ............40

Basic Inspection ......................................................40

ON-VEHICLE REPAIR ...............................41

BCM (BODY CONTROL MODULE) ..................41

Removal and Installation .........................................41

Page 4434 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS-20

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value

(Approx.) I NISSAN TIIDA 2007 Service Repair Manual PCS-20

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value

(Approx.) I](/img/5/57395/w960_57395-4433.png)

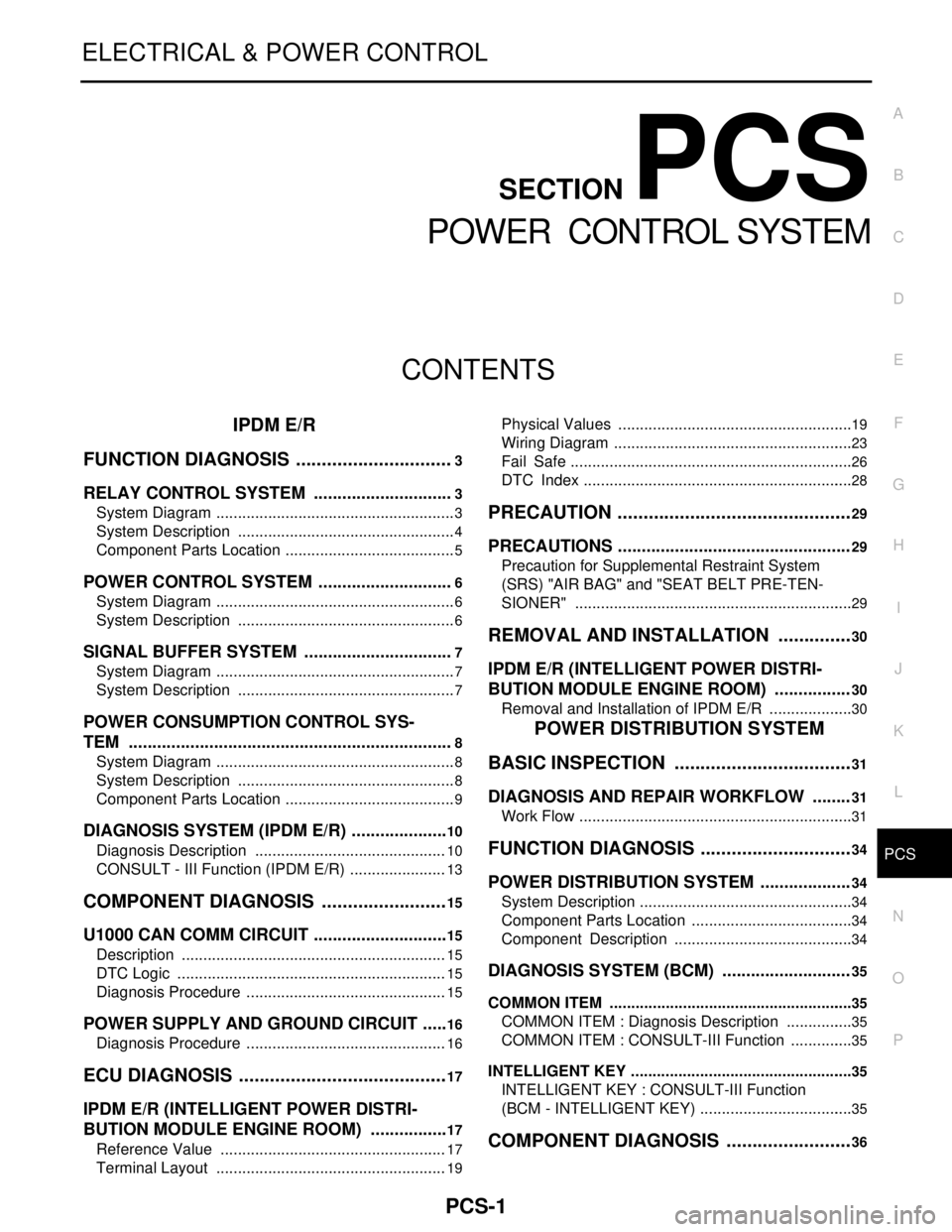

PCS-20

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value

(Approx.) Ignition

switchOperation or condition

1 R Battery power supply Input OFF — Battery voltage

2 G Battery power supply Input OFF — Battery voltage

3 Y ECM Relay Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

4 G ECM relay Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

6GRDaytime light relay

controlInput ON Daytime light system active. Less than battery voltage

Daytime light system inactive. Battery voltage

7 G ECM relay control Input —Ignition switch ON or START 0V

Ignition switch OFF or ACC Battery voltage

8GThrottle control motor

relayOutput —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

11 W A/C compressor OutputON or

STARTA/C switch ON or defrost A/C

switchBattery voltage

A/C switch OFF or defrost A/C

switch0V

12 OIgnition switch sup-

plied powerInput —OFF or ACC 0V

ON or START Battery voltage

14BR

(M/T)

R

(A/T)Fuse 49 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

15 V Fuse 50 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

16 SB Fuse 51 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

19 R Starter motor Output START — Battery voltage

20L

(with

A/C)

LG

(with-

out A/

C)Cooling fan relay-1 Output —Conditions correct for cooling

fan low operation.Battery voltage

Conditions not correct for

cooling fan low operation.0V

21 WIgnition switch START

signalInput START — Battery voltage

22 G Battery power supply Input — — Battery voltage

23 L Cooling fan relay-2 Input —Conditions correct for cooling

fan high operationBattery voltage

Conditions not correct for

cooling fan high operation0V

24 Y Cooling fan relay-3 Output —Conditions correct for cooling

fan high operationBattery voltage

Conditions not correct for

cooling fan high operation0V

27 BR

Tail lamp relay (park-

ing lamps)Output — Lighting switch in 2nd position Battery voltage

Page 4435 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-21

< ECU DIAGNOSIS >[IPDM E/R]

C

D

E

F

G

H

I

J

K

L B A

O

P N

29 PTail lamp relay (park-

ing lamps)Output — Lighting switch in 2nd NISSAN TIIDA 2007 Service Repair Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-21

< ECU DIAGNOSIS >[IPDM E/R]

C

D

E

F

G

H

I

J

K

L B A

O

P N

29 PTail lamp relay (park-

ing lamps)Output — Lighting switch in 2nd](/img/5/57395/w960_57395-4434.png)

PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-21

< ECU DIAGNOSIS >[IPDM E/R]

C

D

E

F

G

H

I

J

K

L B A

O

P N

29 PTail lamp relay (park-

ing lamps)Output — Lighting switch in 2nd position Battery voltage

30 R Fuse 54 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

31 O Fuse 55 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

32 LWiper high speed sig-

nalOutputON or

STARTWiper switchOFF, LO, INT 0V

HI Battery voltage

33 YWiper low speed sig-

nalOutputON or

STARTWiper switchOFF 0V

LO or INT Battery voltage

35 BRStarter relay (inhibit

switch)InputON or

STARTSelector lever in "P" or "N"

(CVT or A/T) or clutch pedal

depressed (M/T)Battery voltage

Selector lever any other posi-

tion (CVT or A/T) or clutch

pedal released (M/T)0V

36 BR Fuel pump relay Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

37 G Oil pressure switch InputON or

STARTEngine running and oil pres-

sure within specificationBattery voltage

Engine not running or oil pres-

sure below specification0V

38 R Wiper auto stop signal InputON or

STARTWipers not in park position Battery voltage

Wipers in park position 0V

39 B Ground Input — — 0V

40 P CAN-L — ON — —

41 L CAN-H — ON — —

46 YThrottle control motor

relay controlInput —Ignition switch ON or START 0V

Ignition switch OFF or ACC Battery voltage

47 GRFuel pump relay con-

trolInput —Ignition switch ON or START 0V

Ignition switch OFF or ACC Battery voltage

50 V Front fog lamp (LH)Output ON or

STARTLighting

switch must

be in the 2ND

position

(LOW beam

is ON) and

the front fog

lamp switchOFF 0V

ON Battery voltage

51 W Front fog lamp (RH) OutputON or

STARTLighting

switch must

be in the 2ND

position

(LOW beam

is ON) and

the front fog

lamp switchOFF 0V

ON Battery voltage

52 LLH Low beam head-

lampOutput — Lighting switch in 2nd position Battery voltage Te r m i n a lWire

colorSignal name

Signal

input/

outputMeasuring condition

Reference value

(Approx.) Ignition

switchOperation or condition

Page 4440 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS-26

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Fail Safe

INFOID:0000000001697599

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is i NISSAN TIIDA 2007 Service Repair Manual PCS-26

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Fail Safe

INFOID:0000000001697599

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is i](/img/5/57395/w960_57395-4439.png)

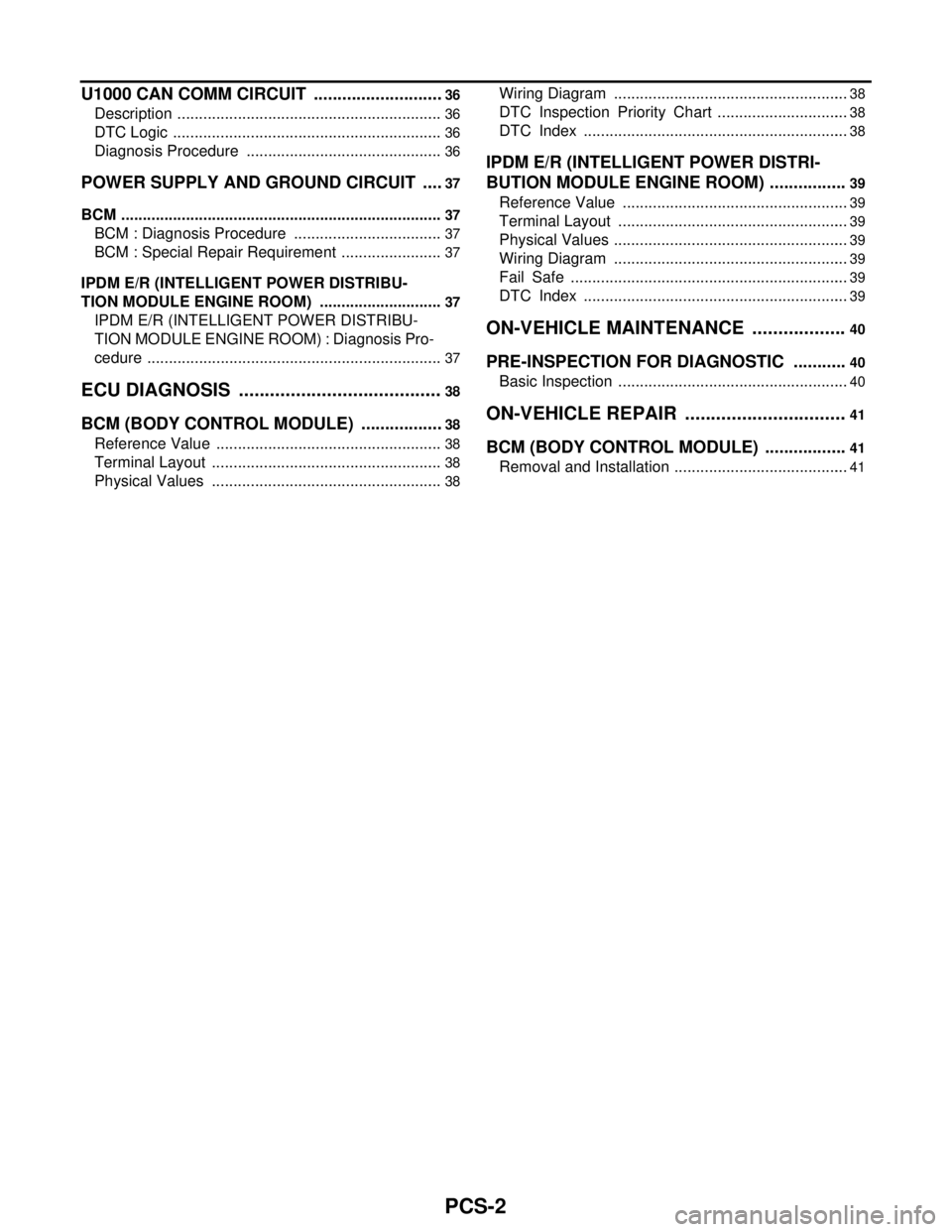

PCS-26

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Fail Safe

INFOID:0000000001697599

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-safe control. After CAN

communication recovers normally, it also returns to normal control.

If No CAN Communication Is Available With ECM

ALMIA0252GB

Page 4441 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-27

< ECU DIAGNOSIS >[IPDM E/R]

C

D

E

F

G

H

I

J

K

L B A

O

P N If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTI NISSAN TIIDA 2007 Service Repair Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-27

< ECU DIAGNOSIS >[IPDM E/R]

C

D

E

F

G

H

I

J

K

L B A

O

P N If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTI](/img/5/57395/w960_57395-4440.png)

PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-27

< ECU DIAGNOSIS >[IPDM E/R]

C

D

E

F

G

H

I

J

K

L B A

O

P N If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation

coil circuit.

If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to

alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

NOTE:

The tail lamp turns OFF when the ignition switch is turned ON.

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop position by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 second activation and 20 second stop five times.

NOTE:

This operation status can be confirmed on the IPDM E/R “DATA MONITOR” that displays “Block” for the item

“WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains

active for 90 seconds.

Control part Fail-safe in operation

Cooling fan Turns ON the cooling fan relay when the ignition switch is turned ON

Turns OFF the cooling fan relay when the ignition switch is turned OFF

Control part Fail-safe in operation

Headlamp Turns ON the headlamp low relay when the ignition switch is turned ON

Turns OFF the headlamp low relay when the ignition switch is turned OFF

Headlamp high relay OFF

Parking lamps

License plate lamps

Tail lamps Turns ON the tail lamp relay when the ignition switch is turned ON

Turns OFF the tail lamp relay when the ignition switch is turned OFF

Front wiper The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

The wiper is operated at LO speed until the ignition switch is turned OFF if the fail-

safe control is activated while the front wiper is set in the INT mode and the front wiper

motor is operating.

Rear window defogger Rear window defogger relay OFF

A/C compressor A/C relay OFF

Front fog lamps Front fog lamp relay OFF

Ignition switch Ignition relay Tail lamp relay

ON ON —

OFF OFF —

Ignition switch Front wiper switch Auto stop signal

ONOFFFront wiper stop position signal cannot be

input 10 seconds.

ON The signal does not change for 10 seconds.

Page 4451 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS

POWER SUPPLY AND GROUND CIRCUIT

PCS-37

< COMPONENT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:00000000 NISSAN TIIDA 2007 Service Repair Manual PCS

POWER SUPPLY AND GROUND CIRCUIT

PCS-37

< COMPONENT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:00000000](/img/5/57395/w960_57395-4450.png)

PCS

POWER SUPPLY AND GROUND CIRCUIT

PCS-37

< COMPONENT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

C

D

E

F

G

H

I

J

K

L B A

O

P N

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000001697613

Refer to BCS-30, "Diagnosis Procedure".

BCM : Special Repair RequirementINFOID:0000000001697614

1.REQUIRED WORK WHEN REPLACING BCM

Initialize control unit. Refer to CONSULT-III Operation Manual.

>> Work end.

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM) : Di-

agnosis Procedure

INFOID:0000000001697615

Refer to PCS-16, "Diagnosis Procedure".

Page 4454 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PCS-40

< ON-VEHICLE MAINTENANCE >[POWER DISTRIBUTION SYSTEM]

PRE-INSPECTION FOR DIAGNOSTIC

ON-VEHICLE MAINTENANCE

PRE-INSPECTION FOR DIAGNOSTIC

Basic InspectionINFOID:0000000001697628

The engine start NISSAN TIIDA 2007 Service Repair Manual PCS-40

< ON-VEHICLE MAINTENANCE >[POWER DISTRIBUTION SYSTEM]

PRE-INSPECTION FOR DIAGNOSTIC

ON-VEHICLE MAINTENANCE

PRE-INSPECTION FOR DIAGNOSTIC

Basic InspectionINFOID:0000000001697628

The engine start](/img/5/57395/w960_57395-4453.png)

PCS-40

< ON-VEHICLE MAINTENANCE >[POWER DISTRIBUTION SYSTEM]

PRE-INSPECTION FOR DIAGNOSTIC

ON-VEHICLE MAINTENANCE

PRE-INSPECTION FOR DIAGNOSTIC

Basic InspectionINFOID:0000000001697628

The engine start function, door lock function, power distribution system and NATS-NVIS system are closely

related to each other regarding control. Narrow down the functional area in question by performing basic

inspection to identify which function is malfunctioning. The vehicle security function can operate only when the

door lock and power distribution system are operating normally. Therefore, it is easy to identify any factor

unique to the vehicle security system by performing the vehicle security operation check after basic inspection.

1. CHECK DOOR LOCK OPERATION

1. Check the door lock for normal operation with the keyfob or Intelligent Key (if equipped) and door request

switch.

Successful door lock operation with the keyfob or Intelligent Key (if equipped) and request SW indicates

that the remote keyless entry receiver and inside key antenna (with Intelligent Key) required for engine

start are functioning normally.

Identify the malfunctioning point by referring to the DLK section if the door cannot be unlocked.

Can the door be locked with the Intelligent Key and door request switch?

YES >> GO TO 2

NO >> Refer to DLK-191, "

DOOR LOCK AND UNLOCK SWITCH : Symptom Table" (with Intelligent Key

without super lock), DLK-420, "

DOOR LOCK AND UNLOCK SWITCH : Symptom Table" (with

Intelligent Key and super lock), DLK-567, "

DOOR LOCK AND UNLOCK SWITCH : Symptom

Table" (without Intelligent Key without super lock) or DLK-718, "DOOR LOCK AND UNLOCK

SWITCH : Symptom Table" (without Intelligent Key with super lock).

2. CHECK ENGINE STARTING

1. Checks that the engine starts.

Does the engine start?

YES >> GO TO 3

NO >> Refer to SEC-76, "

Symptom Table" (with Intelligent Key) or SEC-117, "Symptom Table" (without

Intelligent Key).

3. CHECK STEERING LOCKING (MODELS WITH INTELLIGENT KEY)

1. Does the steering lock when operating door switch after switching the power supply from ON position (or

ACC position) to LOCK position?

If door switch is malfunctioning, BCM cannot lock the steering. If BCM does not detect DTC, steering lock

unit is normal.

Does steering lock?

YES >> GO TO 4

NO >> Refer to STC-29, "

Symptom Chart".

4. CHECK VEHICLE SECURITY SYSTEM

1. Check the vehicle security system for normal operation.

The vehicle security function can operate only when the door lock and power distribution functions are

operating normally.

Therefore, it is easy to identify any factor unique to the vehicle security by performing the vehicle security

operation check after this basic inspection.

>> Refer to SEC-75, "

Symptom Table" (with Intelligent Key) or SEC-116, "Symptom Table" (without

Intelligent Key).

Page 4626 of 5883

SEC-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G

H

I

J

L

M

SECTION SEC

A

B

SEC

N

O

P

CONTENTS

SECURITY CONTROL SYSTEM

WITH INTELLIGENT KEY SYSTEM

BASIC INSPECTION ....................................

4

DIAGNOSIS AND REPAIR WORKFLOW ..........4

Work Flow .................................................................4

INSPECTION AND ADJUSTMENT .....................7

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT ..........................................................

7

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .......

7

ECM RE-COMMUNICATING FUNCTION ...................7

ECM RE-COMMUNICATING FUNCTION : De-

scription .....................................................................

7

ECM RE-COMMUNICATING FUNCTION : Spe-

cial Repair Requirement ............................................

7

FUNCTION DIAGNOSIS ...............................8

INTELLIGENT KEY SYSTEM/ENGINE

START FUNCTION .............................................

8

System Diagram ........................................................8

System Description ...................................................8

Component Parts Location ......................................10

Component Description ...........................................10

NATS (NISSAN ANTI-THEFT SYSTEM) ...........12

System Diagram ......................................................12

System Description .................................................12

Component Parts Location ......................................14

Component Description ..........................................14

DIAGNOSIS SYSTEM (BCM) ............................15

COMMON ITEM .........................................................15

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

15

IMMU ..........................................................................15

IMMU : CONSULT-III Function (BCM - IMMU) .......15

THEFT ALM ...............................................................16

THEFT ALM : CONSULT-III Function (BCM -

THEFT ALM) ...........................................................

16

DIAGNOSIS SYSTEM (INTELLIGENT KEY

UNIT) .................................................................

18

CONSULT-III Function (INTELLIGENT KEY) ..........18

COMPONENT DIAGNOSIS .........................21

U1000 CAN COMM CIRCUIT ...........................21

Description ...............................................................21

DTC Logic ................................................................21

Diagnosis Procedure ...............................................21

U1010 CONTROL UNIT (CAN) .........................22

Description ...............................................................22

DTC Logic ................................................................22

Diagnosis Procedure ...............................................22

Special Repair Requirement ....................................22

B2013 ID DISCORD I-KEY-STRG ....................23

Description ...............................................................23

DTC Logic ................................................................23

Diagnosis Procedure ...............................................23

B2190, P1614 NATS ANTENNA AMP. ............26

Description ...............................................................26

DTC Logic ................................................................26

Diagnosis Procedure ...............................................26

B2191, P1615 DIFFERENCE OF KEY .............29

Description ...............................................................29

DTC Logic ................................................................29

Diagnosis Procedure ...............................................29

B2192, P1611 ID DISCORD, IMMU-ECM .........30

Description ...............................................................30

DTC Logic ................................................................30

Diagnosis Procedure ...............................................30

B2193, P1612 CHAIN OF ECM-IMMU ..............32