engine control NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4952 of 5883

TM-6

Diagnosis Procedure .............................................387

Component Inspection ...........................................390

CAN COMMUNICATION LINE ........................391

Description .............................................................391

On Board Diagnosis Logic .....................................391

Possible Cause ......................................................391

DTC Confirmation Procedure ................................391

Diagnosis Procedure .............................................391

MAIN POWER SUPPLY AND GROUND CIR-

CUIT .................................................................

392

Description .............................................................392

On Board Diagnosis Logic .....................................392

Possible Cause ......................................................392

DTC Confirmation Procedure ................................392

Diagnosis Procedure .............................................392

A/T 1ST GEAR FUNCTION .............................394

Description .............................................................394

On Board Diagnosis Logic .....................................394

Possible Cause ......................................................394

DTC Confirmation Procedure ................................394

Diagnosis Procedure .............................................395

A/T 2ND GEAR FUNCTION ............................397

Description .............................................................397

On Board Diagnosis Logic .....................................397

Possible Cause ......................................................397

DTC Confirmation Procedure ................................397

Diagnosis Procedure .............................................398

A/T 3RD GEAR FUNCTION ............................400

Description .............................................................400

On Board Diagnosis Logic .....................................400

Possible Cause ......................................................400

DTC Confirmation Procedure ................................400

Diagnosis Procedure .............................................401

A/T 4TH GEAR FUNCTION .............................403

Description .............................................................403

On Board Diagnosis Logic .....................................403

Possible Cause ......................................................403

DTC Confirmation Procedure ................................403

Diagnosis Procedure .............................................404

A/T TCC S/V FUNCTION (LOCK-UP) .............408

Description .............................................................408

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

408

On Board Diagnosis Logic .....................................408

Possible Cause ......................................................408

DTC Confirmation Procedure ................................408

Diagnosis Procedure .............................................409

CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ...............................................................

413

Description .............................................................413

On Board Diagnosis Logic .....................................413

Possible Cause ......................................................413

DTC Confirmation Procedure ................................413

Diagnosis Procedure .............................................413

PNP, OD SWITCH AND CLOSED THROT-

TLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUIT .............................................

414

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

414

TCM Terminal and Reference Value ....................414

Diagnosis Procedure .............................................414

Component Inspection ..........................................418

A/T SHIFT LOCK SYSTEM ..............................419

Wiring Diagram - A/T Shift Lock System - ............419

Terminals And Reference Values .........................419

Diagnosis Procedure .............................................420

ECU DIAGNOSIS ......................................422

TCM ..................................................................422

Reference Value ...................................................422

Wiring Diagram - A/T CONTROL SYSTEM - ........426

Fail-Safe ................................................................426

Alphabetical Index .................................................428

SYMPTOM DIAGNOSIS ...........................429

SYSTEM SYMPTOM ........................................429

Symptom Chart .....................................................429

OD OFF Indicator Lamp Does Not Come On .......440

Engine Cannot Be Started in "P" and "N" Position .442

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ...............................................

442

In "N" Position, Vehicle Moves ..............................443

Large Shock "N" → "R" Position ...........................444

Vehicle Does Not Creep Backward in "R" Position .444

Vehicle Does Not Creep Forward in "D", "2" or "1"

Position .................................................................

446

Vehicle Cannot Be Started from D1 ......................447

A/T Does Not Shift: D1→ D2or Does Not Kick-

down: D

4→ D2 ......................................................448

A/T Does Not Shift: D2→ D3 .................................450

A/T Does Not Shift: D3→ D4 .................................451

A/T Does Not Perform Lock-up .............................452

A/T Does Not Hold Lock-up Condition ..................453

Lock-up Is Not Released .......................................454

Engine Speed Does Not Return to Idle (Light

Braking D

4→ D3) ...................................................455

A/T Does Not Shift: D4→ D3, When OD OFF .......456

A/T Does Not Shift: D3→ 22, When Selector Lever

"D" → "2" Position .................................................

456

A/T Does Not Shift: 22→ 11, When Selector Lever

"2" → "1" Position ..................................................

458

Vehicle Does Not Decelerate by Engine Brake ....460

TCM Self-Diagnosis Does Not Activate ................463

PRECAUTION ...........................................465

PRECAUTIONS ................................................465

Page 4953 of 5883

TM-7

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...............................................................

465

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

465

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine (For Type1 Only) .....................

465

Precaution .............................................................466

Service Notice or Precaution .................................467

Wiring Diagram and Trouble Diagnosis ................467

PREPARATION .........................................468

PREPARATION ................................................468

Special Service Tool .............................................468

Commercial Service Tool ......................................471

ON-VEHICLE MAINTENANCE ..................473

A/T FLUID .........................................................473

Checking A/T Fluid ................................................473

Changing A/T Fluid ...............................................473

A/T Fluid Cooler Cleaning .....................................474

STALL TEST ....................................................477

Inspection and Judgment ......................................477

LINE PRESSURE TEST ...................................480

Inspection and Judgment ......................................480

ROAD TEST .....................................................482

Description ............................................................482

Check Before Engine Is Started ............................482

Check at Idle .........................................................483

Cruise Test - Part 1 ...............................................485

Cruise Test - Part 2 ...............................................487

Cruise Test - Part 3 ...............................................488

Vehicle Speed When Shifting Gears .....................490

Vehicle Speed When Performing and Releasing

Complete Lock-up .................................................

490

ON-VEHICLE REPAIR ...............................491

TRANSMISSION CONTROL MODULE ...........491

Exploded View ......................................................491

Removal and Installation .......................................491

SHIFT CONTROL SYSTEM .............................493

Control Device Removal and Installation ..............493

Control Device Disassembly and Assembly ..........496

Selector Lever Knob Removal and Installation .....496

Adjustment of A/T Position ....................................497

Checking of A/T Position .......................................497

KEY INTERLOCK CABLE ...............................499

Removal and Installation .......................................499

AIR BREATHER HOSE ....................................502

Removal and Installation .......................................502

REMOVAL AND INSTALLATION .............503

TRANSAXLE ASSEMBLY ..............................503

Exploded View .......................................................503

Removal and Installation .......................................503

DISASSEMBLY AND ASSEMBLY ............506

OVERHAUL .....................................................506

Component ............................................................506

Oil Channel ............................................................512

Location of Adjusting Shims, Needle Bearings and

Thrust Washers .....................................................

513

Location of Snap Rings .........................................514

DISASSEMBLY ...............................................515

Disassembly ..........................................................515

REPAIR FOR COMPONENT PARTS .............530

Manual Shaft .........................................................530

Oil Pump ................................................................533

Control Valve Assembly ........................................536

Control Valve Upper Body .....................................545

Control Valve Lower Body .....................................548

Reverse Clutch ......................................................551

High Clutch ............................................................555

Forward and Overrun Clutches .............................560

Low & Reverse Brake ............................................566

Rear Internal Gear and Forward Clutch Hub .........571

Output Shaft, Output Gear, Idler Gear, Reduction

Pinion Gear and Bearing Retainer .........................

574

Band Servo Piston Assembly ................................580

Final Drive .............................................................585

ASSEMBLY .....................................................590

Assembly (1) ..........................................................590

Adjustment (1) .......................................................591

Assembly (2) ..........................................................596

Adjustment (2) .......................................................600

Assembly (3) ..........................................................604

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................

612

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

612

General Specification ............................................612

Vehicle Speed at Which Gear Shifting Occurs ......612

Vehicle Speed at When Lock-up Occurs/Releases

..

612

Stall Speed ............................................................612

Line Pressure ........................................................612

Adjusting shims, Needle Bearings, Thrust Wash-

ers and Snap Rings ...............................................

613

Control Valves .......................................................614

Accumulator ...........................................................614

Clutches and Brakes .............................................614

Final Drive .............................................................616

Planetary Carrier ...................................................616

Oil Pump ................................................................616

Input Shaft .............................................................616

Reduction Pinion Gear ..........................................616

Page 4956 of 5883

![NISSAN TIIDA 2007 Service Repair Manual TM-10

< BASIC INSPECTION >[TYPE 1 (4AT: RE4F03B)]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001728290

INTRODUCTION

The TCM receives a signal f NISSAN TIIDA 2007 Service Repair Manual TM-10

< BASIC INSPECTION >[TYPE 1 (4AT: RE4F03B)]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001728290

INTRODUCTION

The TCM receives a signal f](/img/5/57395/w960_57395-4955.png)

TM-10

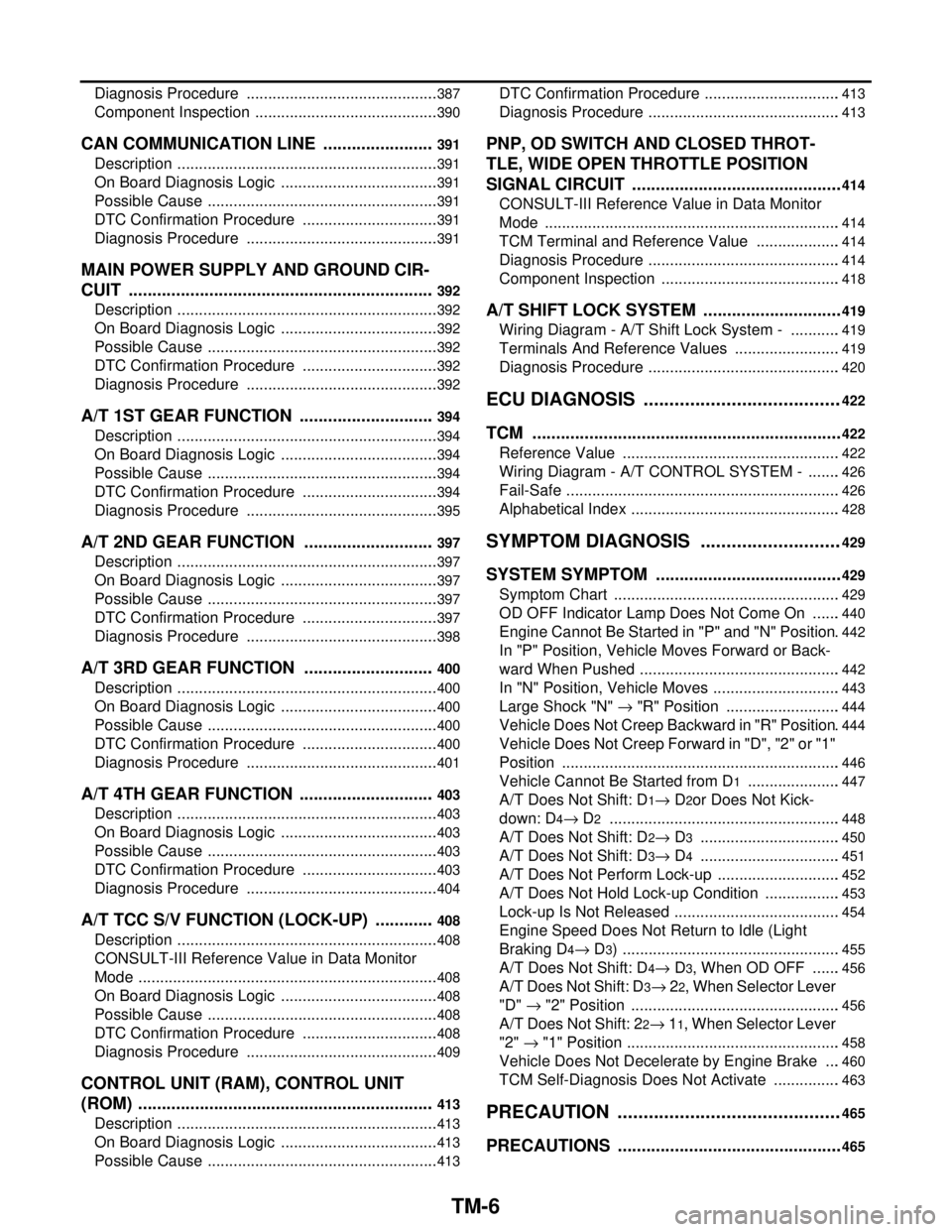

< BASIC INSPECTION >[TYPE 1 (4AT: RE4F03B)]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001728290

INTRODUCTION

The TCM receives a signal from the vehicle speed sensor, accelera-

tor pedal position sensor (throttle position sensor) or PNP switch.

Then provides shift control or lock-up control via A/T solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used with the OBD-related parts of the

A/T system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the A/T system. The A/T system must be in good oper-

ating condition and be free of valve seizure, solenoid valve malfunc-

tion, etc.

It is much more difficult to diagnose an error that occurs intermit-

tently rather than continuously. Most intermittent errors are caused

by poor electric connections or improper wiring. In this case, careful

checking of suspected circuits may help prevent the replacement of

good parts.

A visual check only may not find the cause of the errors. A road test

with CONSULT-III (or GST) or a circuit tester connected should be

performed. Follow the “DETAILED FLOW”.

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such errors, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A “Diagnostic work sheet” as shown on

the example (Refer to TM-11

) should be used.

Start your diagnosis by looking for “conventional” errors first. This will

help troubleshoot driveability errors on an electronically controlled

engine vehicle.

Also check related Service bulletins.

DETAILED FLOW

1.COLLECT THE INFORMATION FROM THE CUSTOMER

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred) using diagnosis worksheet. Refer to TM-11, "

Diagnostic Work Sheet".

>> GO TO 2.

2.CHECK SYMPTOM 1

Check the following items based on the information obtained from the customer.

Fail-safe. Refer to TM-123, "

Fail-Safe".

A/T fluid inspection. Refer to TM-171, "

Checking A/T Fluid".

Stall test. Refer to TM-175, "

Inspection and Judgment".

Line pressure test. Refer to TM-178, "

Inspection and Judgment".

SAT631IB

SAT632I

SEF234G

Page 4960 of 5883

![NISSAN TIIDA 2007 Service Repair Manual TM-14

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

Shift Mechanism

INFOID:0000000001694421

CONSTRUCTION

FUNCTION OF CLUTCH AND BRAKE

CLUTCH AND BAND CHART

1. Torque converter 2. Oi NISSAN TIIDA 2007 Service Repair Manual TM-14

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

Shift Mechanism

INFOID:0000000001694421

CONSTRUCTION

FUNCTION OF CLUTCH AND BRAKE

CLUTCH AND BAND CHART

1. Torque converter 2. Oi](/img/5/57395/w960_57395-4959.png)

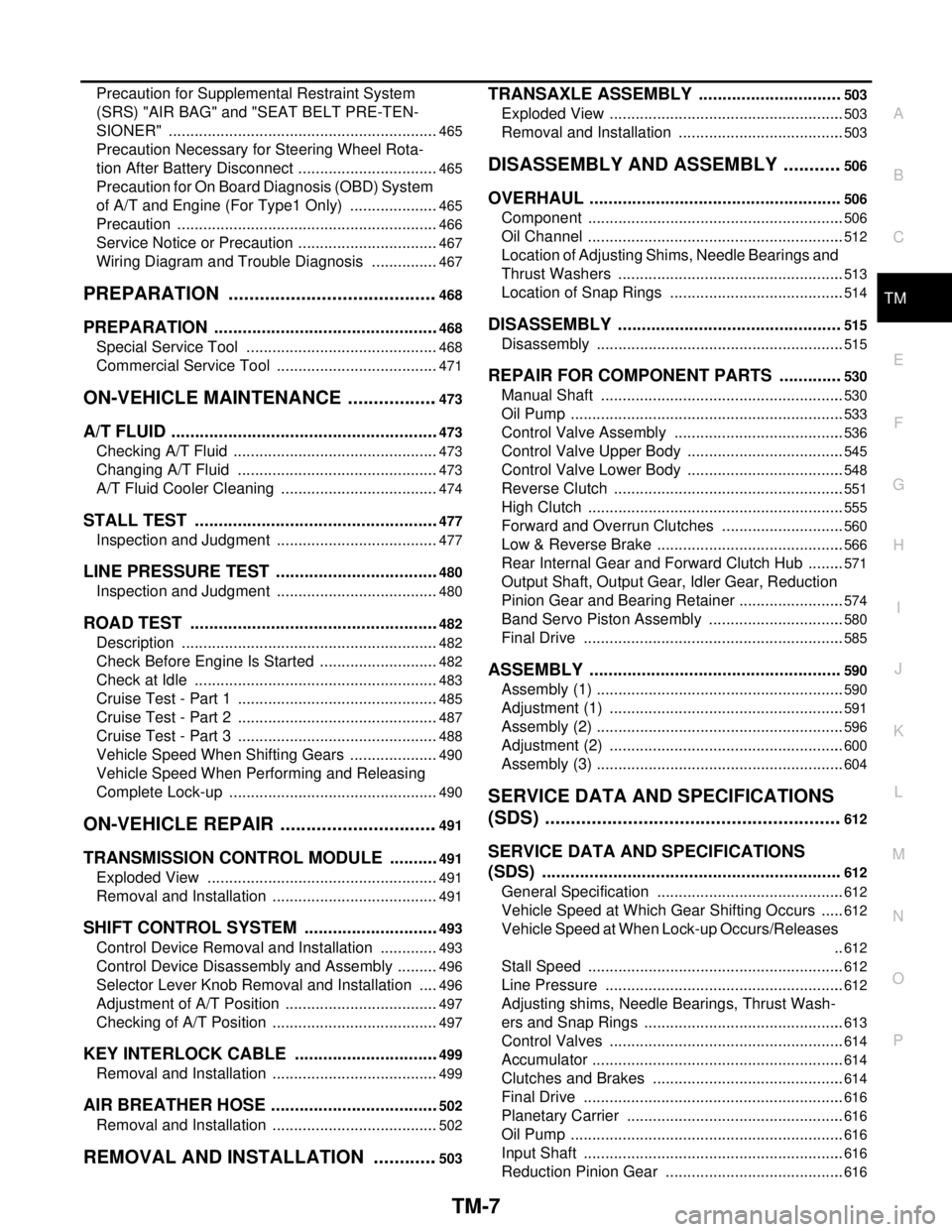

TM-14

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

Shift Mechanism

INFOID:0000000001694421

CONSTRUCTION

FUNCTION OF CLUTCH AND BRAKE

CLUTCH AND BAND CHART

1. Torque converter 2. Oil pump 3. Input shaft

4. Brake band 5. Reverse clutch 6. High clutch

7. Front sun gear 8. Front pinion gear 9. Front internal gear

10. Front planetary carrier 11. Rear sun gear 12. Rear pinion gear

13. Rear internal gear 14. Rear planetary carrier 15. Forward clutch

16. Forward one-way clutch 17. Overrun clutch 18. Low one-way clutch

19. Low & reverse brake 20. Parking pawl 21. Parking gear

22. Output shaft 23. Idle gear 24. Output gear

SAT998I

Clutch and brake components Abbr. Function

5Reverse clutch R/C To transmit input power to front sun gear 7.

6High clutch H/C To transmit input power to front planetary carrier 10.

15Forward clutch F/C To connect front planetary carrier 10 with forward one-way clutch 16.

17Overrun clutch O/C To connect front planetary carrier 10 with rear internal gear 13.

4Brake band B/B To lock front sun gear 7.

16Forward one-way clutch F/O.CWhen forward clutch 15 is engaged, to stop rear internal gear 13 from rotating in

opposite direction against engine revolution.

18Low one-way clutch L/O.CTo stop front planetary carrier 10 from rotating in opposite direction against en-

gine revolution.

19Low & reverse brake L & R/B To lock front planetary carrier 10.

Shift posi-

tionR/C

5H/C

6F/C

15O/C

17Band servo

F/O.C

16L/O.C

18L&R/B

19Lock-

upRemarks

2nd

apply3rd re-

lease4th ap-

ply

PPA R K

POSITION

RREVERSE

POSITION

Page 4961 of 5883

![NISSAN TIIDA 2007 Service Repair Manual A/T CONTROL SYSTEM

TM-15

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

*1: Operates when OD OFF. (OD OFF indicator lamp is on.)

*2: Oil pressure is applied to both NISSAN TIIDA 2007 Service Repair Manual A/T CONTROL SYSTEM

TM-15

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

*1: Operates when OD OFF. (OD OFF indicator lamp is on.)

*2: Oil pressure is applied to both](/img/5/57395/w960_57395-4960.png)

A/T CONTROL SYSTEM

TM-15

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

*1: Operates when OD OFF. (OD OFF indicator lamp is on.)

*2: Oil pressure is applied to both 2nd “apply” side and 3rd “release” side of band servo piston. However, brake band does not contract

because oil pressure area on the “release” side is greater than that on the “apply” side.

*3: Oil pressure is applied to 4th “apply” side on condition *2 above, and brake band contracts.

*4: A/T will not shift to 4th when OD OFF. (OD OFF indicator lamp is on.)

: Operates.

A: Operates when throttle opening is less than specification**, activating engine brake.

B: Operates during “progressive” acceleration.

C: Operates but does not affect power transmission.

D: Operates when throttle opening is less than specification**, but does not affect engine brake.

- **: Overrun clutch remains in engaged condition when throttle opening is less than 1/16.

POWER TRANSMISSION

“N” and “P” Positions

“N” position

Power from the input shaft is not transmitted to the output shaft because the clutches do not operate.

“P” position

NNEUTRAL

POSITION

D*41st *1D B B

2nd *1A BAutomatic

shift

3rd *1A *2C C B

*11 ⇔ 2 ⇔ 3

⇔ 4

4th C *3C C

21stBB

Automatic

shift

1 ⇔ 2 ⇐ 3 2ndB

3rd *2C C B

11stBB

Locks (held

stationary)

in 1st speed

1 ⇐ 2 ⇐ 3 2ndB

3rd *2C C B Shift posi-

tionR/C

5H/C

6F/C

15O/C

17Band servo

F/O.C

16L/O.C

18L&R/B

19Lock-

upRemarks

2nd

apply3rd re-

lease4th ap-

ply

Page 4962 of 5883

![NISSAN TIIDA 2007 Service Repair Manual TM-16

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

Similar to the “N” position, the clutches do not operate. The parking pawl engages with the parking gear to

mechanically hold NISSAN TIIDA 2007 Service Repair Manual TM-16

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

Similar to the “N” position, the clutches do not operate. The parking pawl engages with the parking gear to

mechanically hold](/img/5/57395/w960_57395-4961.png)

TM-16

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

Similar to the “N” position, the clutches do not operate. The parking pawl engages with the parking gear to

mechanically hold the output shaft so that the power train is locked.

“11” Position

“D

1” and “21” Positions

SAT991I

Forward clutch

Forward one-way clutch

Overrun clutch

Low & reverse brakeAs overrun clutch engages, rear internal gear is locked by the operation of low and re-

verse brake.

This is different from that of D

1 and 21.

Engine brake Overrun clutch always engages, therefore engine brake can be obtained when deceler-

ating.

SCIA1816E

Page 4963 of 5883

![NISSAN TIIDA 2007 Service Repair Manual A/T CONTROL SYSTEM

TM-17

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

*: Overrun clutch remains in engaged condition when throttle opening is less than 1/16.

“D2”, NISSAN TIIDA 2007 Service Repair Manual A/T CONTROL SYSTEM

TM-17

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

*: Overrun clutch remains in engaged condition when throttle opening is less than 1/16.

“D2”,](/img/5/57395/w960_57395-4962.png)

A/T CONTROL SYSTEM

TM-17

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

*: Overrun clutch remains in engaged condition when throttle opening is less than 1/16.

“D2”, “22” and “12” Positions

*: Overrun clutch remains in engaged condition when throttle opening is less than 1/16.Forward one-way clutch

Forward clutch

Low one-way clutchRear internal gear is locked to rotate counterclockwise because of the functioning of these three

clutches.

Overrun clutch

engagement conditions

(Engine brake)D

1: OD OFF (OD OFF indicator lamp is on) and throttle opening is less than specification*

2

1: Always engaged

At D

1 and 21 positions, engine brake is not activated due to free turning of low one- way clutch.

SAT377J

Forward clutch

Forward one-way

clutch

Brake bandRear sun gear drives rear planetary carrier and combined front internal gear. Front internal gear now rotates

around front sun gear accompanying front planetary carrier.

As front planetary carrier transfers the power to rear internal gear through forward clutch and forward one-

way clutch, this rotation of rear internal gear increases the speed of rear planetary carrier compared with

that of the 1st speed.

Overrun clutch

engagement conditionsD

2: OD OFF (OD OFF indicator lamp is on) and throttle opening is less than specification*

2

2 and 12: Always engaged

Page 4965 of 5883

![NISSAN TIIDA 2007 Service Repair Manual A/T CONTROL SYSTEM

TM-19

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P “D

4” (OD) Position

SAT379J

High clutch

Brake band

Forward clutch (Does not affect power

NISSAN TIIDA 2007 Service Repair Manual A/T CONTROL SYSTEM

TM-19

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P “D

4” (OD) Position

SAT379J

High clutch

Brake band

Forward clutch (Does not affect power](/img/5/57395/w960_57395-4964.png)

A/T CONTROL SYSTEM

TM-19

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P “D

4” (OD) Position

SAT379J

High clutch

Brake band

Forward clutch (Does not affect power

transmission)Input power is transmitted to front carrier through high clutch.

This front carrier turns around the sun gear which is fixed by brake band and makes

front internal gear (output) turn faster.

Engine brakeAt D

4 position, there is no one-way clutch in the power transaxle line and engine brake

can be obtained when decelerating.

Page 4966 of 5883

![NISSAN TIIDA 2007 Service Repair Manual TM-20

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

“R” Position

SAT380J

Reverse clutch

Low & reverse brakeFront planetary carrier is stationary because of the operation of lo NISSAN TIIDA 2007 Service Repair Manual TM-20

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

“R” Position

SAT380J

Reverse clutch

Low & reverse brakeFront planetary carrier is stationary because of the operation of lo](/img/5/57395/w960_57395-4965.png)

TM-20

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

“R” Position

SAT380J

Reverse clutch

Low & reverse brakeFront planetary carrier is stationary because of the operation of low and reverse brake.

Input power is transmitted to front sun gear through reverse clutch, which drives front

internal gear in the opposite direction.

Engine brakeAs there is no one-way clutch in the power transaxle line, engine brake can be obtained

when decelerating.

Page 4967 of 5883

![NISSAN TIIDA 2007 Service Repair Manual A/T CONTROL SYSTEM

TM-21

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

TCM FunctionINFOID:0000000001694422

The function of the TCM is to:

Receive input signals sent f NISSAN TIIDA 2007 Service Repair Manual A/T CONTROL SYSTEM

TM-21

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

TCM FunctionINFOID:0000000001694422

The function of the TCM is to:

Receive input signals sent f](/img/5/57395/w960_57395-4966.png)

A/T CONTROL SYSTEM

TM-21

< FUNCTION DIAGNOSIS >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

TCM FunctionINFOID:0000000001694422

The function of the TCM is to:

Receive input signals sent from various switches and sensors.

Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

Send required output signals to the respective solenoids.

CONTROL SYSTEM OUTLINE

The automatic transaxle senses vehicle operating conditions through various sensors or signals. It always

controls the optimum shift position and reduces shifting and lock-up shocks.

SAT381J

SWITCHES & SENSORS

⇒TCM

⇒ACTUATORS

PNP switch

Accelerator pedal position signal

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Turbine revolution sensor (Power

train revolution sensor)

Vehicle speed sensor

Overdrive control switch signal

Stop lamp switch signalShift control

Line pressure control

Lock-up control

Overrun clutch control

Fail-safe control

Self-diagnosis

CONSULT-III communication

line controlShift solenoid valve A

Shift solenoid valve B

Overrun clutch solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

OD OFF indicator lamp