light NISSAN TIIDA 2008 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 217 of 2771

SHIFT CONTROL SYSTEM

AT-205

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

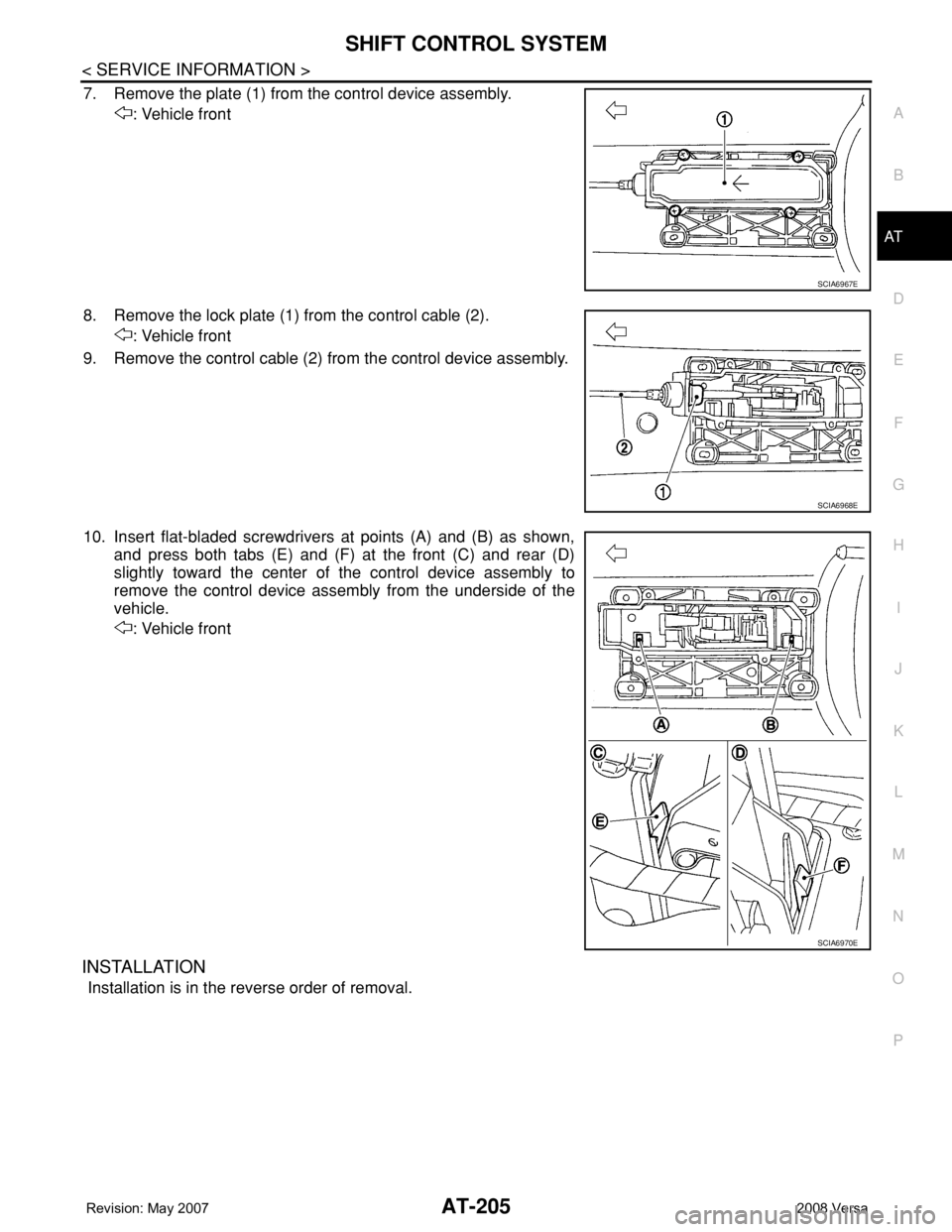

7. Remove the plate (1) from the control device assembly.

: Vehicle front

8. Remove the lock plate (1) from the control cable (2).

: Vehicle front

9. Remove the control cable (2) from the control device assembly.

10. Insert flat-bladed screwdrivers at points (A) and (B) as shown,

and press both tabs (E) and (F) at the front (C) and rear (D)

slightly toward the center of the control device assembly to

remove the control device assembly from the underside of the

vehicle.

: Vehicle front

INSTALLATION

Installation is in the reverse order of removal.

SCIA6967E

SCIA6968E

SCIA6970E

Page 218 of 2771

AT-206

< SERVICE INFORMATION >

SHIFT CONTROL SYSTEM

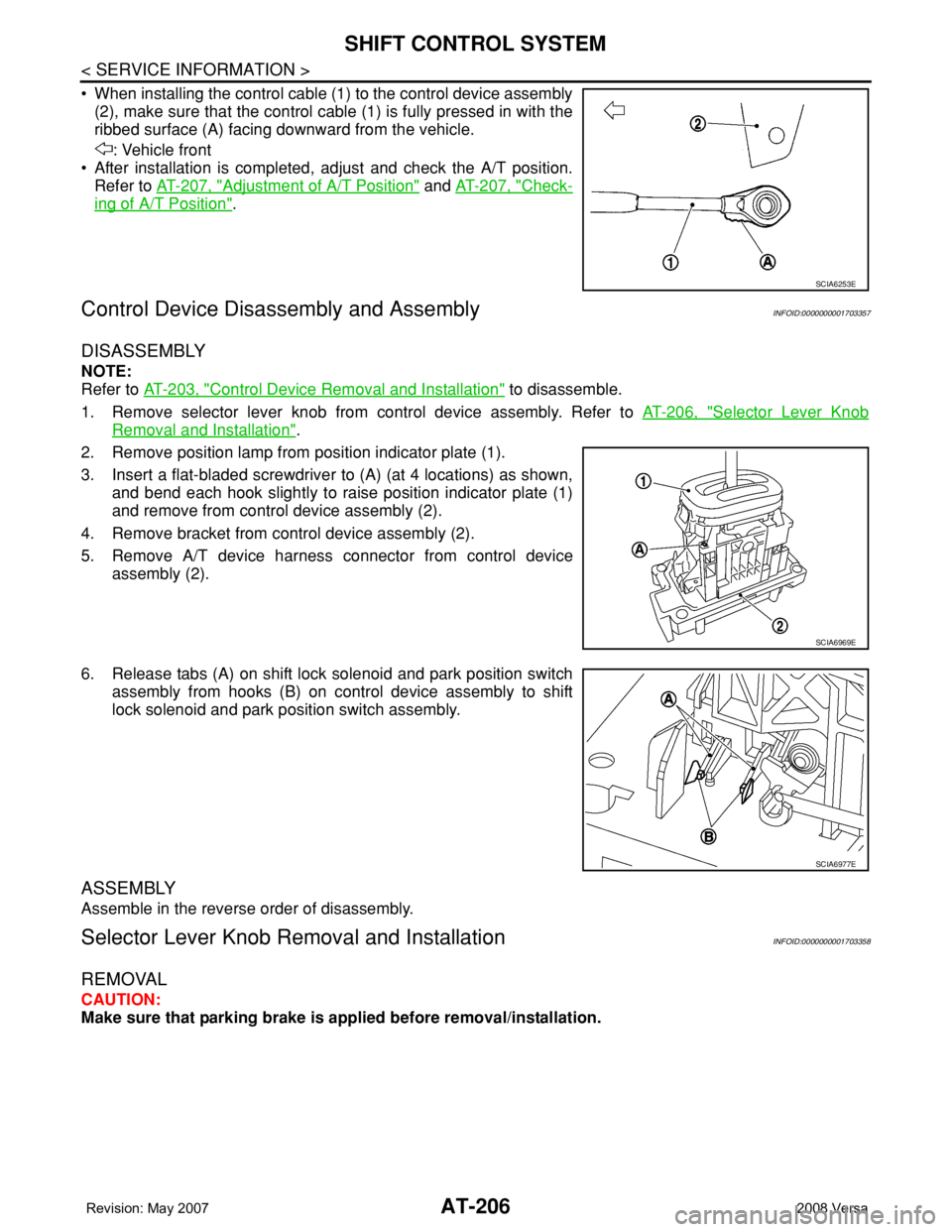

• When installing the control cable (1) to the control device assembly

(2), make sure that the control cable (1) is fully pressed in with the

ribbed surface (A) facing downward from the vehicle.

: Vehicle front

• After installation is completed, adjust and check the A/T position.

Refer to AT-207, "

Adjustment of A/T Position" and AT-207, "Check-

ing of A/T Position".

Control Device Disassembly and AssemblyINFOID:0000000001703357

DISASSEMBLY

NOTE:

Refer to AT-203, "

Control Device Removal and Installation" to disassemble.

1. Remove selector lever knob from control device assembly. Refer to AT-206, "

Selector Lever Knob

Removal and Installation".

2. Remove position lamp from position indicator plate (1).

3. Insert a flat-bladed screwdriver to (A) (at 4 locations) as shown,

and bend each hook slightly to raise position indicator plate (1)

and remove from control device assembly (2).

4. Remove bracket from control device assembly (2).

5. Remove A/T device harness connector from control device

assembly (2).

6. Release tabs (A) on shift lock solenoid and park position switch

assembly from hooks (B) on control device assembly to shift

lock solenoid and park position switch assembly.

ASSEMBLY

Assemble in the reverse order of disassembly.

Selector Lever Knob Removal and InstallationINFOID:0000000001703358

REMOVAL

CAUTION:

Make sure that parking brake is applied before removal/installation.

SCIA6253E

SCIA6969E

SCIA6977E

Page 257 of 2771

DISASSEMBLY

AT-245

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

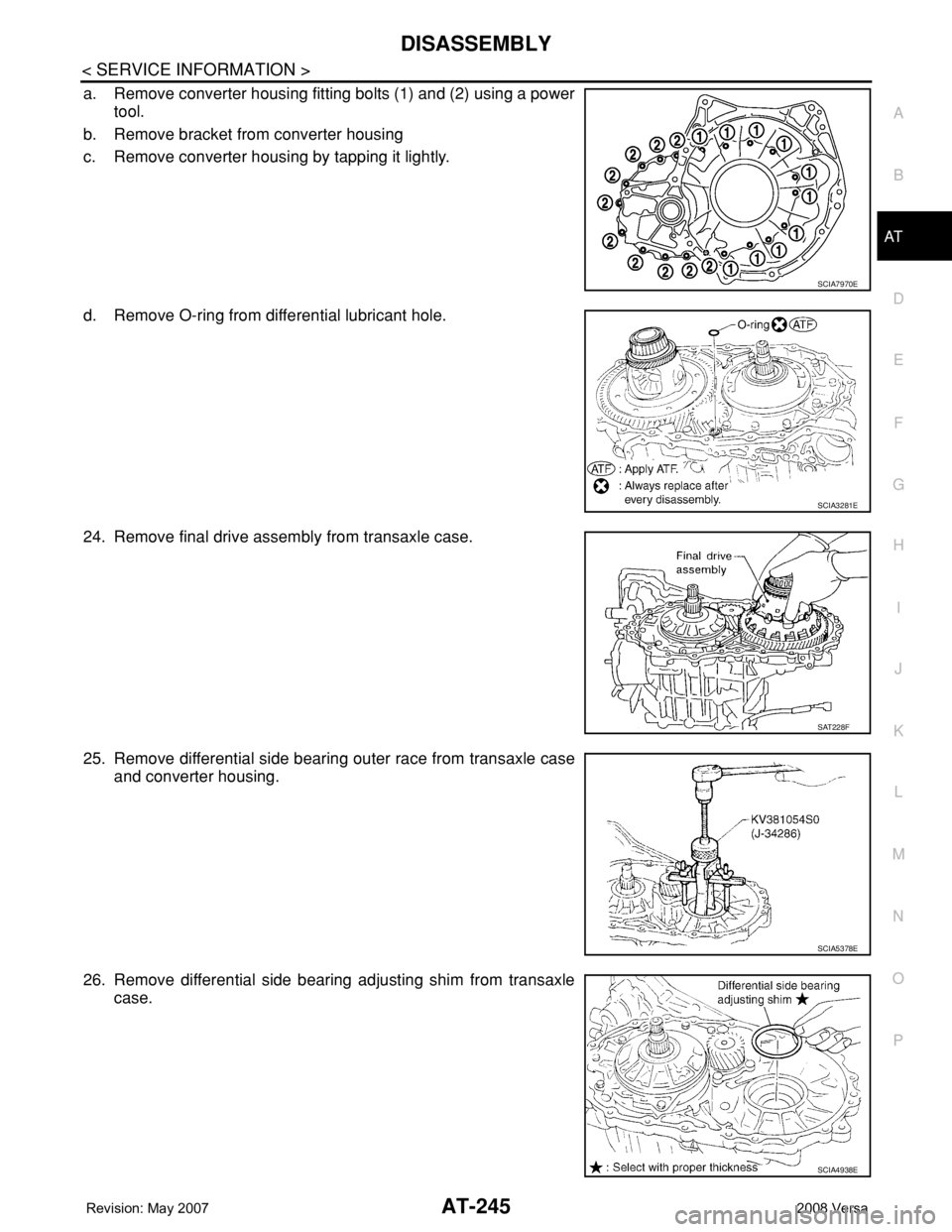

a. Remove converter housing fitting bolts (1) and (2) using a power

tool.

b. Remove bracket from converter housing

c. Remove converter housing by tapping it lightly.

d. Remove O-ring from differential lubricant hole.

24. Remove final drive assembly from transaxle case.

25. Remove differential side bearing outer race from transaxle case

and converter housing.

26. Remove differential side bearing adjusting shim from transaxle

case.

SCIA7970E

SCIA3281E

SAT228F

SCIA5378E

SCIA4938E

Page 265 of 2771

DISASSEMBLY

AT-253

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

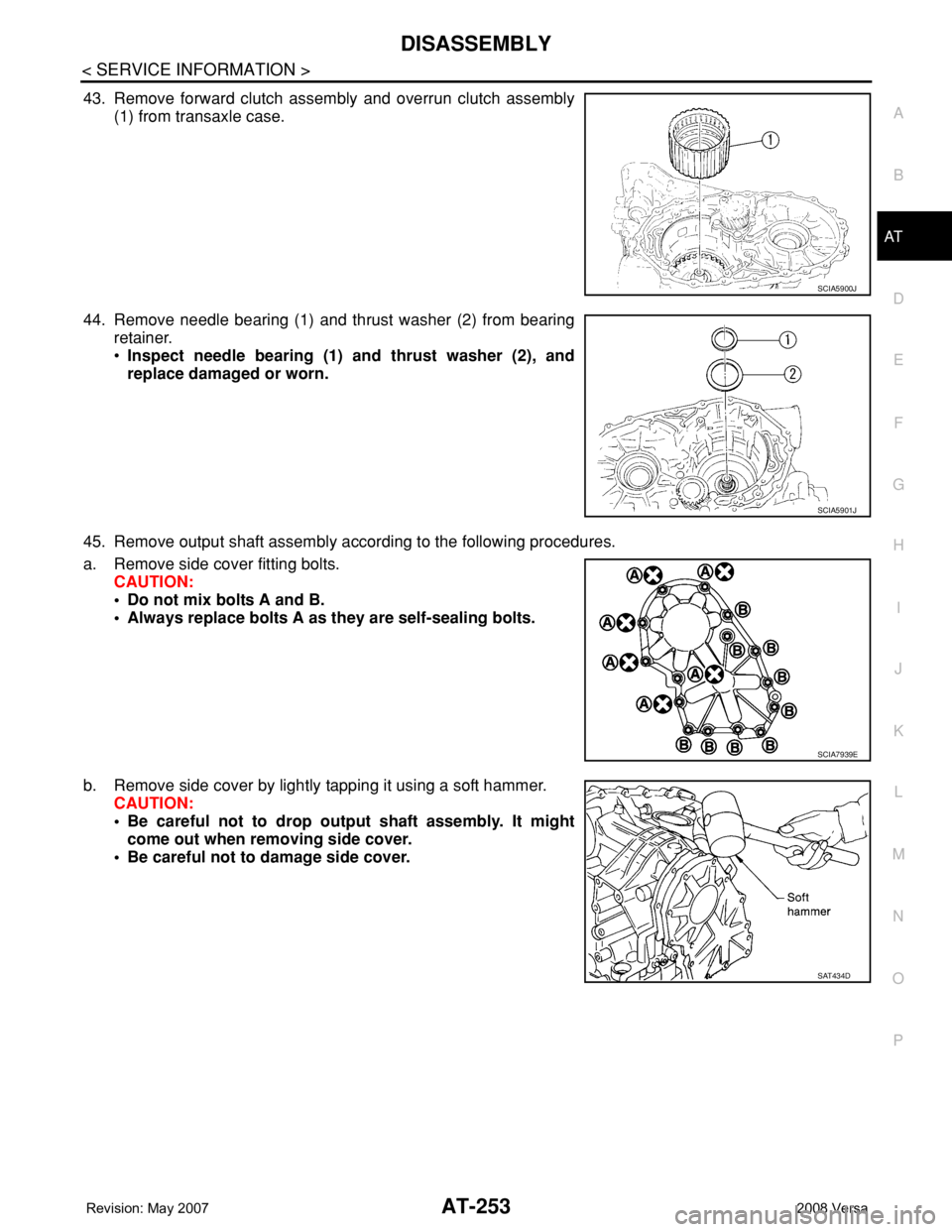

43. Remove forward clutch assembly and overrun clutch assembly

(1) from transaxle case.

44. Remove needle bearing (1) and thrust washer (2) from bearing

retainer.

•Inspect needle bearing (1) and thrust washer (2), and

replace damaged or worn.

45. Remove output shaft assembly according to the following procedures.

a. Remove side cover fitting bolts.

CAUTION:

• Do not mix bolts A and B.

• Always replace bolts A as they are self-sealing bolts.

b. Remove side cover by lightly tapping it using a soft hammer.

CAUTION:

• Be careful not to drop output shaft assembly. It might

come out when removing side cover.

• Be careful not to damage side cover.

SCIA5900J

SCIA5901J

SCIA7939E

SAT434D

Page 283 of 2771

REPAIR FOR COMPONENT PARTS

AT-271

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

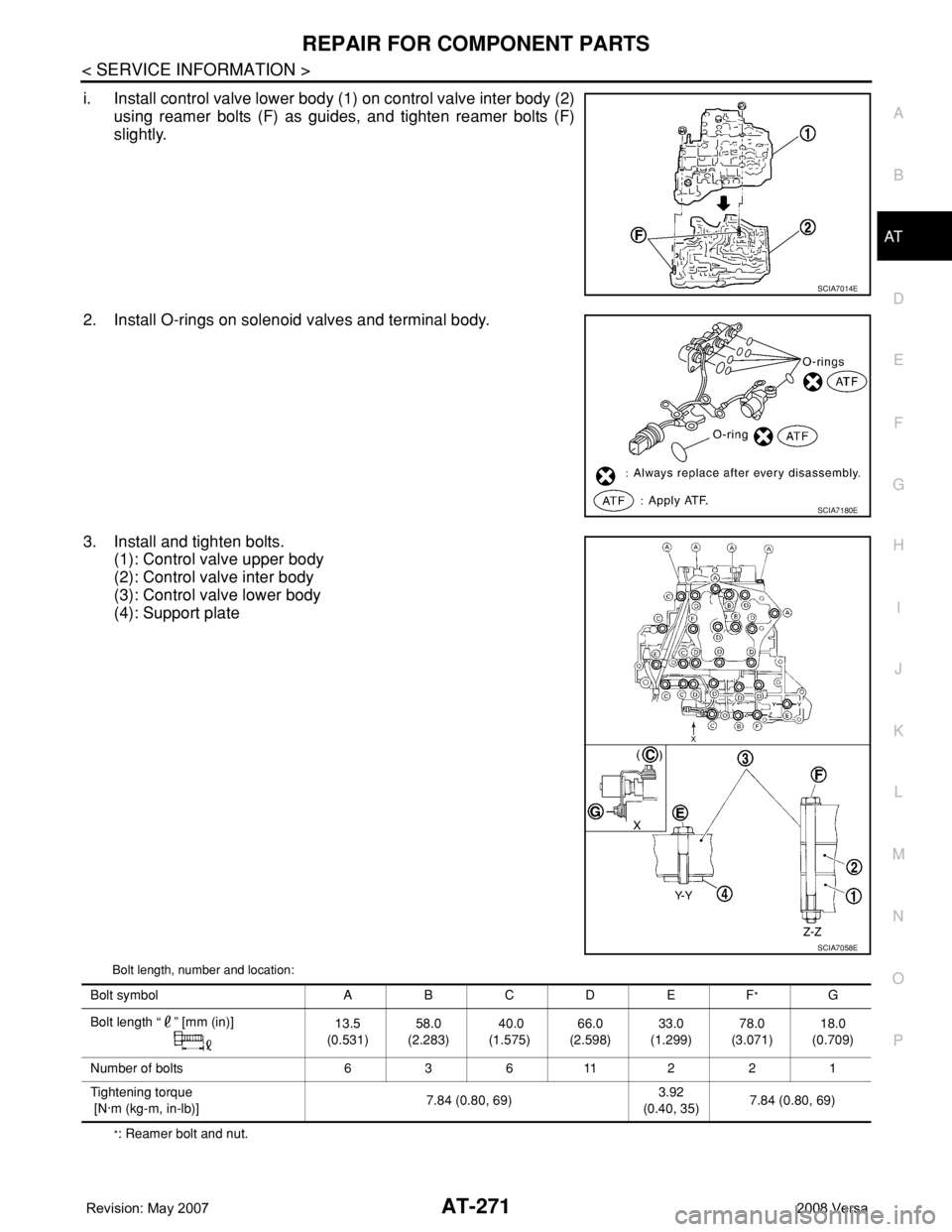

i. Install control valve lower body (1) on control valve inter body (2)

using reamer bolts (F) as guides, and tighten reamer bolts (F)

slightly.

2. Install O-rings on solenoid valves and terminal body.

3. Install and tighten bolts.

(1): Control valve upper body

(2): Control valve inter body

(3): Control valve lower body

(4): Support plate

Bolt length, number and location:

*: Reamer bolt and nut.

SCIA7014E

SCIA7180E

SCIA7058E

Bolt symbol A B C D E F*G

Bolt length “ ” [mm (in)]

13.5

(0.531)58.0

(2.283) 40.0

(1.575)66.0

(2.598)33.0

(1.299)78.0

(3.071)18.0

(0.709)

Number of bolts 6 3 6 11 2 2 1

Tightening torque

[N·m (kg-m, in-lb)]7.84 (0.80, 69)3.92

(0.40, 35)7.84 (0.80, 69)

Page 286 of 2771

AT-274

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

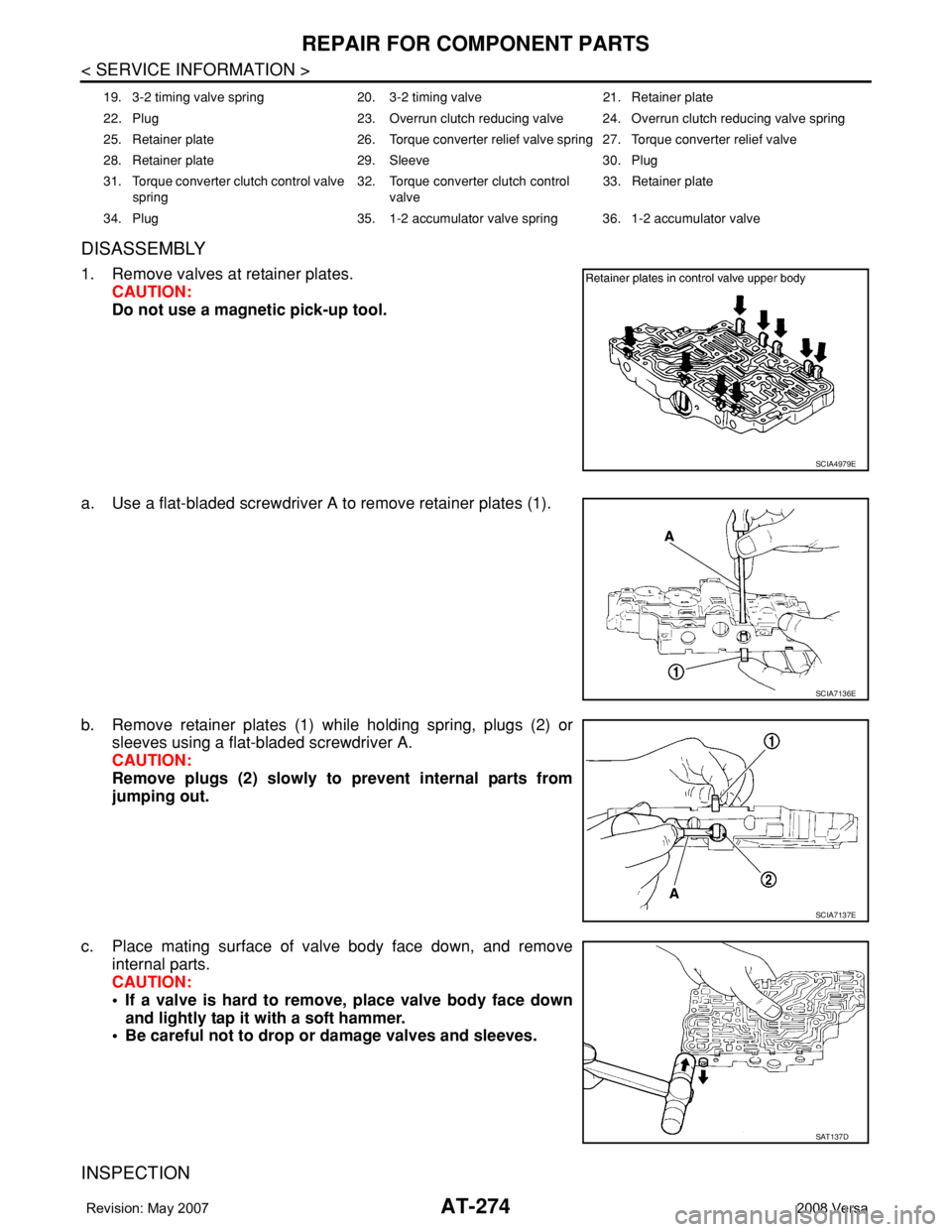

DISASSEMBLY

1. Remove valves at retainer plates.

CAUTION:

Do not use a magnetic pick-up tool.

a. Use a flat-bladed screwdriver A to remove retainer plates (1).

b. Remove retainer plates (1) while holding spring, plugs (2) or

sleeves using a flat-bladed screwdriver A.

CAUTION:

Remove plugs (2) slowly to prevent internal parts from

jumping out.

c. Place mating surface of valve body face down, and remove

internal parts.

CAUTION:

• If a valve is hard to remove, place valve body face down

and lightly tap it with a soft hammer.

• Be careful not to drop or damage valves and sleeves.

INSPECTION

19. 3-2 timing valve spring 20. 3-2 timing valve 21. Retainer plate

22. Plug 23. Overrun clutch reducing valve 24. Overrun clutch reducing valve spring

25. Retainer plate 26. Torque converter relief valve spring 27. Torque converter relief valve

28. Retainer plate 29. Sleeve 30. Plug

31. Torque converter clutch control valve

spring32. Torque converter clutch control

valve33. Retainer plate

34. Plug 35. 1-2 accumulator valve spring 36. 1-2 accumulator valve

SCIA4979E

SCIA7136E

SCIA7137E

SAT137D

Page 295 of 2771

REPAIR FOR COMPONENT PARTS

AT-283

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

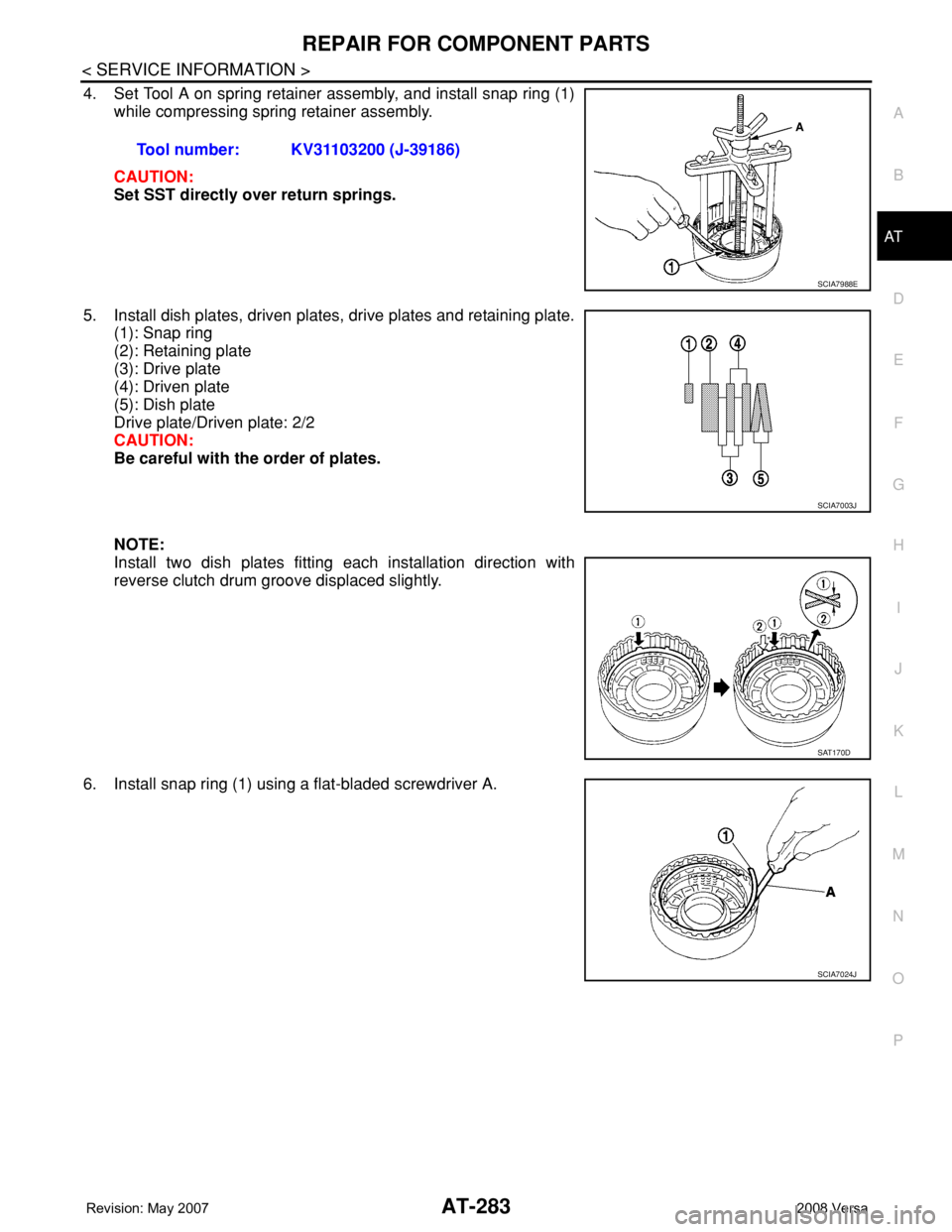

4. Set Tool A on spring retainer assembly, and install snap ring (1)

while compressing spring retainer assembly.

CAUTION:

Set SST directly over return springs.

5. Install dish plates, driven plates, drive plates and retaining plate.

(1): Snap ring

(2): Retaining plate

(3): Drive plate

(4): Driven plate

(5): Dish plate

Drive plate/Driven plate: 2/2

CAUTION:

Be careful with the order of plates.

NOTE:

Install two dish plates fitting each installation direction with

reverse clutch drum groove displaced slightly.

6. Install snap ring (1) using a flat-bladed screwdriver A.Tool number: KV31103200 (J-39186)

SCIA7988E

SCIA7003J

SAT170D

SCIA7024J

Page 311 of 2771

REPAIR FOR COMPONENT PARTS

AT-299

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

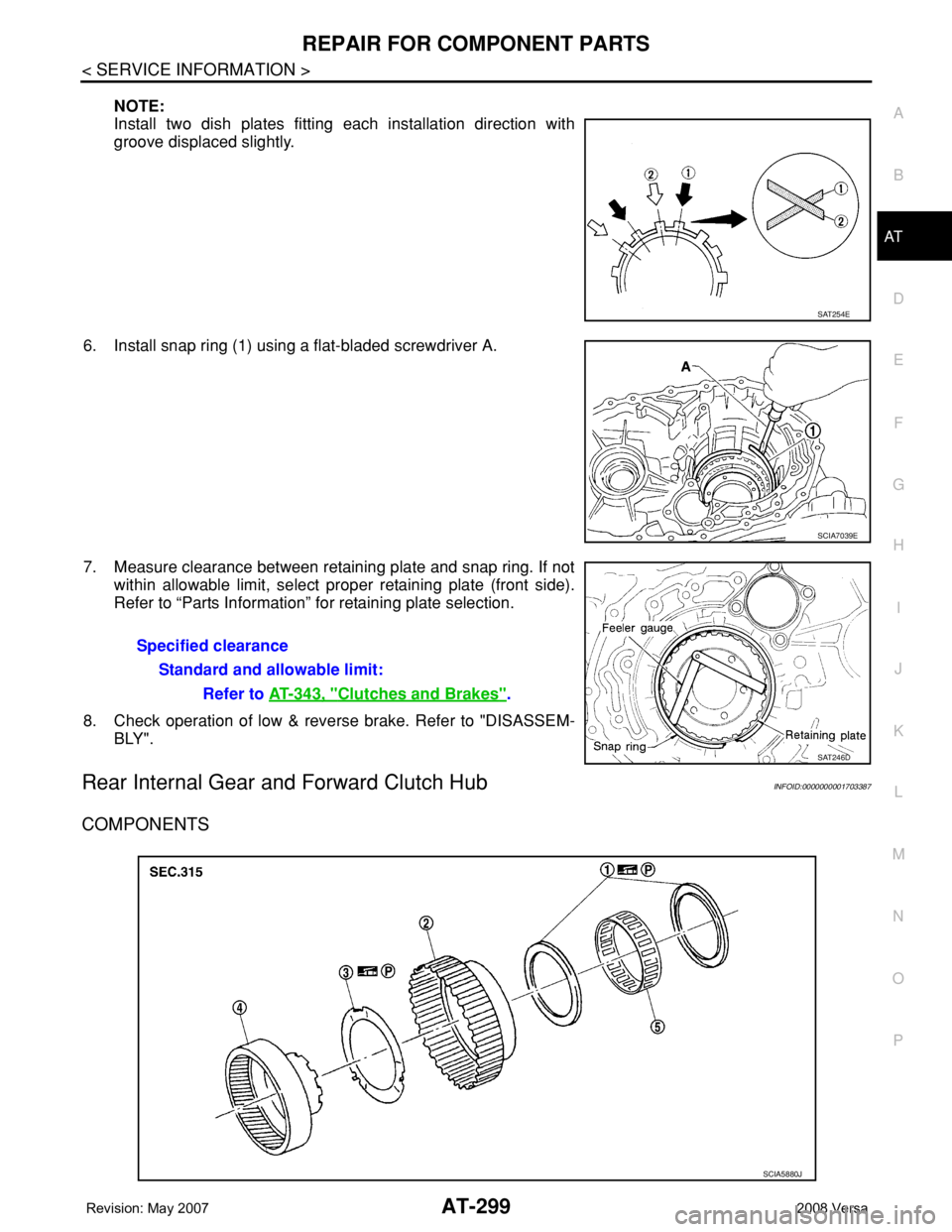

NOTE:

Install two dish plates fitting each installation direction with

groove displaced slightly.

6. Install snap ring (1) using a flat-bladed screwdriver A.

7. Measure clearance between retaining plate and snap ring. If not

within allowable limit, select proper retaining plate (front side).

Refer to “Parts Information” for retaining plate selection.

8. Check operation of low & reverse brake. Refer to "DISASSEM-

BLY".

Rear Internal Gear and Forward Clutch HubINFOID:0000000001703387

COMPONENTS

SAT254E

SCIA7039E

Specified clearance

Standard and allowable limit:

Refer to AT-343, "

Clutches and Brakes".

SAT246D

SCIA5880J

Page 332 of 2771

AT-320

< SERVICE INFORMATION >

ASSEMBLY

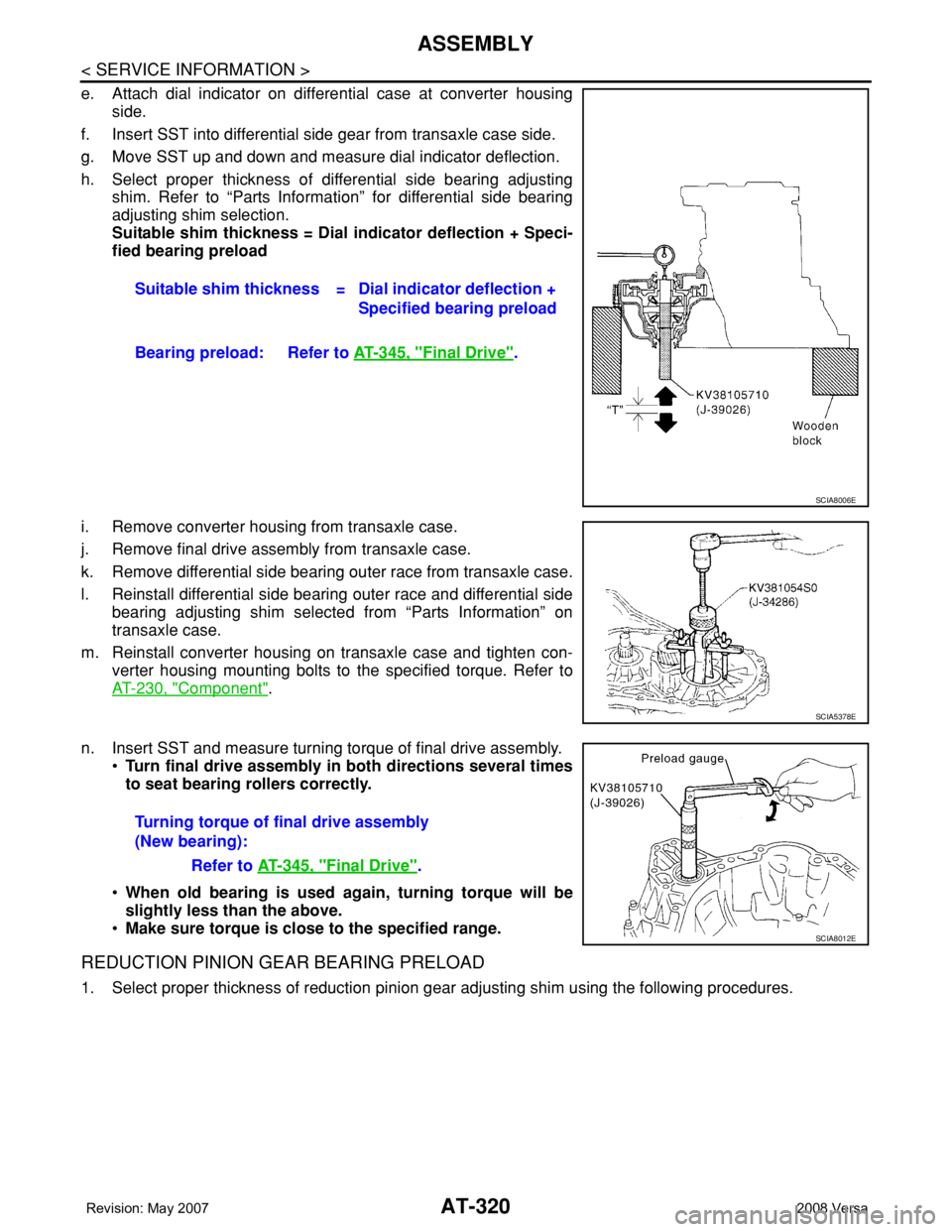

e. Attach dial indicator on differential case at converter housing

side.

f. Insert SST into differential side gear from transaxle case side.

g. Move SST up and down and measure dial indicator deflection.

h. Select proper thickness of differential side bearing adjusting

shim. Refer to “Parts Information” for differential side bearing

adjusting shim selection.

Suitable shim thickness = Dial indicator deflection + Speci-

fied bearing preload

i. Remove converter housing from transaxle case.

j. Remove final drive assembly from transaxle case.

k. Remove differential side bearing outer race from transaxle case.

l. Reinstall differential side bearing outer race and differential side

bearing adjusting shim selected from “Parts Information” on

transaxle case.

m. Reinstall converter housing on transaxle case and tighten con-

verter housing mounting bolts to the specified torque. Refer to

AT-230, "

Component".

n. Insert SST and measure turning torque of final drive assembly.

•Turn final drive assembly in both directions several times

to seat bearing rollers correctly.

•When old bearing is used again, turning torque will be

slightly less than the above.

•Make sure torque is close to the specified range.

REDUCTION PINION GEAR BEARING PRELOAD

1. Select proper thickness of reduction pinion gear adjusting shim using the following procedures.Suitable shim thickness = Dial indicator deflection +

Specified bearing preload

Bearing preload: Refer to AT-345, "

Final Drive".

SCIA8006E

SCIA5378E

Turning torque of final drive assembly

(New bearing):

Refer to AT-345, "

Final Drive".

SCIA8012E

Page 337 of 2771

ASSEMBLY

AT-325

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

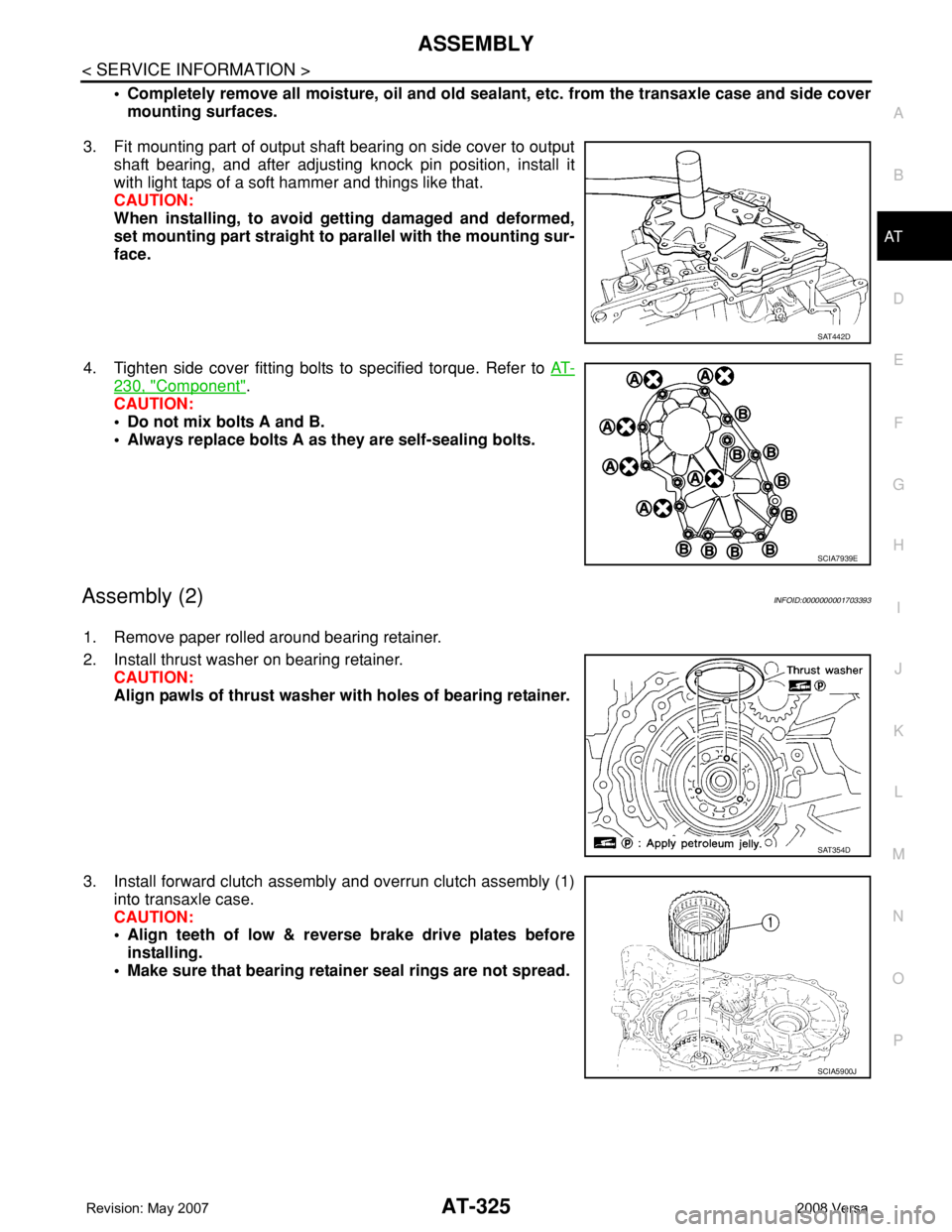

• Completely remove all moisture, oil and old sealant, etc. from the transaxle case and side cover

mounting surfaces.

3. Fit mounting part of output shaft bearing on side cover to output

shaft bearing, and after adjusting knock pin position, install it

with light taps of a soft hammer and things like that.

CAUTION:

When installing, to avoid getting damaged and deformed,

set mounting part straight to parallel with the mounting sur-

face.

4. Tighten side cover fitting bolts to specified torque. Refer to AT-

230, "Component".

CAUTION:

• Do not mix bolts A and B.

• Always replace bolts A as they are self-sealing bolts.

Assembly (2)INFOID:0000000001703393

1. Remove paper rolled around bearing retainer.

2. Install thrust washer on bearing retainer.

CAUTION:

Align pawls of thrust washer with holes of bearing retainer.

3. Install forward clutch assembly and overrun clutch assembly (1)

into transaxle case.

CAUTION:

• Align teeth of low & reverse brake drive plates before

installing.

• Make sure that bearing retainer seal rings are not spread.

SAT442D

SCIA7939E

SAT354D

SCIA5900J