NISSAN TIIDA 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 4161 of 4331

SC

N

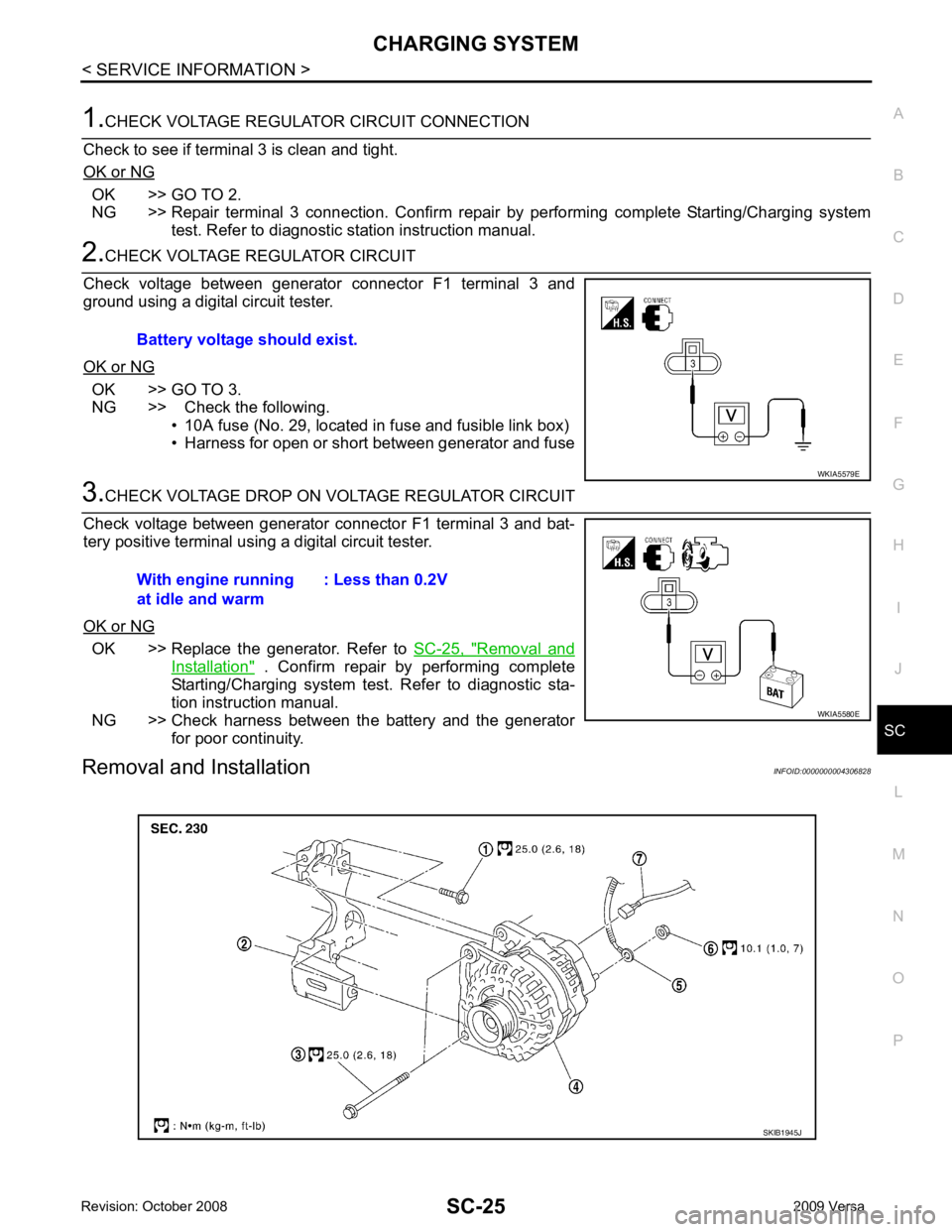

O P OK >> GO TO 2.

NG >> Repair terminal 3 connection. Confirm repair by performing complete Starting/Charging system

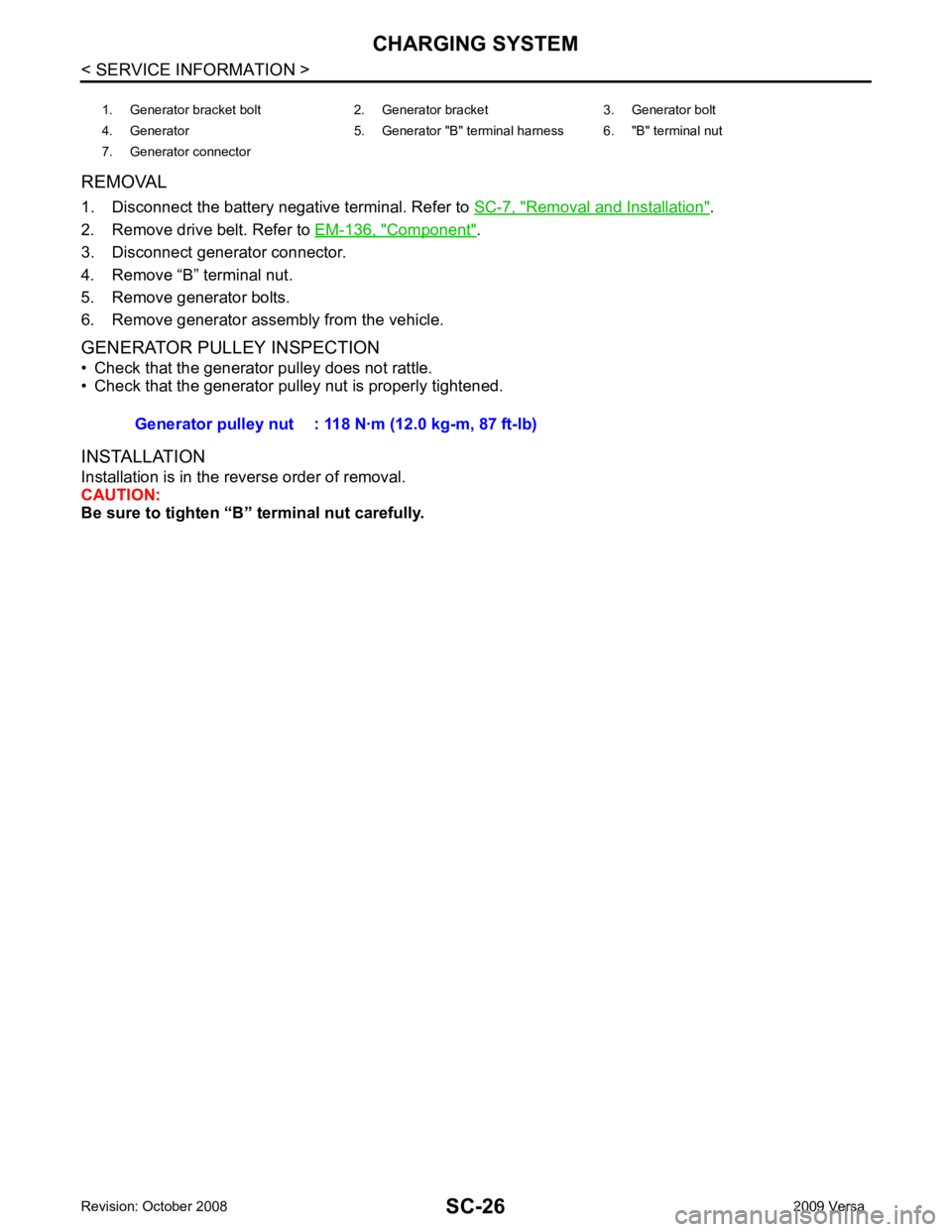

test. Refer to diagnostic station instruction manual. OK >> GO TO 3.

NG >> Check the following.

• 10A fuse (No. 29, located in fuse and fusible link box)

• Harness for open or short between generator and fuse OK >> Replace the generator. Refer to

SC-25, " Removal and

Installation " . Confirm repair by performing complete

Starting/Charging system test. Refer to diagnostic sta-

tion instruction manual.

NG >> Check harness between the battery and the generator for poor continuity.

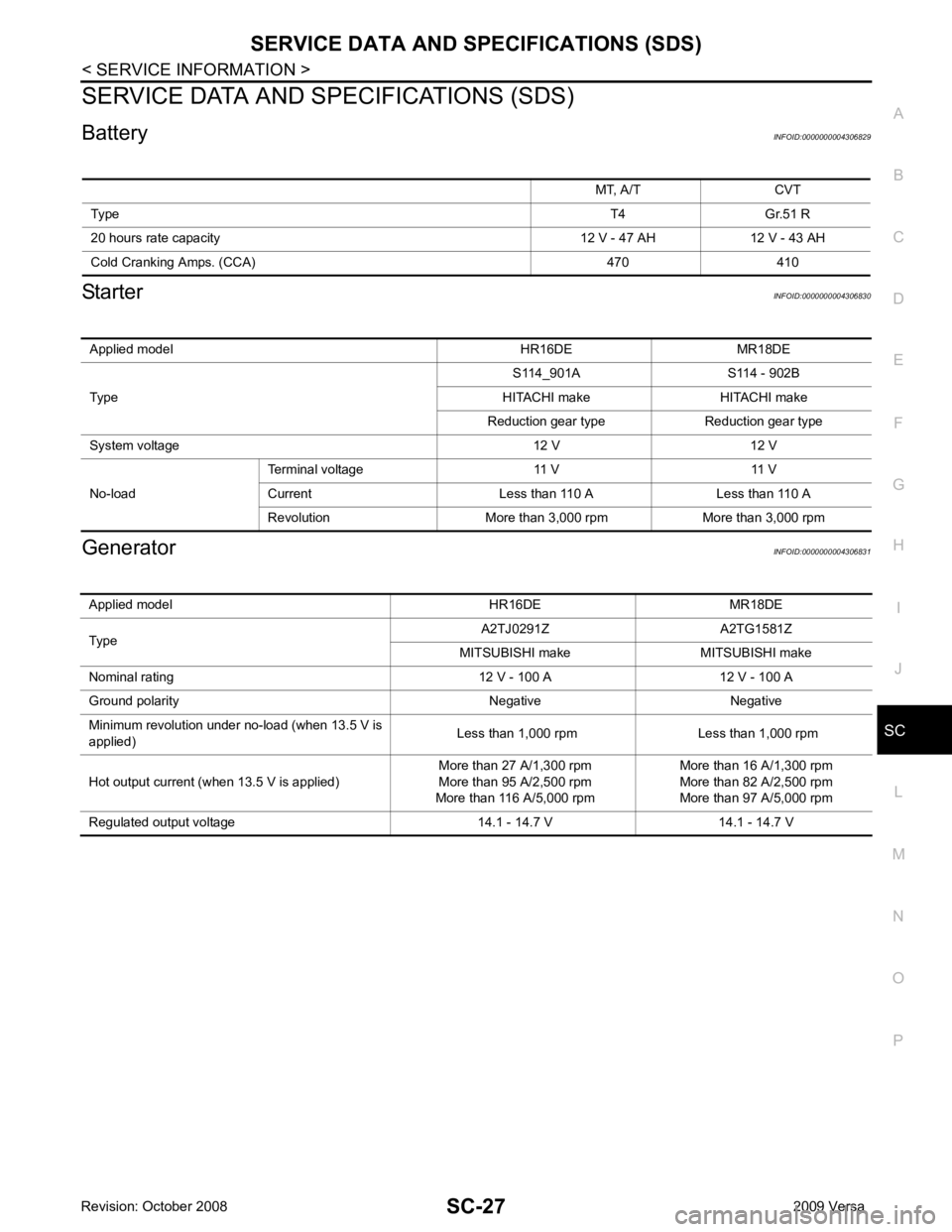

Removal and Installation INFOID:0000000004306828

Battery voltage should exist.

Page 4162 of 4331

Removal and Installation " .

2. Remove drive belt. Refer to EM-136, " Component " .

3. Disconnect generator connector.

4. Remove “B” terminal nut.

5. Remove generator bolts.

6. Remove generator assembly from the vehicle.

GENERATOR PULLEY INSPECTION

• Check that the generator pulley does not rattle.

• Check that the generator pulley nut is properly tightened.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Be sure to tighten “B” terminal nut carefully. 1. Generator bracket bolt 2. Generator bracket 3. Generator bolt

4. Generator 5. Generator "B" terminal harness 6. "B" terminal nut

7. Generator connector

Generator pulley nut : 118 N·m (12.0 kg-m, 87 ft-lb)

Page 4163 of 4331

SC

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

Battery INFOID:0000000004306829

Starter INFOID:0000000004306830

Generator INFOID:0000000004306831

MT, A/T CVT

Type T4 Gr.51 R

20 hours rate capacity 12 V - 47 AH 12 V - 43 AH

Cold Cranking Am ps. (CCA) 470 410Applied model HR16DE MR18DE

Type S114_901A S114 - 902B

HITACHI make HITACHI make

Reduction gear type Reduction gear type

System voltage 12 V 12 V

No-load Terminal voltage 11 V 11 V

Current Less than 110 A Less than 110 A

Revolution More than 3,000 rpm More than 3,000 rpm Applied model HR16DE MR18DE

Type A2TJ0291Z A2TG1581Z

MITSUBISHI make MITSUBISHI make

Nominal rating 12 V - 100 A 12 V - 100 A

Ground polarity Negative Negative

Minimum revolution under no-load (when 13.5 V is

applied) Less than 1,000 rpm Less than 1,000 rpm

Hot output current (when 13.5 V is applied) More than 27 A/1,300 rpm

More than 95 A/2,500 rpm

More than 116 A/5,000 rpm More than 16 A/1,300 rpm

More than 82 A/2,500 rpm

More than 97 A/5,000 rpm

Regulated output voltage 14.1 - 14.7 V 14.1 - 14.7 V

Page 4164 of 4331

SE

N

O P

CONTENTS

SEAT

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Service Notice ..................................................... ......2

Precaution ........................................................... ......3

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool .................................... ......4

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................5

Work Flow ........................................................... ......5 Generic Squeak and Rattle Troubleshooting .......

.....7

Diagnostic Worksheet .......................................... .....9

FRONT SEAT .................................................... 11

Driver Seat ........................................................... ....11

Passenger Seat ................................................... ....12

Removal and Installation ..................................... ....12

Disassembly and Assembly ................................. ....13

REAR SEAT ...................................................... 15

Component Parts Drawing .................................. ....15

Removal and Installation ..................................... ....16

Disassembly and Assembly ................................. ....18

Component Parts Drawing .................................. ....21

Removal and Installation ..................................... ....22

Disassembly and Assembly ................................. ....24

Removal and Installation ..................................... ....26

Disassembly and Assembly ................................. ....26

Page 4165 of 4331

Page 4166 of 4331

SE

N

O P

• Handle trim, molding instruments, grille, etc. carefully during removing or installing. Be careful not to oil or

damage them.

• Apply sealing compound where necessary when installing parts.

• When applying sealing compound, be careful that the sealing compound does not protrude from parts.

• When replacing any metal parts (for example body outer panel, member, etc.), be sure to take rust preven-

tion measures.

Precaution INFOID:0000000004306501

• When removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

• When removing parts with a screwdriver or other tool , protect parts by wrapping tools with vinyl or tape.

• Keep removed parts protected with cloth.

• If a clip is deformed or damaged, replace it.

• If an unreusable part is removed, replace it with a new one.

• Tighten bolts and nuts firmly to the specified torque.

• After re-assembly has been completed, make sure each part functions correctly.

• Remove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tight ly. After wiping the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Then wipe the area with a soft dry cloth.

• Do not use any organic solvent, such as thinner or benzine.

Page 4167 of 4331

SE-4< SERVICE INFORMATION >

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000004306502

The actual shapes of Kent -Moore tools may differ from those of special service tools illustrated here.

Commercial Service Tool INFOID:0000000004306503

Tool number

(Kent-Moore No.)

Tool name Description

—

(J-39570)

Chassis ear Locating the noise

—

(J-43980)

NISSAN Squeak and Rattle

Kit Repairing the cause of noise SIIA0993E

SIIA0994E

(Kent-Moore No.)

Tool name Description

(J-39565)

Engine ear Locating the noiseSIIA0995E

Page 4168 of 4331

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-5

< SERVICE INFORMATION >

C

D E

F

G H

J

K L

M A

B SE

N

O P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

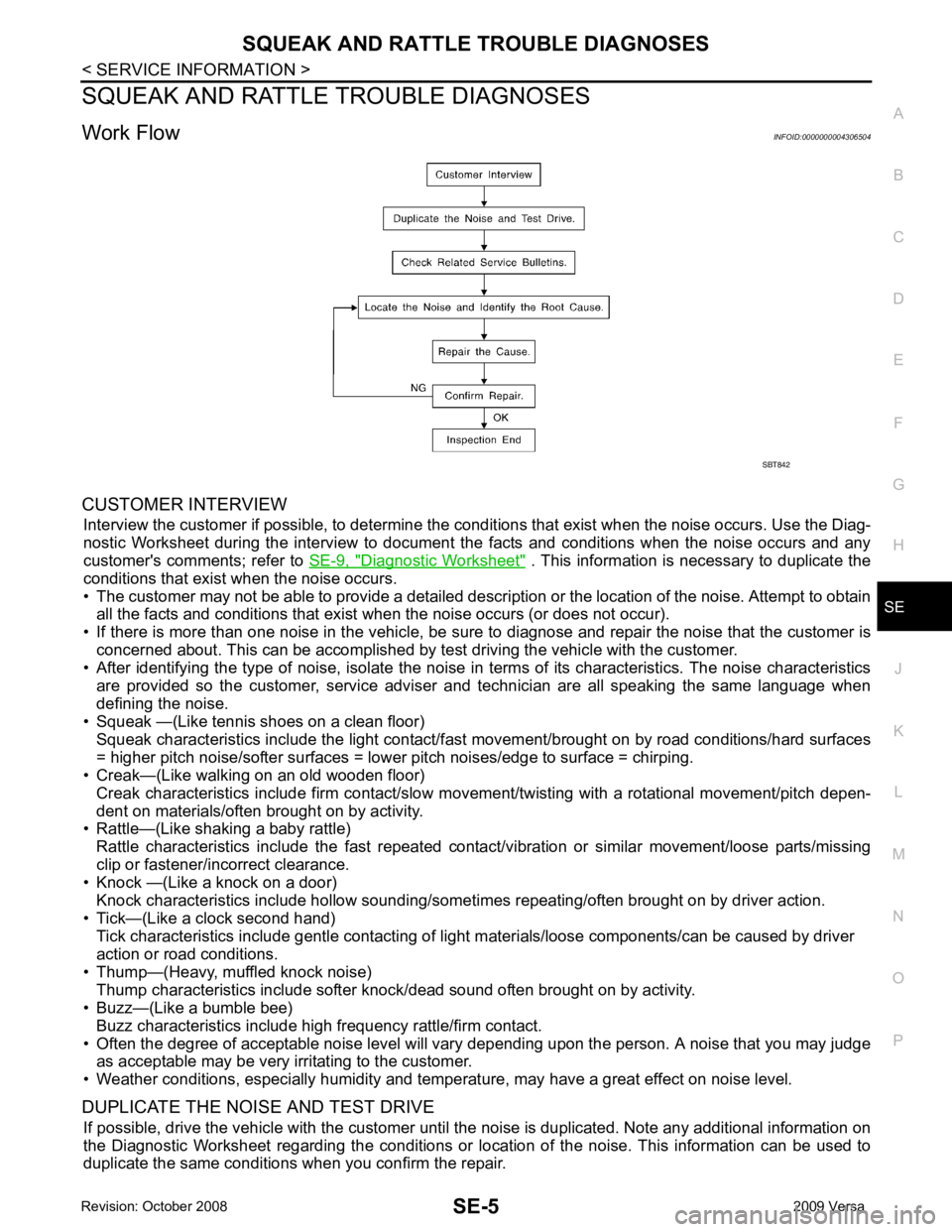

Work Flow INFOID:0000000004306504

CUSTOMER INTERVIEW Interview the customer if possible, to determine the c onditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to SE-9, " Diagnostic Worksheet " . This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair. SBT842

Page 4169 of 4331

Generic Squeak and Rattle Troubleshooting " .

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A NISSAN Squeak and Rattle Kit (J-43980) is av ailable through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISS AN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94 ×5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-71L02: 15 ×25

mm (0.59 ×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50 ×50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97 in)

FELT CLOTH TAPE

Used to insulate where movemen t does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59 ×0.98 in) pad/68239-13E00: 5 mm (0.20 in ) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movemen t is present. Ideal for instrument panel applications.

Page 4170 of 4331

SE

N

O P

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle Troubleshooting INFOID:0000000004306505

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket