NISSAN X-TRAIL 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 2691 of 3833

REAR FINAL DRIVE ASSEMBLY

RFD-15

C

E

F

G

H

I

J

K

L

MA

B

RFD

Inspection Before DisassemblyEDS0010D

OVERALL PRELOAD TORQUE

1. Drain the oil.

2. Remove electronically controlled coupling assembly.

Refer to “Electronically Controlled Coupling Assembly”.

3. Rotate the drive pinion gear back and forth in 2 - 3 times to check for abnormal noise and rotation mal-

function.

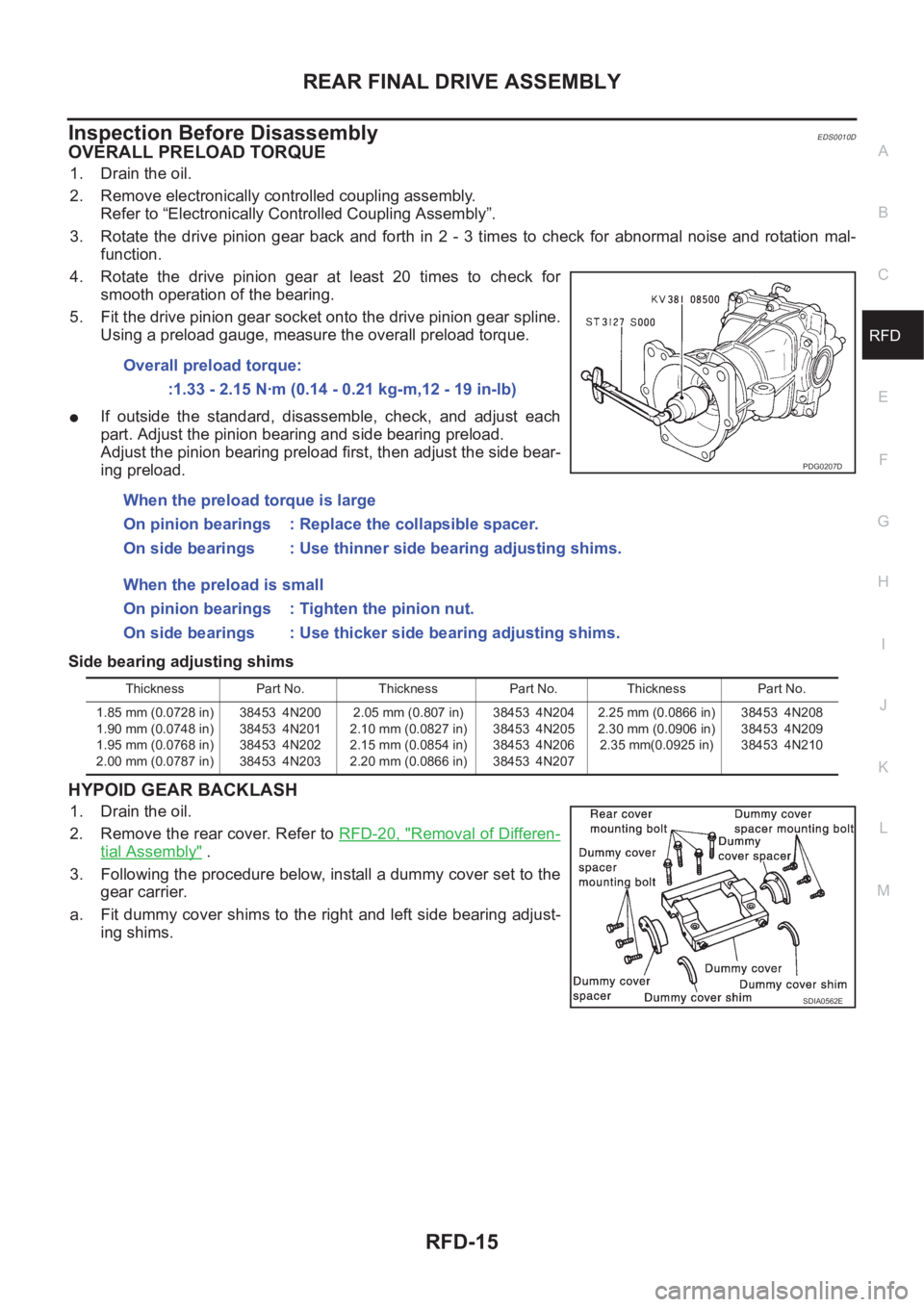

4. Rotate the drive pinion gear at least 20 times to check for

smooth operation of the bearing.

5. Fit the drive pinion gear socket onto the drive pinion gear spline.

Using a preload gauge, measure the overall preload torque.

●If outside the standard, disassemble, check, and adjust each

part. Adjust the pinion bearing and side bearing preload.

Adjust the pinion bearing preload first, then adjust the side bear-

ing preload.

Side bearing adjusting shims

HYPOID GEAR BACKLASH

1. Drain the oil.

2. Remove the rear cover. Refer to RFD-20, "

Removal of Differen-

tial Assembly" .

3. Following the procedure below, install a dummy cover set to the

gear carrier.

a. Fit dummy cover shims to the right and left side bearing adjust-

ing shims.Overall preload torque:

:1.33 - 2.15 N·m (0.14 - 0.21 kg-m,12 - 19 in-lb)

When the preload torque is large

On pinion bearings : Replace the collapsible spacer.

On side bearings : Use thinner side bearing adjusting shims.

When the preload is small

On pinion bearings : Tighten the pinion nut.

On side bearings : Use thicker side bearing adjusting shims.

PDG0207D

Thickness Part No. Thickness Part No. Thickness Part No.

1.85 mm (0.0728 in)

1.90 mm (0.0748 in)

1.95 mm (0.0768 in)

2.00 mm (0.0787 in)38453 4N200

38453 4N201

38453 4N202

38453 4N2032.05 mm (0.807 in)

2.10 mm (0.0827 in)

2.15 mm (0.0854 in)

2.20 mm (0.0866 in)38453 4N204

38453 4N205

38453 4N206

38453 4N2072.25 mm (0.0866 in)

2.30 mm (0.0906 in)

2.35 mm(0.0925 in)38453 4N208

38453 4N209

38453 4N210

SDIA0562E

Page 2692 of 3833

RFD-16

REAR FINAL DRIVE ASSEMBLY

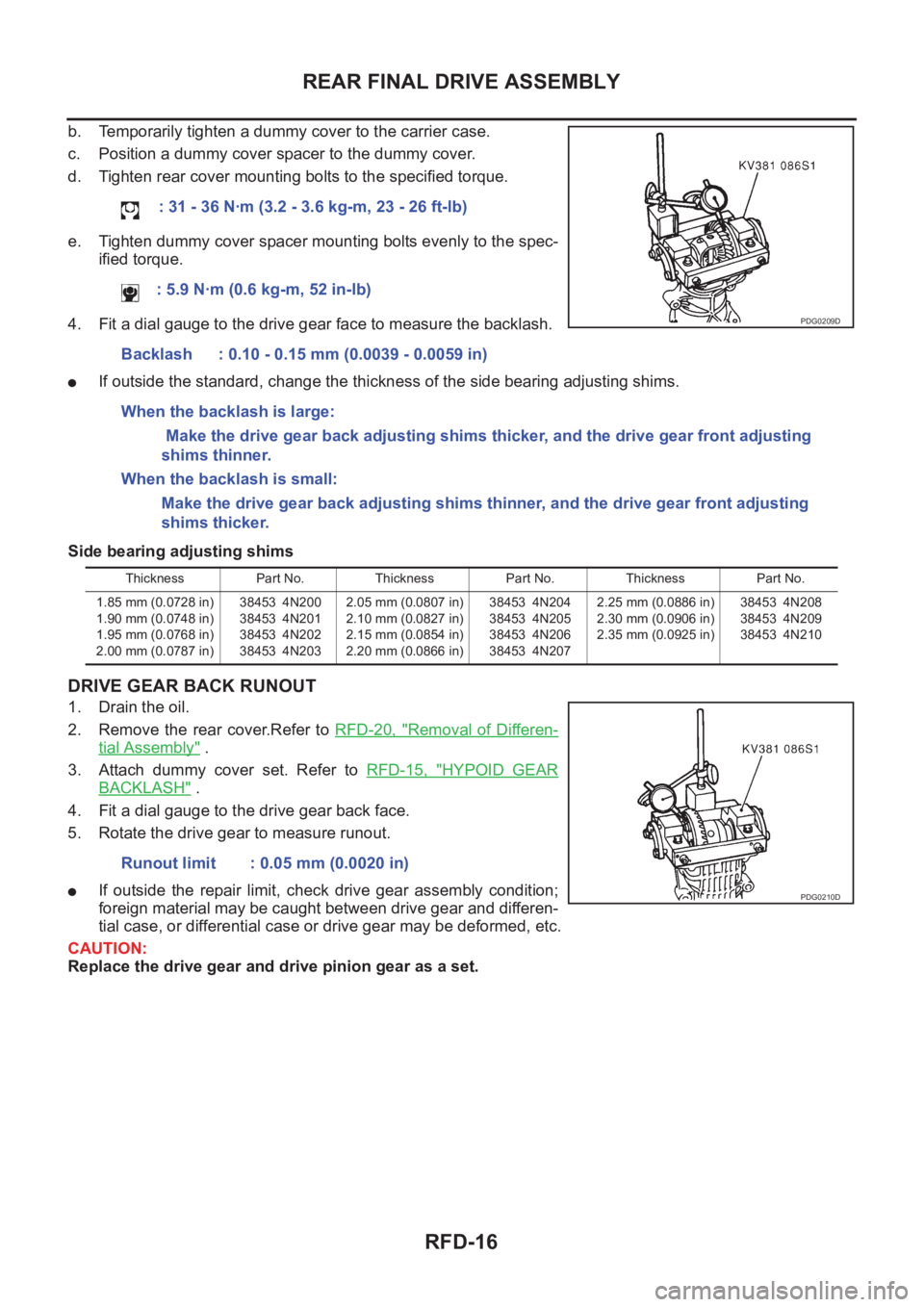

b. Temporarily tighten a dummy cover to the carrier case.

c. Position a dummy cover spacer to the dummy cover.

d. Tighten rear cover mounting bolts to the specified torque.

e. Tighten dummy cover spacer mounting bolts evenly to the spec-

ified torque.

4. Fit a dial gauge to the drive gear face to measure the backlash.

●If outside the standard, change the thickness of the side bearing adjusting shims.

Side bearing adjusting shims

DRIVE GEAR BACK RUNOUT

1. Drain the oil.

2. Remove the rear cover.Refer to RFD-20, "

Removal of Differen-

tial Assembly" .

3. Attach dummy cover set. Refer to RFD-15, "

HYPOID GEAR

BACKLASH" .

4. Fit a dial gauge to the drive gear back face.

5. Rotate the drive gear to measure runout.

●If outside the repair limit, check drive gear assembly condition;

foreign material may be caught between drive gear and differen-

tial case, or differential case or drive gear may be deformed, etc.

CAUTION:

Replace the drive gear and drive pinion gear as a set.: 31 - 36 N·m (3.2 - 3.6 kg-m, 23 - 26 ft-lb)

: 5.9 N·m (0.6 kg-m, 52 in-lb)

Backlash : 0.10 - 0.15 mm (0.0039 - 0.0059 in)

When the backlash is large:

Make the drive gear back adjusting shims thicker, and the drive gear front adjusting

shims thinner.

When the backlash is small:

Make the drive gear back adjusting shims thinner, and the drive gear front adjusting

shims thicker.

PDG0209D

Thickness Part No. Thickness Part No. Thickness Part No.

1.85 mm (0.0728 in)

1.90 mm (0.0748 in)

1.95 mm (0.0768 in)

2.00 mm (0.0787 in)38453 4N200

38453 4N201

38453 4N202

38453 4N2032.05 mm (0.0807 in)

2.10 mm (0.0827 in)

2.15 mm (0.0854 in)

2.20 mm (0.0866 in)38453 4N204

38453 4N205

38453 4N206

38453 4N2072.25 mm (0.0886 in)

2.30 mm (0.0906 in)

2.35 mm (0.0925 in)38453 4N208

38453 4N209

38453 4N210

Runout limit : 0.05 mm (0.0020 in)

PDG0210D

Page 2693 of 3833

REAR FINAL DRIVE ASSEMBLY

RFD-17

C

E

F

G

H

I

J

K

L

MA

B

RFD

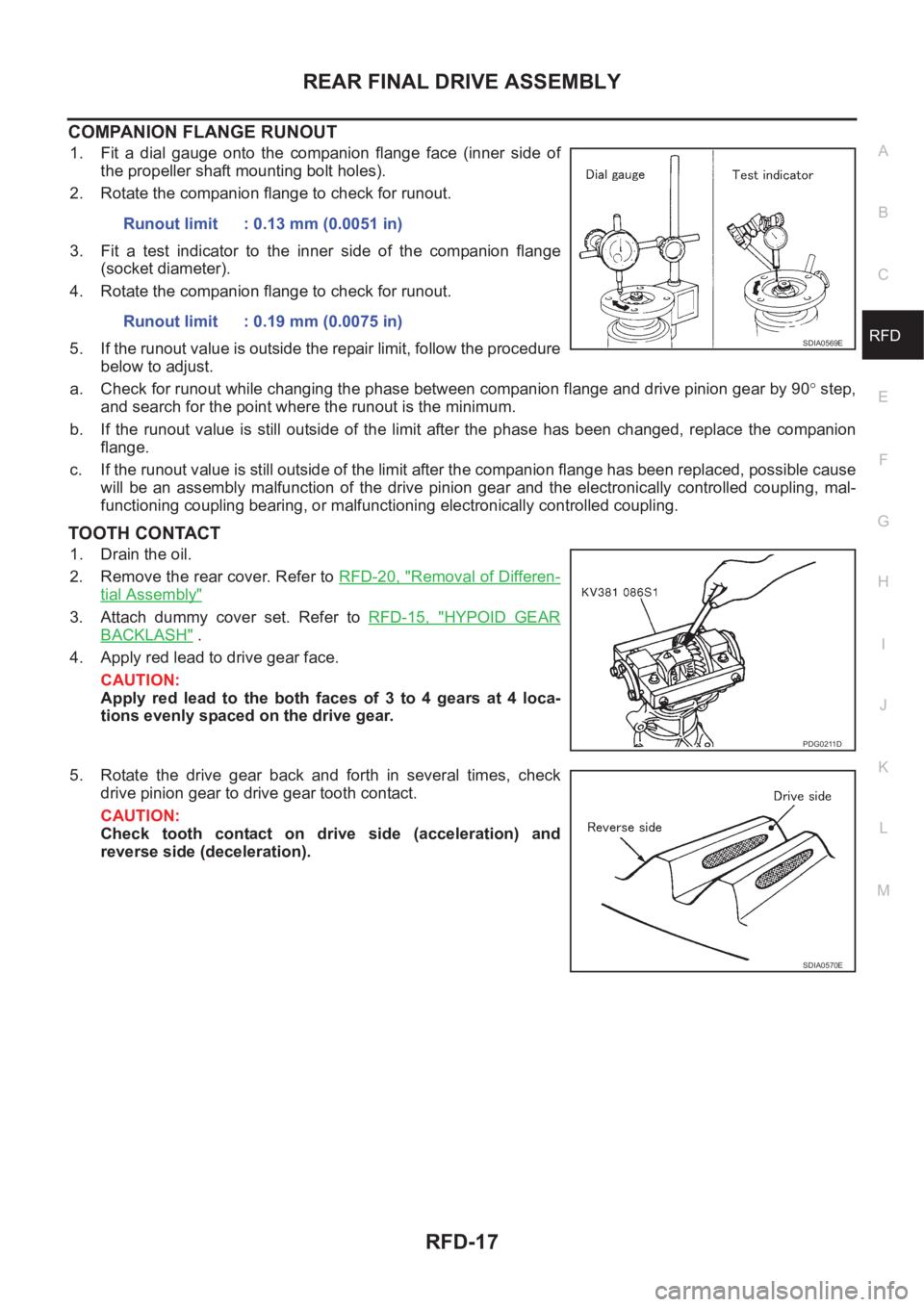

COMPANION FLANGE RUNOUT

1. Fit a dial gauge onto the companion flange face (inner side of

the propeller shaft mounting bolt holes).

2. Rotate the companion flange to check for runout.

3. Fit a test indicator to the inner side of the companion flange

(socket diameter).

4. Rotate the companion flange to check for runout.

5. If the runout value is outside the repair limit, follow the procedure

below to adjust.

a. Check for runout while changing the phase between companion flange and drive pinion gear by 90° step,

and search for the point where the runout is the minimum.

b. If the runout value is still outside of the limit after the phase has been changed, replace the companion

flange.

c. If the runout value is still outside of the limit after the companion flange has been replaced, possible cause

will be an assembly malfunction of the drive pinion gear and the electronically controlled coupling, mal-

functioning coupling bearing, or malfunctioning electronically controlled coupling.

TOOTH CONTACT

1. Drain the oil.

2. Remove the rear cover. Refer to RFD-20, "

Removal of Differen-

tial Assembly"

3. Attach dummy cover set. Refer to RFD-15, "HYPOID GEAR

BACKLASH" .

4. Apply red lead to drive gear face.

CAUTION:

Apply red lead to the both faces of 3 to 4 gears at 4 loca-

tions evenly spaced on the drive gear.

5. Rotate the drive gear back and forth in several times, check

drive pinion gear to drive gear tooth contact.

CAUTION:

Check tooth contact on drive side (acceleration) and

reverse side (deceleration).Runout limit : 0.13 mm (0.0051 in)

Runout limit : 0.19 mm (0.0075 in)

SDIA0569E

PDG0211D

SDIA0570E

Page 2694 of 3833

RFD-18

REAR FINAL DRIVE ASSEMBLY

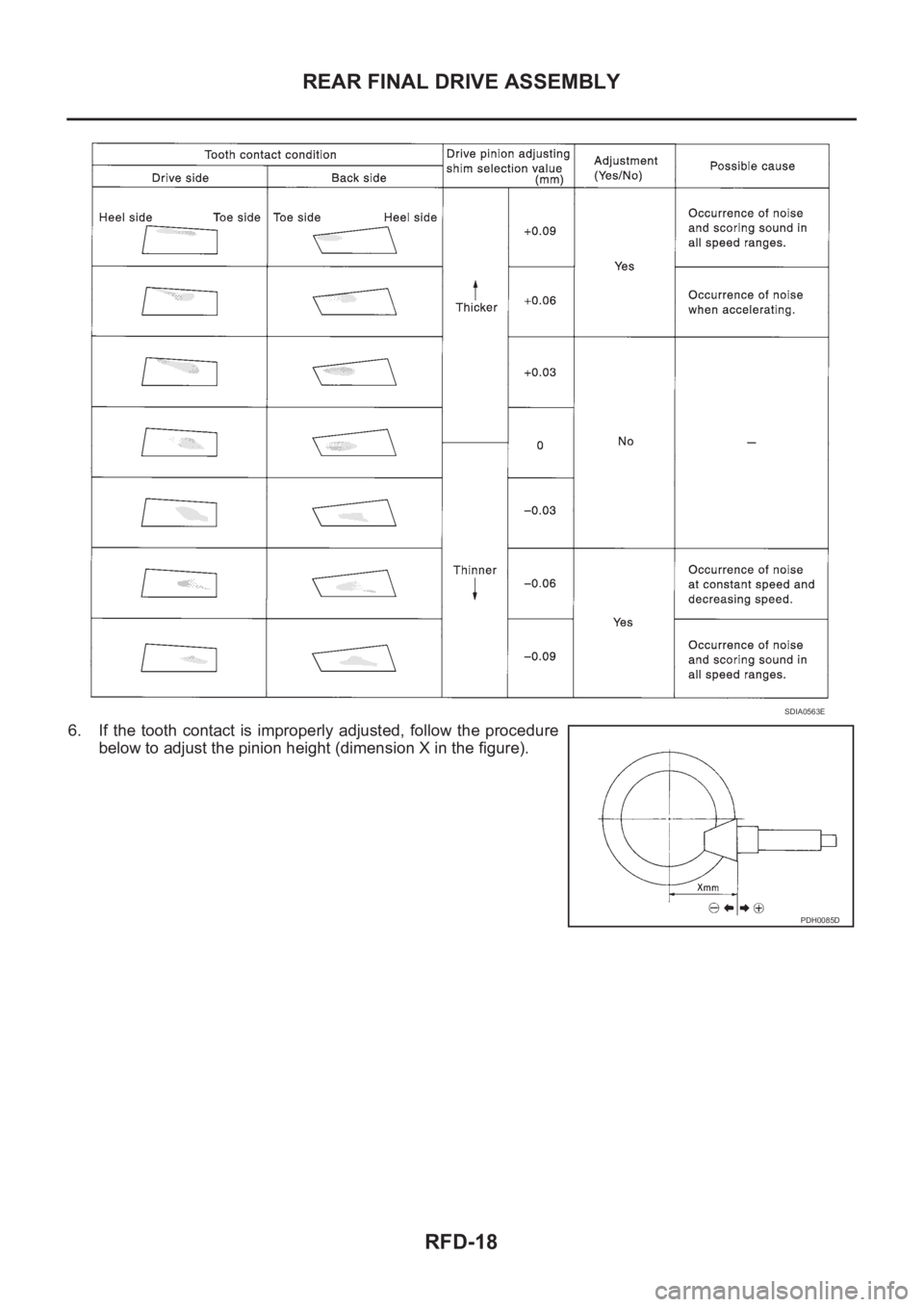

6. If the tooth contact is improperly adjusted, follow the procedure

below to adjust the pinion height (dimension X in the figure).

SDIA0563E

PDH0085D

Page 2695 of 3833

REAR FINAL DRIVE ASSEMBLY

RFD-19

C

E

F

G

H

I

J

K

L

MA

B

RFD

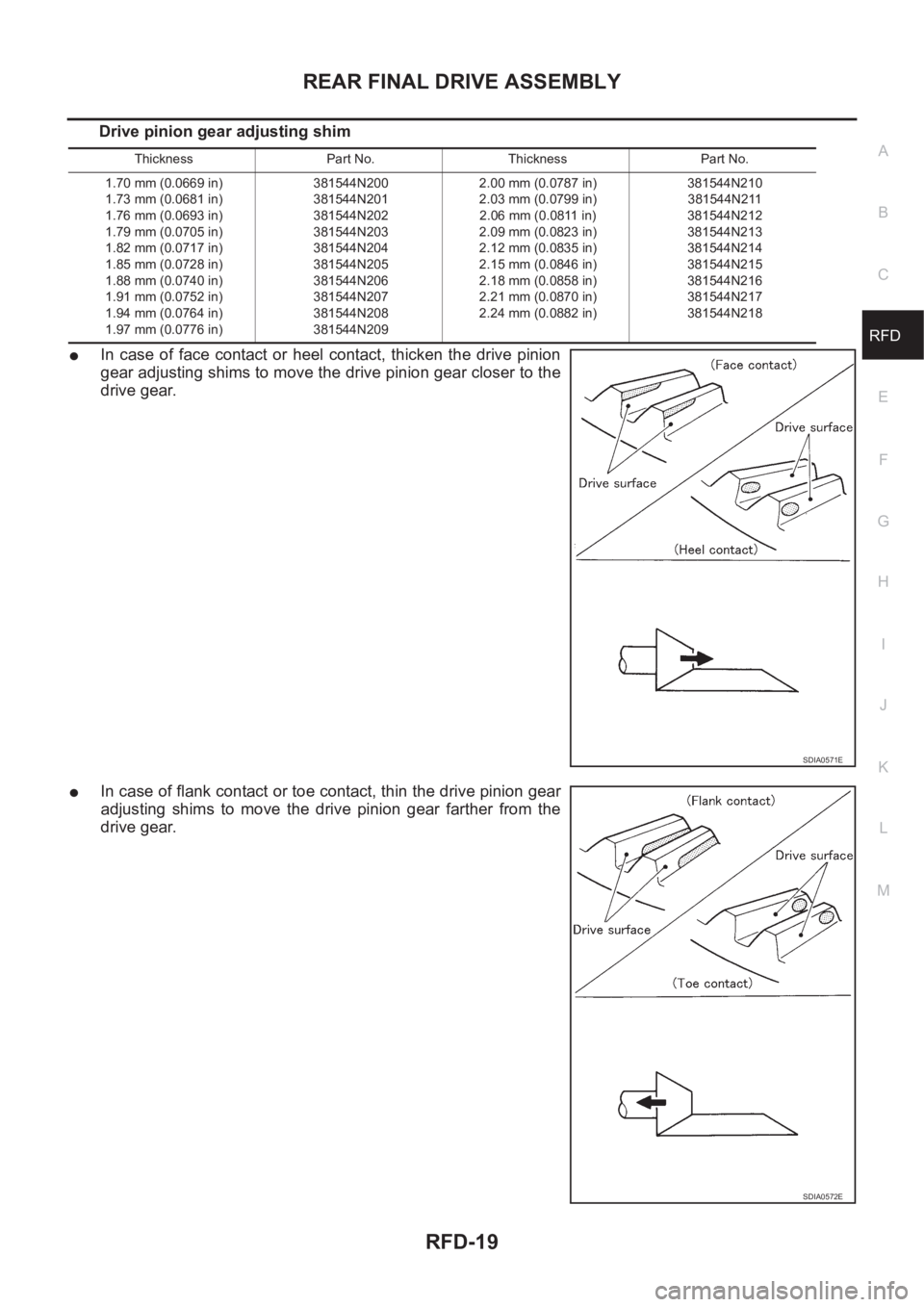

Drive pinion gear adjusting shim

●In case of face contact or heel contact, thicken the drive pinion

gear adjusting shims to move the drive pinion gear closer to the

drive gear.

●In case of flank contact or toe contact, thin the drive pinion gear

adjusting shims to move the drive pinion gear farther from the

drive gear.

Thickness Part No. Thickness Part No.

1.70 mm (0.0669 in)

1.73 mm (0.0681 in)

1.76 mm (0.0693 in)

1.79 mm (0.0705 in)

1.82 mm (0.0717 in)

1.85 mm (0.0728 in)

1.88 mm (0.0740 in)

1.91 mm (0.0752 in)

1.94 mm (0.0764 in)

1.97 mm (0.0776 in)381544N200

381544N201

381544N202

381544N203

381544N204

381544N205

381544N206

381544N207

381544N208

381544N2092.00 mm (0.0787 in)

2.03 mm (0.0799 in)

2.06 mm (0.0811 in)

2.09 mm (0.0823 in)

2.12 mm (0.0835 in)

2.15 mm (0.0846 in)

2.18 mm (0.0858 in)

2.21 mm (0.0870 in)

2.24 mm (0.0882 in)381544N210

381544N211

381544N212

381544N213

381544N214

381544N215

381544N216

381544N217

381544N218

SDIA0571E

SDIA0572E

Page 2696 of 3833

RFD-20

REAR FINAL DRIVE ASSEMBLY

Disassembly and Assembly

EDS0010E

DISASSEMBLY

Removal of Electronically Controlled Coupling Assembly

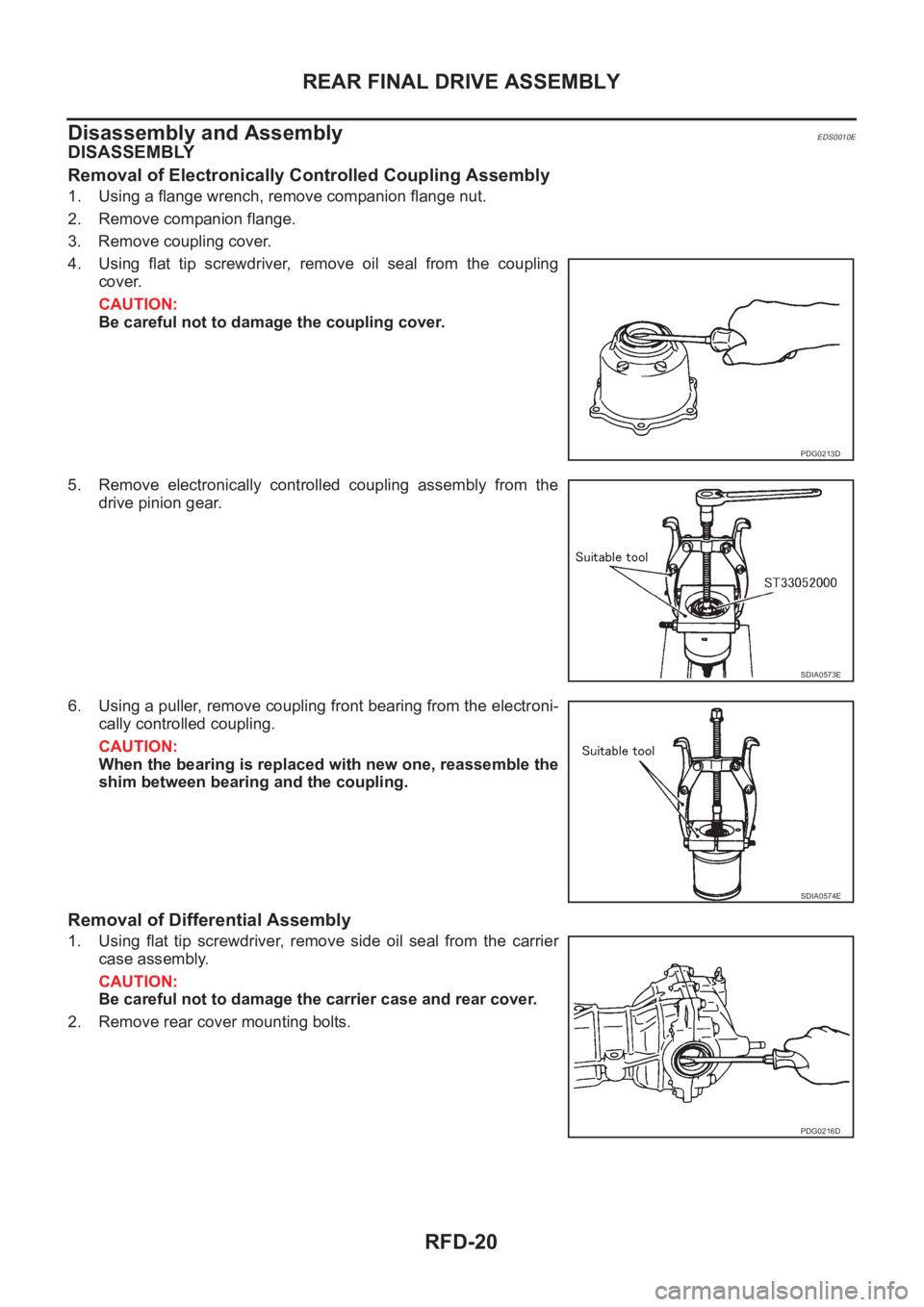

1. Using a flange wrench, remove companion flange nut.

2. Remove companion flange.

3. Remove coupling cover.

4. Using flat tip screwdriver, remove oil seal from the coupling

cover.

CAUTION:

Be careful not to damage the coupling cover.

5. Remove electronically controlled coupling assembly from the

drive pinion gear.

6. Using a puller, remove coupling front bearing from the electroni-

cally controlled coupling.

CAUTION:

When the bearing is replaced with new one, reassemble the

shim between bearing and the coupling.

Removal of Differential Assembly

1. Using flat tip screwdriver, remove side oil seal from the carrier

case assembly.

CAUTION:

Be careful not to damage the carrier case and rear cover.

2. Remove rear cover mounting bolts.

PDG0213D

SDIA0573E

SDIA0574E

PDG0216D

Page 2697 of 3833

REAR FINAL DRIVE ASSEMBLY

RFD-21

C

E

F

G

H

I

J

K

L

MA

B

RFD

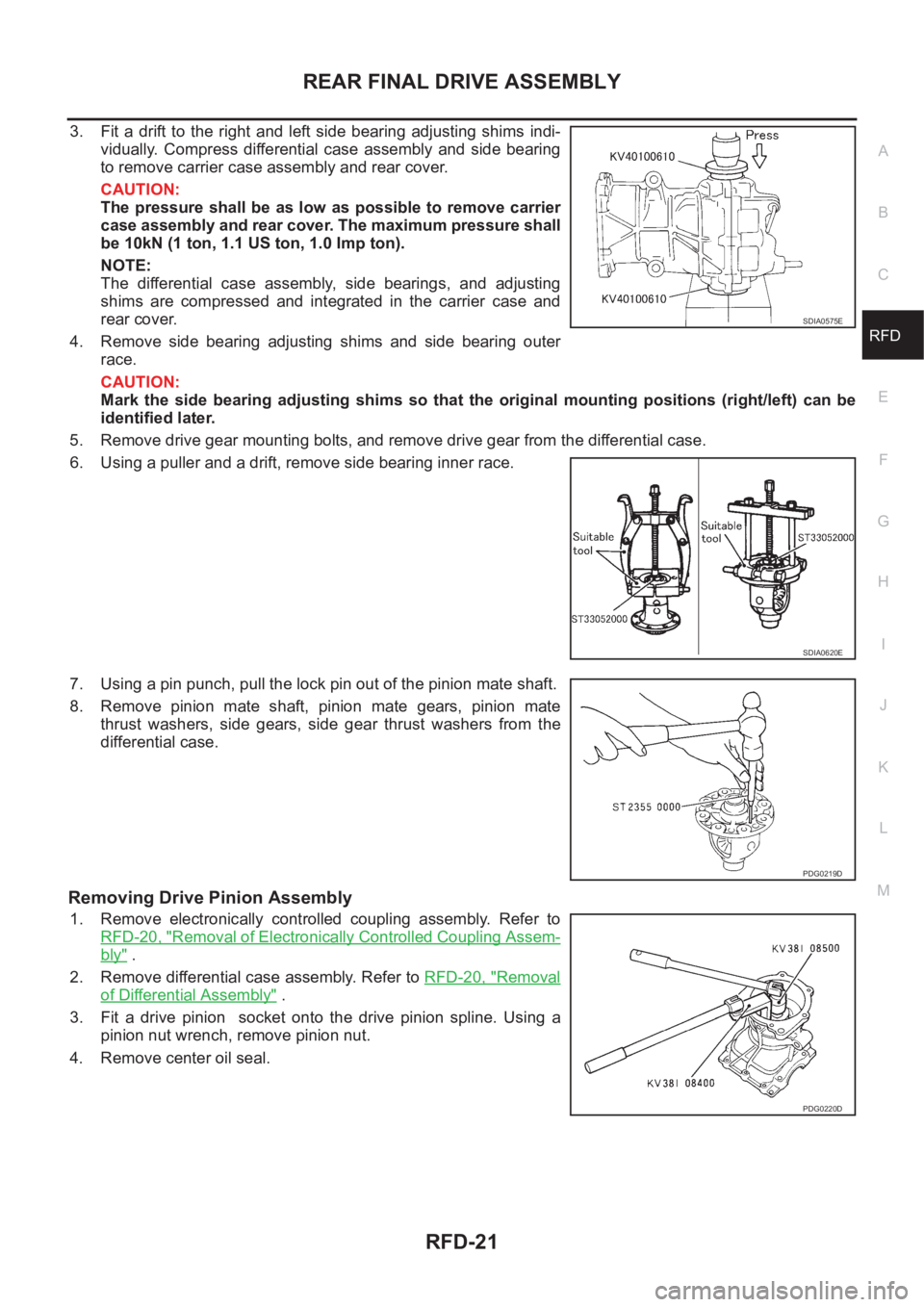

3. Fit a drift to the right and left side bearing adjusting shims indi-

vidually. Compress differential case assembly and side bearing

to remove carrier case assembly and rear cover.

CAUTION:

The pressure shall be as low as possible to remove carrier

case assembly and rear cover. The maximum pressure shall

be 10kN (1 ton, 1.1 US ton, 1.0 Imp ton).

NOTE:

The differential case assembly, side bearings, and adjusting

shims are compressed and integrated in the carrier case and

rear cover.

4. Remove side bearing adjusting shims and side bearing outer

race.

CAUTION:

Mark the side bearing adjusting shims so that the original mounting positions (right/left) can be

identified later.

5. Remove drive gear mounting bolts, and remove drive gear from the differential case.

6. Using a puller and a drift, remove side bearing inner race.

7. Using a pin punch, pull the lock pin out of the pinion mate shaft.

8. Remove pinion mate shaft, pinion mate gears, pinion mate

thrust washers, side gears, side gear thrust washers from the

differential case.

Removing Drive Pinion Assembly

1. Remove electronically controlled coupling assembly. Refer to

RFD-20, "

Removal of Electronically Controlled Coupling Assem-

bly" .

2. Remove differential case assembly. Refer to RFD-20, "

Removal

of Differential Assembly" .

3. Fit a drive pinion socket onto the drive pinion spline. Using a

pinion nut wrench, remove pinion nut.

4. Remove center oil seal.

SDIA0575E

SDIA0620E

PDG0219D

PDG0220D

Page 2698 of 3833

RFD-22

REAR FINAL DRIVE ASSEMBLY

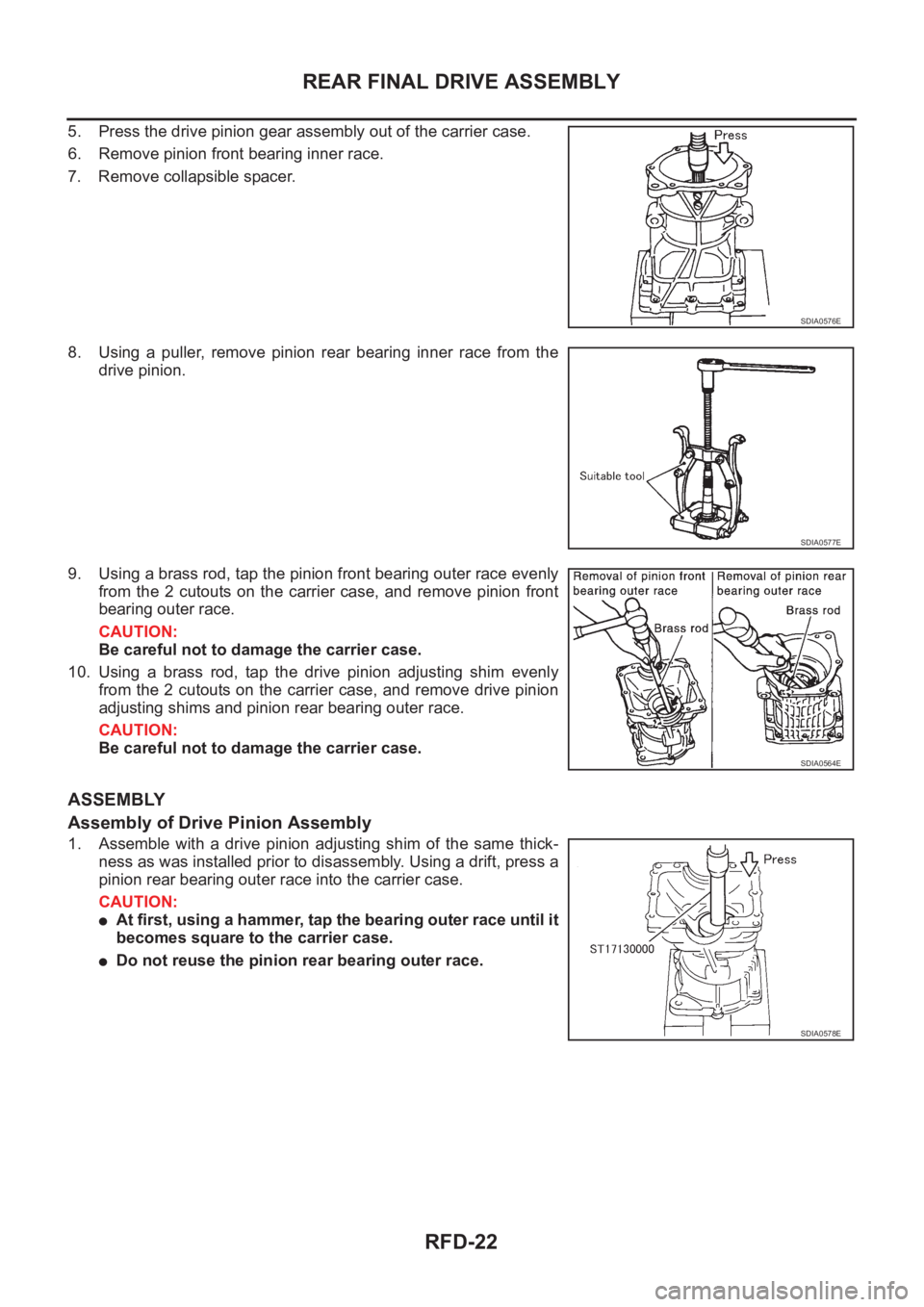

5. Press the drive pinion gear assembly out of the carrier case.

6. Remove pinion front bearing inner race.

7. Remove collapsible spacer.

8. Using a puller, remove pinion rear bearing inner race from the

drive pinion.

9. Using a brass rod, tap the pinion front bearing outer race evenly

from the 2 cutouts on the carrier case, and remove pinion front

bearing outer race.

CAUTION:

Be careful not to damage the carrier case.

10. Using a brass rod, tap the drive pinion adjusting shim evenly

from the 2 cutouts on the carrier case, and remove drive pinion

adjusting shims and pinion rear bearing outer race.

CAUTION:

Be careful not to damage the carrier case.

ASSEMBLY

Assembly of Drive Pinion Assembly

1. Assemble with a drive pinion adjusting shim of the same thick-

ness as was installed prior to disassembly. Using a drift, press a

pinion rear bearing outer race into the carrier case.

CAUTION:

●At first, using a hammer, tap the bearing outer race until it

becomes square to the carrier case.

●Do not reuse the pinion rear bearing outer race.

SDIA0576E

SDIA0577E

SDIA0564E

SDIA0578E

Page 2699 of 3833

REAR FINAL DRIVE ASSEMBLY

RFD-23

C

E

F

G

H

I

J

K

L

MA

B

RFD

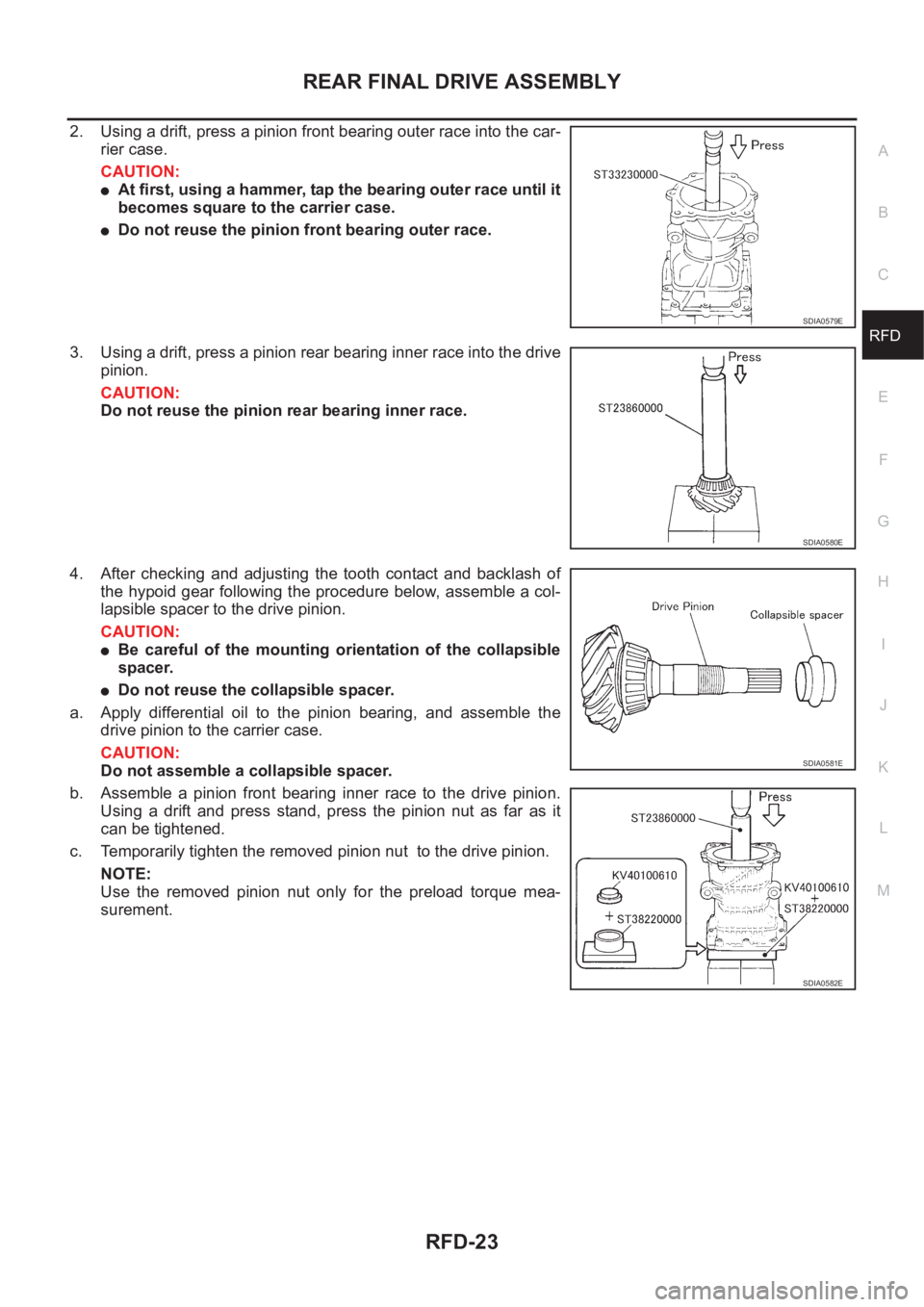

2. Using a drift, press a pinion front bearing outer race into the car-

rier case.

CAUTION:

●At first, using a hammer, tap the bearing outer race until it

becomes square to the carrier case.

●Do not reuse the pinion front bearing outer race.

3. Using a drift, press a pinion rear bearing inner race into the drive

pinion.

CAUTION:

Do not reuse the pinion rear bearing inner race.

4. After checking and adjusting the tooth contact and backlash of

the hypoid gear following the procedure below, assemble a col-

lapsible spacer to the drive pinion.

CAUTION:

●Be careful of the mounting orientation of the collapsible

spacer.

●Do not reuse the collapsible spacer.

a. Apply differential oil to the pinion bearing, and assemble the

drive pinion to the carrier case.

CAUTION:

Do not assemble a collapsible spacer.

b. Assemble a pinion front bearing inner race to the drive pinion.

Using a drift and press stand, press the pinion nut as far as it

can be tightened.

c. Temporarily tighten the removed pinion nut to the drive pinion.

NOTE:

Use the removed pinion nut only for the preload torque mea-

surement.

SDIA0579E

SDIA0580E

SDIA0581E

SDIA0582E

Page 2700 of 3833

RFD-24

REAR FINAL DRIVE ASSEMBLY

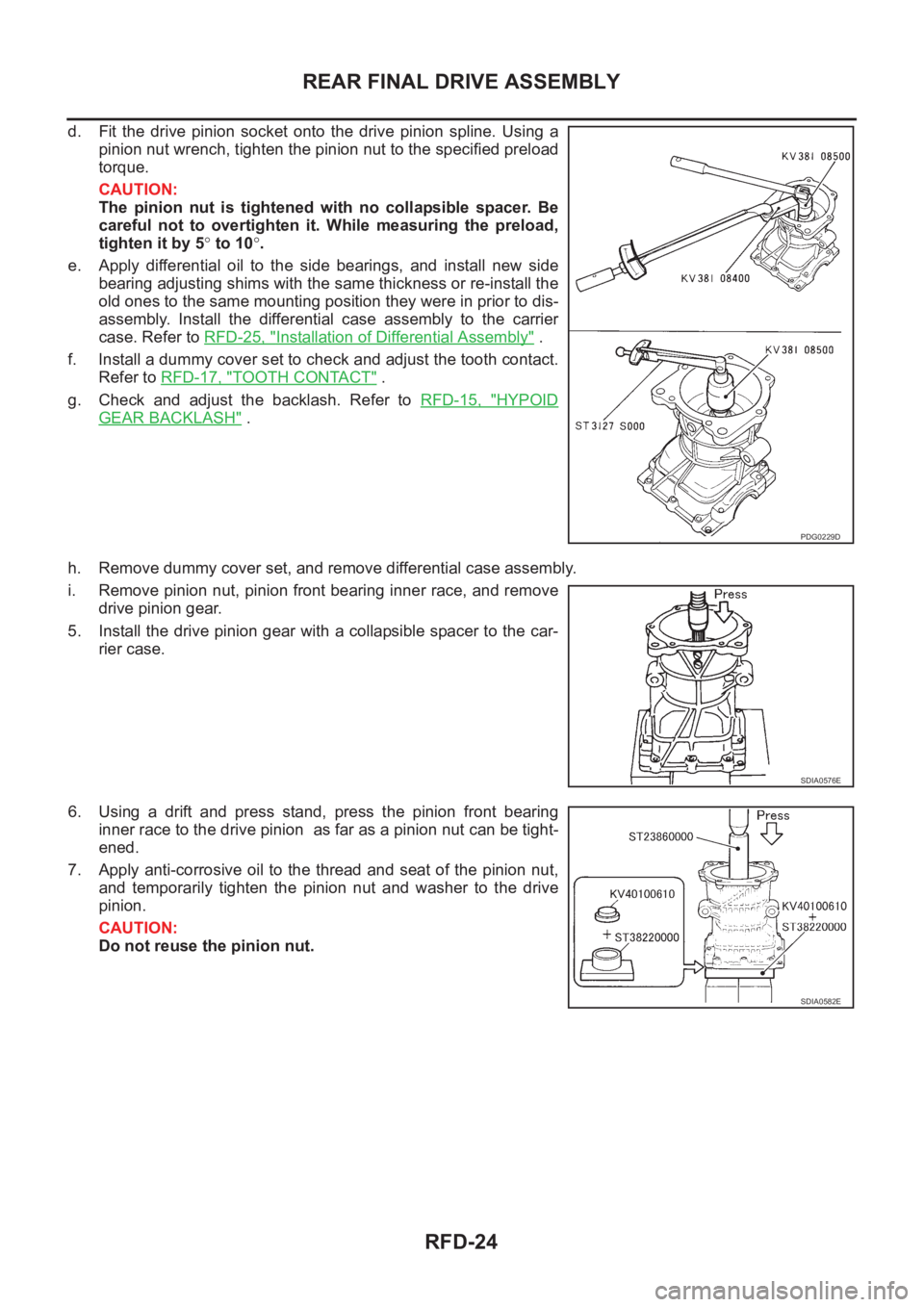

d. Fit the drive pinion socket onto the drive pinion spline. Using a

pinion nut wrench, tighten the pinion nut to the specified preload

torque.

CAUTION:

The pinion nut is tightened with no collapsible spacer. Be

careful not to overtighten it. While measuring the preload,

tighten it by 5° to 10°.

e. Apply differential oil to the side bearings, and install new side

bearing adjusting shims with the same thickness or re-install the

old ones to the same mounting position they were in prior to dis-

assembly. Install the differential case assembly to the carrier

case. Refer to RFD-25, "

Installation of Differential Assembly" .

f. Install a dummy cover set to check and adjust the tooth contact.

Refer to RFD-17, "

TOOTH CONTACT" .

g. Check and adjust the backlash. Refer to RFD-15, "

HYPOID

GEAR BACKLASH" .

h. Remove dummy cover set, and remove differential case assembly.

i. Remove pinion nut, pinion front bearing inner race, and remove

drive pinion gear.

5. Install the drive pinion gear with a collapsible spacer to the car-

rier case.

6. Using a drift and press stand, press the pinion front bearing

inner race to the drive pinion as far as a pinion nut can be tight-

ened.

7. Apply anti-corrosive oil to the thread and seat of the pinion nut,

and temporarily tighten the pinion nut and washer to the drive

pinion.

CAUTION:

Do not reuse the pinion nut.

PDG0229D

SDIA0576E

SDIA0582E