NISSAN X-TRAIL 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 2701 of 3833

REAR FINAL DRIVE ASSEMBLY

RFD-25

C

E

F

G

H

I

J

K

L

MA

B

RFD

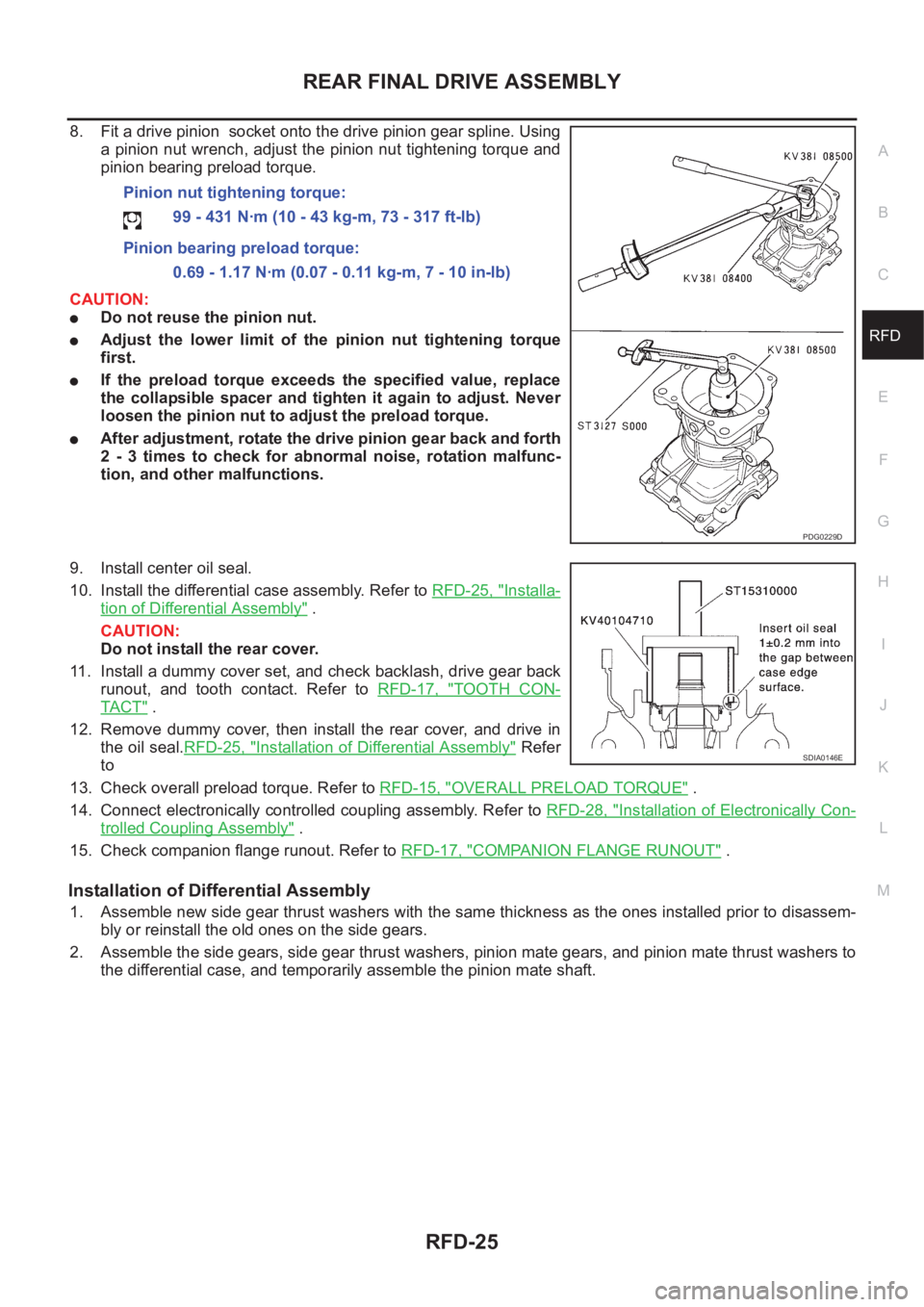

8. Fit a drive pinion socket onto the drive pinion gear spline. Using

a pinion nut wrench, adjust the pinion nut tightening torque and

pinion bearing preload torque.

CAUTION:

●Do not reuse the pinion nut.

●Adjust the lower limit of the pinion nut tightening torque

first.

●If the preload torque exceeds the specified value, replace

the collapsible spacer and tighten it again to adjust. Never

loosen the pinion nut to adjust the preload torque.

●After adjustment, rotate the drive pinion gear back and forth

2 - 3 times to check for abnormal noise, rotation malfunc-

tion, and other malfunctions.

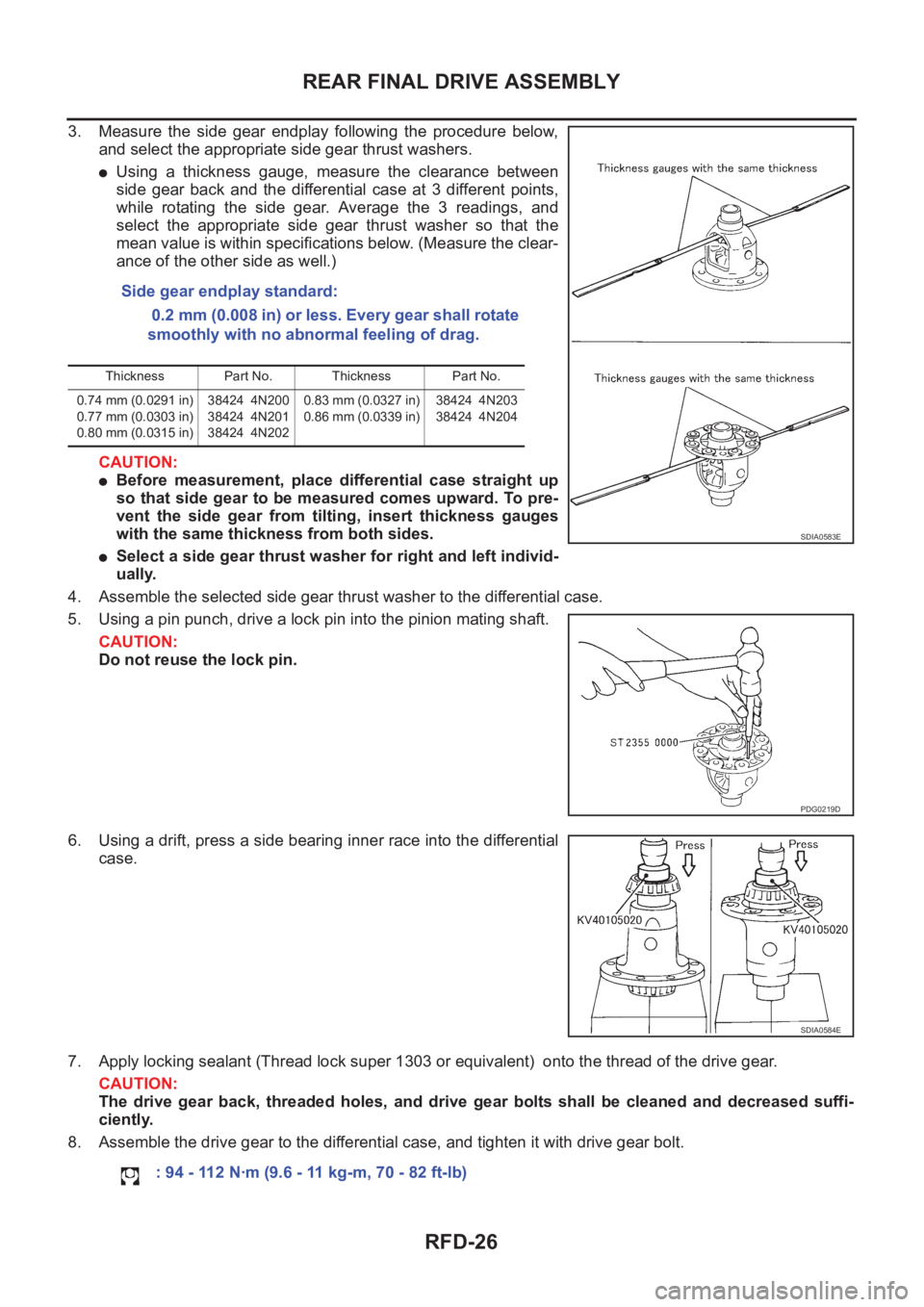

9. Install center oil seal.

10. Install the differential case assembly. Refer to RFD-25, "

Installa-

tion of Differential Assembly" .

CAUTION:

Do not install the rear cover.

11. Install a dummy cover set, and check backlash, drive gear back

runout, and tooth contact. Refer to RFD-17, "

TOOTH CON-

TA C T" .

12. Remove dummy cover, then install the rear cover, and drive in

the oil seal.RFD-25, "

Installation of Differential Assembly" Refer

to

13. Check overall preload torque. Refer to RFD-15, "

OVERALL PRELOAD TORQUE" .

14. Connect electronically controlled coupling assembly. Refer to RFD-28, "

Installation of Electronically Con-

trolled Coupling Assembly" .

15. Check companion flange runout. Refer to RFD-17, "

COMPANION FLANGE RUNOUT" .

Installation of Differential Assembly

1. Assemble new side gear thrust washers with the same thickness as the ones installed prior to disassem-

bly or reinstall the old ones on the side gears.

2. Assemble the side gears, side gear thrust washers, pinion mate gears, and pinion mate thrust washers to

the differential case, and temporarily assemble the pinion mate shaft. Pinion nut tightening torque:

99 - 431 N·m (10 - 43 kg-m, 73 - 317 ft-lb)

Pinion bearing preload torque:

0.69 - 1.17 N·m (0.07 - 0.11 kg-m, 7 - 10 in-lb)

PDG0229D

SDIA0146E

Page 2702 of 3833

RFD-26

REAR FINAL DRIVE ASSEMBLY

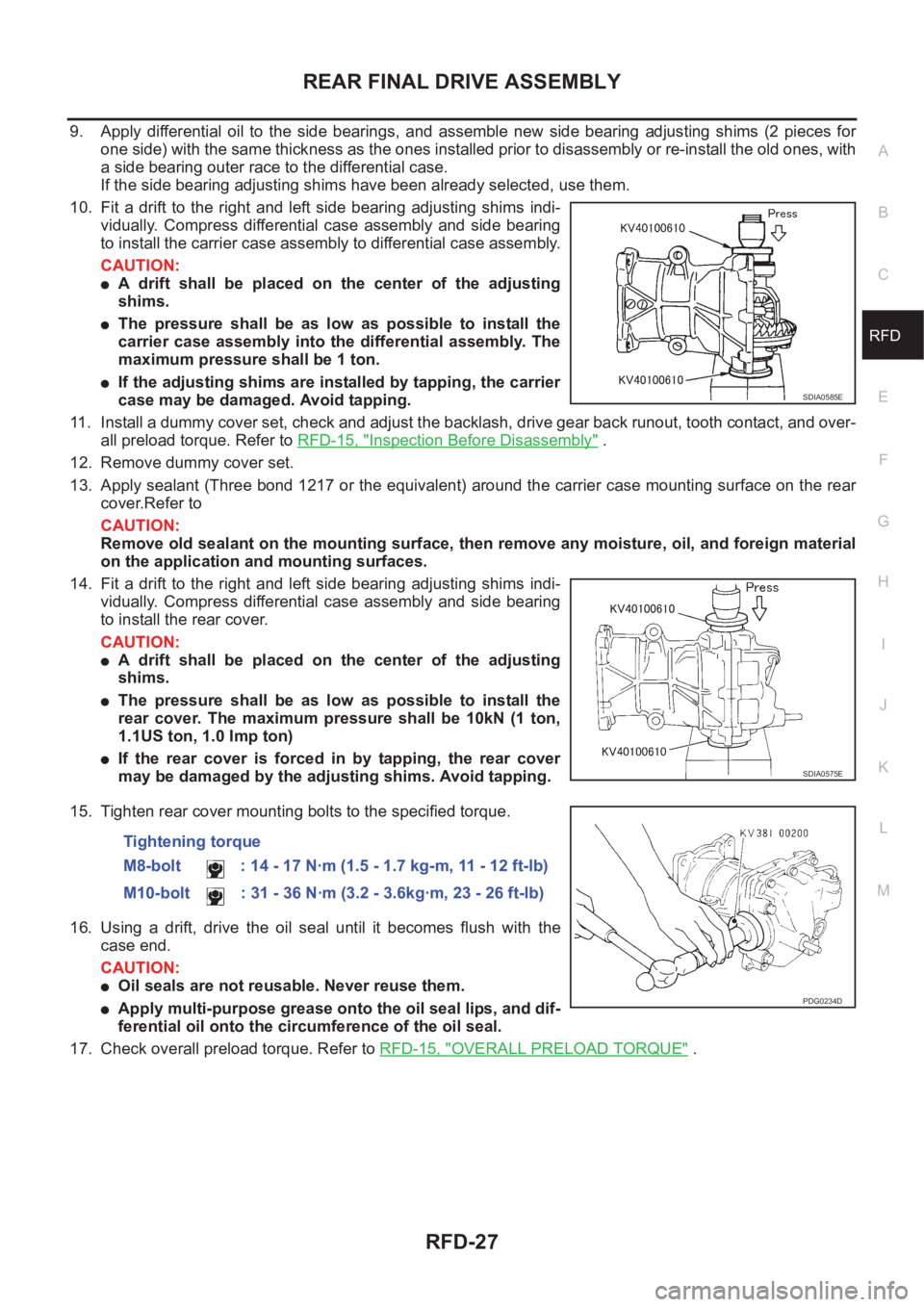

3. Measure the side gear endplay following the procedure below,

and select the appropriate side gear thrust washers.

●Using a thickness gauge, measure the clearance between

side gear back and the differential case at 3 different points,

while rotating the side gear. Average the 3 readings, and

select the appropriate side gear thrust washer so that the

mean value is within specifications below. (Measure the clear-

ance of the other side as well.)

CAUTION:

●Before measurement, place differential case straight up

so that side gear to be measured comes upward. To pre-

vent the side gear from tilting, insert thickness gauges

with the same thickness from both sides.

●Select a side gear thrust washer for right and left individ-

ually.

4. Assemble the selected side gear thrust washer to the differential case.

5. Using a pin punch, drive a lock pin into the pinion mating shaft.

CAUTION:

Do not reuse the lock pin.

6. Using a drift, press a side bearing inner race into the differential

case.

7. Apply locking sealant (Thread lock super 1303 or equivalent) onto the thread of the drive gear.

CAUTION:

The drive gear back, threaded holes, and drive gear bolts shall be cleaned and decreased suffi-

ciently.

8. Assemble the drive gear to the differential case, and tighten it with drive gear bolt. Side gear endplay standard:

0.2 mm (0.008 in) or less. Every gear shall rotate

smoothly with no abnormal feeling of drag.

Thickness Part No. Thickness Part No.

0.74 mm (0.0291 in)

0.77 mm (0.0303 in)

0.80 mm (0.0315 in)38424 4N200

38424 4N201

38424 4N2020.83 mm (0.0327 in)

0.86 mm (0.0339 in)38424 4N203

38424 4N204

SDIA0583E

PDG0219D

SDIA0584E

: 94 - 112 N·m (9.6 - 11 kg-m, 70 - 82 ft-lb)

Page 2703 of 3833

REAR FINAL DRIVE ASSEMBLY

RFD-27

C

E

F

G

H

I

J

K

L

MA

B

RFD

9. Apply differential oil to the side bearings, and assemble new side bearing adjusting shims (2 pieces for

one side) with the same thickness as the ones installed prior to disassembly or re-install the old ones, with

a side bearing outer race to the differential case.

If the side bearing adjusting shims have been already selected, use them.

10. Fit a drift to the right and left side bearing adjusting shims indi-

vidually. Compress differential case assembly and side bearing

to install the carrier case assembly to differential case assembly.

CAUTION:

●A drift shall be placed on the center of the adjusting

shims.

●The pressure shall be as low as possible to install the

carrier case assembly into the differential assembly. The

maximum pressure shall be 1 ton.

●If the adjusting shims are installed by tapping, the carrier

case may be damaged. Avoid tapping.

11. Install a dummy cover set, check and adjust the backlash, drive gear back runout, tooth contact, and over-

all preload torque. Refer to RFD-15, "

Inspection Before Disassembly" .

12. Remove dummy cover set.

13. Apply sealant (Three bond 1217 or the equivalent) around the carrier case mounting surface on the rear

cover.Refer to

CAUTION:

Remove old sealant on the mounting surface, then remove any moisture, oil, and foreign material

on the application and mounting surfaces.

14. Fit a drift to the right and left side bearing adjusting shims indi-

vidually. Compress differential case assembly and side bearing

to install the rear cover.

CAUTION:

●A drift shall be placed on the center of the adjusting

shims.

●The pressure shall be as low as possible to install the

rear cover. The maximum pressure shall be 10kN (1 ton,

1.1US ton, 1.0 Imp ton)

●If the rear cover is forced in by tapping, the rear cover

may be damaged by the adjusting shims. Avoid tapping.

15. Tighten rear cover mounting bolts to the specified torque.

16. Using a drift, drive the oil seal until it becomes flush with the

case end.

CAUTION:

●Oil seals are not reusable. Never reuse them.

●Apply multi-purpose grease onto the oil seal lips, and dif-

ferential oil onto the circumference of the oil seal.

17. Check overall preload torque. Refer to RFD-15, "

OVERALL PRELOAD TORQUE" .

SDIA0585E

SDIA0575E

Tightening torque

M8-bolt : 14 - 17 N·m (1.5 - 1.7 kg-m, 11 - 12 ft-lb)

M10-bolt : 31 - 36 N·m (3.2 - 3.6kg·m, 23 - 26 ft-lb)

PDG0234D

Page 2704 of 3833

RFD-28

REAR FINAL DRIVE ASSEMBLY

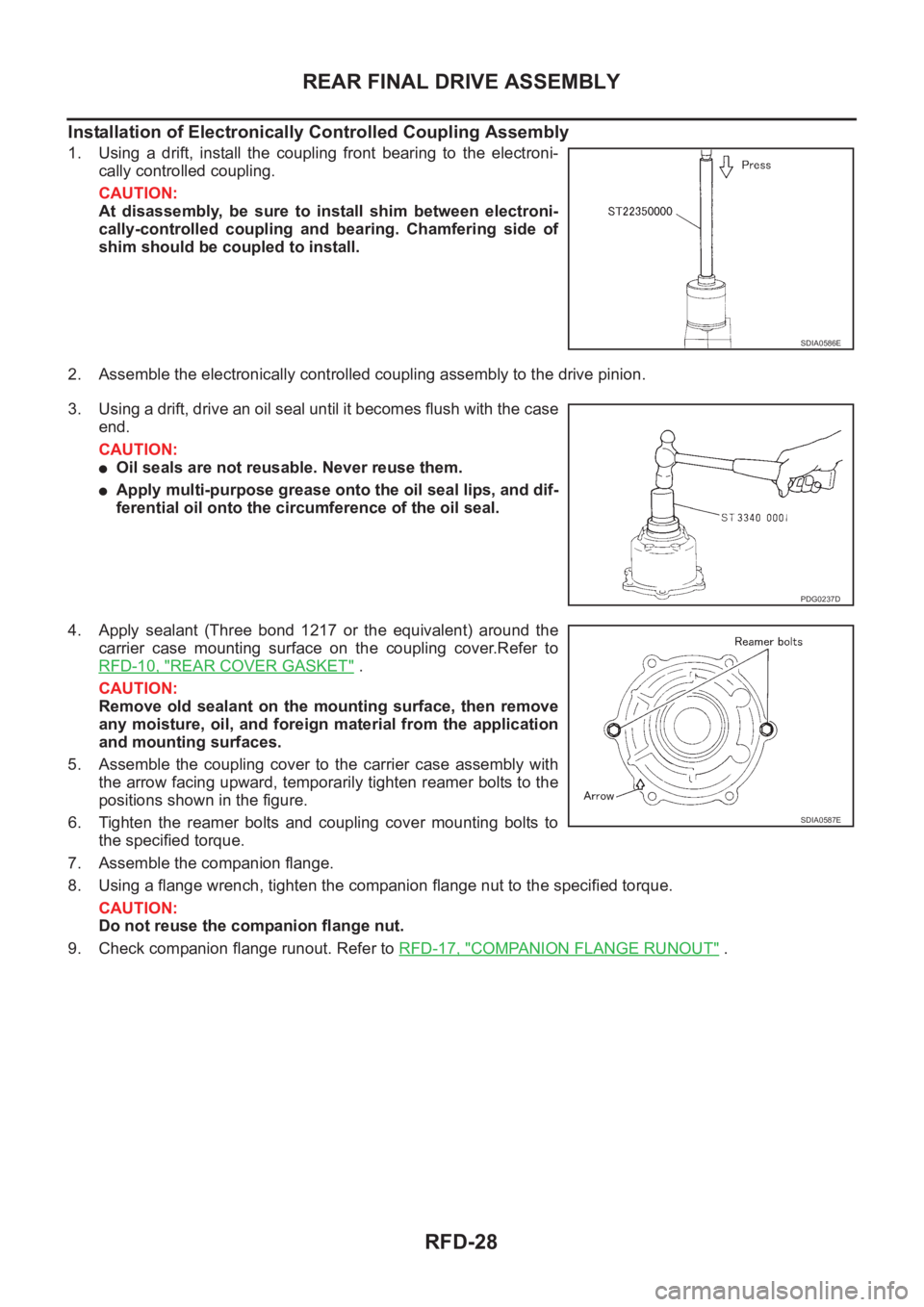

Installation of Electronically Controlled Coupling Assembly

1. Using a drift, install the coupling front bearing to the electroni-

cally controlled coupling.

CAUTION:

At disassembly, be sure to install shim between electroni-

cally-controlled coupling and bearing. Chamfering side of

shim should be coupled to install.

2. Assemble the electronically controlled coupling assembly to the drive pinion.

3. Using a drift, drive an oil seal until it becomes flush with the case

end.

CAUTION:

●Oil seals are not reusable. Never reuse them.

●Apply multi-purpose grease onto the oil seal lips, and dif-

ferential oil onto the circumference of the oil seal.

4. Apply sealant (Three bond 1217 or the equivalent) around the

carrier case mounting surface on the coupling cover.Refer to

RFD-10, "

REAR COVER GASKET" .

CAUTION:

Remove old sealant on the mounting surface, then remove

any moisture, oil, and foreign material from the application

and mounting surfaces.

5. Assemble the coupling cover to the carrier case assembly with

the arrow facing upward, temporarily tighten reamer bolts to the

positions shown in the figure.

6. Tighten the reamer bolts and coupling cover mounting bolts to

the specified torque.

7. Assemble the companion flange.

8. Using a flange wrench, tighten the companion flange nut to the specified torque.

CAUTION:

Do not reuse the companion flange nut.

9. Check companion flange runout. Refer to RFD-17, "

COMPANION FLANGE RUNOUT" .

SDIA0586E

PDG0237D

SDIA0587E

Page 2705 of 3833

SERVICE DATA AND SPECIFICATIONS (SDS)

RFD-29

C

E

F

G

H

I

J

K

L

MA

B

RFD

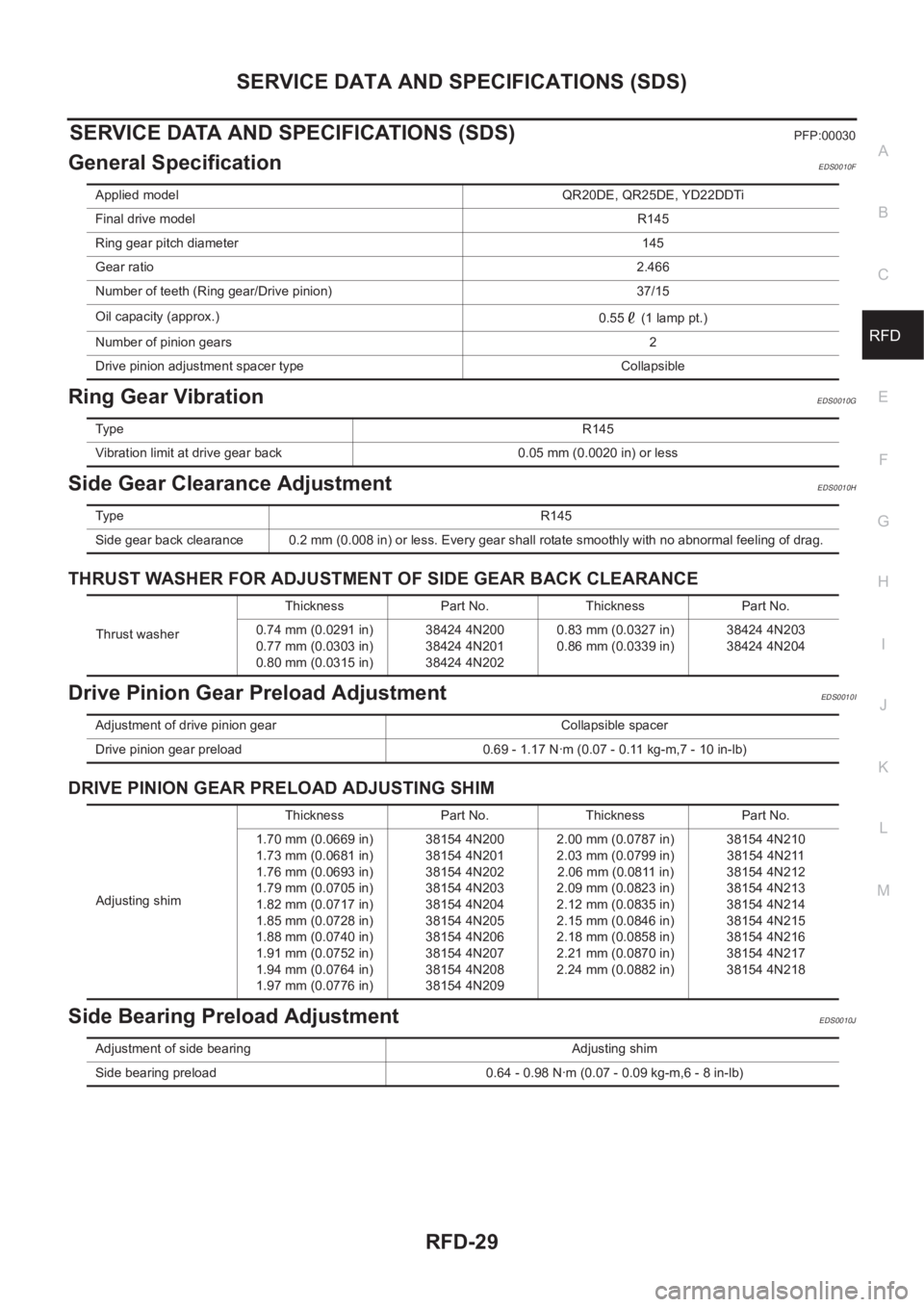

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationEDS0010F

Ring Gear VibrationEDS0010G

Side Gear Clearance AdjustmentEDS0010H

THRUST WASHER FOR ADJUSTMENT OF SIDE GEAR BACK CLEARANCE

Drive Pinion Gear Preload AdjustmentEDS0010I

DRIVE PINION GEAR PRELOAD ADJUSTING SHIM

Side Bearing Preload AdjustmentEDS0010J

Applied model QR20DE, QR25DE, YD22DDTi

Final drive modelR145

Ring gear pitch diameter 145

Gear ratio2.466

Number of teeth (Ring gear/Drive pinion) 37/15

Oil capacity (approx.)

0.55 (1 lamp pt.)

Number of pinion gears2

Drive pinion adjustment spacer type Collapsible

Ty p eR145

Vibration limit at drive gear back 0.05 mm (0.0020 in) or less

Ty p e R 1 4 5

Side gear back clearance 0.2 mm (0.008 in) or less. Every gear shall rotate smoothly with no abnormal feeling of drag.

Thrust washerThickness Part No. Thickness Part No.

0.74 mm (0.0291 in)

0.77 mm (0.0303 in)

0.80 mm (0.0315 in)38424 4N200

38424 4N201

38424 4N2020.83 mm (0.0327 in)

0.86 mm (0.0339 in)38424 4N203

38424 4N204

Adjustment of drive pinion gear Collapsible spacer

Drive pinion gear preload 0.69 - 1.17 N·m (0.07 - 0.11 kg-m,7 - 10 in-lb)

Adjusting shimThickness Part No. Thickness Part No.

1.70 mm (0.0669 in)

1.73 mm (0.0681 in)

1.76 mm (0.0693 in)

1.79 mm (0.0705 in)

1.82 mm (0.0717 in)

1.85 mm (0.0728 in)

1.88 mm (0.0740 in)

1.91 mm (0.0752 in)

1.94 mm (0.0764 in)

1.97 mm (0.0776 in)38154 4N200

38154 4N201

38154 4N202

38154 4N203

38154 4N204

38154 4N205

38154 4N206

38154 4N207

38154 4N208

38154 4N2092.00 mm (0.0787 in)

2.03 mm (0.0799 in)

2.06 mm (0.0811 in)

2.09 mm (0.0823 in)

2.12 mm (0.0835 in)

2.15 mm (0.0846 in)

2.18 mm (0.0858 in)

2.21 mm (0.0870 in)

2.24 mm (0.0882 in)38154 4N210

38154 4N211

38154 4N212

38154 4N213

38154 4N214

38154 4N215

38154 4N216

38154 4N217

38154 4N218

Adjustment of side bearing Adjusting shim

Side bearing preload 0.64 - 0.98 N·m (0.07 - 0.09 kg-m,6 - 8 in-lb)

Page 2706 of 3833

RFD-30

SERVICE DATA AND SPECIFICATIONS (SDS)

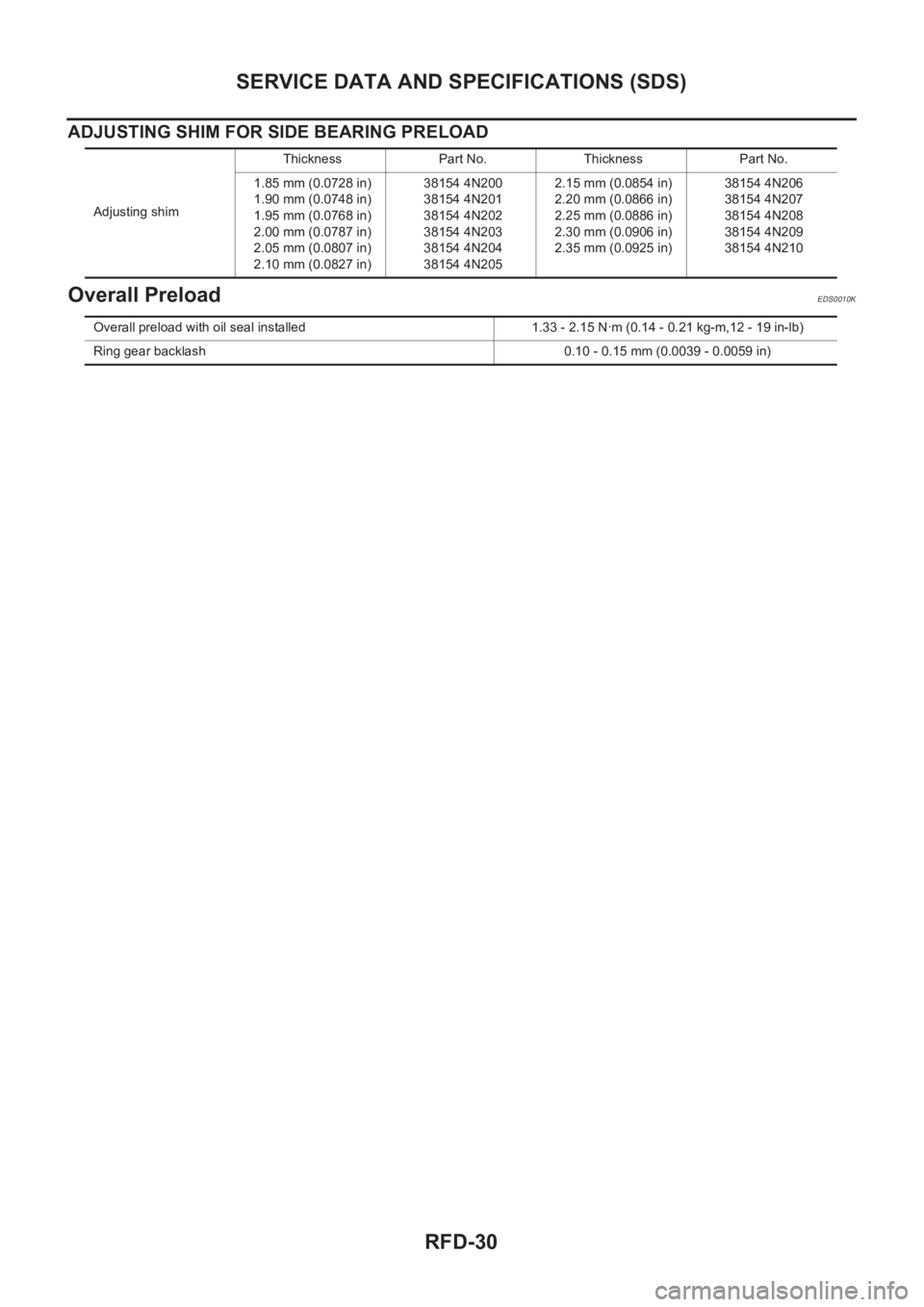

ADJUSTING SHIM FOR SIDE BEARING PRELOAD

Overall PreloadEDS0010K

Adjusting shimThickness Part No. Thickness Part No.

1.85 mm (0.0728 in)

1.90 mm (0.0748 in)

1.95 mm (0.0768 in)

2.00 mm (0.0787 in)

2.05 mm (0.0807 in)

2.10 mm (0.0827 in)38154 4N200

38154 4N201

38154 4N202

38154 4N203

38154 4N204

38154 4N2052.15 mm (0.0854 in)

2.20 mm (0.0866 in)

2.25 mm (0.0886 in)

2.30 mm (0.0906 in)

2.35 mm (0.0925 in)38154 4N206

38154 4N207

38154 4N208

38154 4N209

38154 4N210

Overall preload with oil seal installed 1.33 - 2.15 N·m (0.14 - 0.21 kg-m,12 - 19 in-lb)

Ring gear backlash 0.10 - 0.15 mm (0.0039 - 0.0059 in)

Page 2707 of 3833

FSU-1

FRONT SUSPENSION

E SUSPENSION

CONTENTS

C

D

F

G

H

I

J

K

L

M

SECTION

A

B

FSU

FRONT SUSPENSION

PRECAUTIONS .......................................................... 2

Caution ..................................................................... 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 4

NVH Troubleshooting Chart ..................................... 4

FRONT SUSPENSION ASSEMBLY ........................... 5

Components ............................................................. 5

On-Vehicle Inspection and Service .......................... 6

LOOSENESS, BACKLASH AND DAMAGE OF

MOUNTING PARTS AND CONNECTIONS .......... 6

Wheel Alignment ...................................................... 6

DESCRIPTION ...................................................... 6

PRELIMINARY INSPECTION ............................... 6

INSPECTION OF CAMBER, CASTER, AND

KINGPIN INCLINATION ANGLES ........................ 6

STEERING ANGLE INSPECTION ........................ 7

COIL SPRING AND SHOCK ABSORBER ................. 8

Removal and Installation .......................................... 8

REMOVAL ............................................................. 8INSTALLATION ..................................................... 8

Disassembly and Assembly ...................................... 8

DISASSEMBLY ..................................................... 8

INSPECTION AFTER DISASSEMBLY .................. 8

ASSEMBLY ........................................................... 9

TRANSVERSE LINK ................................................. 10

Removal and Installation ........................................ 10

REMOVAL ........................................................... 10

INSPECTION AFTER REMOVAL ....................... 10

INSTALLATION ................................................... 10

STABILIZER BAR ..................................................... 11

Removal and Installation ........................................ 11

REMOVAL ........................................................... 11

INSPECTION AFTER REMOVAL ....................... 11

INSTALLATION ................................................... 11

FRONT SUSPENSION MEMBER ............................. 12

Removal and Installation ........................................ 12

REMOVAL ........................................................... 12

INSTALLATION ................................................... 12

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 13

General Specification ............................................. 13

Wheel Alignment (Unladen) .................................... 13

Ball Joint ................................................................. 13

Wheelarch Height (Unladen) .................................. 13

Page 2708 of 3833

FSU-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

CautionEES0006Z

●When installing rubber bushings, final tightening must be carried out under unladen conditions with tires

on flat, level ground. Oil will shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

●“Unladen condition” means that fuel, coolant and lubricant are full and ready for drive. However, spare tire,

jack, and hand tools should be unloaded.

●After installing the removed suspension parts, always check wheel alignment and adjust if necessary.

●Replace the caulking nut with a new one. Install a new nut without wiping the oil off before tightening.

Page 2709 of 3833

PREPARATION

FSU-3

C

D

F

G

H

I

J

K

L

MA

B

FSU

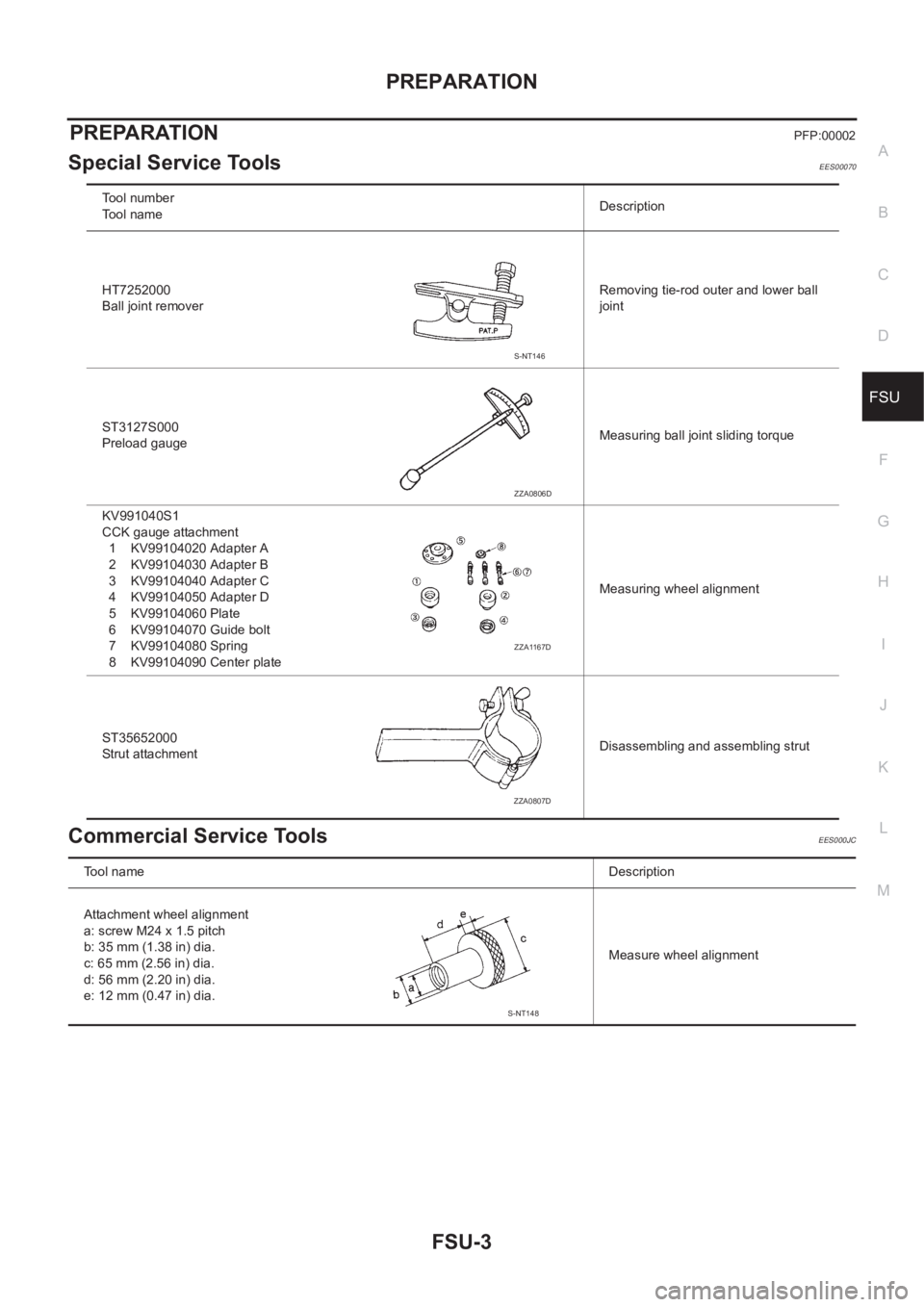

PREPARATIONPFP:00002

Special Service ToolsEES00070

Commercial Service ToolsEES000JC

Tool number

Tool nameDescription

HT7252000

Ball joint removerRemoving tie-rod outer and lower ball

joint

ST3127S000

Preload gaugeMeasuring ball joint sliding torque

KV991040S1

CCK gauge attachment

1 KV99104020 Adapter A

2 KV99104030 Adapter B

3 KV99104040 Adapter C

4 KV99104050 Adapter D

5 KV99104060 Plate

6 KV99104070 Guide bolt

7 KV99104080 Spring

8 KV99104090 Center plateMeasuring wheel alignment

ST35652000

Strut attachmentDisassembling and assembling strut

S-NT146

ZZA0806D

ZZA1167D

ZZA0807D

To o l n a m eDescription

Attachment wheel alignment

a: screw M24 x 1.5 pitch

b: 35 mm (1.38 in) dia.

c: 65 mm (2.56 in) dia.

d: 56 mm (2.20 in) dia.

e: 12 mm (0.47 in) dia.Measure wheel alignment

S-NT148

Page 2710 of 3833

FSU-4

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

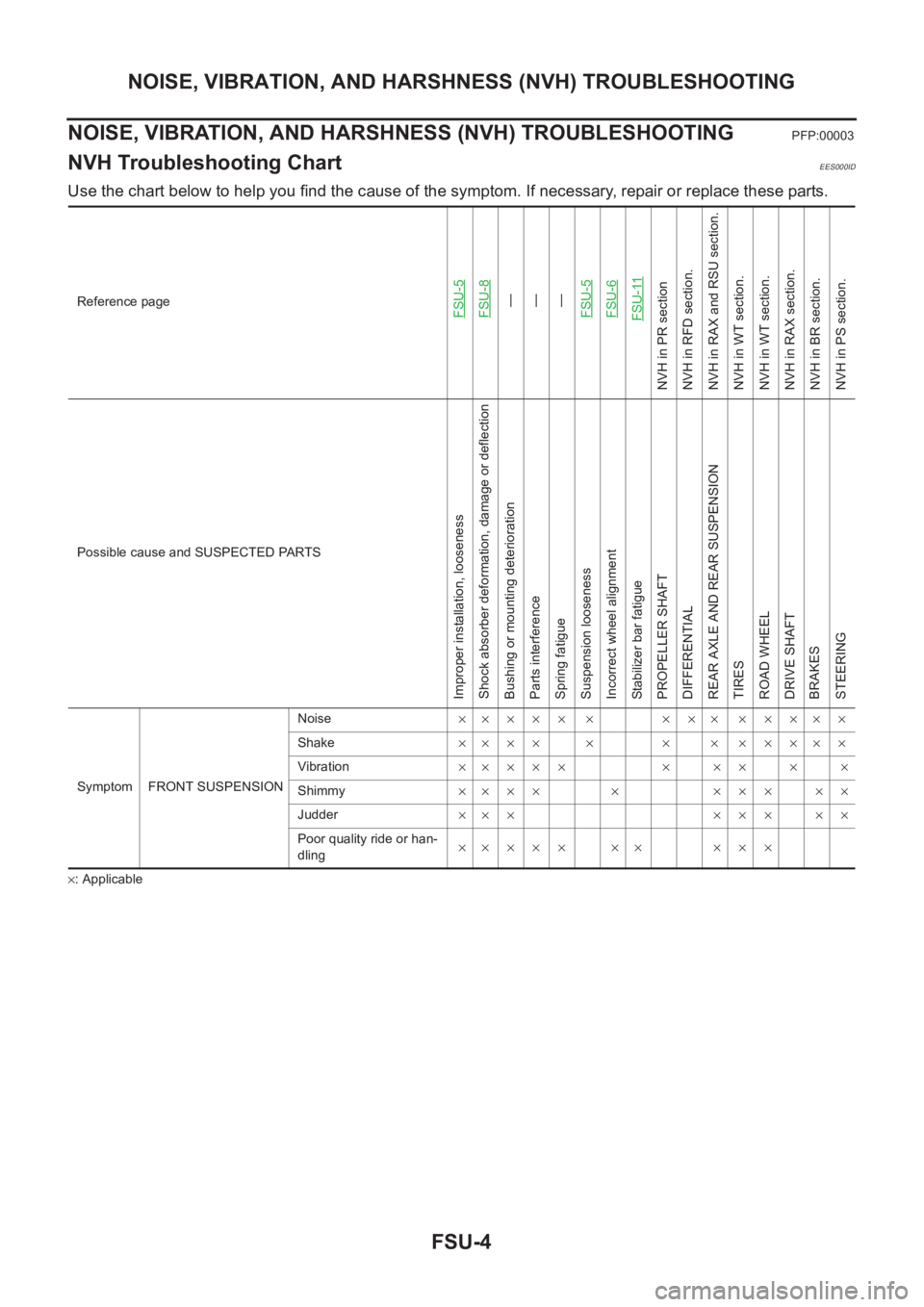

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

NVH Troubleshooting ChartEES000ID

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

FSU-5FSU-8—

—

—

FSU-5FSU-6FSU-11

NVH in PR section

NVH in RFD section.

NVH in RAX and RSU section.

NVH in WT section.

NVH in WT section.

NVH in RAX section.

NVH in BR section.

NVH in PS section.

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Stabilizer bar fatigue

PROPELLER SHAFT

DIFFERENTIAL

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

Symptom FRONT SUSPENSIONNoise××××× × ××× ×××××

Shake×××× × × × ×××××

Vibration××××× × ×× × ×

Shimmy×××× × ××× ××

Judder××× ××× ××

Poor quality ride or han-

dling×× × × × ×× × × ×