NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2531 of 3066

CHASSIS AND BODY MAINTENANCE

MA-39

C

D

E

F

G

H

I

J

K

MA

B

MA

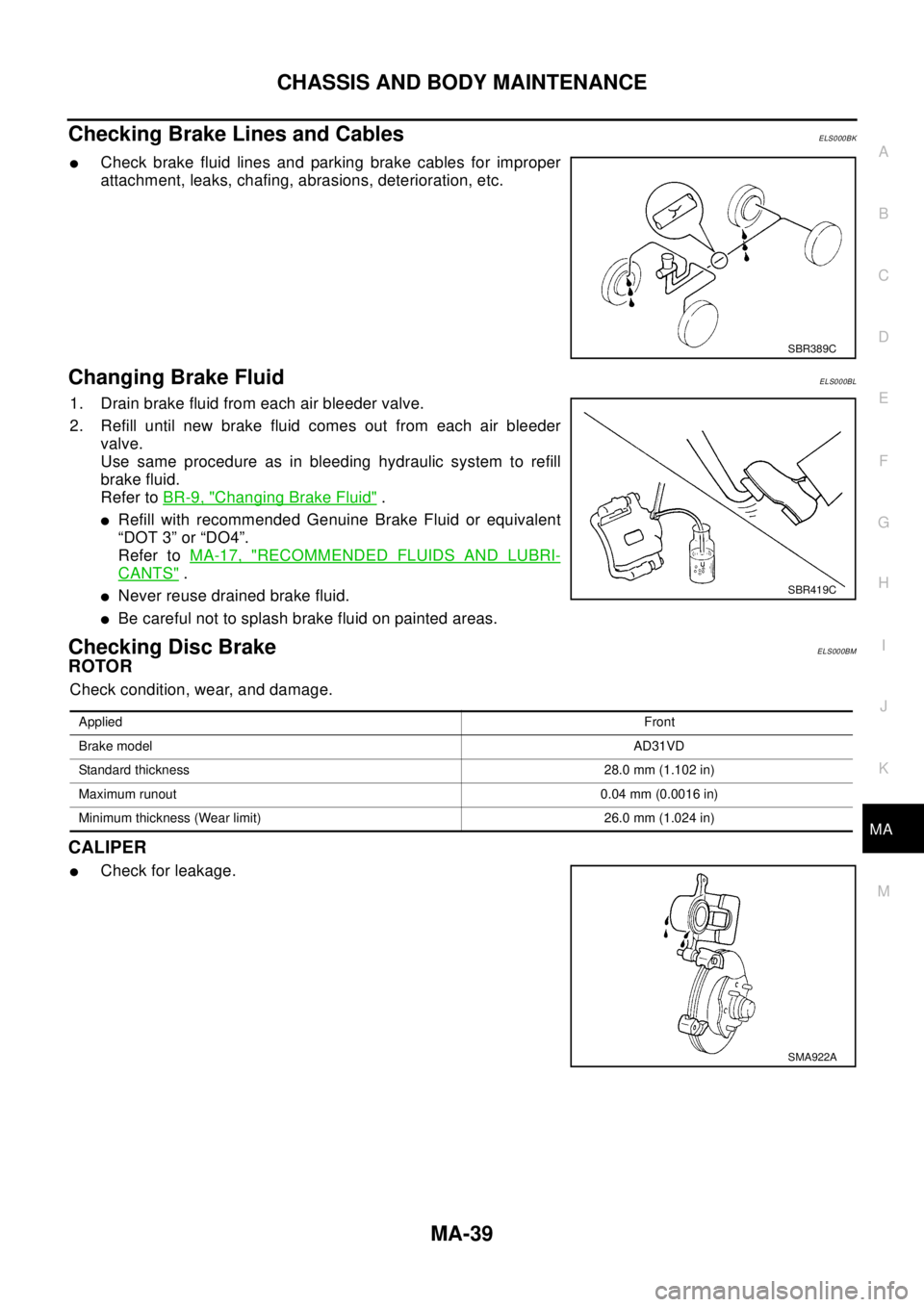

Checking Brake Lines and CablesELS000BK

lCheck brake fluid lines and parking brake cables for improper

attachment, leaks, chafing, abrasions, deterioration, etc.

Changing Brake FluidELS000BL

1. Drain brake fluid from each air bleeder valve.

2. Refill until new brake fluid comes out from each air bleeder

valve.

Use same procedure as in bleeding hydraulic system to refill

brake fluid.

Refer toBR-9, "

Changing Brake Fluid".

lRefill with recommended Genuine Brake Fluid or equivalent

“DOT 3” or “DO4”.

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS".

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.

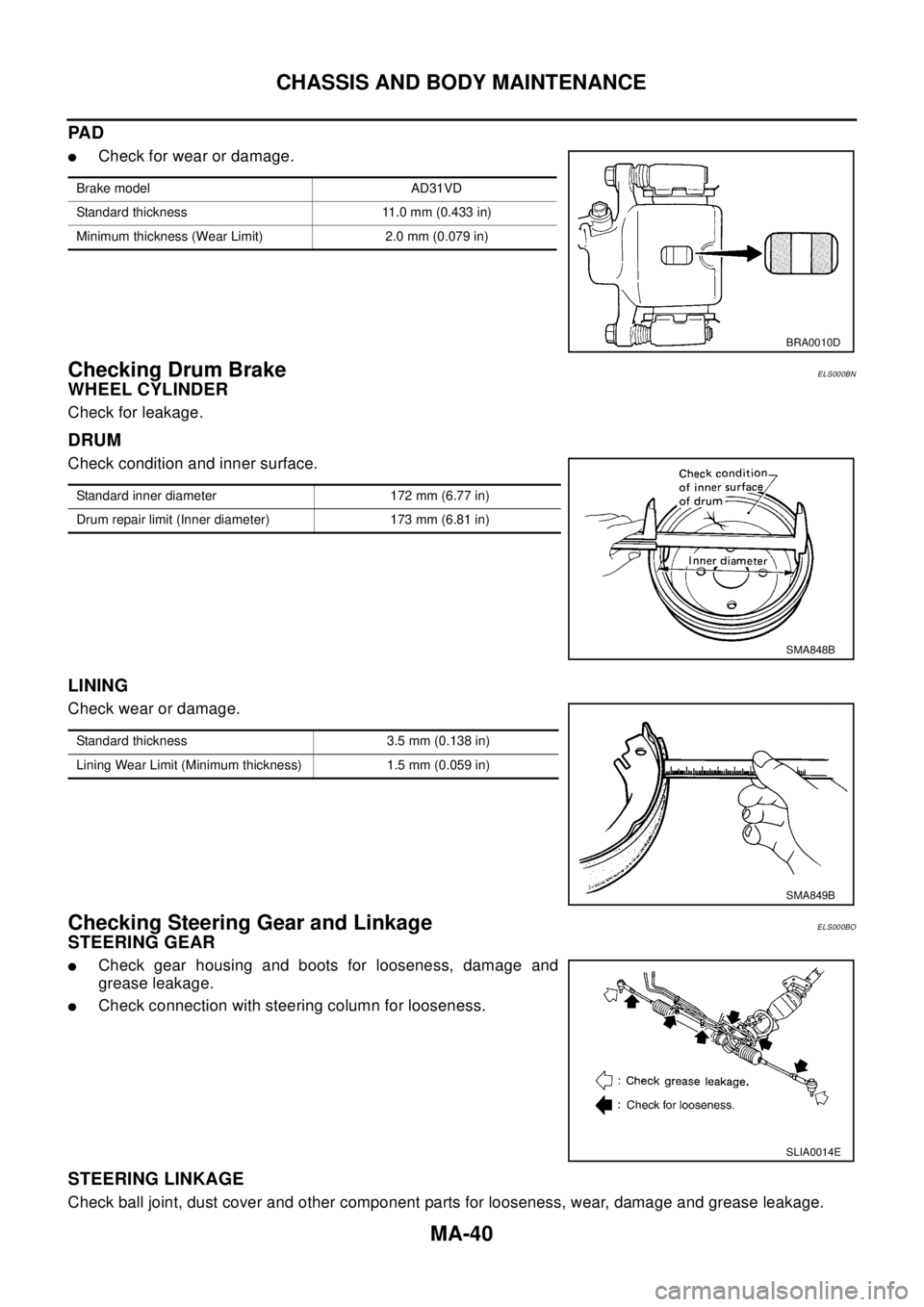

Checking Disc BrakeELS000BM

ROTOR

Check condition, wear, and damage.

CALIPER

lCheck for leakage.

SBR389C

SBR419C

AppliedFront

Brake modelAD31VD

Standard thickness 28.0 mm (1.102 in)

Maximum runout0.04 mm (0.0016 in)

Minimum thickness (Wear limit) 26.0 mm (1.024 in)

SMA922A

Page 2532 of 3066

MA-40

CHASSIS AND BODY MAINTENANCE

PA D

lCheck for wear or damage.

Checking Drum BrakeELS000BN

WHEEL CYLINDER

Check for leakage.

DRUM

Check condition and inner surface.

LINING

Check wear or damage.

Checking Steering Gear and LinkageELS000BO

STEERING GEAR

lCheck gear housing and boots for looseness, damage and

grease leakage.

lCheck connection with steering column for looseness.

STEERING LINKAGE

Check ball joint, dust cover and other component parts for looseness, wear, damage and grease leakage.

Brake model AD31VD

Standard thickness 11.0 mm (0.433 in)

Minimum thickness (Wear Limit) 2.0 mm (0.079 in)

BRA0010D

Standard inner diameter 172 mm (6.77 in)

Drum repair limit (Inner diameter) 173 mm (6.81 in)

SMA848B

Standard thickness 3.5 mm (0.138 in)

Lining Wear Limit (Minimum thickness) 1.5 mm (0.059 in)

SMA849B

SLIA0014E

Page 2533 of 3066

CHASSIS AND BODY MAINTENANCE

MA-41

C

D

E

F

G

H

I

J

K

MA

B

MA

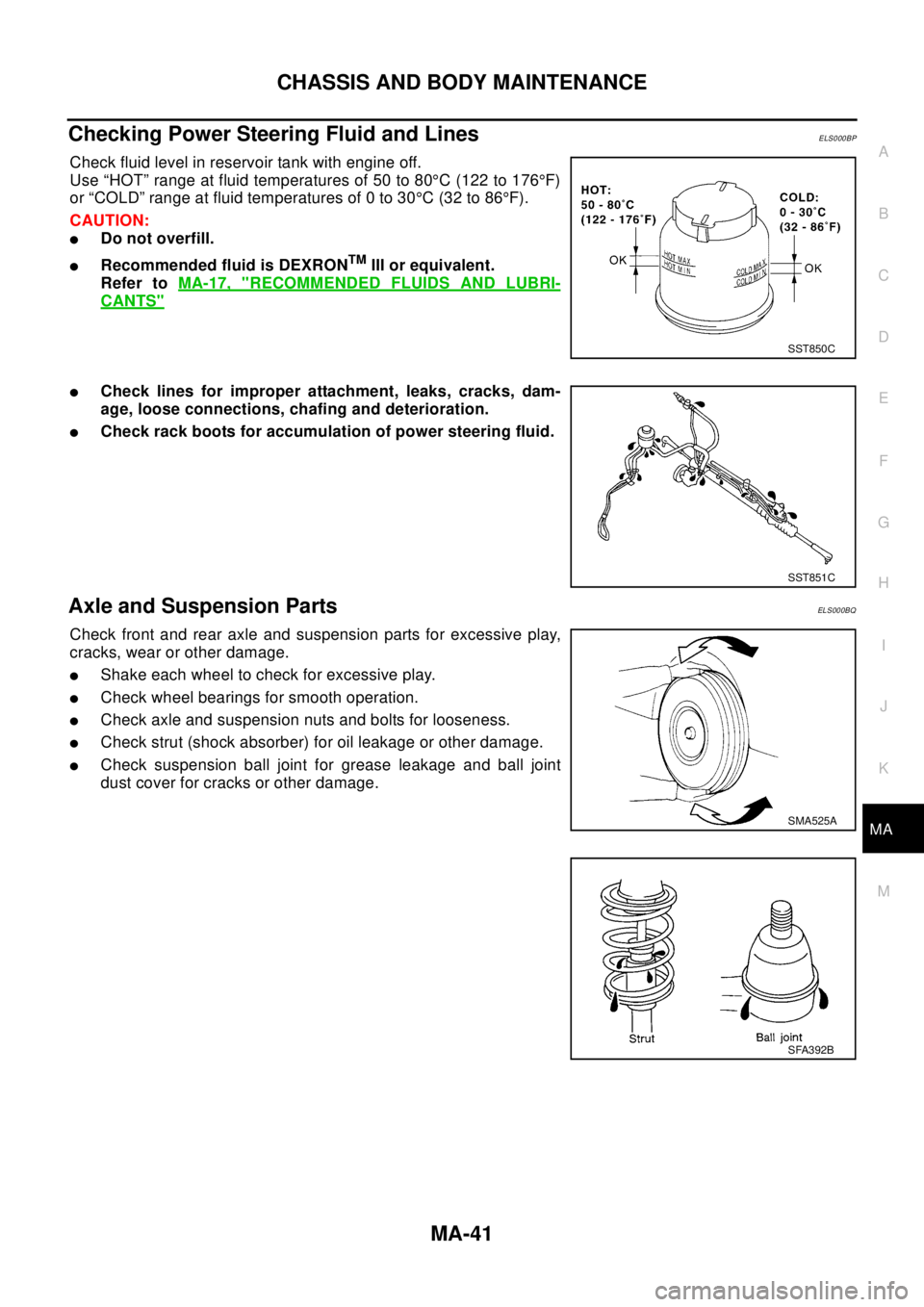

Checking Power Steering Fluid and LinesELS000BP

Check fluid level in reservoir tank with engine off.

Use “HOT” range at fluid temperatures of 50 to 80°C (122 to 176°F)

or “COLD” range at fluid temperatures of 0 to 30°C(32to86°F).

CAUTION:

lDo not overfill.

lRecommended fluid is DEXRONTMIII or equivalent.

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS"

lCheck lines for improper attachment, leaks, cracks, dam-

age, loose connections, chafing and deterioration.

lCheck rack boots for accumulation of power steering fluid.

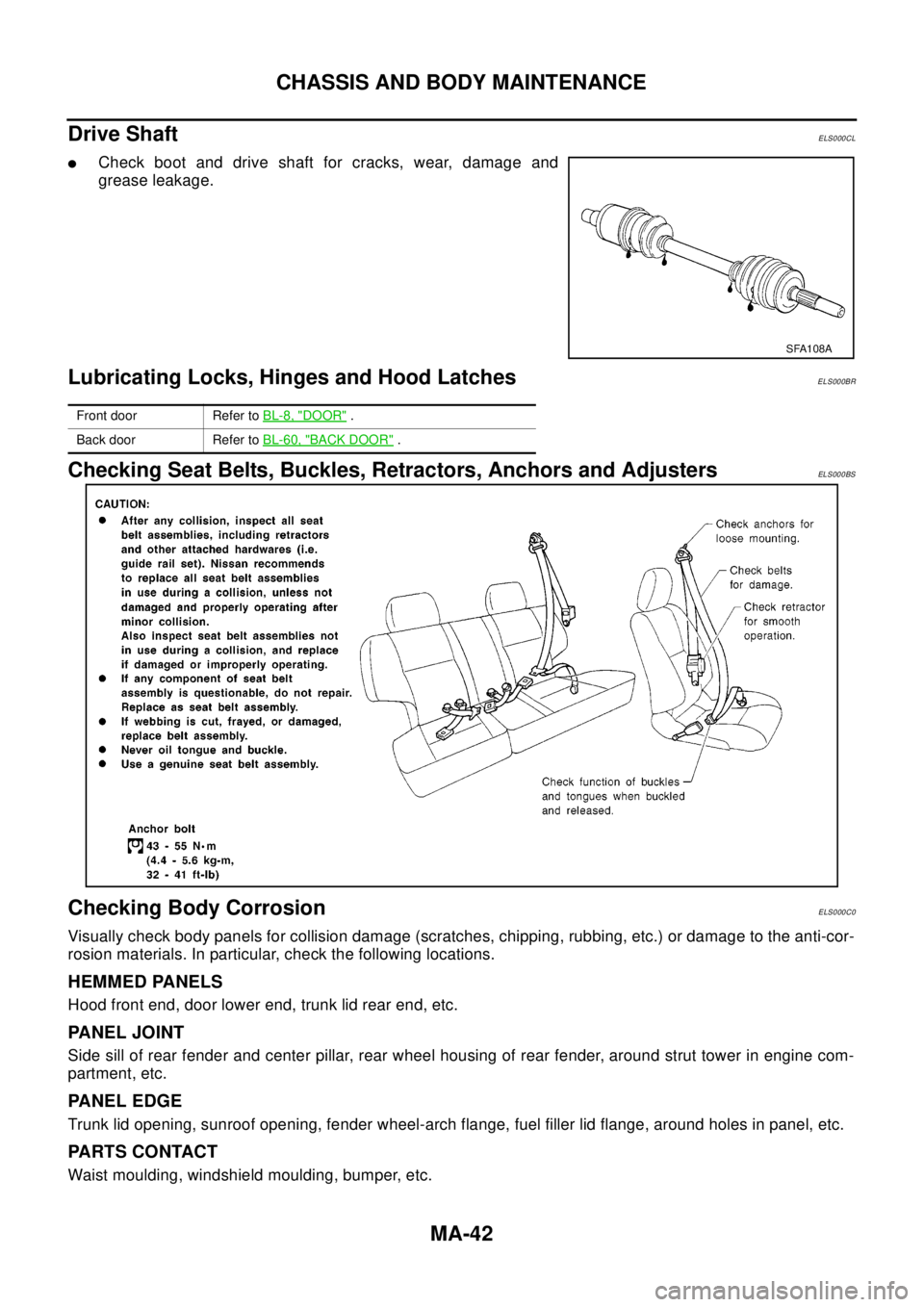

Axle and Suspension PartsELS000BQ

Check front and rear axle and suspension parts for excessive play,

cracks, wear or other damage.

lShake each wheel to check for excessive play.

lCheck wheel bearings for smooth operation.

lCheck axle and suspension nuts and bolts for looseness.

lCheck strut (shock absorber) for oil leakage or other damage.

lCheck suspension ball joint for grease leakage and ball joint

dust cover for cracks or other damage.

SST850C

SST851C

SMA525A

SFA392B

Page 2534 of 3066

MA-42

CHASSIS AND BODY MAINTENANCE

Drive Shaft

ELS000CL

lCheck boot and drive shaft for cracks, wear, damage and

grease leakage.

Lubricating Locks, Hinges and Hood LatchesELS000BR

Checking Seat Belts, Buckles, Retractors, Anchors and AdjustersELS000BS

Checking Body CorrosionELS000C0

Visually check body panels for collision damage (scratches, chipping, rubbing, etc.) or damage to the anti-cor-

rosion materials. In particular, check the following locations.

HEMMED PANELS

Hood front end, door lower end, trunk lid rear end, etc.

PANEL JOINT

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine com-

partment, etc.

PANEL EDGE

Trunk lid opening, sunroof opening, fender wheel-arch flange, fuel filler lid flange, around holes in panel, etc.

PA R T S C O N TA C T

Waist moulding, windshield moulding, bumper, etc.

SFA108A

Front door Refer toBL-8, "DOOR".

Back door Refer toBL-60, "

BACK DOOR".

Page 2535 of 3066

CHASSIS AND BODY MAINTENANCE

MA-43

C

D

E

F

G

H

I

J

K

MA

B

MA

PROTECTORS

Damage or condition of mudguard, fender protector, chipping protector, etc.

ANTI-CORROSION MATERIALS

Damage or separation of anti-corrosion materials under the body.

DRAIN HOLES

Condition of drain holes at door and side sill. When repairing corroded areas, refer to the Corrosion Repair

Manual.

Page 2536 of 3066

MA-44

SERVICE DATA AND SPECIFICATIONS (SDS)

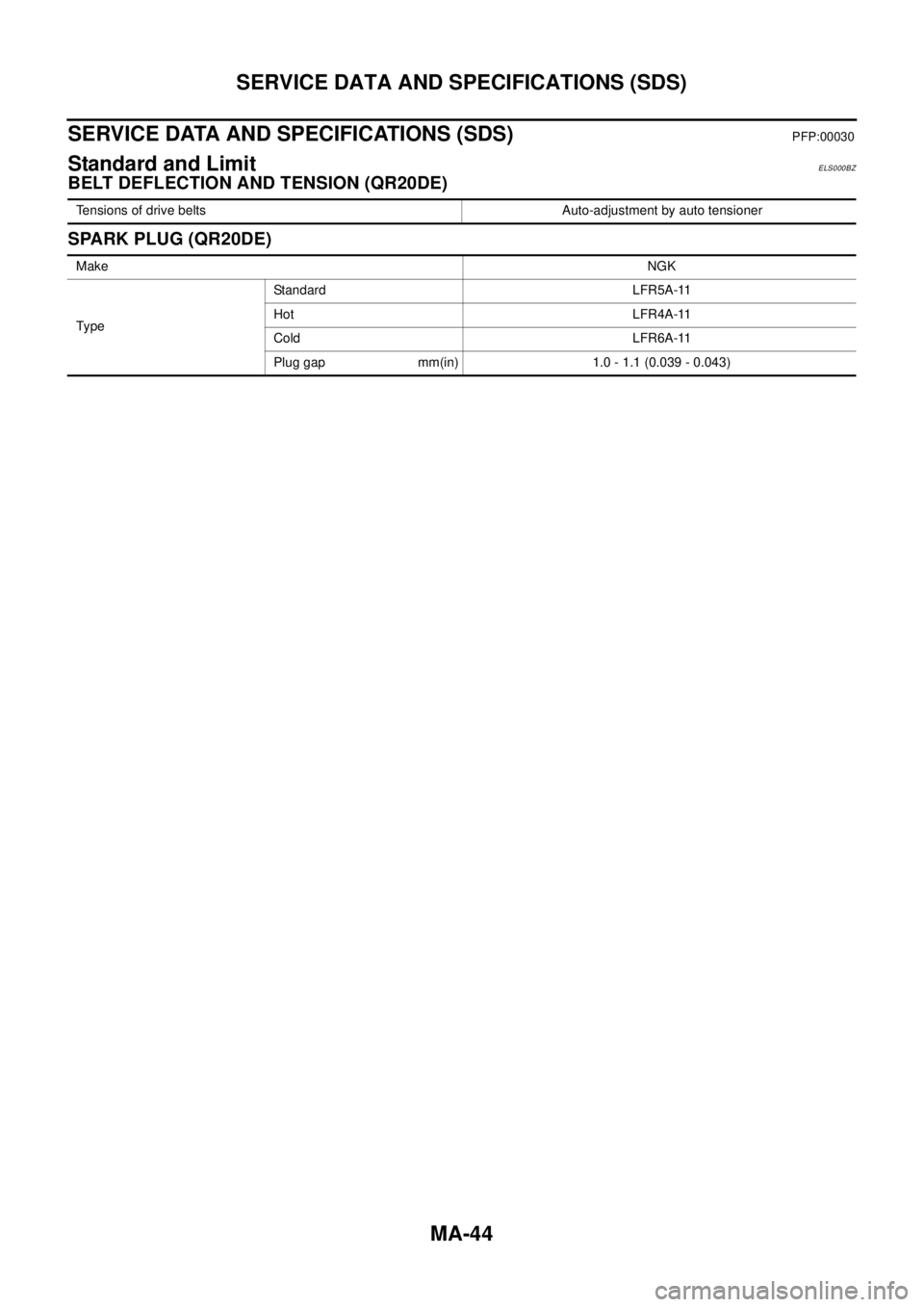

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitELS000BZ

BELT DEFLECTION AND TENSION (QR20DE)

SPARK PLUG (QR20DE)

Tensions of drive belts Auto-adjustment by auto tensioner

MakeNGK

Ty peStandard LFR5A-11

Hot LFR4A-11

Cold LFR6A-11

Plug gap mm(in) 1.0 - 1.1 (0.039 - 0.043)

Page 2537 of 3066

MT-1

MANUAL TRANSAXLE

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTION

A

B

MT

MANUAL TRANSAXLE

PRECAUTIONS .......................................................... 3

Caution ..................................................................... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 6

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 8

NVH Troubleshooting Chart ..................................... 8

MANUAL TRANSAXLE ......................................... 8

DESCRIPTION ............................................................ 9

Cross-sectional View ................................................ 9

DOUBLE-CONE SYNCHRONIZER .................... 10

REVERSE GEAR NOISE PREVENTION FUNC-

TION (SYNCHRONIZING METHOD) ................. 10

M/T OIL ......................................................................11

Changing M/T Oil ....................................................11

DRAINING ............................................................11

FILLING ................................................................11

Checking M/T Oil .....................................................11

OIL LEAKAGE AND OIL LEVEL ..........................11

SIDE OIL SEAL ........................................................ 12

Removal and Installation ........................................ 12

REMOVAL ........................................................... 12

INSTALLATION ................................................... 12

POSITION SWITCH .................................................. 13

Checking ................................................................ 13

BACK-UP LAMP SWITCH .................................. 13

PARK/NEUTRAL POSITION SWITCH ............... 13

CONTROL LINKAGE ............................................... 14

Removal and Installation of Control Device and

Cable ...................................................................... 14

AIR BREATHER HOSE ............................................ 15

Removal and Installation ........................................ 15

TRANSAXLE ASSEMBLY ........................................ 16

Removal and Installation ........................................ 16

REMOVAL ........................................................... 16

INSTALLATION ................................................... 17

Component Parts (RS5F51A) ................................ 18CASE AND HOUSING COMPONENTS .............. 18

GEAR COMPONENTS ....................................... 19

SHIFT CONTROL COMPONENTS ..................... 21

FINAL DRIVE COMPONENTS ........................... 22

Component Parts (RS6F51A) ................................. 23

CASE AND HOUSING COMPONENTS .............. 23

GEAR COMPONENTS ....................................... 24

SHIFT CONTROL COMPONENTS ..................... 26

FINAL DRIVE COMPONENTS ........................... 27

Disassembly and Assembly (RS5F51A) ................. 27

DISASSEMBLY ................................................... 27

ASSEMBLY ......................................................... 30

Disassembly and Assembly (RS6F51A) ................. 35

DISASSEMBLY ................................................... 35

ASSEMBLY ......................................................... 39

Adjustment (RS5F51A) ........................................... 44

INPUTSHAFT END PLAY ................................... 44

DIFFERENTIAL SIDE BEARING PRELOAD ...... 45

MAINSHAFT END PLAY ..................................... 46

REVERSE IDLER GEAR END PLAY .................. 47

Adjustment (RS6F51A) ........................................... 48

INPUTSHAFT END PLAY ................................... 48

DIFFERENTIAL SIDE BEARING PRELOAD ...... 49

MAINSHAFT END PLAY ..................................... 51

REVERSE IDLER GEAR END PLAY .................. 52

INPUT SHAFT AND GEARS .................................... 53

Assembly and Disassembly (RS5F51A) ................. 53

DISASSEMBLY ................................................... 53

INSPECTION AFTER DISASSEMBLY ................ 54

ASSEMBLY ......................................................... 55

Assembly and Disassembly (RS6F51A) ................. 60

DISASSEMBLY ................................................... 60

INSPECTION AFTER DISASSEMBLY ................ 61

ASSEMBLY ......................................................... 62

MAINSHAFT AND GEARS ....................................... 67

Assembly and Disassembly (RS5F51A) ................. 67

DISASSEMBLY ................................................... 67

INSPECTION AFTER DISASSEMBLY ................ 68

Page 2538 of 3066

MT-2

ASSEMBLY ......................................................... 70

Assembly and Disassembly (RS6F51A) ................. 74

DISASSEMBLY ................................................... 74

INSPECTION AFTER DISASSEMBLY ................ 76

ASSEMBLY ......................................................... 77

REVERSE IDLER SHAFT AND GEARS .................. 83

Assembly and Disassembly (RS5F51A) ................. 83

DISASSEMBLY ................................................... 83

INSPECTION AFTER DISASSEMBLY ................ 83

ASSEMBLY ......................................................... 84

Assembly and Disassembly (RS6F51A) ................. 84

DISASSEMBLY ................................................... 84

INSPECTION AFTER DISASSEMBLY ................ 84

ASSEMBLY ......................................................... 85

FINAL DRIVE ............................................................ 86

Assembly and Disassembly (RS5F51A) ................. 86

PRE-INSPECTION .............................................. 86

DISASSEMBLY ................................................... 86

INSPECTION AFTER DISASSEMBLY ................ 87

ASSEMBLY ......................................................... 87

Assembly and Disassembly (RS6F51A) ................. 89

PRE-INSPECTION .............................................. 89

DISASSEMBLY ................................................... 90

INSPECTION AFTER DISASSEMBLY ................ 91

ASSEMBLY ......................................................... 91

SHIFT CONTROL ...................................................... 94

Inspection (RS5F51A) ............................................ 94

SHIFT FORK ....................................................... 94

Inspection (RS6F51A) ............................................ 95

SHIFT FORK ....................................................... 95SERVICE DATA AND SPECIFICATIONS (SDS) ......96

General Specifications ............................................96

TRANSAXLE ........................................................96

FINAL GEAR ........................................................97

Gear End Play .........................................................97

Clearance Between Baulk Ring and Gear ..............97

3RD,4TH,5TH,6TH & REVERSE BAULK RING... 97

1ST AND 2ND DOUBLE BAULK RING ...............97

Available Snap Rings ..............................................98

INPUT SHAFT SPACER ......................................98

5TH MAIN GEAR .................................................98

Available C-rings .....................................................98

MAINSHAFT C-RING ..........................................98

Available Thrust Washer .........................................98

INPUT SHAFT THRUST WASHER .....................98

DIFFERENTIALSIDE GEAR THRUST WASHER

...99

Available Adjusting Shims .......................................99

MAINSHAFT ADJUSTING SHIM .........................99

INPUT SAFT REAR BEARING ADJUSTING

SHIM ....................................................................99

MAINSAFT REAR BEARING ADJUSTING SHIM.100

REVERASE IDLER GEAR ADJUSTING SHIM . 100

6TH MAIN GEAR ADJUSTING SHIM ................ 100

Available Shims .................................................... 100

BEARING PRELOAD ......................................... 100

DIFFERENTIAL SIDE BEARING ADJUSTING

SHIM(S) ............................................................. 100

Page 2539 of 3066

PRECAUTIONS

MT-3

D

E

F

G

H

I

J

K

L

MA

B

MT

PRECAUTIONSPFP:00001

CautionECS001WO

lDo not reuse transaxle oil, once it has been drained.

lCheck oil level or replace oil with vehicle on level ground.

lDuring removal or installation, keep inside of transaxle clear of dust or dirt.

lCheck for the correct installation status prior to removal or disassembly. If mating marks are required, be

certain they do not interfere with the function of the parts they are applied to.

lIn principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, observe it.

lBe careful not to damage sliding surfaces and mating surfaces.

Page 2540 of 3066

MT-4

PREPARATION

PREPARATION

PFP:00002

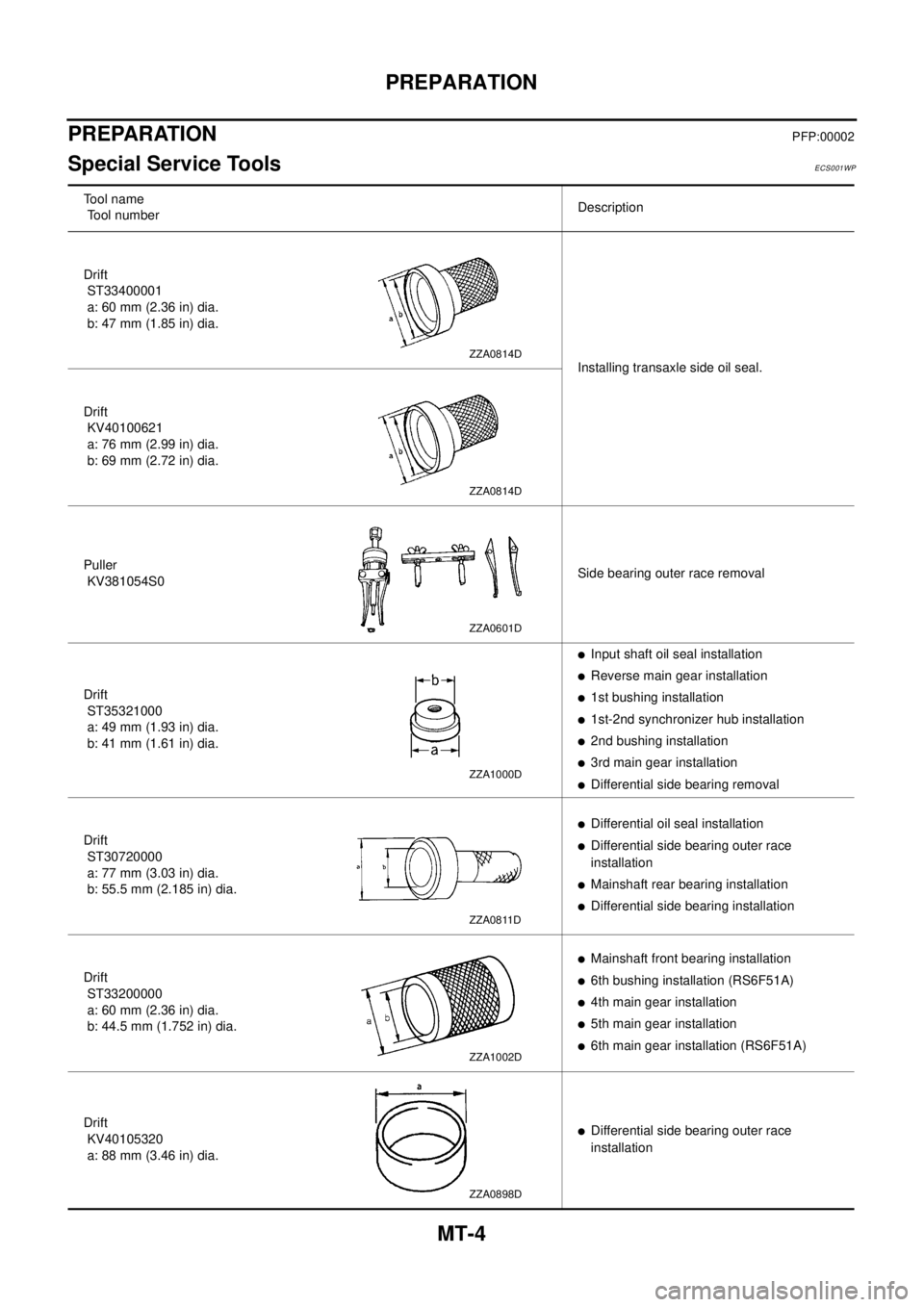

Special Service ToolsECS001WP

Tool name

Tool numberDescription

Drift

ST33400001

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

Installing transaxle side oil seal.

Drift

KV40100621

a: 76 mm (2.99 in) dia.

b: 69 mm (2.72 in) dia.

Puller

KV381054S0Side bearing outer race removal

Drift

ST35321000

a: 49 mm (1.93 in) dia.

b: 41 mm (1.61 in) dia.

lInput shaft oil seal installation

lReverse main gear installation

l1st bushing installation

l1st-2nd synchronizer hub installation

l2nd bushing installation

l3rd main gear installation

lDifferential side bearing removal

Drift

ST30720000

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

lDifferential oil seal installation

lDifferential side bearing outer race

installation

lMainshaft rear bearing installation

lDifferential side bearing installation

Drift

ST33200000

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

lMainshaft front bearing installation

l6th bushing installation (RS6F51A)

l4th main gear installation

l5th main gear installation

l6th main gear installation (RS6F51A)

Drift

KV40105320

a: 88 mm (3.46 in) dia.

lDifferential side bearing outer race

installation

ZZA0814D

ZZA0814D

ZZA0601D

ZZA1000D

ZZA0811D

ZZA1002D

ZZA0898D