NISSAN X-TRAIL 2003 Electronic Repair Manual

X-TRAIL 2003

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57402/w960_57402-0.png

NISSAN X-TRAIL 2003 Electronic Repair Manual

Trending: water pump, headlamp, spare wheel, engine oil, fuse diagram, cruise control, trunk release

Page 2541 of 3066

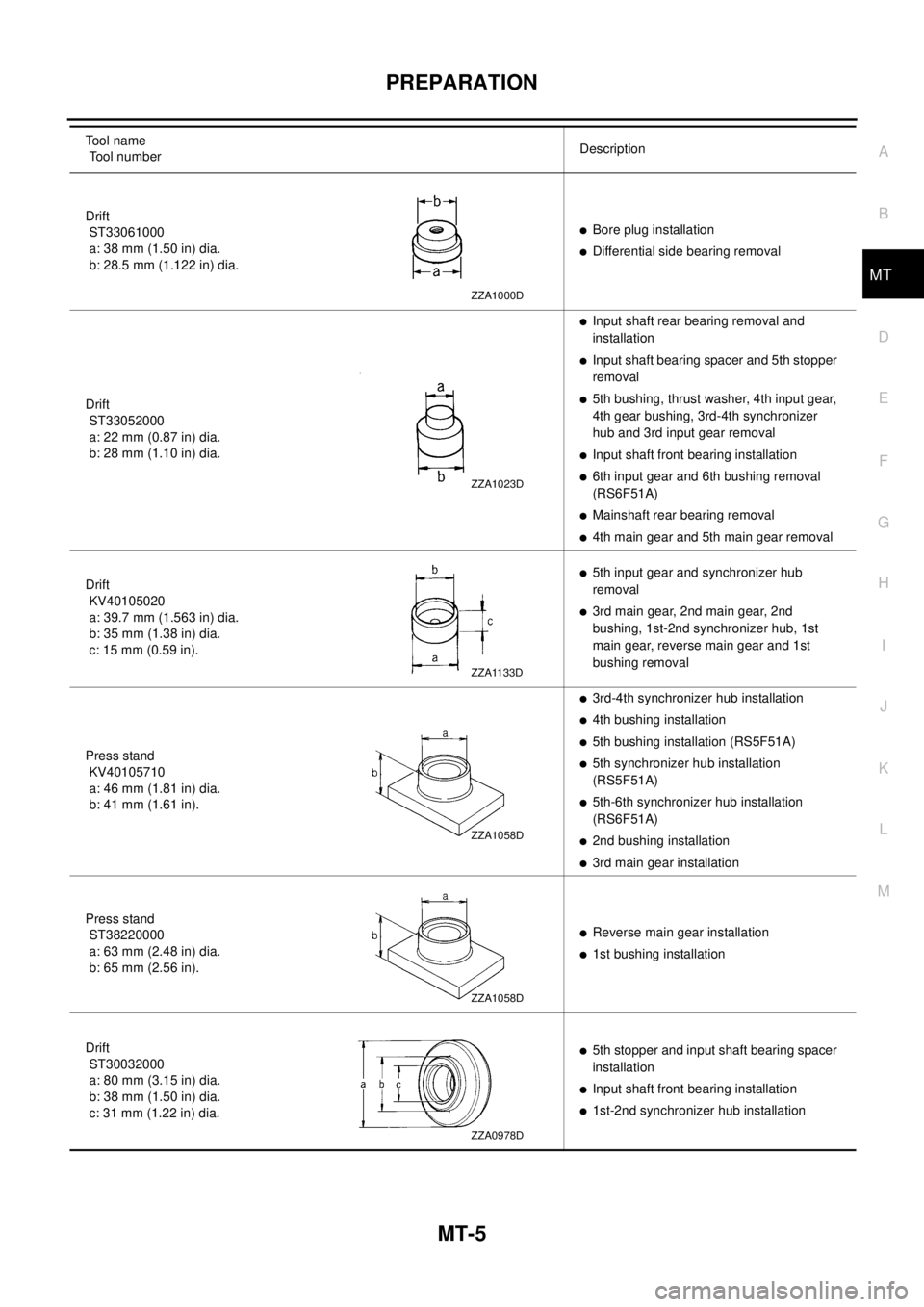

PREPARATION

MT-5

D

E

F

G

H

I

J

K

L

MA

B

MT

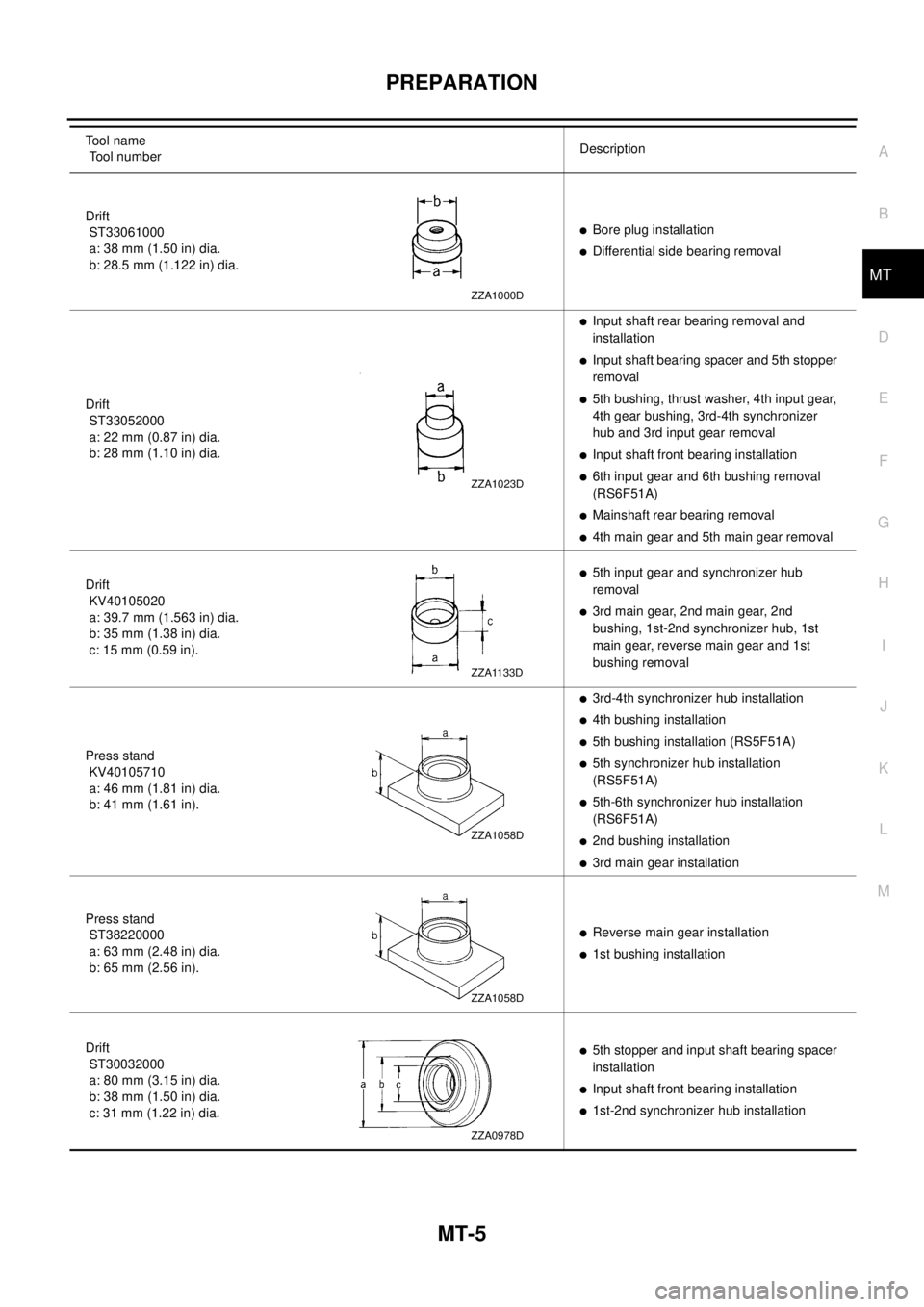

Drift

ST33061000

a: 38 mm (1.50 in) dia.

b: 28.5 mm (1.122 in) dia.lBore plug installation

lDifferential side bearing removal

Drift

ST33052000

a: 22 mm (0.87 in) dia.

b: 28 mm (1.10 in) dia.

lInput shaft rear bearing removal and

installation

lInput shaft bearing spacer and 5th stopper

removal

l5th bushing, thrust washer, 4th input gear,

4th gear bushing, 3rd-4th synchronizer

hub and 3rd input gear removal

lInput shaft front bearing installation

l6th input gear and 6th bushing removal

(RS6F51A)

lMainshaft rear bearing removal

l4th main gear and 5th main gear removal

Drift

KV40105020

a: 39.7 mm (1.563 in) dia.

b: 35 mm (1.38 in) dia.

c: 15 mm (0.59 in).

l5th input gear and synchronizer hub

removal

l3rd main gear, 2nd main gear, 2nd

bushing, 1st-2nd synchronizer hub, 1st

main gear, reverse main gear and 1st

bushing removal

Press stand

KV40105710

a: 46 mm (1.81 in) dia.

b: 41 mm (1.61 in).

l3rd-4th synchronizer hub installation

l4th bushing installation

l5th bushing installation (RS5F51A)

l5th synchronizer hub installation

(RS5F51A)

l5th-6th synchronizer hub installation

(RS6F51A)

l2nd bushing installation

l3rd main gear installation

Press stand

ST38220000

a: 63 mm (2.48 in) dia.

b: 65 mm (2.56 in).

lReverse main gear installation

l1st bushing installation

Drift

ST30032000

a: 80 mm (3.15 in) dia.

b: 38 mm (1.50 in) dia.

c: 31 mm (1.22 in) dia.

l5th stopper and input shaft bearing spacer

installation

lInput shaft front bearing installation

l1st-2nd synchronizer hub installation To o l n a m e

Tool numberDescription

ZZA1000D

ZZA1023D

ZZA1133D

ZZA1058D

ZZA1058D

ZZA0978D

Page 2542 of 3066

MT-6

PREPARATION

Commercial Service Tools

ECS004NA

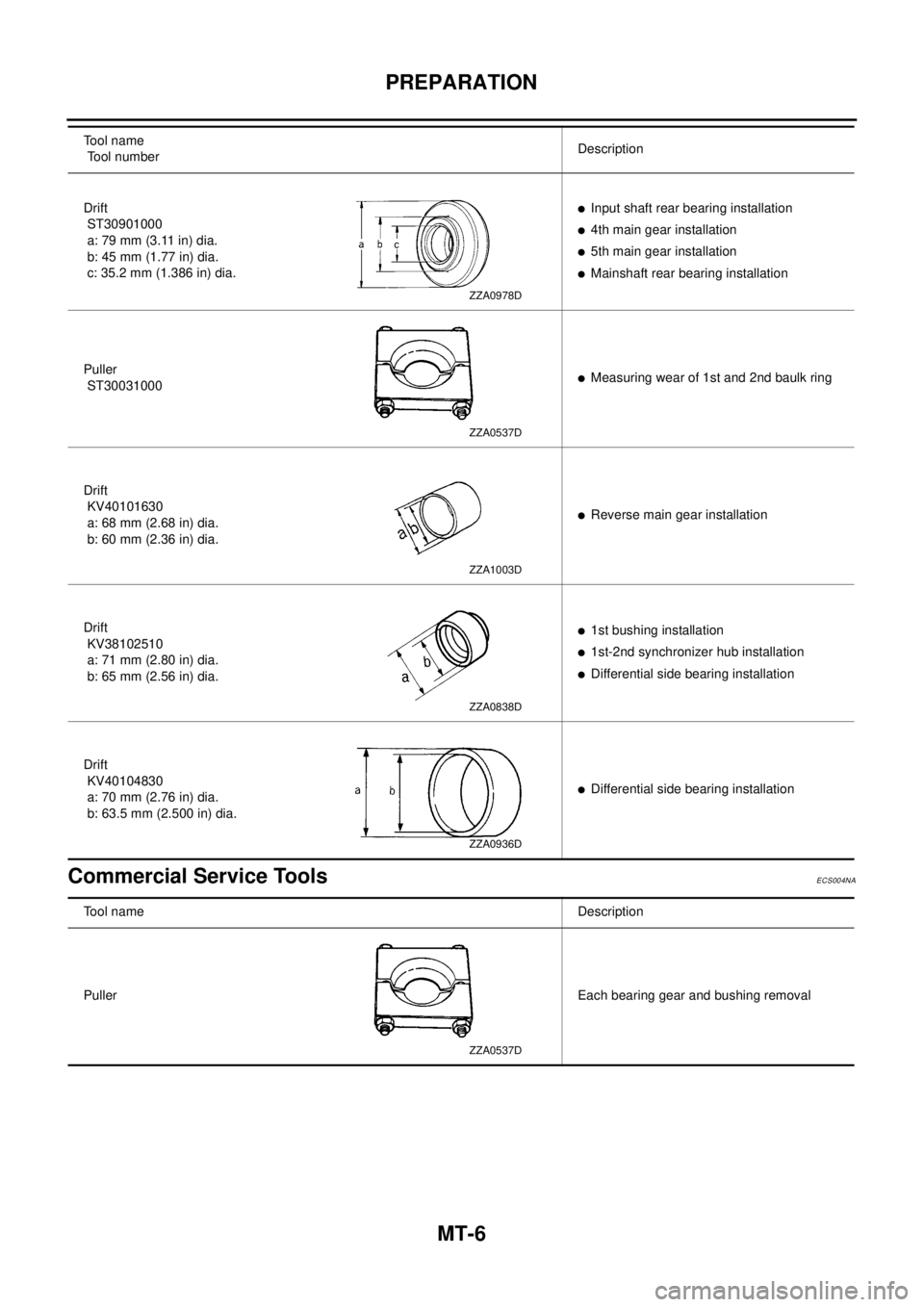

Drift

ST30901000

a: 79 mm (3.11 in) dia.

b: 45 mm (1.77 in) dia.

c: 35.2 mm (1.386 in) dia.lInput shaft rear bearing installation

l4th main gear installation

l5th main gear installation

lMainshaft rear bearing installation

Puller

ST30031000

lMeasuring wear of 1st and 2nd baulk ring

Drift

KV40101630

a: 68 mm (2.68 in) dia.

b: 60 mm (2.36 in) dia.

lReverse main gear installation

Drift

KV38102510

a: 71 mm (2.80 in) dia.

b: 65 mm (2.56 in) dia.

l1st bushing installation

l1st-2nd synchronizer hub installation

lDifferential side bearing installation

Drift

KV40104830

a: 70 mm (2.76 in) dia.

b: 63.5 mm (2.500 in) dia.

lDifferential side bearing installation Tool name

Tool numberDescription

ZZA0978D

ZZA0537D

ZZA1003D

ZZA0838D

ZZA0936D

Tool nameDescription

PullerEach bearing gear and bushing removal

ZZA0537D

Page 2543 of 3066

PREPARATION

MT-7

D

E

F

G

H

I

J

K

L

MA

B

MT

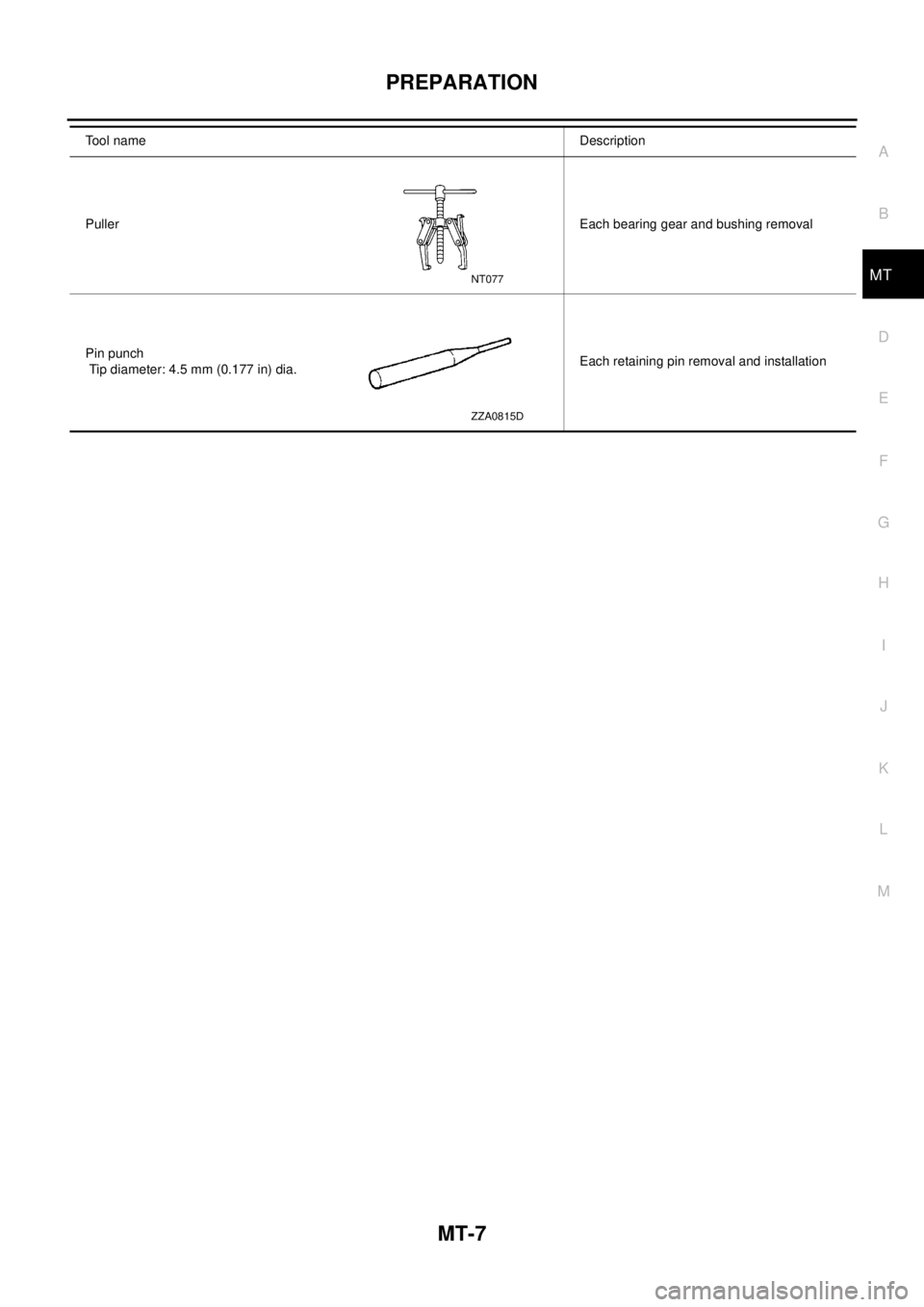

PullerEach bearing gear and bushing removal

Pin punch

Tip diameter: 4.5 mm (0.177 in) dia.Each retaining pin removal and installation To o l n a m eDescription

NT077

ZZA0815D

Page 2544 of 3066

MT-8

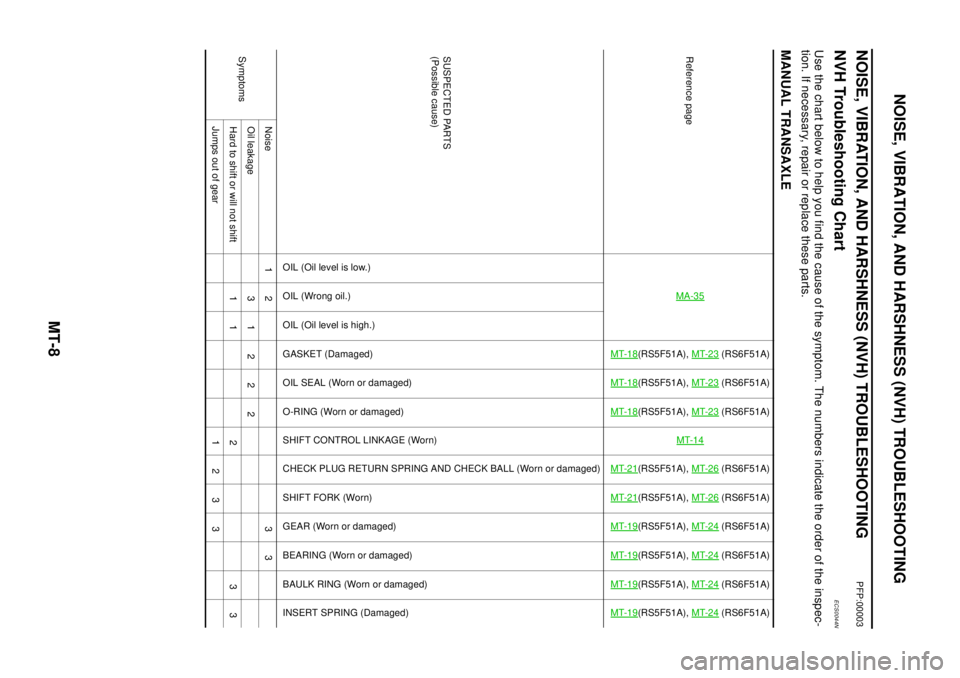

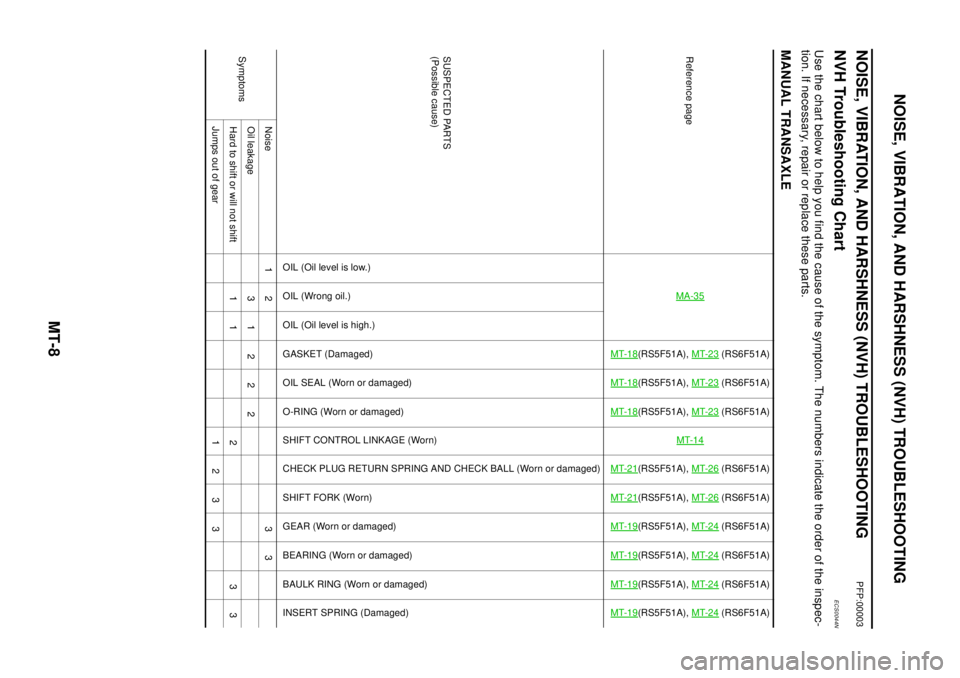

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

NVH Troubleshooting ChartECS0044N

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

MANUAL TRANSAXLE

Reference pageMA-35

MT-18

(RS5F51A),MT-23

(RS6F51A)

MT-18

(RS5F51A),MT-23

(RS6F51A)

MT-18

(RS5F51A),MT-23

(RS6F51A)

MT-14

MT-21

(RS5F51A),MT-26

(RS6F51A)

MT-21

(RS5F51A),MT-26

(RS6F51A)

MT-19

(RS5F51A),MT-24

(RS6F51A)

MT-19

(RS5F51A),MT-24

(RS6F51A)

MT-19

(RS5F51A),MT-24

(RS6F51A)

MT-19

(RS5F51A),MT-24

(RS6F51A)

SUSPECTED PARTS

(Possible cause)

OIL (Oil level is low.)

OIL(Wrongoil.)

OIL (Oil level is high.)

GASKET (Damaged)

OIL SEAL (Worn or damaged)

O-RING (Worn or damaged)

SHIFT CONTROL LINKAGE (Worn)

CHECK PLUG RETURN SPRING AND CHECK BALL (Worn or damaged)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

INSERT SPRING (Damaged)

SymptomsNoise 1 2 3 3

Oilleakage 31222

Hard to shift or will not shift 1 1 2 3 3

Jumps out of gear 1 2 3 3

Page 2545 of 3066

DESCRIPTION

MT-9

D

E

F

G

H

I

J

K

L

MA

B

MT

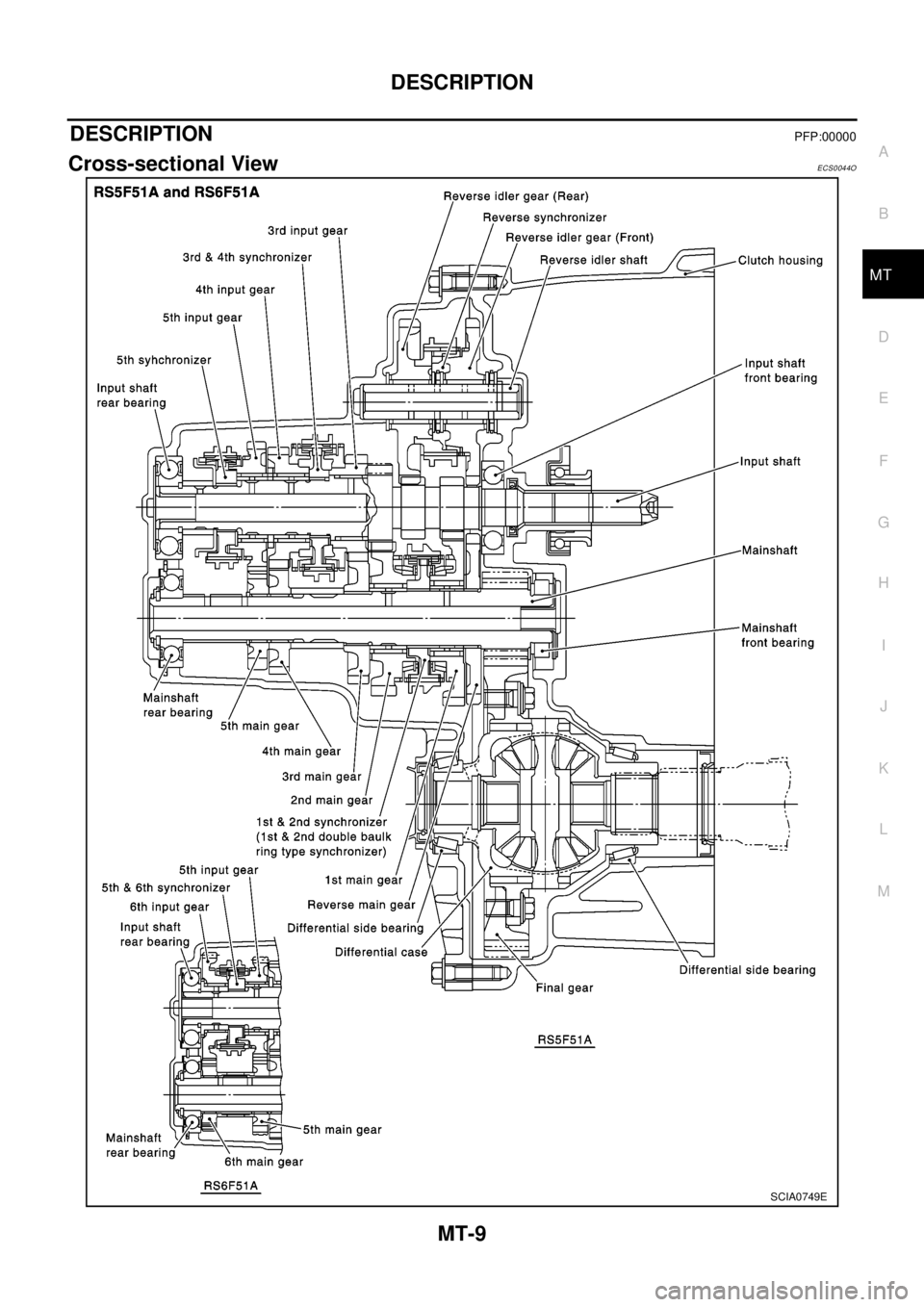

DESCRIPTIONPFP:00000

Cross-sectional ViewECS0044O

SCIA0749E

Page 2546 of 3066

MT-10

DESCRIPTION

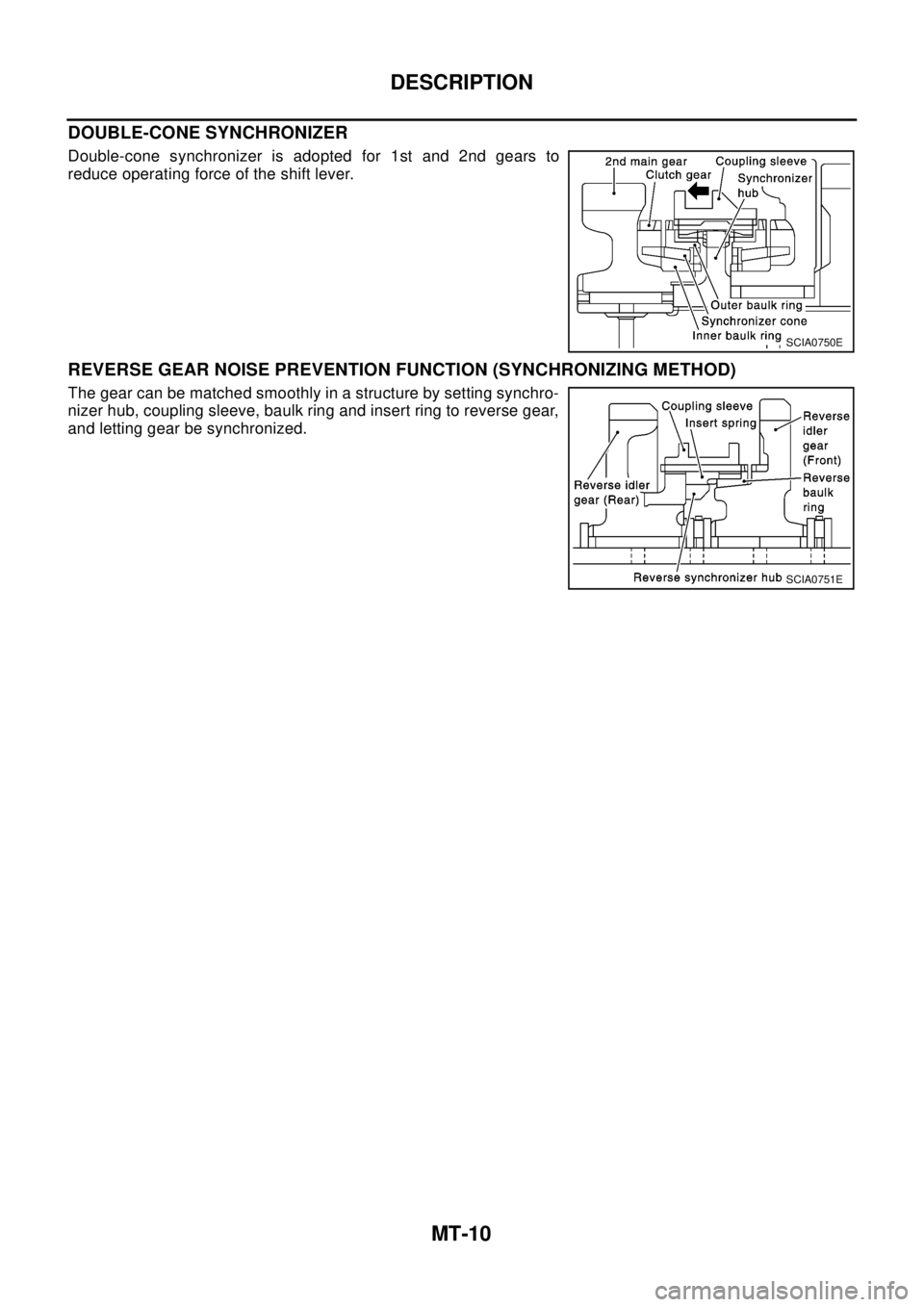

DOUBLE-CONE SYNCHRONIZER

Double-cone synchronizer is adopted for 1st and 2nd gears to

reduce operating force of the shift lever.

REVERSE GEAR NOISE PREVENTION FUNCTION (SYNCHRONIZING METHOD)

The gear can be matched smoothly in a structure by setting synchro-

nizer hub, coupling sleeve, baulk ring and insert ring to reverse gear,

and letting gear be synchronized.

SCIA0750E

SCIA0751E

Page 2547 of 3066

M/T OIL

MT-11

D

E

F

G

H

I

J

K

L

MA

B

MT

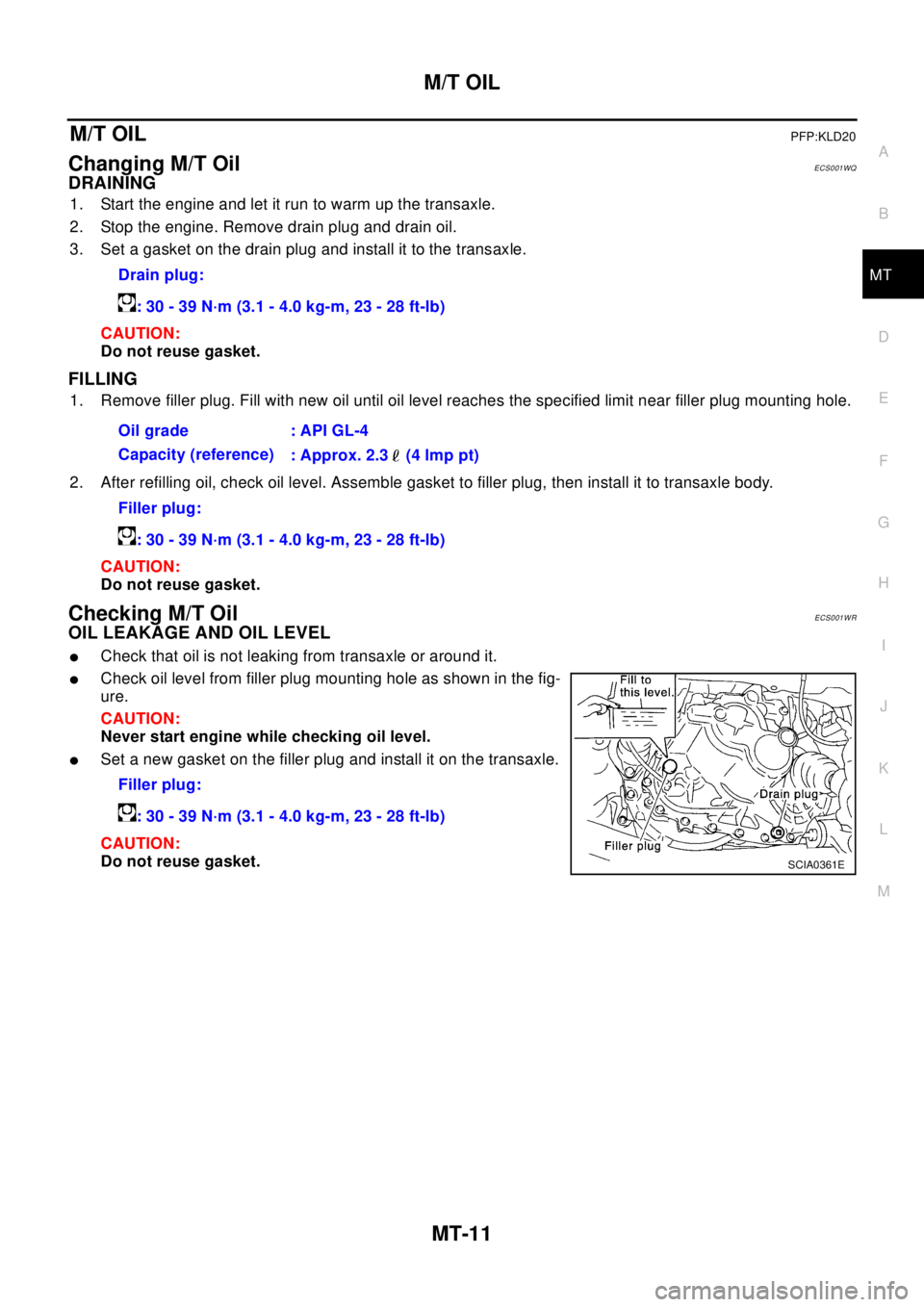

M/T OILPFP:KLD20

Changing M/T OilECS001WQ

DRAINING

1. Start the engine and let it run to warm up the transaxle.

2. Stop the engine. Remove drain plug and drain oil.

3. Set a gasket on the drain plug and install it to the transaxle.

CAUTION:

Do not reuse gasket.

FILLING

1. Remove filler plug. Fill with new oil until oil level reaches the specified limit near filler plug mounting hole.

2. After refilling oil, check oil level. Assemble gasket to filler plug, then install it to transaxle body.

CAUTION:

Do not reuse gasket.

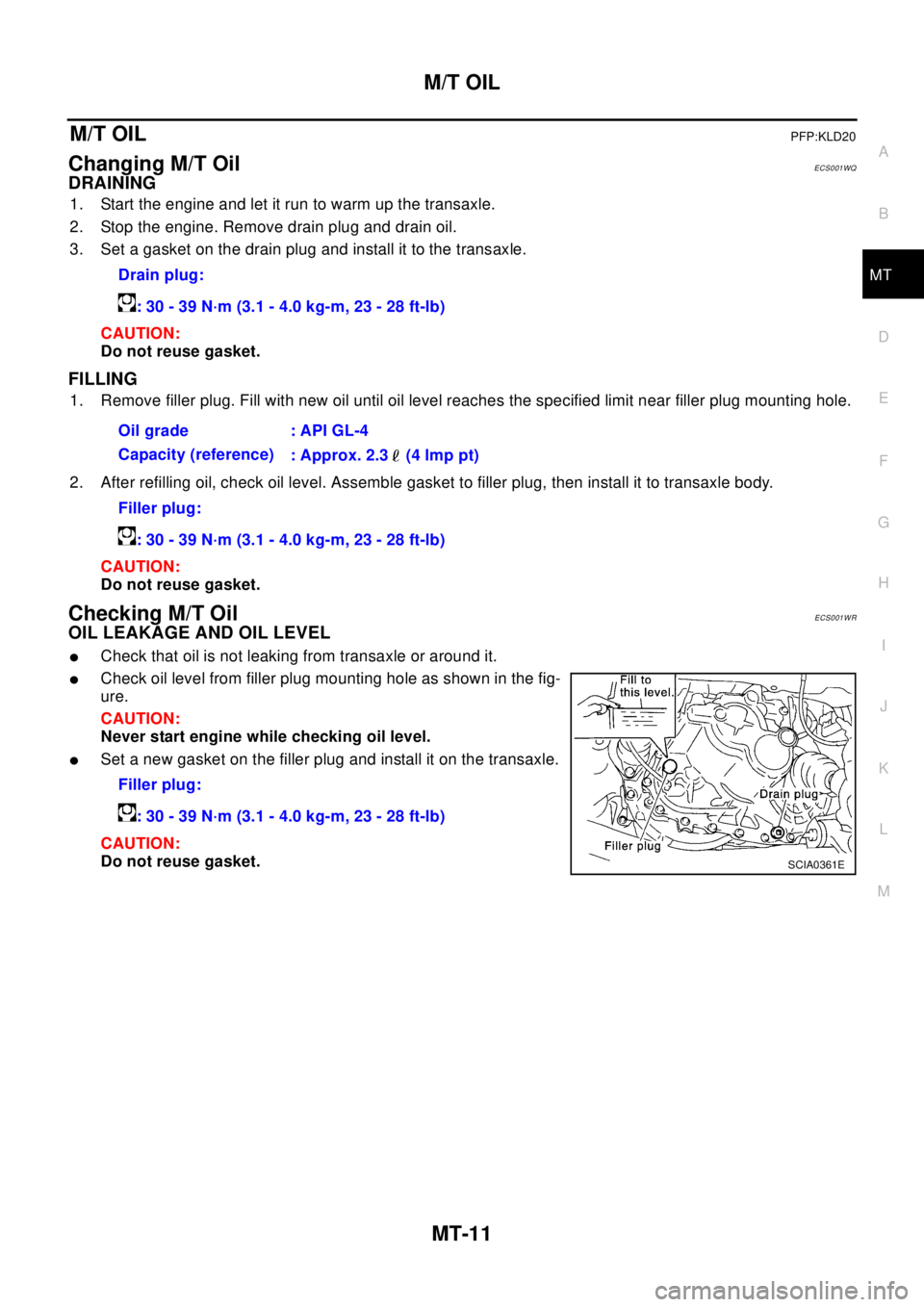

Checking M/T OilECS001WR

OIL LEAKAGE AND OIL LEVEL

lCheck that oil is not leaking from transaxle or around it.

lCheck oil level from filler plug mounting hole as shown in the fig-

ure.

CAUTION:

Never start engine while checking oil level.

lSet a new gasket on the filler plug and install it on the transaxle.

CAUTION:

Do not reuse gasket.Drain plug:

: 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

Oil grade : API GL-4

Capacity (reference)

: Approx. 2.3 (4 lmp pt)

Filler plug:

: 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

Filler plug:

: 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

SCIA0361E

Page 2548 of 3066

MT-12

SIDE OIL SEAL

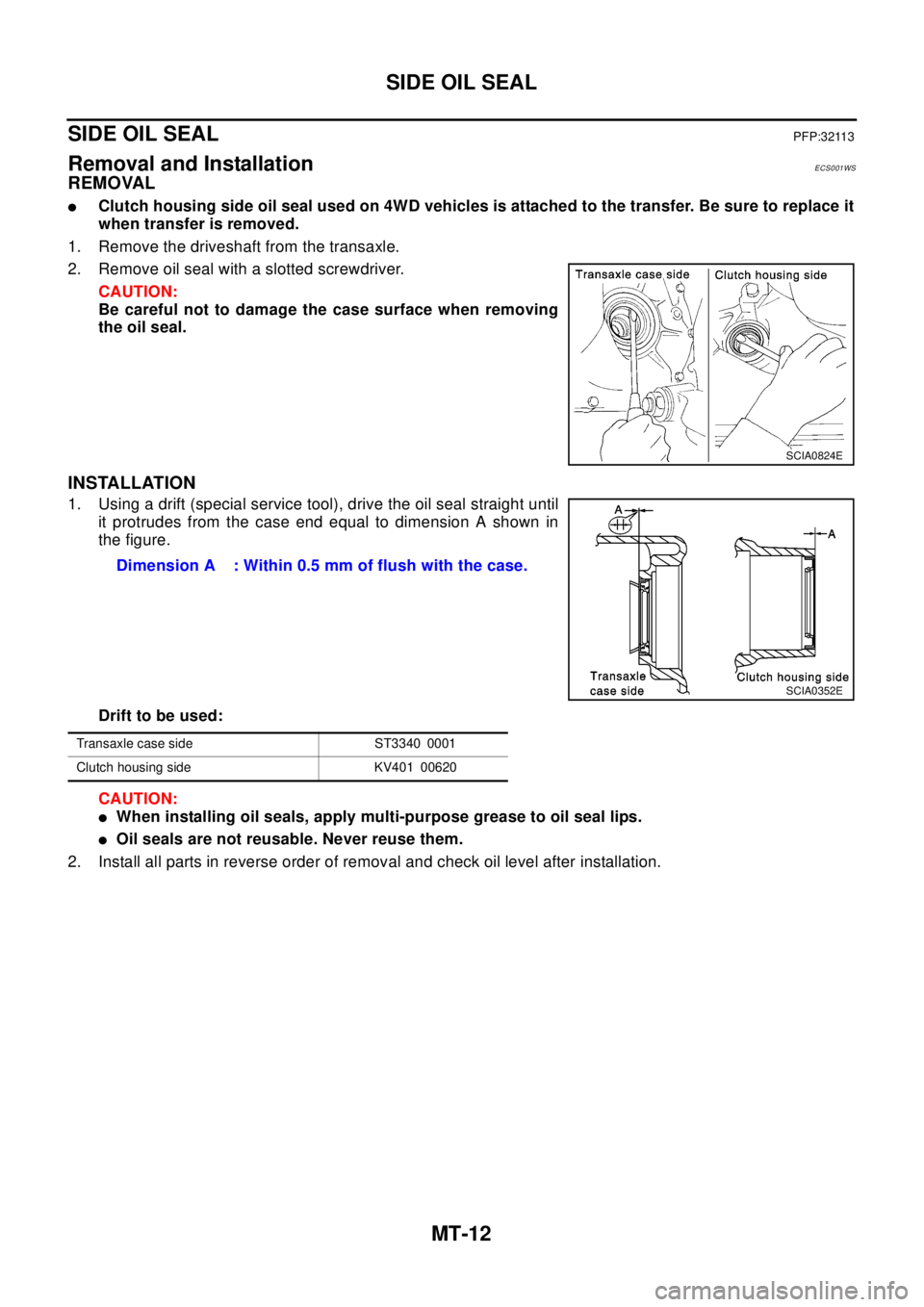

SIDE OIL SEAL

PFP:32113

Removal and InstallationECS001WS

REMOVAL

lClutch housing side oil seal used on 4WD vehicles is attached to the transfer. Be sure to replace it

when transfer is removed.

1. Remove the driveshaft from the transaxle.

2. Remove oil seal with a slotted screwdriver.

CAUTION:

Be careful not to damage the case surface when removing

the oil seal.

INSTALLATION

1. Using a drift (special service tool), drive the oil seal straight until

it protrudes from the case end equal to dimension A shown in

the figure.

Drift to be used:

CAUTION:

lWhen installing oil seals, apply multi-purpose grease to oil seal lips.

lOil seals are not reusable. Never reuse them.

2. Install all parts in reverse order of removal and check oil level after installation.

SCIA0824E

Dimension A : Within 0.5 mm of flush with the case.

SCIA0352E

Transaxle case side ST3340 0001

Clutch housing side KV401 00620

Page 2549 of 3066

POSITION SWITCH

MT-13

D

E

F

G

H

I

J

K

L

MA

B

MT

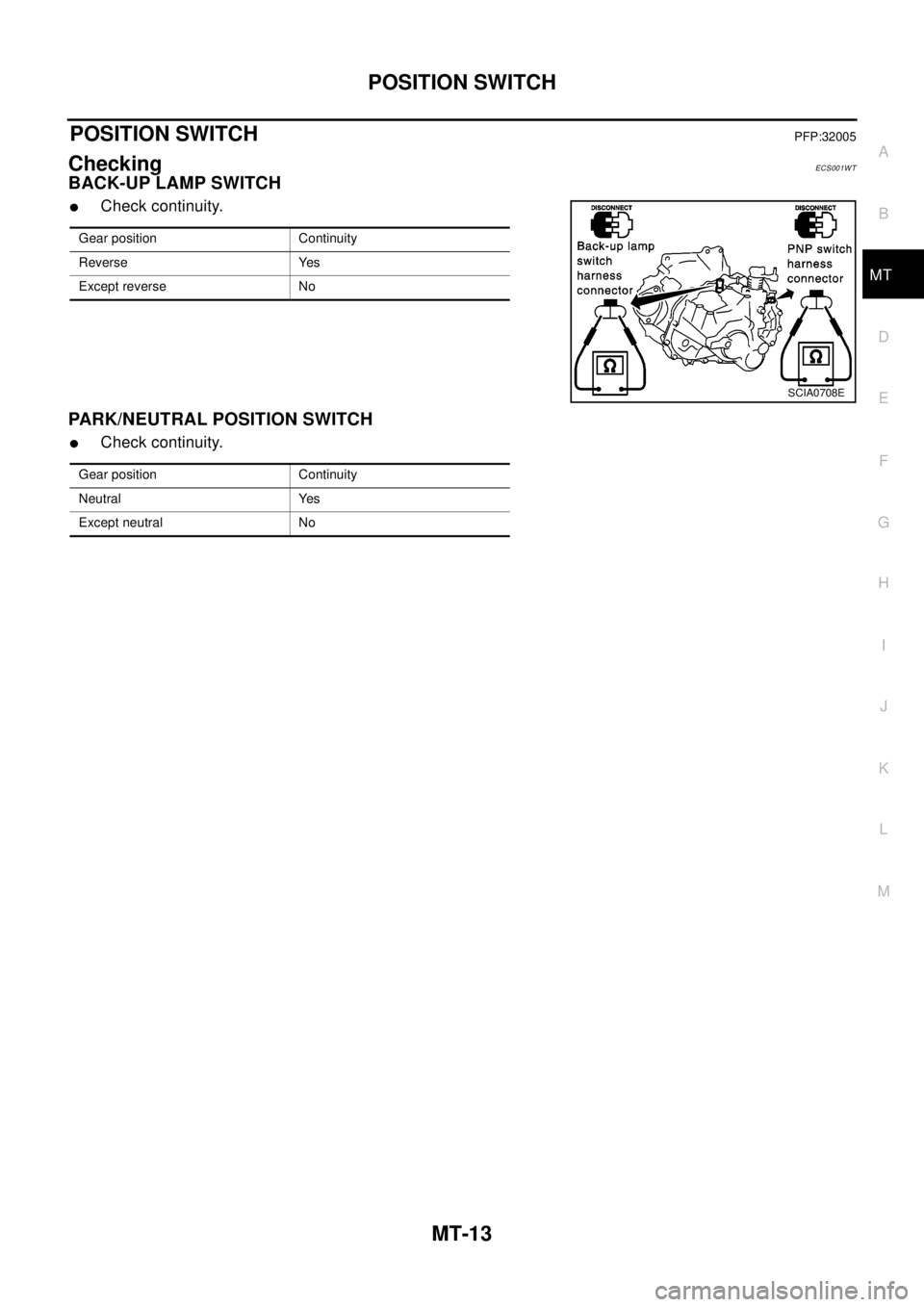

POSITION SWITCHPFP:32005

CheckingECS001WT

BACK-UP LAMP SWITCH

lCheck continuity.

PARK/NEUTRAL POSITION SWITCH

lCheck continuity.

Gear position Continuity

Reverse Yes

Except reverse No

SCIA0708E

Gear position Continuity

Neutral Yes

Except neutral No

Page 2550 of 3066

MT-14

CONTROL LINKAGE

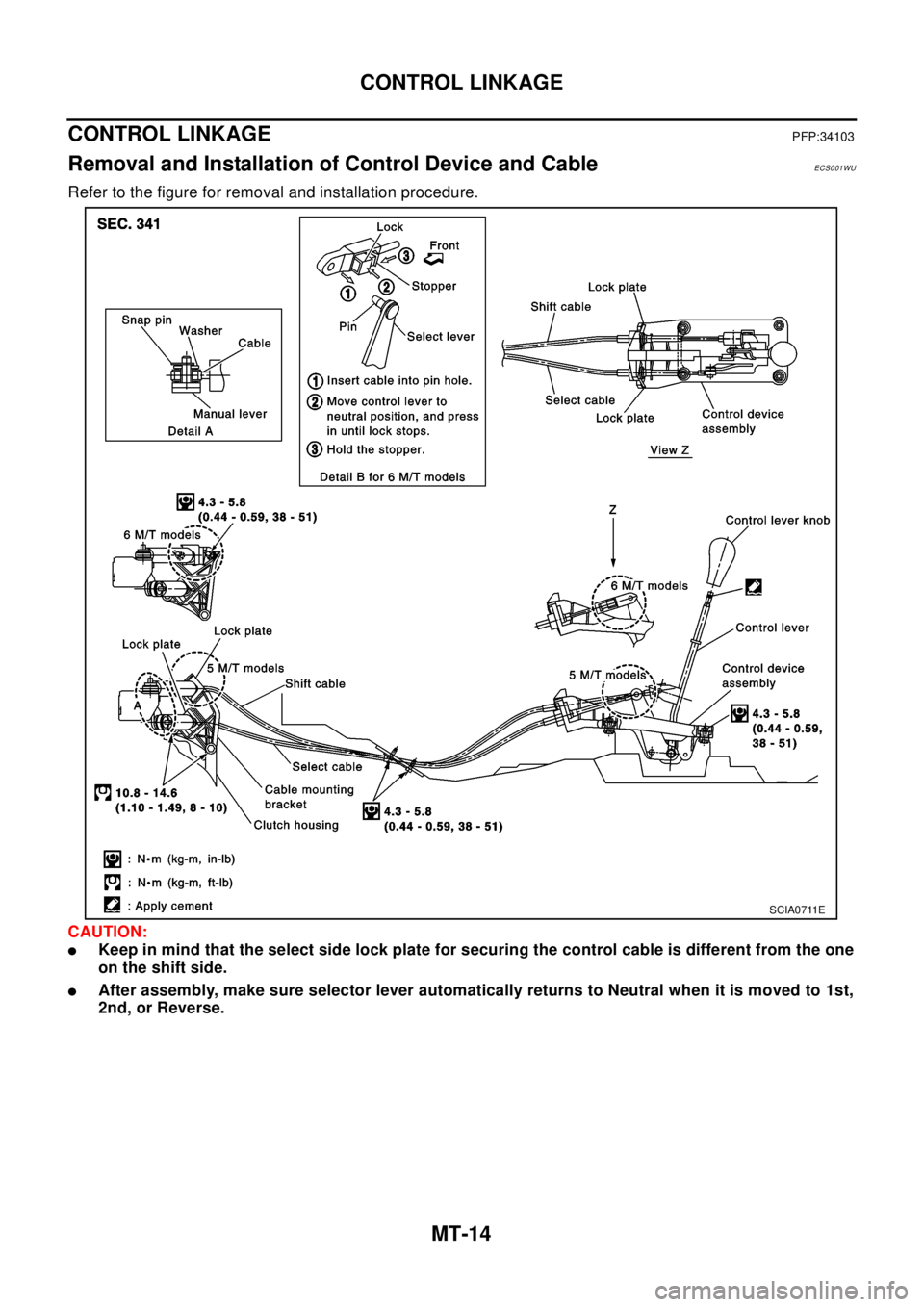

CONTROL LINKAGE

PFP:34103

Removal and Installation of Control Device and CableECS001WU

Refer to the figure for removal and installation procedure.

CAUTION:

lKeep in mind that the select side lock plate for securing the control cable is different from the one

on the shift side.

lAfter assembly, make sure selector lever automatically returns to Neutral when it is moved to 1st,

2nd, or Reverse.

SCIA0711E

Trending: weight, key battery, wheelbase, radio, cooling, transmission oil, service