NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2521 of 3066

ENGINE MAINTENANCE (YD22DDTI)

MA-29

C

D

E

F

G

H

I

J

K

MA

B

MA

10. Warm up engine, and check for sound of coolant flow while running engine from idle up to 3,000 rpm with

heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.

11. If sound is heard, bleed air from cooling system by repeating steps 5 through 7 until coolant level no

longer drops.

lClean excess coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator with water until water spills from the air relief hole, then close air relief flag. Fill radiator and

reservoir tank with water and reinstall radiator cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water.

6. Repeat steps 1 through 5 until clear water begins to drain from radiator.

Checking Cooling SystemELS000C4

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly turn it a quarter turn to

allow built-up pressure to escape. Carefully remove the cap by turning it all the way.

CHECKING COOLING SYSTEM HOSES

Check hoses for improper attachment, leaks, cracks, damage, loose connections, chafing and deterioration.

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows.

lBe careful not to bend or damage the radiator fins.

lWhen radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape the harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downwards.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically downwards.

lUse compressed air lower than 490 kpa (5 kg/cm2, 71psi) and keep distance more than 30 cm(11.8 in).

5. Blow air again into all the radiator core surface once per minute until no water sprays out.

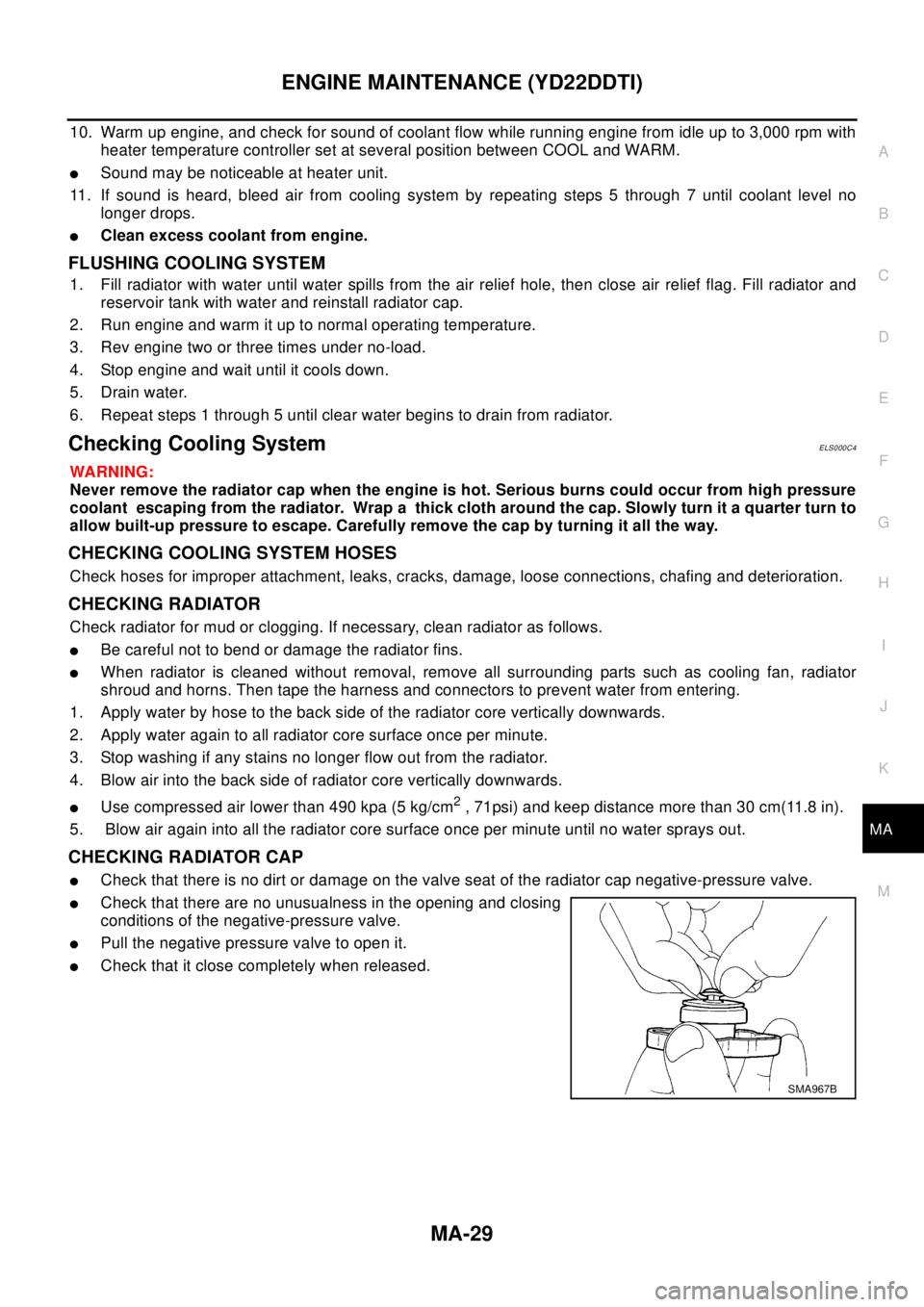

CHECKING RADIATOR CAP

lCheck that there is no dirt or damage on the valve seat of the radiator cap negative-pressure valve.

lCheck that there are no unusualness in the opening and closing

conditions of the negative-pressure valve.

lPull the negative pressure valve to open it.

lCheck that it close completely when released.

SMA967B

Page 2522 of 3066

MA-30

ENGINE MAINTENANCE (YD22DDTI)

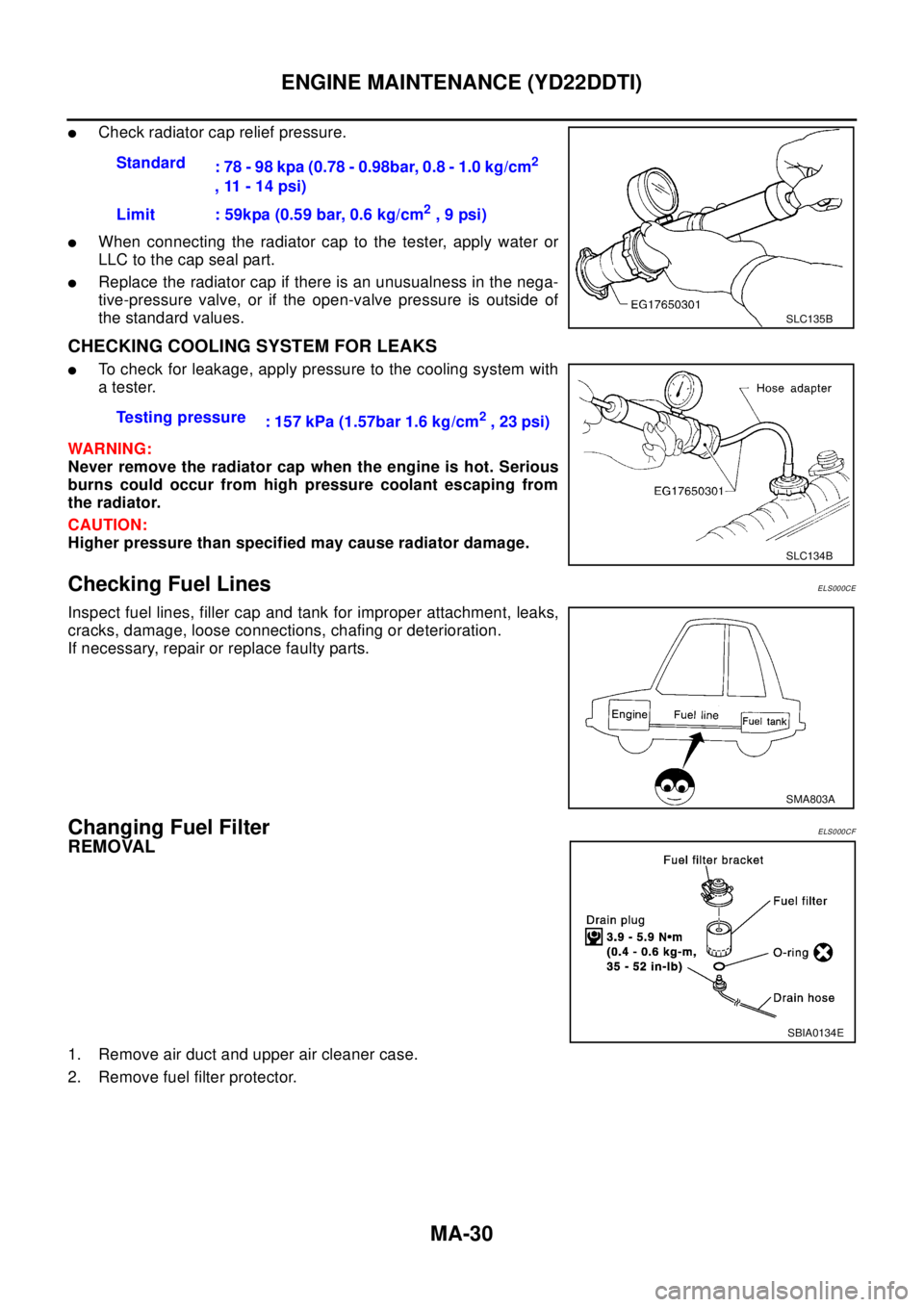

lCheck radiator cap relief pressure.

lWhen connecting the radiator cap to the tester, apply water or

LLC to the cap seal part.

lReplace the radiator cap if there is an unusualness in the nega-

tive-pressure valve, or if the open-valve pressure is outside of

the standard values.

CHECKING COOLING SYSTEM FOR LEAKS

lTo check for leakage, apply pressure to the cooling system with

atester.

WAR NIN G:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

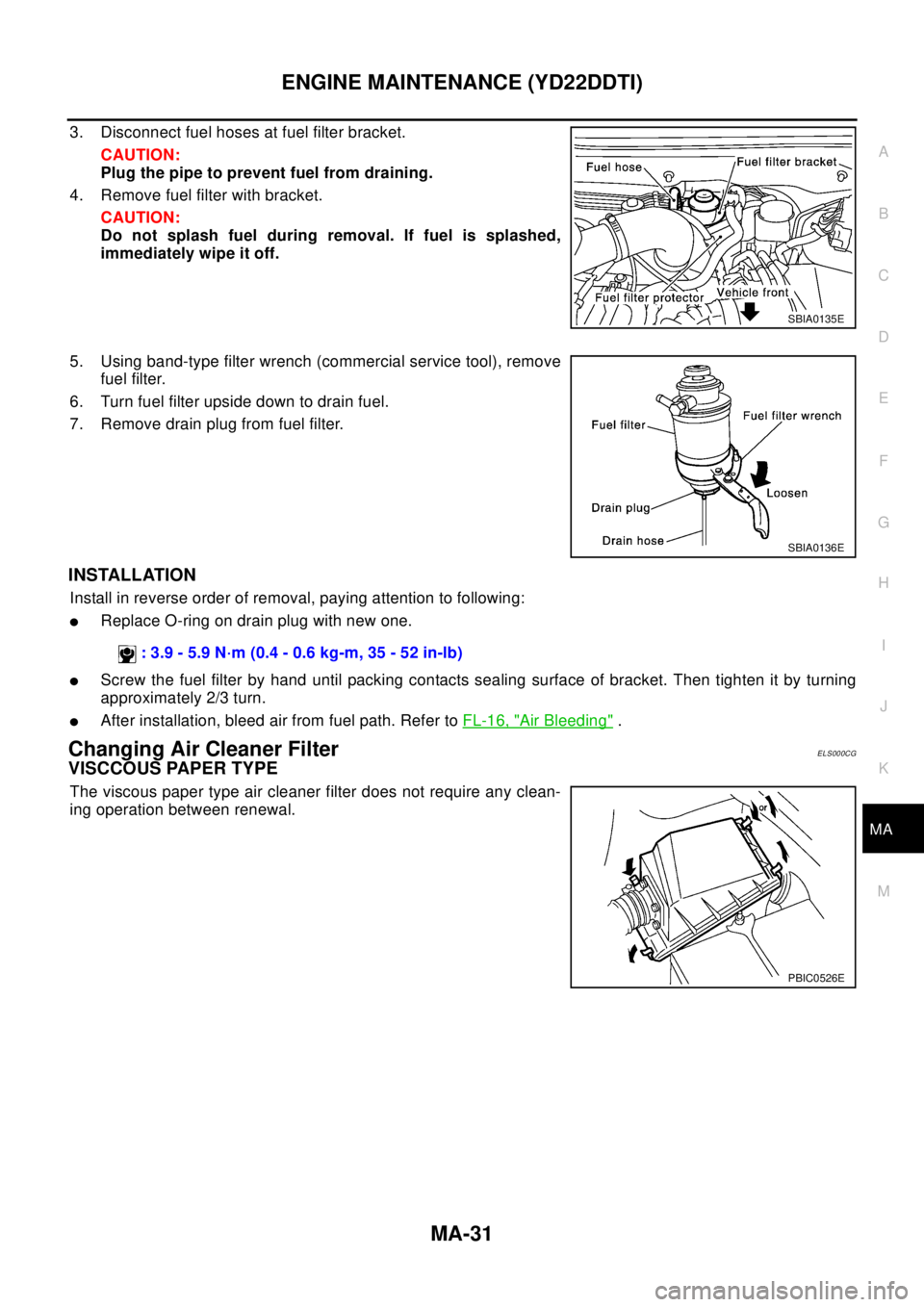

Checking Fuel LinesELS000CE

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or deterioration.

If necessary, repair or replace faulty parts.

Changing Fuel FilterELS000CF

REMOVAL

1. Remove air duct and upper air cleaner case.

2. Remove fuel filter protector.Standard

: 78 - 98 kpa (0.78 - 0.98bar, 0.8 - 1.0 kg/cm

2

,11-14psi)

Limit : 59kpa (0.59 bar, 0.6 kg/cm

2,9psi)

SLC135B

Testing pressure

: 157 kPa (1.57bar 1.6 kg/cm2,23psi)

SLC134B

SMA803A

SBIA0134E

Page 2523 of 3066

ENGINE MAINTENANCE (YD22DDTI)

MA-31

C

D

E

F

G

H

I

J

K

MA

B

MA

3. Disconnect fuel hoses at fuel filter bracket.

CAUTION:

Plug the pipe to prevent fuel from draining.

4. Remove fuel filter with bracket.

CAUTION:

Do not splash fuel during removal. If fuel is splashed,

immediately wipe it off.

5. Using band-type filter wrench (commercial service tool), remove

fuel filter.

6. Turn fuel filter upside down to drain fuel.

7. Remove drain plug from fuel filter.

INSTALLATION

Install in reverse order of removal, paying attention to following:

lReplace O-ring on drain plug with new one.

lScrew the fuel filter by hand until packing contacts sealing surface of bracket. Then tighten it by turning

approximately 2/3 turn.

lAfter installation, bleed air from fuel path. Refer toFL-16, "Air Bleeding".

Changing Air Cleaner FilterELS000CG

VISCCOUS PAPER TYPE

The viscous paper type air cleaner filter does not require any clean-

ing operation between renewal.

SBIA0135E

SBIA0136E

: 3.9 - 5.9 N·m (0.4 - 0.6 kg-m, 35 - 52 in-lb)

PBIC0526E

Page 2524 of 3066

MA-32

ENGINE MAINTENANCE (YD22DDTI)

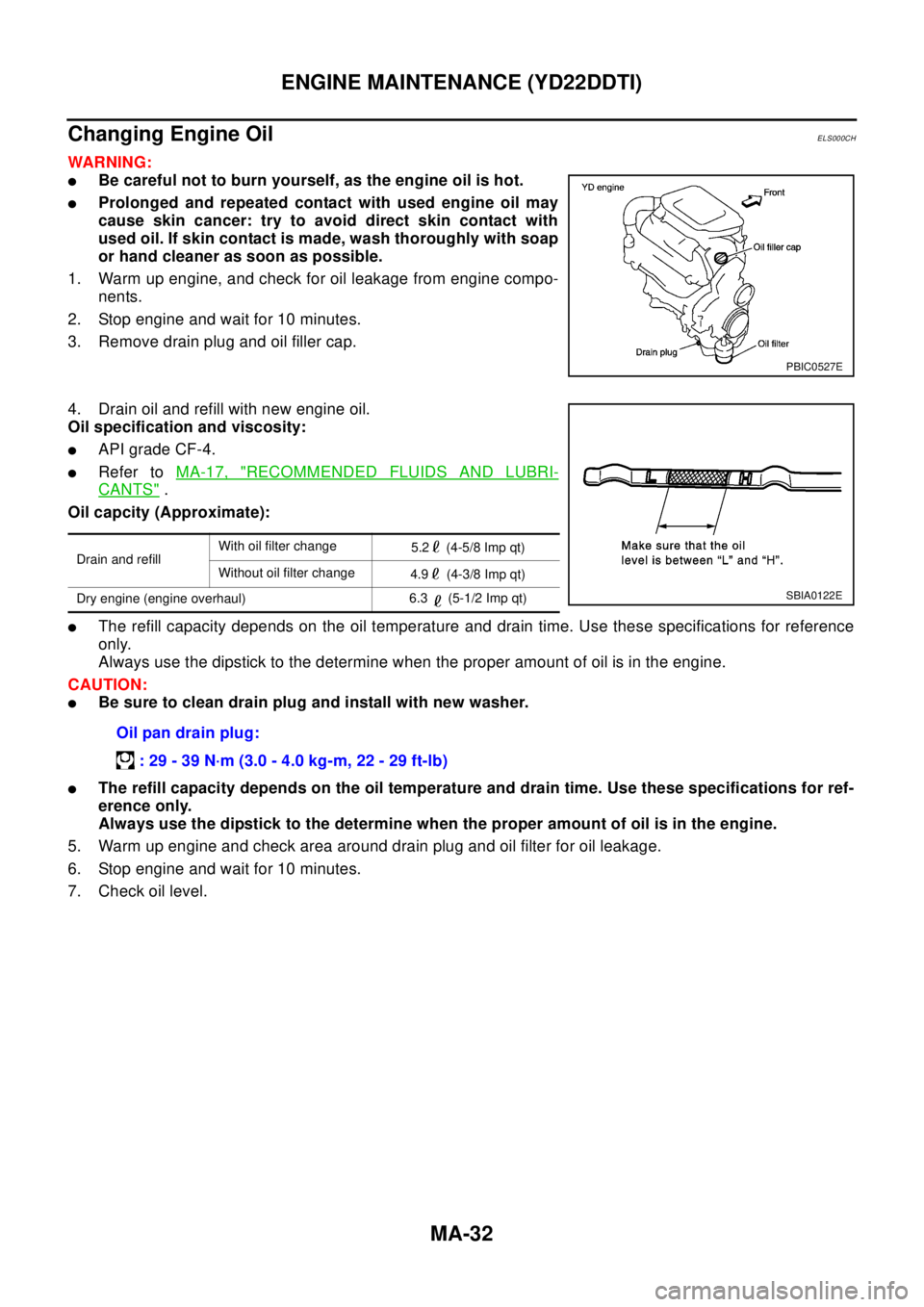

Changing Engine Oil

ELS000CH

WAR NIN G:

lBe careful not to burn yourself, as the engine oil is hot.

lProlonged and repeated contact with used engine oil may

cause skin cancer: try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with soap

or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine compo-

nents.

2. Stop engine and wait for 10 minutes.

3. Remove drain plug and oil filler cap.

4. Drain oil and refill with new engine oil.

Oil specification and viscosity:

lAPI grade CF-4.

lRefer toMA-17, "RECOMMENDED FLUIDS AND LUBRI-

CANTS".

Oil capcity (Approximate):

lThe refill capacity depends on the oil temperature and drain time. Use these specifications for reference

only.

Always use the dipstick to the determine when the proper amount of oil is in the engine.

CAUTION:

lBe sure to clean drain plug and install with new washer.

lThe refill capacity depends on the oil temperature and drain time. Use these specifications for ref-

erence only.

Always use the dipstick to the determine when the proper amount of oil is in the engine.

5. Warm up engine and check area around drain plug and oil filter for oil leakage.

6. Stop engine and wait for 10 minutes.

7. Check oil level.

PBIC0527E

Drain and refillWith oil filter change

5.2 (4-5/8 Imp qt)

Without oil filter change

4.9 (4-3/8 Imp qt)

Dry engine (engine overhaul)6.3 (5-1/2 Imp qt)

Oil pan drain plug:

:29-39N·m(3.0-4.0kg-m,22-29ft-lb)

SBIA0122E

Page 2525 of 3066

ENGINE MAINTENANCE (YD22DDTI)

MA-33

C

D

E

F

G

H

I

J

K

MA

B

MA

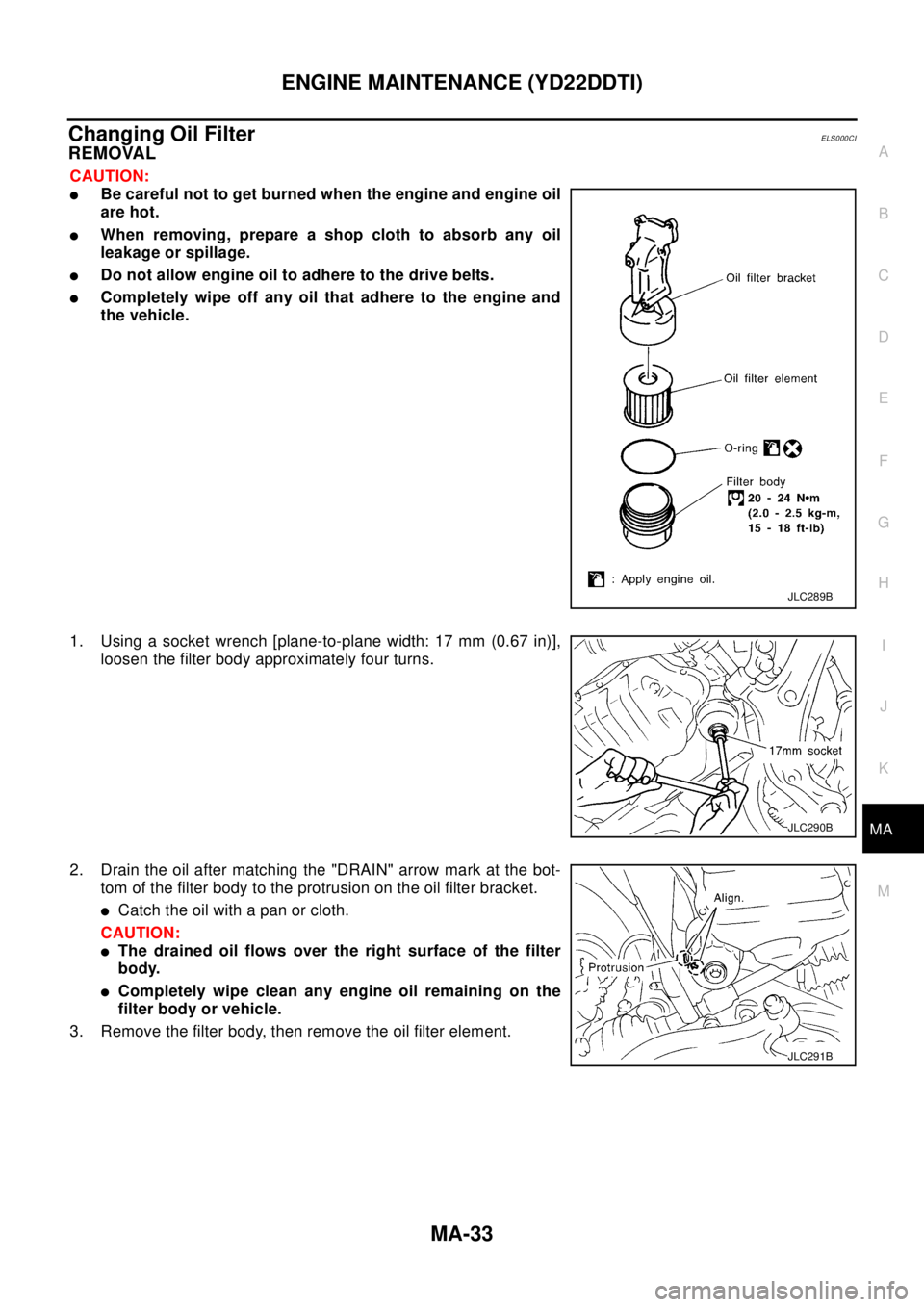

Changing Oil FilterELS000CI

REMOVAL

CAUTION:

lBe careful not to get burned when the engine and engine oil

are hot.

lWhen removing, prepare a shop cloth to absorb any oil

leakage or spillage.

lDo not allow engine oil to adhere to the drive belts.

lCompletely wipe off any oil that adhere to the engine and

the vehicle.

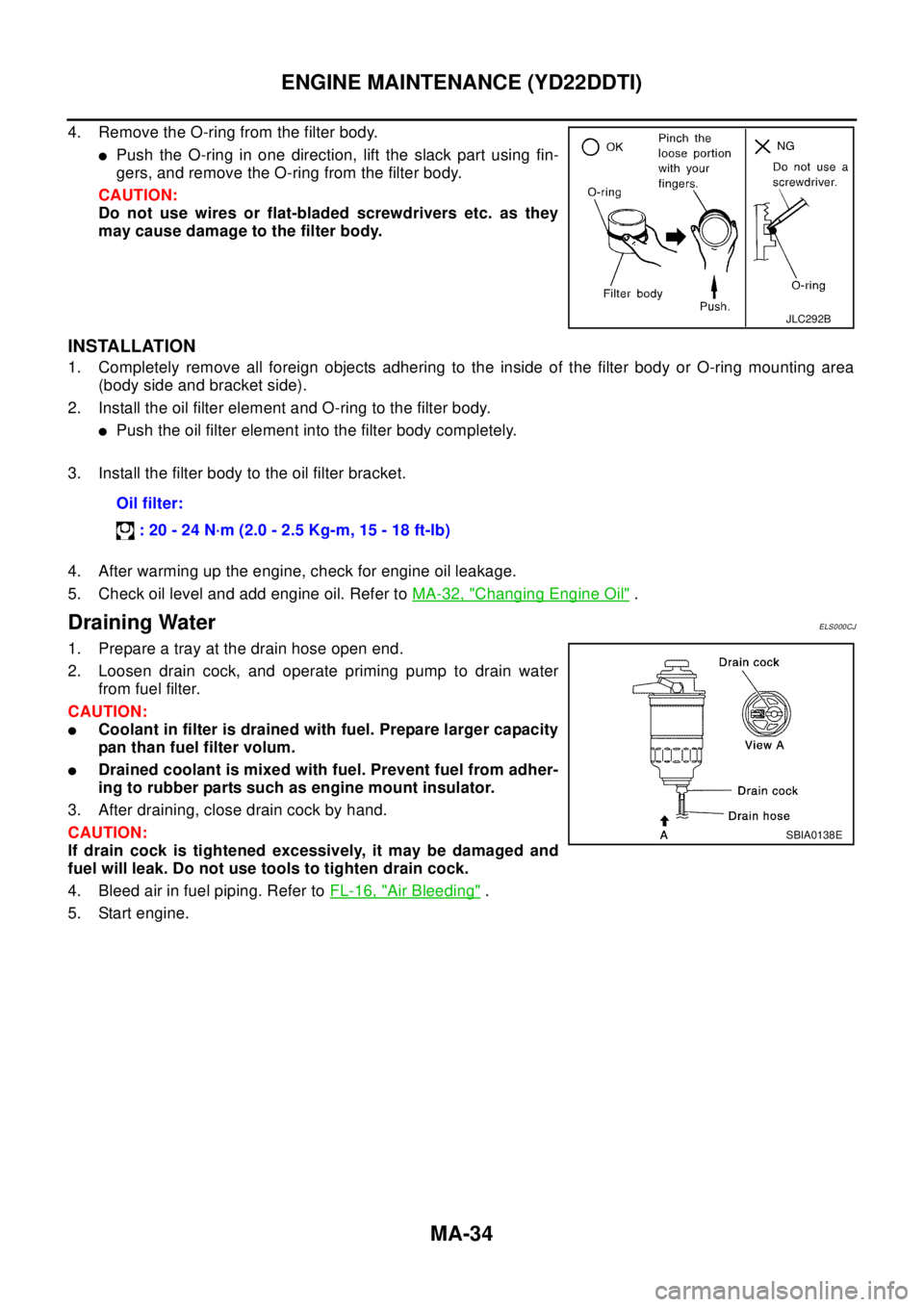

1. Using a socket wrench [plane-to-plane width: 17 mm (0.67 in)],

loosen the filter body approximately four turns.

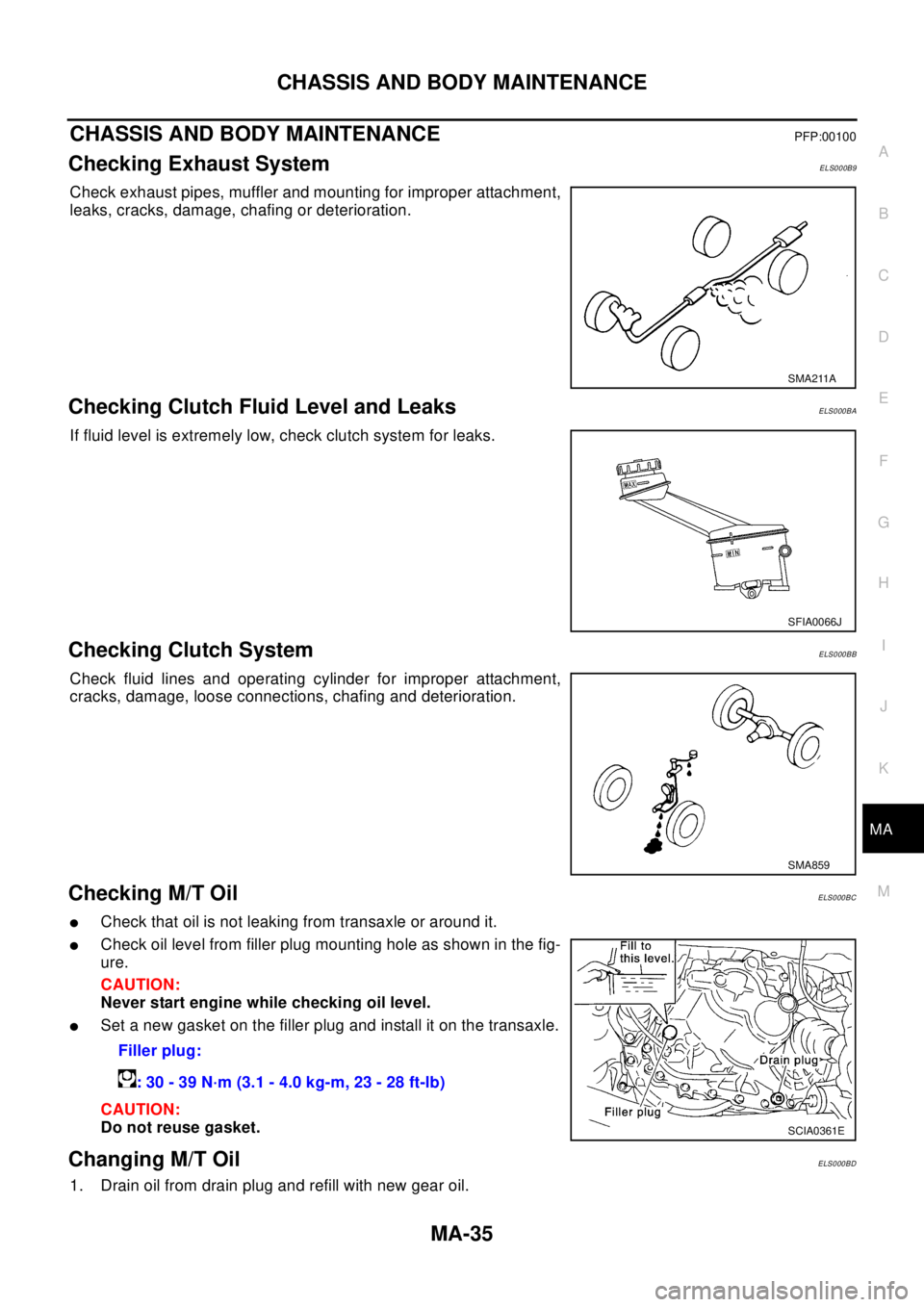

2. Drain the oil after matching the "DRAIN" arrow mark at the bot-

tom of the filter body to the protrusion on the oil filter bracket.

lCatch the oil with a pan or cloth.

CAUTION:

lThe drained oil flows over the right surface of the filter

body.

lCompletely wipe clean any engine oil remaining on the

filter body or vehicle.

3. Remove the filter body, then remove the oil filter element.

JLC289B

JLC290B

JLC291B

Page 2526 of 3066

MA-34

ENGINE MAINTENANCE (YD22DDTI)

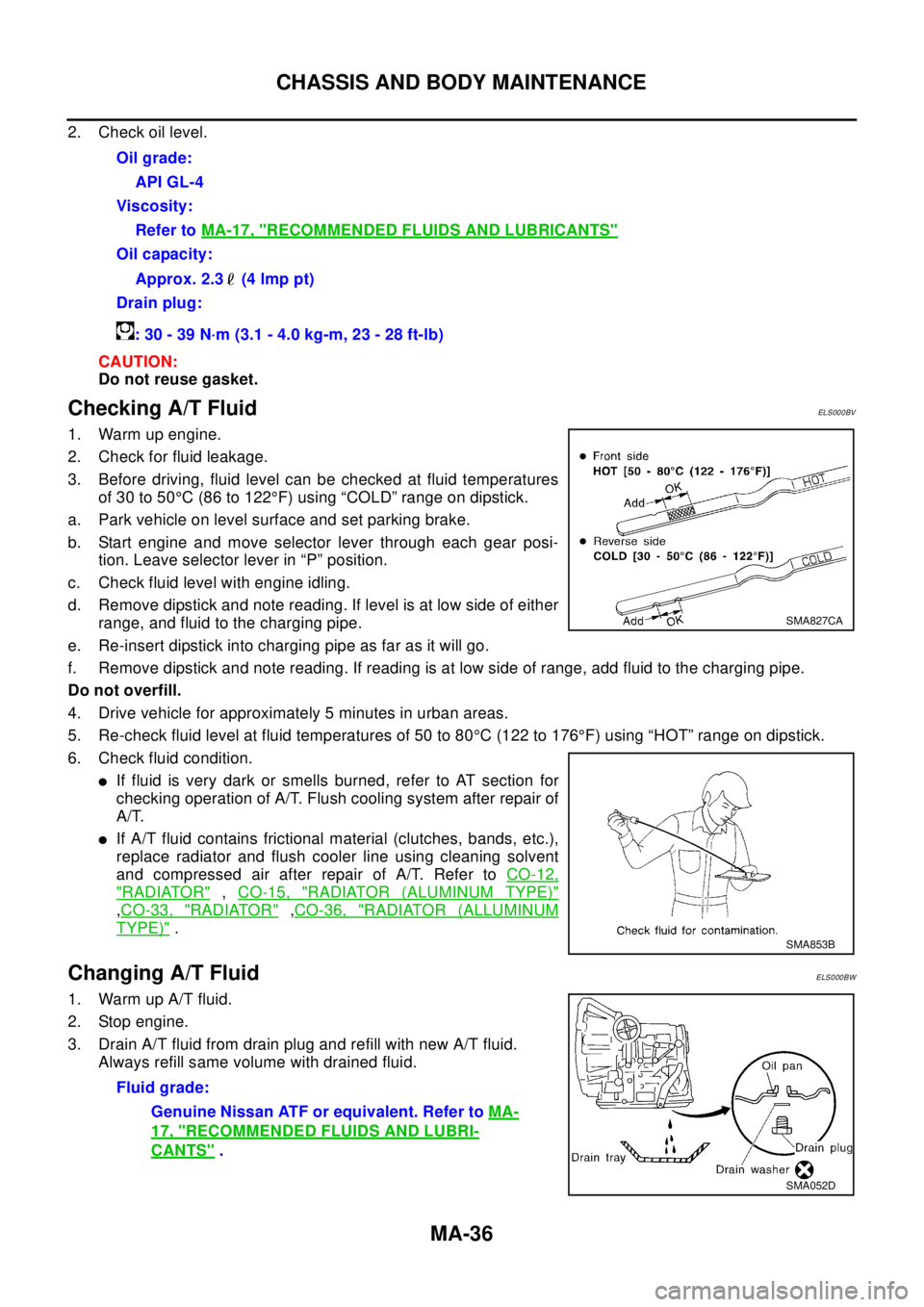

4. Remove the O-ring from the filter body.

lPush the O-ring in one direction, lift the slack part using fin-

gers, and remove the O-ring from the filter body.

CAUTION:

Do not use wires or flat-bladed screwdrivers etc. as they

may cause damage to the filter body.

INSTALLATION

1. Completely remove all foreign objects adhering to the inside of the filter body or O-ring mounting area

(body side and bracket side).

2. Install the oil filter element and O-ring to the filter body.

lPush the oil filter element into the filter body completely.

3. Install the filter body to the oil filter bracket.

4. After warming up the engine, check for engine oil leakage.

5. Check oil level and add engine oil. Refer toMA-32, "

Changing Engine Oil".

Draining WaterELS000CJ

1. Prepare a tray at the drain hose open end.

2. Loosen drain cock, and operate priming pump to drain water

from fuel filter.

CAUTION:

lCoolant in filter is drained with fuel. Prepare larger capacity

pan than fuel filter volum.

lDrained coolant is mixed with fuel. Prevent fuel from adher-

ing to rubber parts such as engine mount insulator.

3. After draining, close drain cock by hand.

CAUTION:

If drain cock is tightened excessively, it may be damaged and

fuel will leak. Do not use tools to tighten drain cock.

4. Bleed air in fuel piping. Refer toFL-16, "

Air Bleeding".

5. Start engine.

JLC292B

Oil filter:

:20-24N·m(2.0-2.5Kg-m,15-18ft-lb)

SBIA0138E

Page 2527 of 3066

CHASSIS AND BODY MAINTENANCE

MA-35

C

D

E

F

G

H

I

J

K

MA

B

MA

CHASSIS AND BODY MAINTENANCEPFP:00100

Checking Exhaust SystemELS000B9

Check exhaust pipes, muffler and mounting for improper attachment,

leaks, cracks, damage, chafing or deterioration.

Checking Clutch Fluid Level and LeaksELS000BA

If fluid level is extremely low, check clutch system for leaks.

Checking Clutch SystemELS000BB

Check fluid lines and operating cylinder for improper attachment,

cracks, damage, loose connections, chafing and deterioration.

Checking M/T OilELS000BC

lCheck that oil is not leaking from transaxle or around it.

lCheck oil level from filler plug mounting hole as shown in the fig-

ure.

CAUTION:

Never start engine while checking oil level.

lSet a new gasket on the filler plug and install it on the transaxle.

CAUTION:

Do not reuse gasket.

Changing M/T OilELS000BD

1. Drain oil from drain plug and refill with new gear oil.

SMA211A

SFIA0066J

SMA859

Filler plug:

: 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

SCIA0361E

Page 2528 of 3066

MA-36

CHASSIS AND BODY MAINTENANCE

2. Check oil level.

CAUTION:

Do not reuse gasket.

Checking A/T FluidELS000BV

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50°C (86 to 122°F) using “COLD” range on dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of either

range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side of range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80°C (122 to 176°F) using “HOT” range on dipstick.

6. Check fluid condition.

lIf fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

lIf A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer toCO-12,

"RADIATOR",CO-15, "RADIATOR (ALUMINUM TYPE)"

,CO-33, "RADIATOR",CO-36, "RADIATOR (ALLUMINUM

TYPE)".

Changing A/T FluidELS000BW

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.Oil grade:

API GL-4

Viscosity:

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRICANTS"

Oil capacity:

Approx. 2.3 (4 lmp pt)

Drain plug:

: 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

SMA827CA

SMA853B

Fluid grade:

Genuine Nissan ATF or equivalent. Refer toMA-

17, "RECOMMENDED FLUIDS AND LUBRI-

CANTS".

SMA052D

Page 2529 of 3066

CHASSIS AND BODY MAINTENANCE

MA-37

C

D

E

F

G

H

I

J

K

MA

B

MA

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to “Checking A/T Fluid”. If fluid is still dirty, repeat steps 2 through 5.

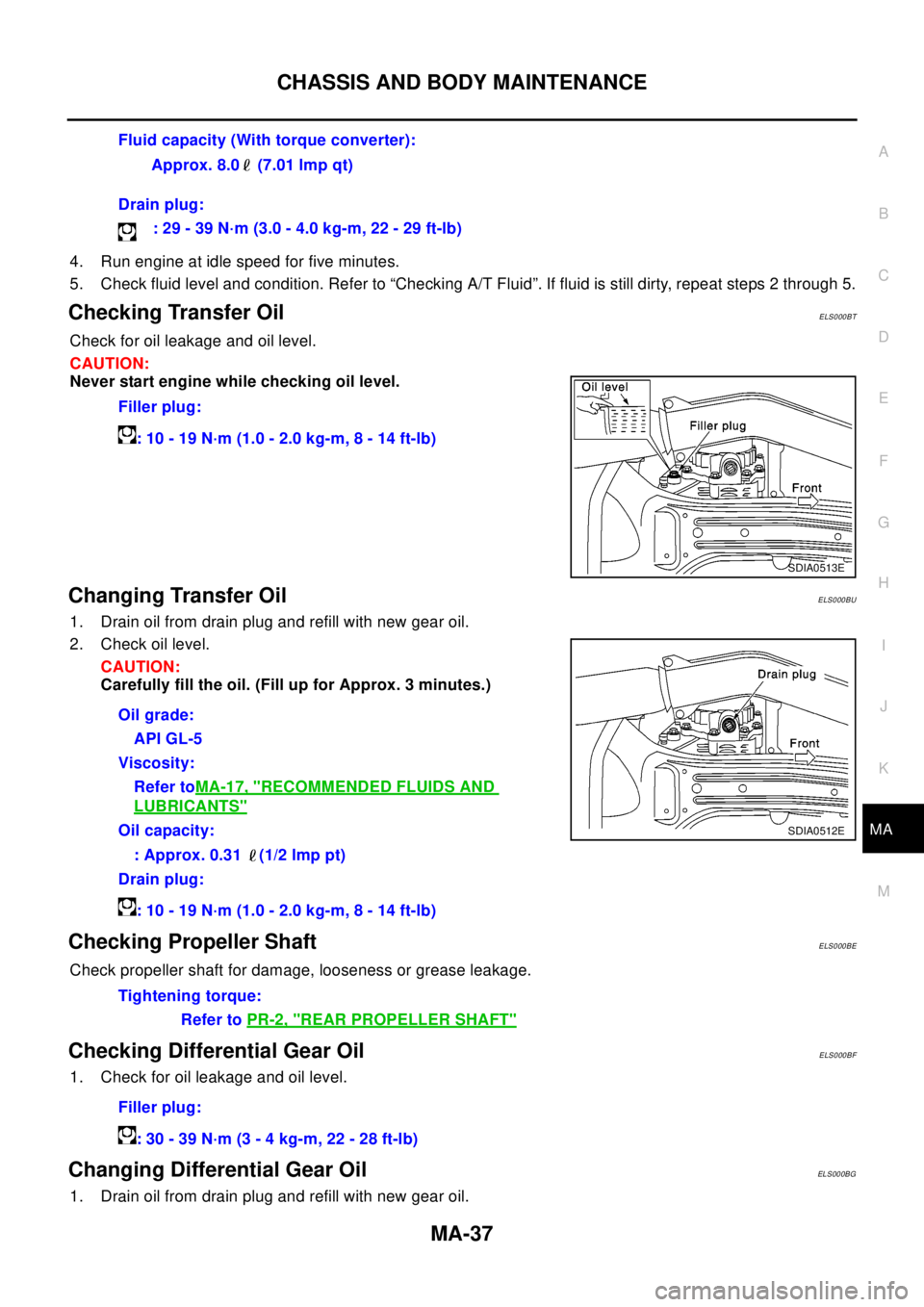

Checking Transfer OilELS000BT

Check for oil leakage and oil level.

CAUTION:

Never start engine while checking oil level.

Changing Transfer OilELS000BU

1. Drain oil from drain plug and refill with new gear oil.

2. Check oil level.

CAUTION:

Carefully fill the oil. (Fill up for Approx. 3 minutes.)

Checking Propeller ShaftELS000BE

Check propeller shaft for damage, looseness or grease leakage.

Checking Differential Gear OilELS000BF

1. Check for oil leakage and oil level.

Changing Differential Gear OilELS000BG

1. Drain oil from drain plug and refill with new gear oil.Fluid capacity (With torque converter):

Approx. 8.0 (7.01 lmp qt)

Drain plug:

:29-39N·m(3.0-4.0kg-m,22-29ft-lb)

Filler plug:

:10-19N·m(1.0-2.0kg-m,8-14ft-lb)

SDIA0513E

Oil grade:

API GL-5

Viscosity:

Refer toMA-17, "

RECOMMENDED FLUIDS AND

LUBRICANTS"

Oil capacity:

: Approx. 0.31 (1/2 lmp pt)

Drain plug:

:10-19N·m(1.0-2.0kg-m,8-14ft-lb)SDIA0512E

Tightening torque:

Refer toPR-2, "

REAR PROPELLER SHAFT"

Filler plug:

:30-39N·m(3-4kg-m,22-28ft-lb)

Page 2530 of 3066

MA-38

CHASSIS AND BODY MAINTENANCE

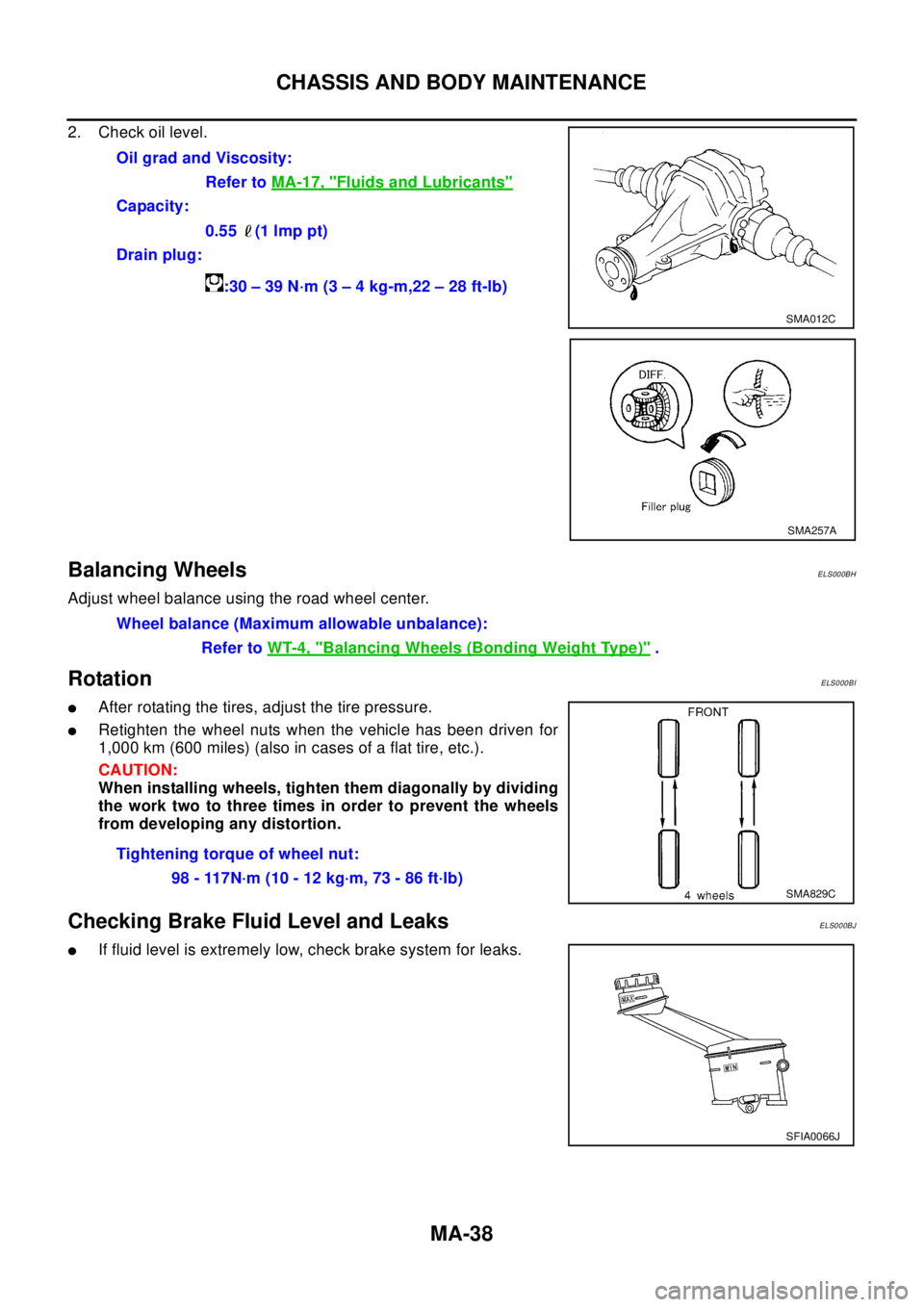

2. Check oil level.

Balancing WheelsELS000BH

Adjust wheel balance using the road wheel center.

RotationELS000BI

lAfter rotating the tires, adjust the tire pressure.

lRetighten the wheel nuts when the vehicle has been driven for

1,000 km (600 miles) (also in cases of a flat tire, etc.).

CAUTION:

When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

Checking Brake Fluid Level and LeaksELS000BJ

lIf fluid level is extremely low, check brake system for leaks.Oil grad and Viscosity:

Refer toMA-17, "

Fluids and Lubricants"

Capacity:

0.55 (1 lmp pt)

Drain plug:

:30–39N·m(3–4kg-m,22–28ft-lb)

SMA012C

SMA257A

Wheel balance (Maximum allowable unbalance):

Refer toWT-4, "

Balancing Wheels (Bonding Weight Type)".

Tightening torque of wheel nut:

98 - 117N·m (10 - 12 kg·m, 73 - 86 ft·lb)

SMA829C

SFIA0066J