light NISSAN X-TRAIL 2003 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 485 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual DISASSEMBLY

AT-479

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

b. Remove side cover by lightly tapping it with a soft hammer.

lBe careful not to drop output shaft assembly. It might

come out when removing side co NISSAN X-TRAIL 2003 Electronic Owners Manual DISASSEMBLY

AT-479

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

b. Remove side cover by lightly tapping it with a soft hammer.

lBe careful not to drop output shaft assembly. It might

come out when removing side co](/img/5/57402/w960_57402-484.png)

DISASSEMBLY

AT-479

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

b. Remove side cover by lightly tapping it with a soft hammer.

lBe careful not to drop output shaft assembly. It might

come out when removing side cover.

c. Remove adjusting shim.

d. Remove output shaft assembly.

lIf output shaft assembly came off with side cover, tap cover

with a soft hammer to separate.

SAT434D

SAT440D

SAT035F

SAT435D

Page 502 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual AT-496

[ALL]

REPAIR FOR COMPONENT PARTS

k. Install lower body on inter body using reamer boltsfas guides

and tighten reamer boltsfslightly.

2. Install O-rings to solenoid valves and terminal body.

lAp NISSAN X-TRAIL 2003 Electronic Owners Manual AT-496

[ALL]

REPAIR FOR COMPONENT PARTS

k. Install lower body on inter body using reamer boltsfas guides

and tighten reamer boltsfslightly.

2. Install O-rings to solenoid valves and terminal body.

lAp](/img/5/57402/w960_57402-501.png)

AT-496

[ALL]

REPAIR FOR COMPONENT PARTS

k. Install lower body on inter body using reamer boltsfas guides

and tighten reamer boltsfslightly.

2. Install O-rings to solenoid valves and terminal body.

lApply ATF to O-rings.

3. Install and tighten bolts.

Bolt length, number and location:

SAT126DA

SCIA0804E

Bolt symbolabcde f g

Bolt length “ ” mm (in)

13.5

(0.531)58.0

(2.283)40.0

(1.575)66.0

(2.598)33.0

(1.299)78.0

(3.071)18.0

(0.709)

Number of bolts 6 3 6 11 2 2 1

SAT704J

Page 505 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual REPAIR FOR COMPONENT PARTS

AT-499

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

DISASSEMBLY

1. Remove valves at retainer plates.

lDo not use a magnetic pick-up tool.

a. Use a screwdriver to remove retainer plates.

NISSAN X-TRAIL 2003 Electronic Owners Manual REPAIR FOR COMPONENT PARTS

AT-499

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

DISASSEMBLY

1. Remove valves at retainer plates.

lDo not use a magnetic pick-up tool.

a. Use a screwdriver to remove retainer plates.](/img/5/57402/w960_57402-504.png)

REPAIR FOR COMPONENT PARTS

AT-499

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

DISASSEMBLY

1. Remove valves at retainer plates.

lDo not use a magnetic pick-up tool.

a. Use a screwdriver to remove retainer plates.

b. Remove retainer plates while holding spring, plugs or sleeves.

lRemove plugs slowly to prevent internal parts from jump-

ing out.

c. Place mating surface of valve body face down, and remove

internal parts.

lIf a valve is hard to remove, place valve body face down

and lightly tap it with a soft hammer.

lBe careful not to drop or damage valves and sleeves.

SAT551G

SAT553G

SAT554G

SAT137D

Page 548 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual AT-542

[ALL]

ASSEMBLY

9. Remove converter housing from transmission case.

10. Remove final drive assembly from transmission case.

11. Remove differential side bearing outer race from transmission

case NISSAN X-TRAIL 2003 Electronic Owners Manual AT-542

[ALL]

ASSEMBLY

9. Remove converter housing from transmission case.

10. Remove final drive assembly from transmission case.

11. Remove differential side bearing outer race from transmission

case](/img/5/57402/w960_57402-547.png)

AT-542

[ALL]

ASSEMBLY

9. Remove converter housing from transmission case.

10. Remove final drive assembly from transmission case.

11. Remove differential side bearing outer race from transmission

case.

12. Reinstall differential side bearing outer race and shim(s)

selected from SDS table on transmission case.

13. Reinstall converter housing on transmission case and tighten

transmission case fixing bolts to the specified torque. Refer to

AT-461, "

OVERHAUL".

14. Insert Tool and measure turning torque of final drive assembly.

lTurn final drive assembly in both directions several times

to seat bearing rollers correctly.

lWhen old bearing is used again, turning torque will be

slightly less than the above.

lMake sure torque is close to the specified range.

REDUCTION PINION GEAR BEARING PRELOAD

1. Remove transmission case and final drive assembly from con-

verter housing.

2. Select proper thickness of reduction pinion gear bearing adjust-

ing shim using the following procedures.

a. Place reduction pinion gear on transmission case as shown.

b. Place idler gear bearing on transmission case.

c. Measure dimensions “B” “C” and “D” and calculate dimension

“A”.

SAT010FC

Turning torque of final drive assembly (New bearing) :

0.78 - 1.37 N-m (8.0 - 14.0 kg-cm, 6.9 - 12.2 in-lb)

Preload adapter : KV38105210

SAT188FA

SAT332DA

A=D-(B + C)

“A” : Distance between the surface of idler gear bear-

ing inner race and the adjusting shim mating

surface of reduction pinion gear.

SAT333DA

Page 590 of 3066

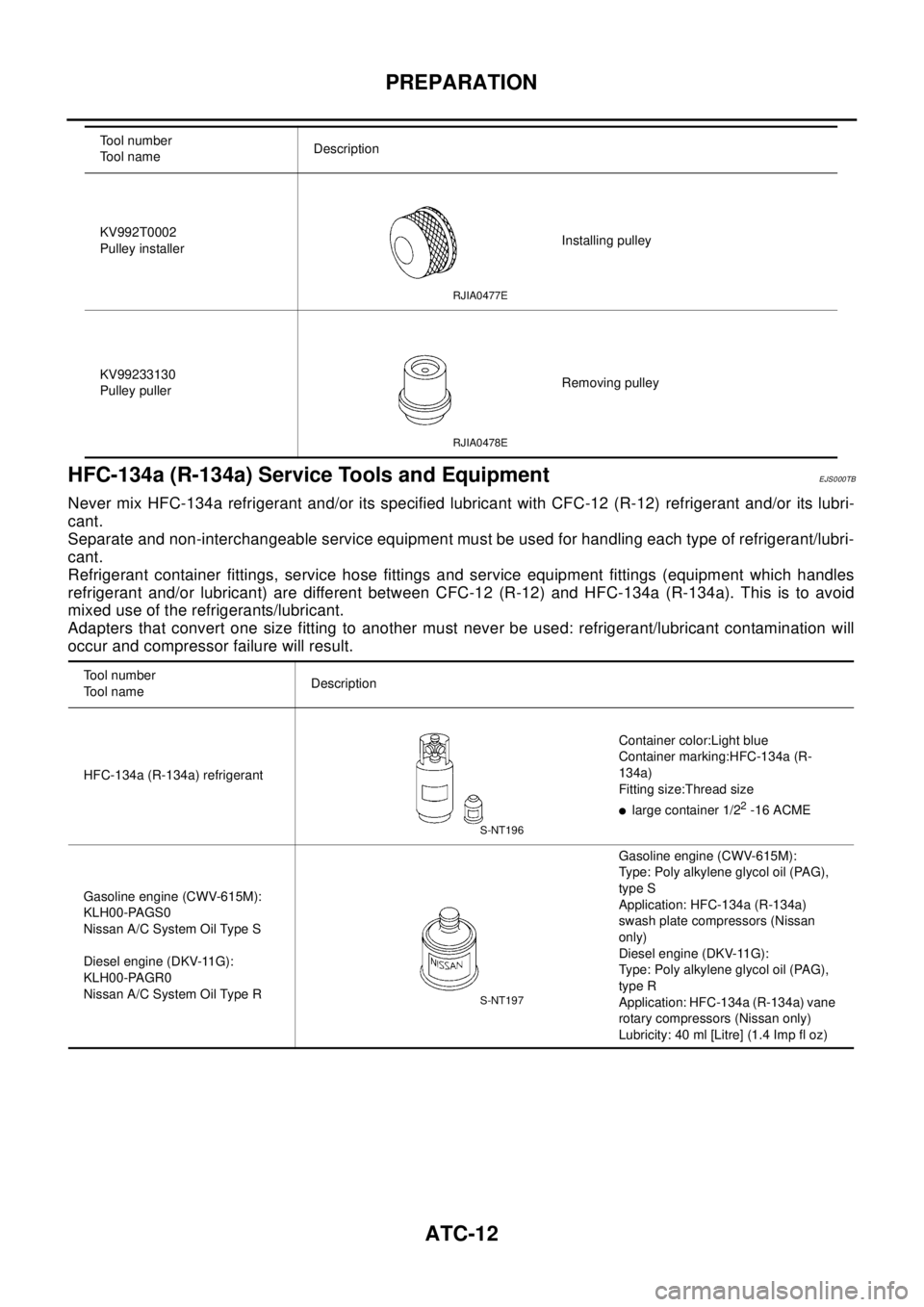

ATC-12

PREPARATION

HFC-134a (R-134a) Service Tools and Equipment

EJS000TB

Never mix HFC-134a refrigerant and/or its specified lubricant with CFC-12 (R-12) refrigerant and/or its lubri-

cant.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/lubri-

cant.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or lubricant) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Adapters that convert one size fitting to another must never be used: refrigerant/lubricant contamination will

occur and compressor failure will result.

KV992T0002

Pulley installerInstalling pulley

KV99233130

Pulley pullerRemoving pulley Tool number

Tool nameDescription

RJIA0477E

RJIA0478E

Tool number

Tool nameDescription

HFC-134a (R-134a) refrigerantContainer color:Light blue

Container marking:HFC-134a (R-

134a)

Fitting size:Thread size

llarge container 1/22-16 ACME

Gasoline engine (CWV-615M):

KLH00-PAGS0

Nissan A/C System Oil Type S

Diesel engine (DKV-11G):

KLH00-PAGR0

Nissan A/C System Oil Type RGasoline engine (CWV-615M):

Type: Poly alkylene glycol oil (PAG),

type S

Application: HFC-134a (R-134a)

swash plate compressors (Nissan

only)

Diesel engine (DKV-11G):

Type: Poly alkylene glycol oil (PAG),

type R

Application: HFC-134a (R-134a) vane

rotary compressors (Nissan only)

Lubricity: 40 ml [Litre] (1.4 Imp fl oz)

S-NT196

S-NT197

Page 591 of 3066

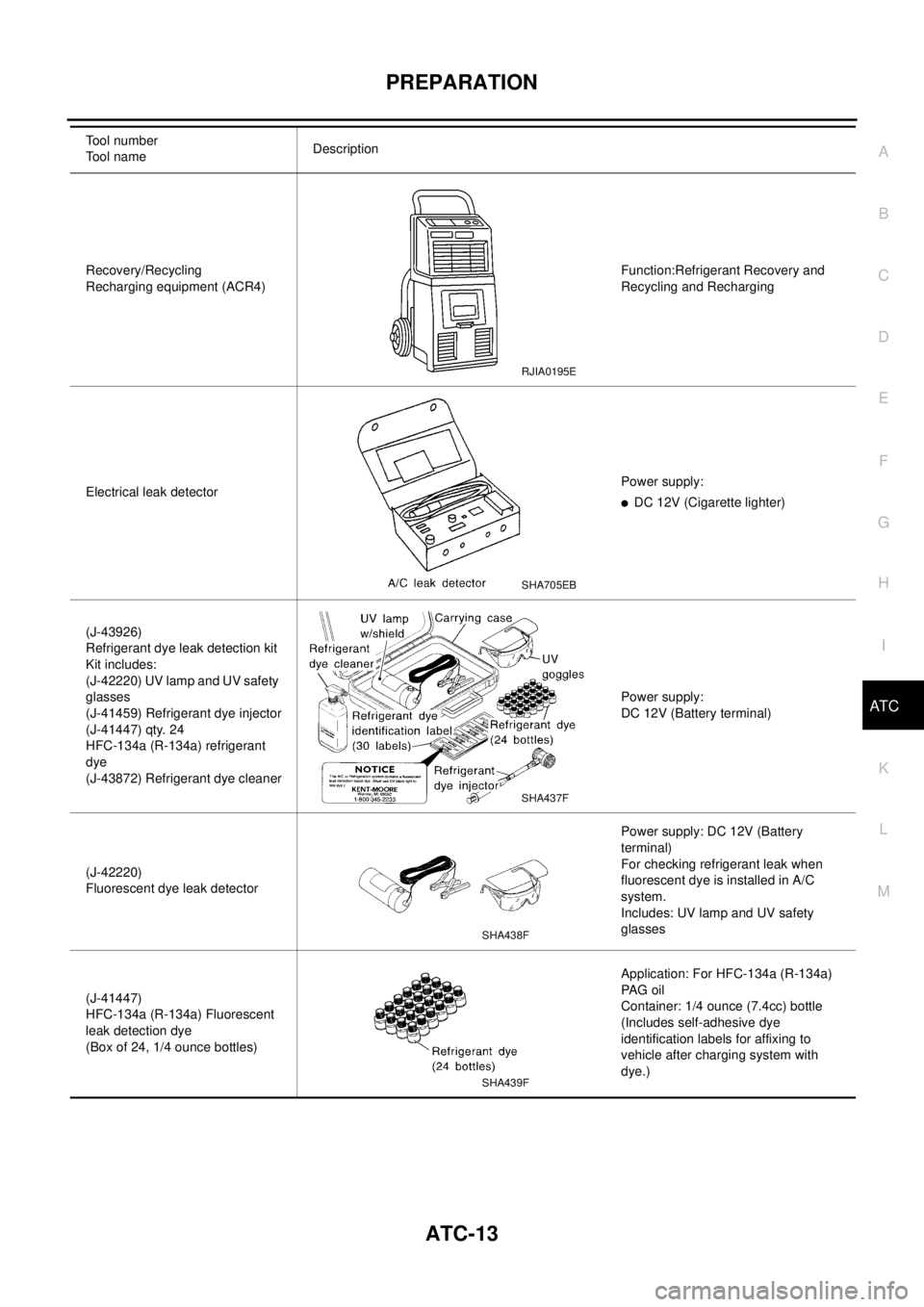

PREPARATION

ATC-13

C

D

E

F

G

H

I

K

L

MA

B

AT C

Recovery/Recycling

Recharging equipment (ACR4)Function:Refrigerant Recovery and

Recycling and Recharging

Electrical leak detectorPower supply:

lDC 12V (Cigarette lighter)

(J-43926)

Refrigerant dye leak detection kit

Kit includes:

(J-42220) UV lamp and UV safety

glasses

(J-41459) Refrigerant dye injector

(J-41447) qty. 24

HFC-134a (R-134a) refrigerant

dye

(J-43872) Refrigerant dye cleanerPower supply:

DC 12V (Battery terminal)

(J-42220)

Fluorescent dye leak detectorPower supply: DC 12V (Battery

terminal)

For checking refrigerant leak when

fluorescent dye is installed in A/C

system.

Includes: UV lamp and UV safety

glasses

(J-41447)

HFC-134a (R-134a) Fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)Application: For HFC-134a (R-134a)

PA G o i l

Container: 1/4 ounce (7.4cc) bottle

(Includes self-adhesive dye

identification labels for affixing to

vehicle after charging system with

dye.) Tool number

To o l n a m eDescription

RJIA0195E

SHA705EB

SHA437F

SHA438F

SHA439F

Page 619 of 3066

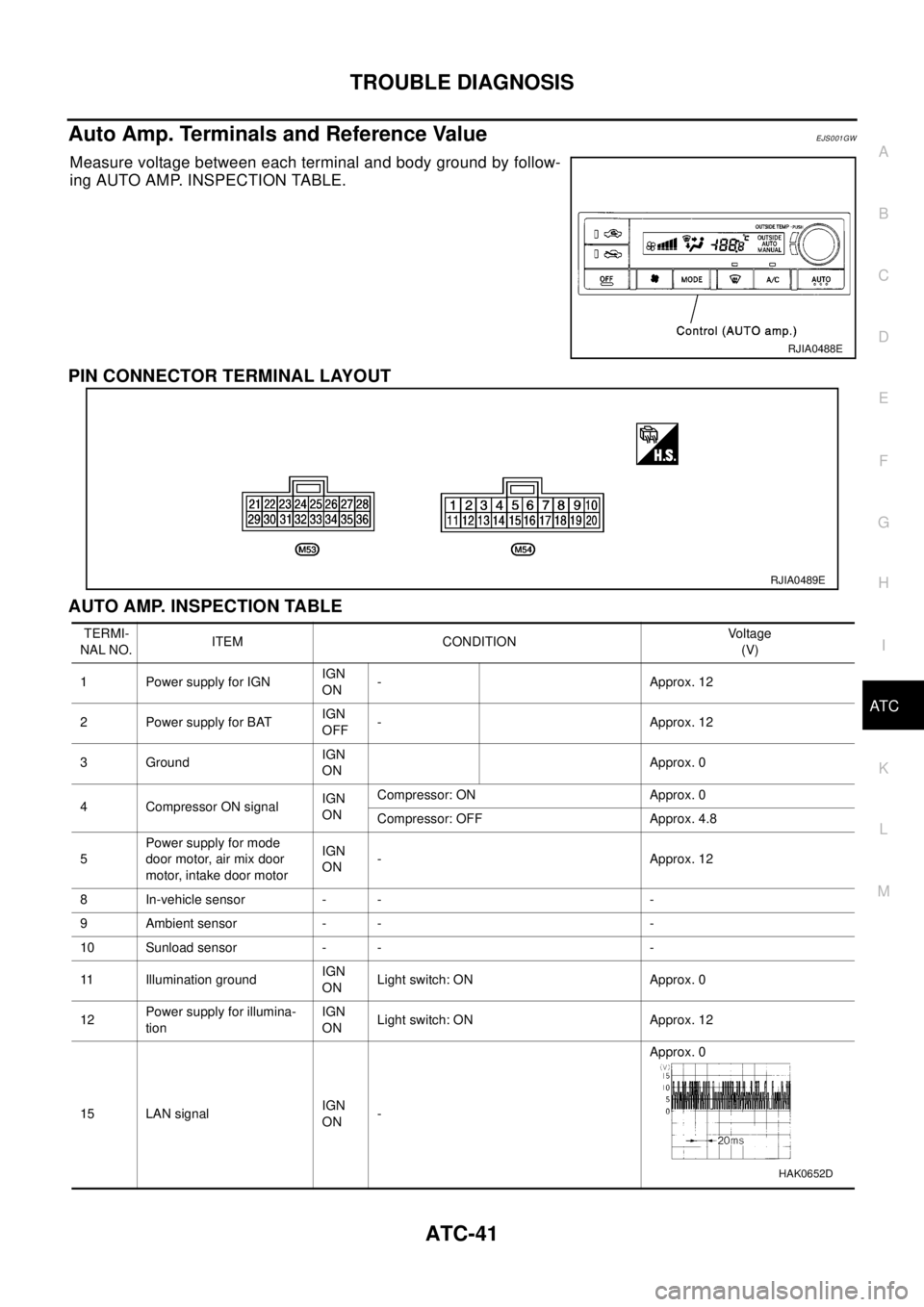

TROUBLE DIAGNOSIS

ATC-41

C

D

E

F

G

H

I

K

L

MA

B

AT C

Auto Amp. Terminals and Reference ValueEJS001GW

Measure voltage between each terminal and body ground by follow-

ing AUTO AMP. INSPECTION TABLE.

PIN CONNECTOR TERMINAL LAYOUT

AUTO AMP. INSPECTION TABLE

RJIA0488E

RJIA0489E

TERMI-

NAL NO.ITEM CONDITIONVo l ta g e

(V)

1 Power supply for IGNIGN

ON- Approx. 12

2 Power supply for BATIGN

OFF- Approx. 12

3 GroundIGN

ONApprox. 0

4 Compressor ON signalIGN

ONCompressor: ON Approx. 0

Compressor: OFF Approx. 4.8

5Power supply for mode

door motor, air mix door

motor, intake door motorIGN

ON- Approx. 12

8 In-vehicle sensor - - -

9 Ambient sensor - - -

10 Sunload sensor - - -

11 Illumination groundIGN

ONLight switch: ON Approx. 0

12Power supply for illumina-

tionIGN

ONLight switch: ON Approx. 12

15 LAN signalIGN

ON-Approx. 0

HAK0652D

Page 626 of 3066

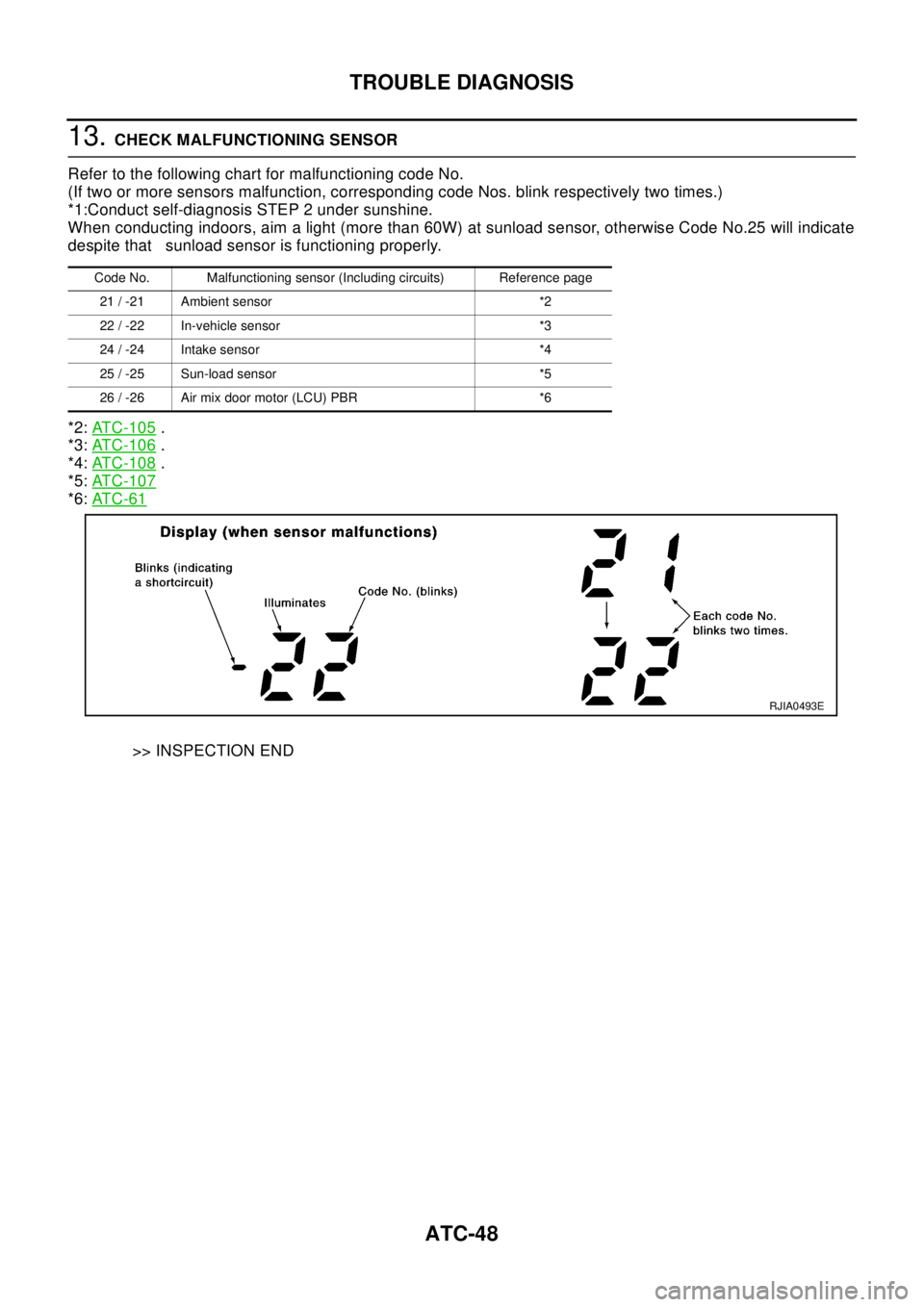

ATC-48

TROUBLE DIAGNOSIS

13.CHECK MALFUNCTIONING SENSOR

Refer to the following chart for malfunctioning code No.

(If two or more sensors malfunction, corresponding code Nos. blink respectively two times.)

*1:Conduct self-diagnosis STEP 2 under sunshine.

When conducting indoors, aim a light (more than 60W) at sunload sensor, otherwise Code No.25 will indicate

despite that sunload sensor is functioning properly.

*2:AT C - 1 0 5

.

*3:AT C - 1 0 6

.

*4:AT C - 1 0 8

.

*5:AT C - 1 0 7

*6:AT C - 6 1

>> INSPECTION END

Code No. Malfunctioning sensor (Including circuits) Reference page

21 / -21 Ambient sensor *2

22 / -22 In-vehicle sensor *3

24 / -24 Intake sensor *4

25 / -25 Sun-load sensor *5

26 / -26 Air mix door motor (LCU) PBR *6

RJIA0493E

Page 630 of 3066

ATC-52

TROUBLE DIAGNOSIS

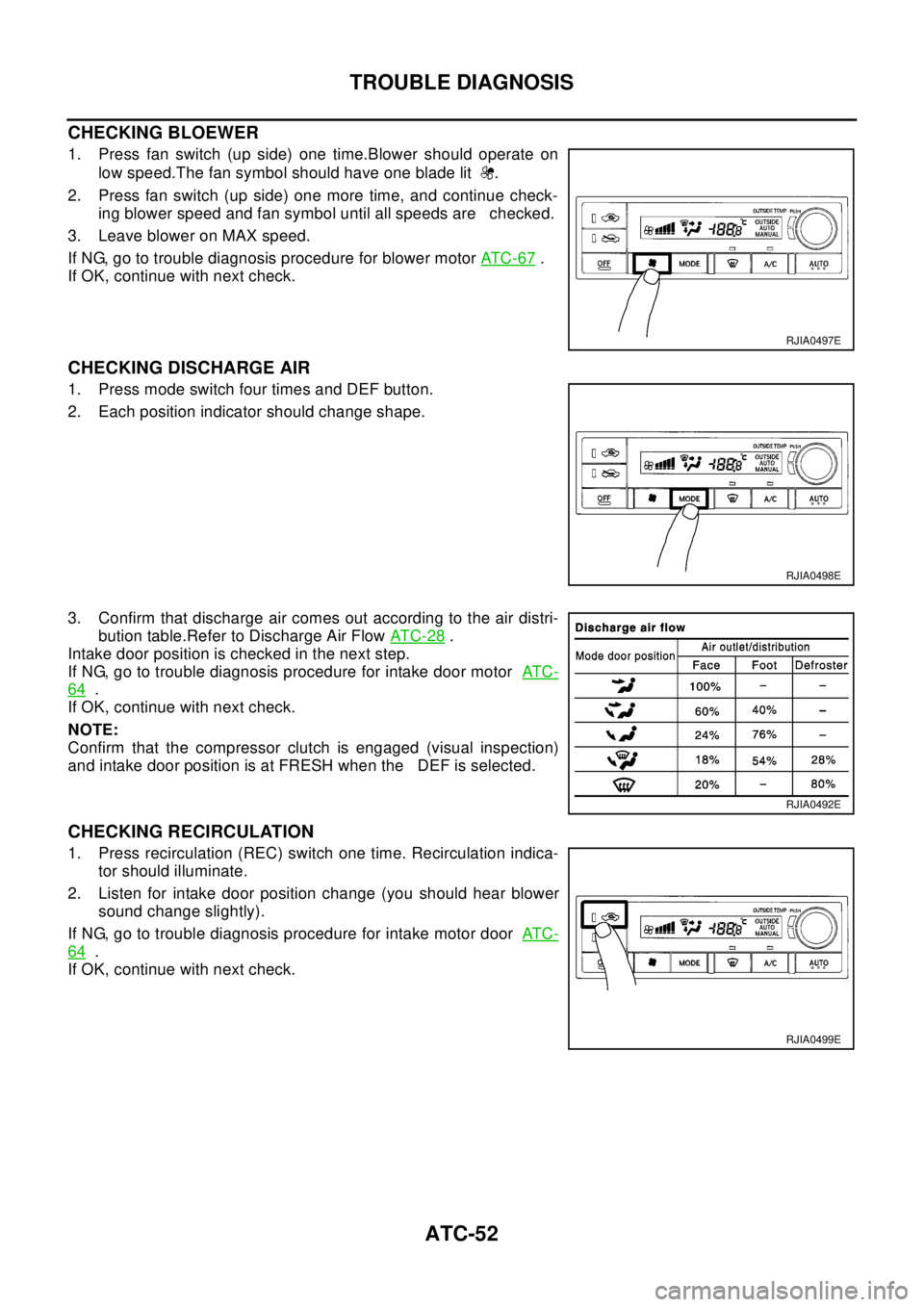

CHECKING BLOEWER

1. Press fan switch (up side) one time.Blower should operate on

low speed.The fan symbol should have one blade lit .

2. Press fan switch (up side) one more time, and continue check-

ing blower speed and fan symbol until all speeds are checked.

3. Leave blower on MAX speed.

If NG, go to trouble diagnosis procedure for blower motorAT C - 6 7

.

If OK, continue with next check.

CHECKING DISCHARGE AIR

1. Press mode switch four times and DEF button.

2. Each position indicator should change shape.

3. Confirm that discharge air comes out according to the air distri-

bution table.Refer to Discharge Air FlowAT C - 2 8

.

Intake door position is checked in the next step.

If NG, go to trouble diagnosis procedure for intake door motorAT C -

64.

If OK, continue with next check.

NOTE:

Confirm that the compressor clutch is engaged (visual inspection)

and intake door position is at FRESH when the DEF is selected.

CHECKING RECIRCULATION

1. Press recirculation (REC) switch one time. Recirculation indica-

tor should illuminate.

2. Listen for intake door position change (you should hear blower

sound change slightly).

If NG, go to trouble diagnosis procedure for intake motor doorAT C -

64.

If OK, continue with next check.

RJIA0497E

RJIA0498E

RJIA0492E

RJIA0499E

Page 666 of 3066

ATC-88

TROUBLE DIAGNOSIS

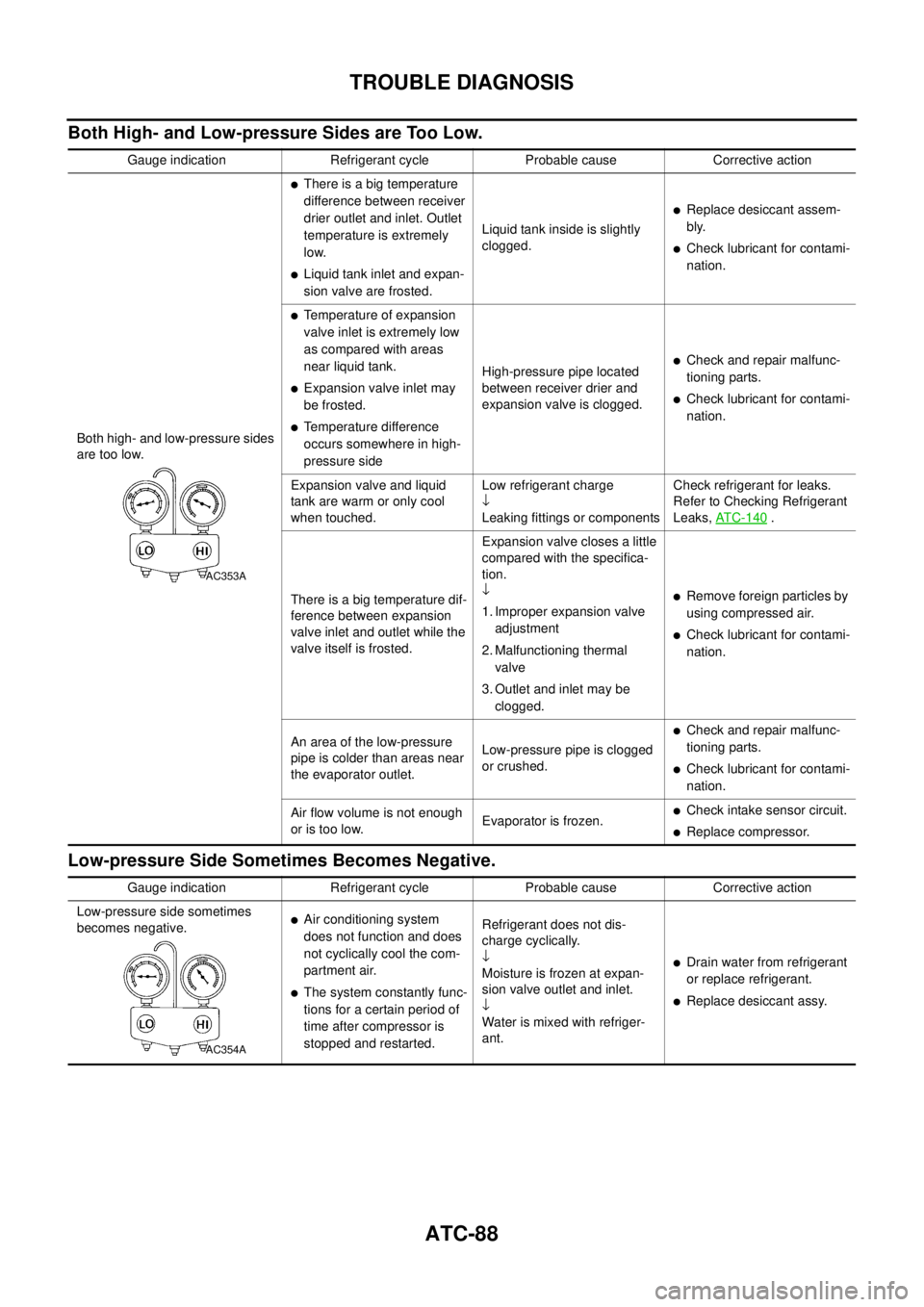

Both High- and Low-pressure Sides are Too Low.

Low-pressure Side Sometimes Becomes Negative.

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure sides

are too low.

lThere is a big temperature

difference between receiver

drier outlet and inlet. Outlet

temperature is extremely

low.

lLiquid tank inlet and expan-

sion valve are frosted.Liquid tank inside is slightly

clogged.

lReplace desiccant assem-

bly.

lCheck lubricant for contami-

nation.

lTemperature of expansion

valve inlet is extremely low

as compared with areas

near liquid tank.

lExpansion valve inlet may

be frosted.

lTemperature difference

occurs somewhere in high-

pressure sideHigh-pressure pipe located

between receiver drier and

expansion valve is clogged.

lCheck and repair malfunc-

tioning parts.

lCheck lubricant for contami-

nation.

Expansion valve and liquid

tank are warm or only cool

when touched.Low refrigerant charge

¯

Leaking fittings or componentsCheck refrigerant for leaks.

Refer to Checking Refrigerant

Leaks,AT C - 1 4 0

.

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted.Expansion valve closes a little

compared with the specifica-

tion.

¯

1. Improper expansion valve

adjustment

2. Malfunctioning thermal

valve

3. Outlet and inlet may be

clogged.

lRemove foreign particles by

using compressed air.

lCheck lubricant for contami-

nation.

An area of the low-pressure

pipe is colder than areas near

the evaporator outlet.Low-pressure pipe is clogged

or crushed.

lCheck and repair malfunc-

tioning parts.

lCheck lubricant for contami-

nation.

Air flow volume is not enough

or is too low.Evaporator is frozen.

lCheck intake sensor circuit.

lReplace compressor.

AC353A

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side sometimes

becomes negative.

lAir conditioning system

does not function and does

not cyclically cool the com-

partment air.

lThe system constantly func-

tions for a certain period of

time after compressor is

stopped and restarted.Refrigerant does not dis-

charge cyclically.

¯

Moisture is frozen at expan-

sion valve outlet and inlet.

¯

Water is mixed with refriger-

ant.

lDrain water from refrigerant

or replace refrigerant.

lReplace desiccant assy.

AC354A