engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1083 of 3066

COMBINATION METERS (RHD MODELS)

DI-29

C

D

E

F

G

H

I

J

L

MA

B

DI

3.SEGMENTS CHECK

Check odo/trip meter segment.

Do all segments illuminate ?

YES >> GO TO 4.

NO >> Replace combination meter.

4.CHECK FUEL WARNING LAMP

Check fuel warning lamp in diagnosis mode. Refer toDI-28, "

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode".

Do fuel warning lamp illuminate?

OK >> GO TO 5.

NG >> Replace combination meter.

5.CHECK METER CIRCUIT

Check indication of each meter/gauge in diagnosis mode. Refer toDI-28, "

Meter/Gauge Operation and Odo/

Trip Meter Segment Check in Diagnosis Mode".

OK or NG ?

OK >> GO TO symptom chart.

NG >> Replace combination meter.

SYMPTOM CHART

Symptom Possible cause Repair procedure

Fuel warning lamp is

malfunctioning.

1. Sensor Signal

–Engine revolution signal

–Fuel gauge

–Water temp gauge

2. Unified meter control unit1. Check the sensor for malfunctioning meter/gauge.

–Inspection/Engine Speed Signal (Refer toDI-30, "Inspection/

Engine Speed Signal")

–Inspection/Fuel Level Sensor Unit (Refer toDI-33, "Inspection/

Fuel Level Sensor Unit")

–Inspection/Water Temperature Gauge (Refer toDI-31, "Inspec-

tion/Water Temperature Gauge /Gasoline Engine Models"or )

2. Replace combination meter One of tachometer/fuel

gauge/water temp. gauge is

malfunctioning.

Speedometer and odo/trip

meter is malfunctioning.1. Sensor Signal

–Vehicle speed signal

2. Unified meter control unit1. Check the sensor for malfunctioning meter/gauge.–Inspection/Vehicle Speed Signal (Refer toDI-32, "Inspection/

Vehicle speed signal")

2. Replace combination meter

Multiple meter/gauge are

malfunctioning.

lUnified meter control unitlReplace combination meter.

Page 1084 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual DI-30

COMBINATION METERS (RHD MODELS)

Power Supply and Ground Circuit Check

EKS0030O

1.POWER SUPPLY CIRCUIT CHECK

OK or NG ?

OK >> GO TO 2.

NG >>

l10A fuse [No. 11, located in fuse block (J/B)].

l10A NISSAN X-TRAIL 2003 Electronic Repair Manual DI-30

COMBINATION METERS (RHD MODELS)

Power Supply and Ground Circuit Check

EKS0030O

1.POWER SUPPLY CIRCUIT CHECK

OK or NG ?

OK >> GO TO 2.

NG >>

l10A fuse [No. 11, located in fuse block (J/B)].

l10A](/img/5/57402/w960_57402-1083.png)

DI-30

COMBINATION METERS (RHD MODELS)

Power Supply and Ground Circuit Check

EKS0030O

1.POWER SUPPLY CIRCUIT CHECK

OK or NG ?

OK >> GO TO 2.

NG >>

l10A fuse [No. 11, located in fuse block (J/B)].

l10A fuse [No. 28, located in fuse block (J/B)].

lHarness for open or short between fuse and combination meter.

2.GROUND CIRCUIT CHECK

OK or NG ?

OK >> Inspection end.

NG >> Harness for open ground circuit.

Inspection/Engine Speed SignalEKS0030P

1.CHECK ECM OUTPUT

1. Start engine.

2. Check voltage between combination meter harness connector

M46 terminals 41 (L/OR) and ground at idle and 2,000 rpm.

OK or NG ?

OK >> Engine speed signal is OK.

NG >> Harness for open or short between ECM and combina-

tion meter.

Terminals Ignition switch position

(+)

(-)OFF ACC ON

ConnectorTe r m i n a l

(wire

color)

M46 58(L) GroundBattery

voltageBattery

voltageBattery

voltage

M46 59(W/L) Ground 0V 0VBattery

voltage

SKIA1019E

Te r m i n a l s

Continuity (+)

(-)

Connector Terminal

M46 60 Ground Yes

SKIA1020E

Higher rpm = Higher voltage

Lower rpm = Lower voltage

Voltage should change with rpm.

SKIA1021E

Page 1085 of 3066

COMBINATION METERS (RHD MODELS)

DI-31

C

D

E

F

G

H

I

J

L

MA

B

DI

Inspection/Water Temperature Gauge /Gasoline Engine ModelsEKS0030Q

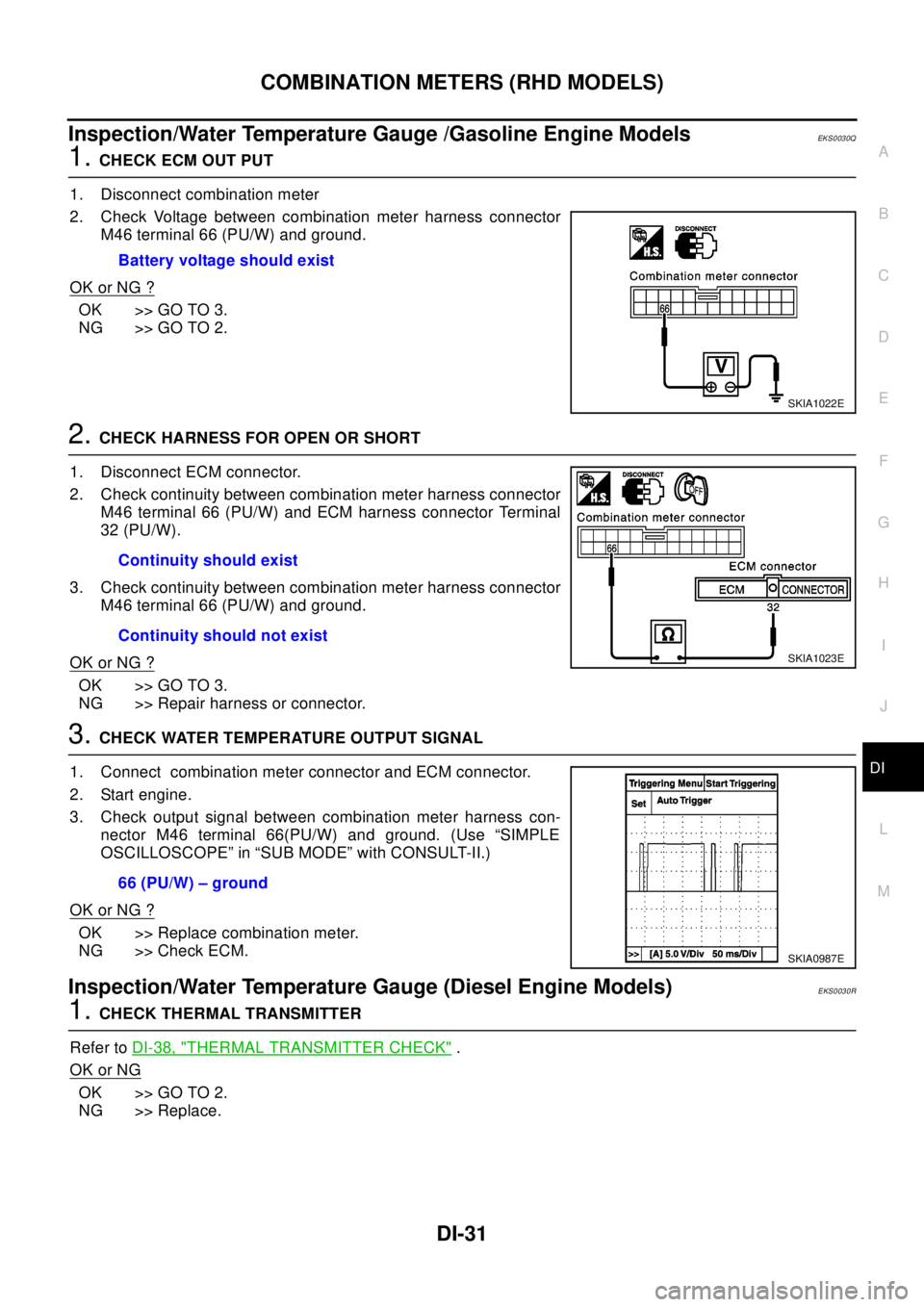

1.CHECK ECM OUT PUT

1. Disconnect combination meter

2. Check Voltage between combination meter harness connector

M46 terminal 66 (PU/W) and ground.

OK or NG ?

OK >> GO TO 3.

NG >> GO TO 2.

2.CHECK HARNESS FOR OPEN OR SHORT

1. Disconnect ECM connector.

2. Check continuity between combination meter harness connector

M46 terminal 66 (PU/W) and ECM harness connector Terminal

32 (PU/W).

3. Check continuity between combination meter harness connector

M46 terminal 66 (PU/W) and ground.

OK or NG ?

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK WATER TEMPERATURE OUTPUT SIGNAL

1. Connect combination meter connector and ECM connector.

2. Start engine.

3. Check output signal between combination meter harness con-

nector M46 terminal 66(PU/W) and ground. (Use “SIMPLE

OSCILLOSCOPE” in “SUB MODE” with CONSULT-II.)

OK or NG ?

OK >> Replace combination meter.

NG >> Check ECM.

Inspection/Water Temperature Gauge (Diesel Engine Models)EKS0030R

1.CHECK THERMAL TRANSMITTER

Refer toDI-38, "

THERMAL TRANSMITTER CHECK".

OK or NG

OK >> GO TO 2.

NG >> Replace.Battery voltage should exist

SKIA1022E

Continuity should exist

Continuity should not exist

SKIA1023E

66 (PU/W) – ground

SKIA0987E

Page 1087 of 3066

COMBINATION METERS (RHD MODELS)

DI-33

C

D

E

F

G

H

I

J

L

MA

B

DI

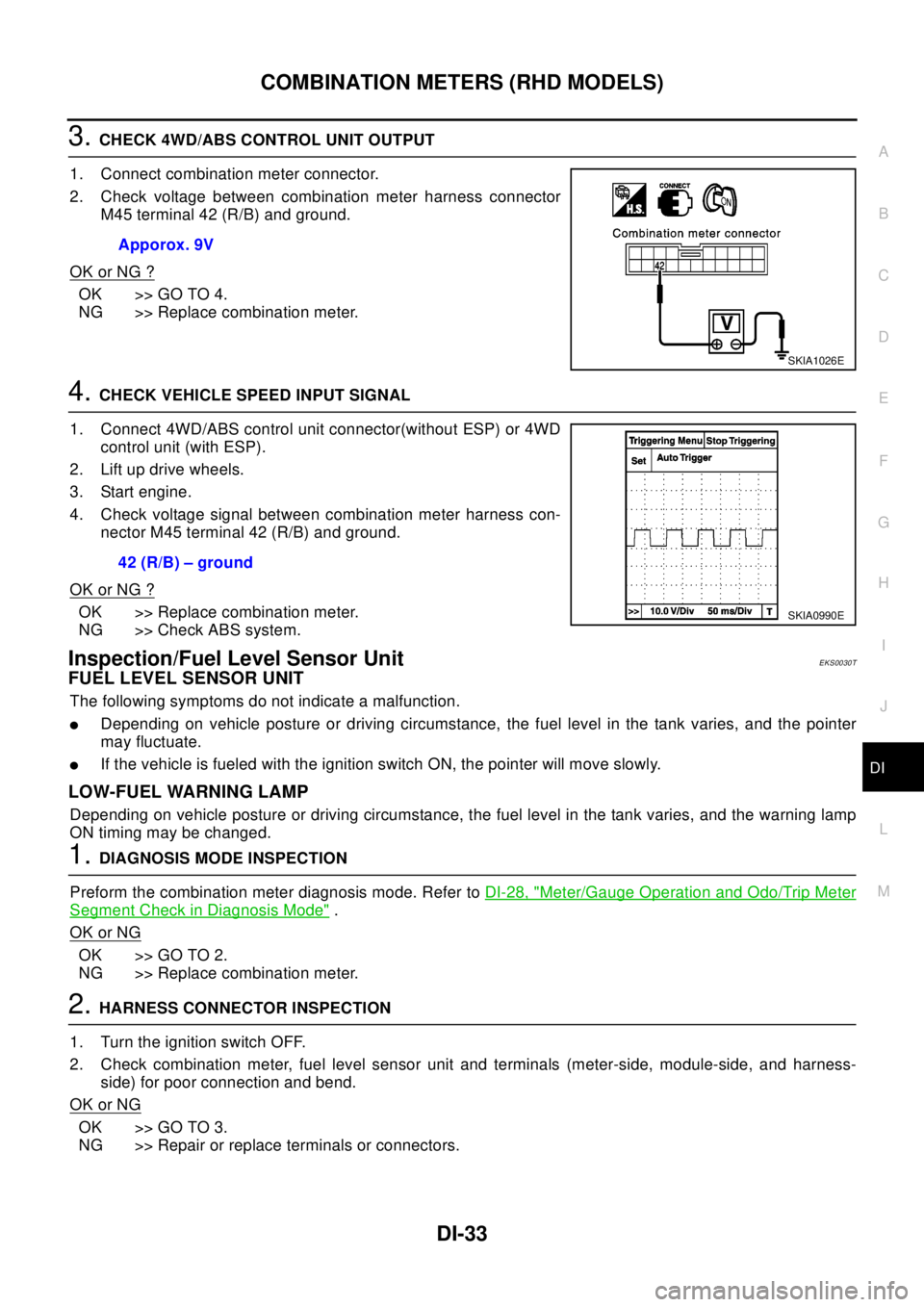

3.CHECK 4WD/ABS CONTROL UNIT OUTPUT

1. Connect combination meter connector.

2. Check voltage between combination meter harness connector

M45 terminal 42 (R/B) and ground.

OK or NG ?

OK >> GO TO 4.

NG >> Replace combination meter.

4.CHECK VEHICLE SPEED INPUT SIGNAL

1. Connect 4WD/ABS control unit connector(without ESP) or 4WD

control unit (with ESP).

2. Lift up drive wheels.

3. Start engine.

4. Check voltage signal between combination meter harness con-

nector M45 terminal 42 (R/B) and ground.

OK or NG ?

OK >> Replace combination meter.

NG >> Check ABS system.

Inspection/Fuel Level Sensor UnitEKS0030T

FUEL LEVEL SENSOR UNIT

The following symptoms do not indicate a malfunction.

lDepending on vehicle posture or driving circumstance, the fuel level in the tank varies, and the pointer

may fluctuate.

lIf the vehicle is fueled with the ignition switch ON, the pointer will move slowly.

LOW-FUEL WARNING LAMP

Depending on vehicle posture or driving circumstance, the fuel level in the tank varies, and the warning lamp

ON timing may be changed.

1.DIAGNOSIS MODE INSPECTION

Preform the combination meter diagnosis mode. Refer toDI-28, "

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode".

OK or NG

OK >> GO TO 2.

NG >> Replace combination meter.

2.HARNESS CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Check combination meter, fuel level sensor unit and terminals (meter-side, module-side, and harness-

side) for poor connection and bend.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace terminals or connectors.Apporox. 9V

SKIA1026E

42 (R/B) – ground

SKIA0990E

Page 1088 of 3066

DI-34

COMBINATION METERS (RHD MODELS)

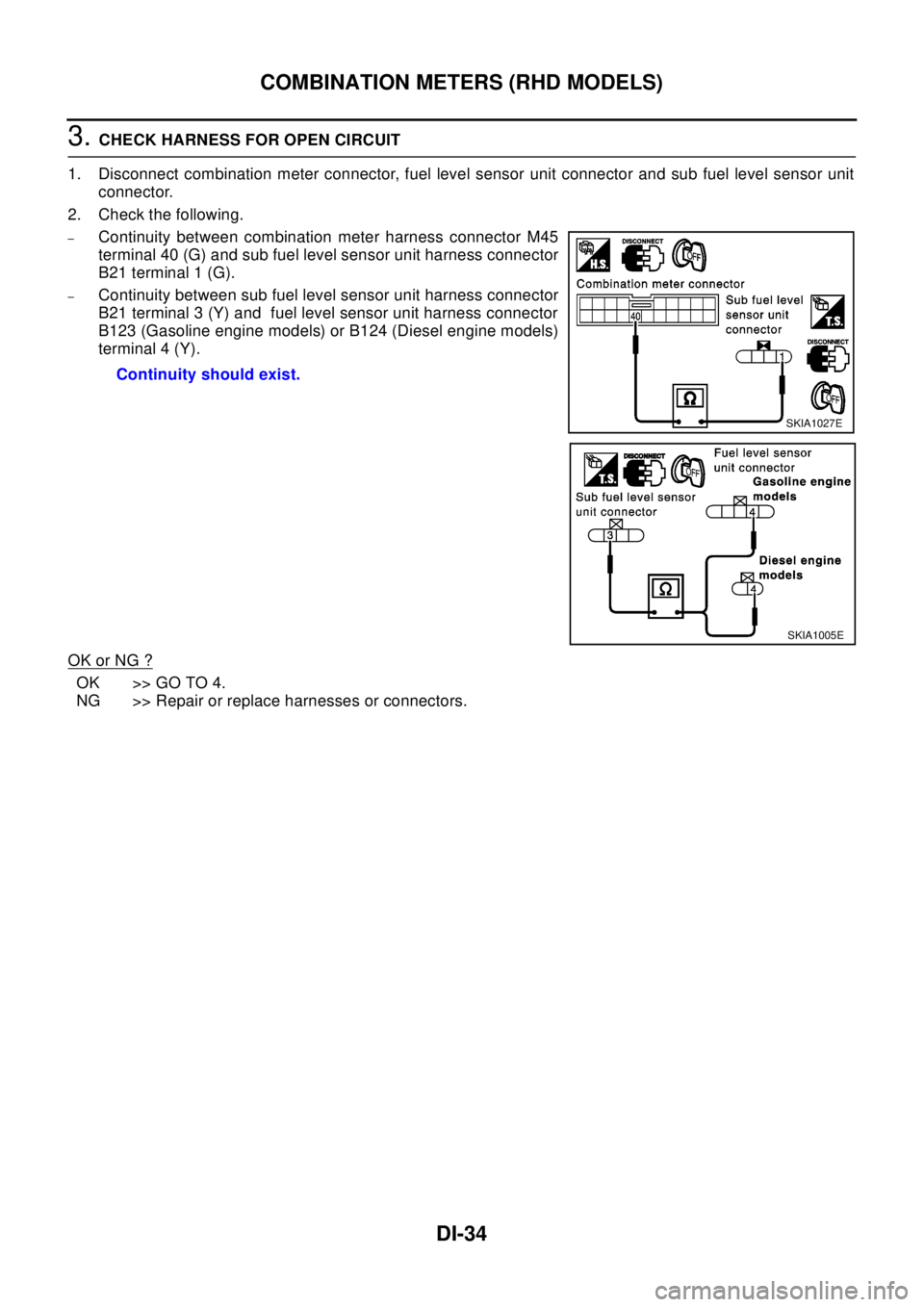

3.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect combination meter connector, fuel level sensor unit connector and sub fuel level sensor unit

connector.

2. Check the following.

–Continuity between combination meter harness connector M45

terminal 40 (G) and sub fuel level sensor unit harness connector

B21 terminal 1 (G).

–Continuity between sub fuel level sensor unit harness connector

B21 terminal 3 (Y) and fuel level sensor unit harness connector

B123 (Gasoline engine models) or B124 (Diesel engine models)

terminal 4 (Y).

OK or NG ?

OK >> GO TO 4.

NG >> Repair or replace harnesses or connectors.Continuity should exist.

SKIA1027E

SKIA1005E

Page 1089 of 3066

COMBINATION METERS (RHD MODELS)

DI-35

C

D

E

F

G

H

I

J

L

MA

B

DI

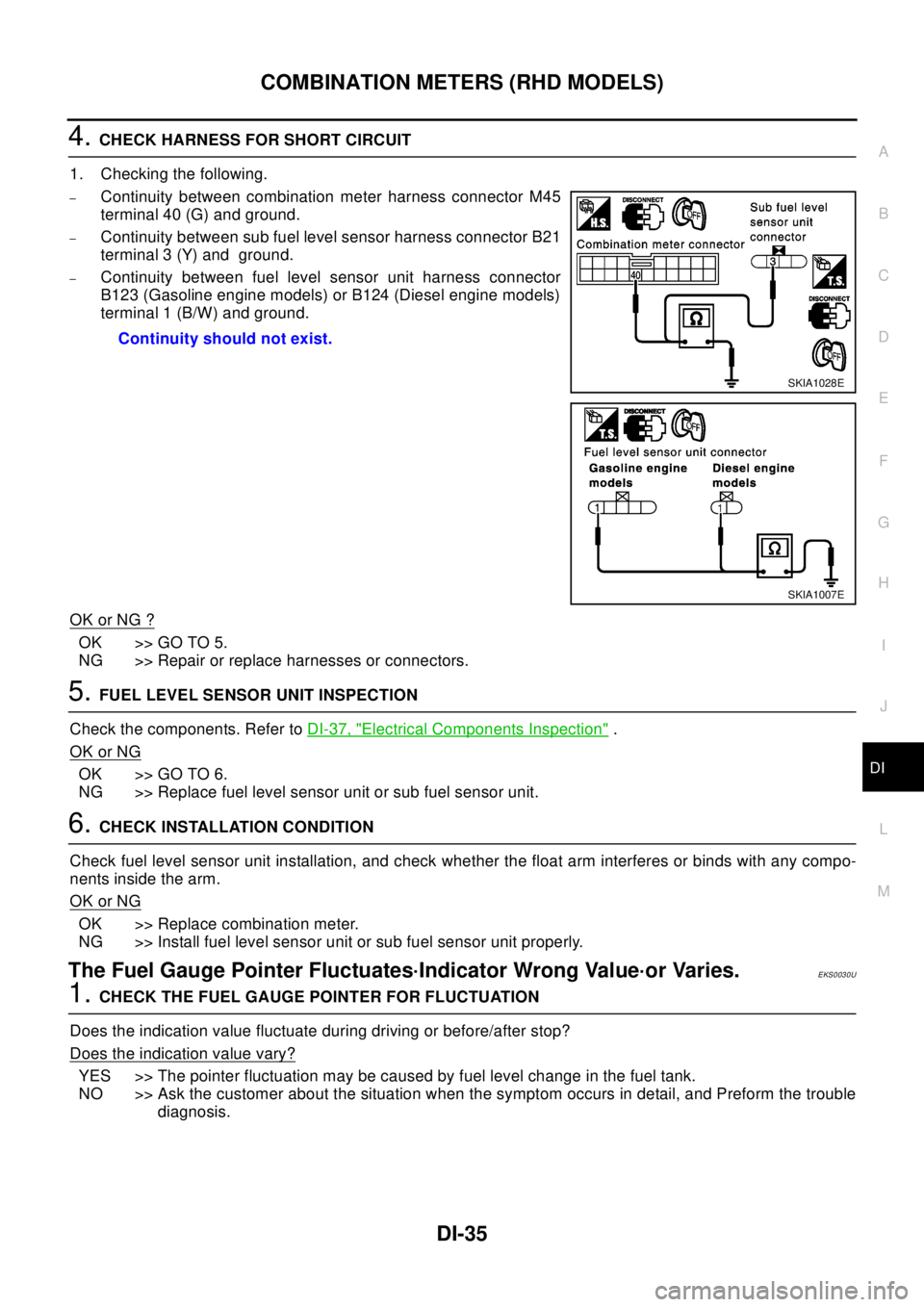

4.CHECK HARNESS FOR SHORT CIRCUIT

1. Checking the following.

–Continuity between combination meter harness connector M45

terminal 40 (G) and ground.

–Continuity between sub fuel level sensor harness connector B21

terminal 3 (Y) and ground.

–Continuity between fuel level sensor unit harness connector

B123 (Gasoline engine models) or B124 (Diesel engine models)

terminal 1 (B/W) and ground.

OK or NG ?

OK >> GO TO 5.

NG >> Repair or replace harnesses or connectors.

5.FUEL LEVEL SENSOR UNIT INSPECTION

Check the components. Refer toDI-37, "

Electrical Components Inspection".

OK or NG

OK >> GO TO 6.

NG >> Replace fuel level sensor unit or sub fuel sensor unit.

6.CHECK INSTALLATION CONDITION

Check fuel level sensor unit installation, and check whether the float arm interferes or binds with any compo-

nents inside the arm.

OK or NG

OK >> Replace combination meter.

NG >> Install fuel level sensor unit or sub fuel sensor unit properly.

The Fuel Gauge Pointer Fluctuates·Indicator Wrong Value·or Varies.EKS0030U

1.CHECK THE FUEL GAUGE POINTER FOR FLUCTUATION

Does the indication value fluctuate during driving or before/after stop?

Does the indication value vary?

YES >> The pointer fluctuation may be caused by fuel level change in the fuel tank.

NO >> Ask the customer about the situation when the symptom occurs in detail, and Preform the trouble

diagnosis. Continuity should not exist.

SKIA1028E

SKIA1007E

Page 1090 of 3066

DI-36

COMBINATION METERS (RHD MODELS)

The Fuel Gauge Does Not Move to F-position.

EKS0030V

1.QUESTIONNAIRE 1

Does it take a long time for the pointer to move to F-position?

YES?

YES >> GO TO 2.

NO >> GO TO 3.

2.QUESTIONNAIRE 2

Was the vehicle fueled with the ignition switch ON?

YES ?

YES >> Be sure to fuel the vehicle with the ignition switch OFF. Otherwise it will take a long time to move

to F-position because of the characteristic of the fuel gauge.

NO >> GO TO 3.

3.QUESTIONNAIRE 3

Is the floor or the vehicle inclined?

YES?

YES >> It may not be filled fully.

NO >> GO TO 4.

4.QUESTIONNAIRE 4

During driving, does the fuel gauge pointer move gradually toward E-position?

YES ?

YES >> Check the components. Refer toDI-37, "Electrical Components Inspection".

NO >> The float arm may interfere or bind with any of the components in the fuel tank.

The Fuel Gauge Does Not Work.EKS0030W

1.HARNESS CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Check combination meter, fuel level sensor unit, sub fuel level sensor unit and terminals (meter-side,

module-side, and harness-side) for poor connection and bend.

OK or NG

OK >> GO TO 2.

NG >> Repair connector.

2.CHECK INSTALLATION CONDITION

Check fuel level sensor unit or sub fuel level sensor unit installation (refer toFL-4, "

FUEL LEVEL SENSOR

UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY"for QR engine models orFL-17, "FUEL LEVEL SEN-

SOR UNIT"for YD engine models, and check whether the float arm interferes or binds with any components

inside the arm.

OK or NG

OK >> Fuel level sensor unit is OK.

NG >> Check fuel level sensor unit or sub fuel level sensor unit. Refer toDI-37, "

Electrical Components

Inspection".

Page 1091 of 3066

COMBINATION METERS (RHD MODELS)

DI-37

C

D

E

F

G

H

I

J

L

MA

B

DI

Low Fuel Warning Lamp Illuminate or Not IlluminateEKS0030X

1.DIAGNOSIS MODE INSPECTION

Preform combination meter diagnosis mode. Refer toDI-28, "

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode".

OK or NG

OK >> Check fuel level sensor unit or sub fuel level sensor unit. Refer toDI-37, "Electrical Components

Inspection".

NG >> Replace combination meter.

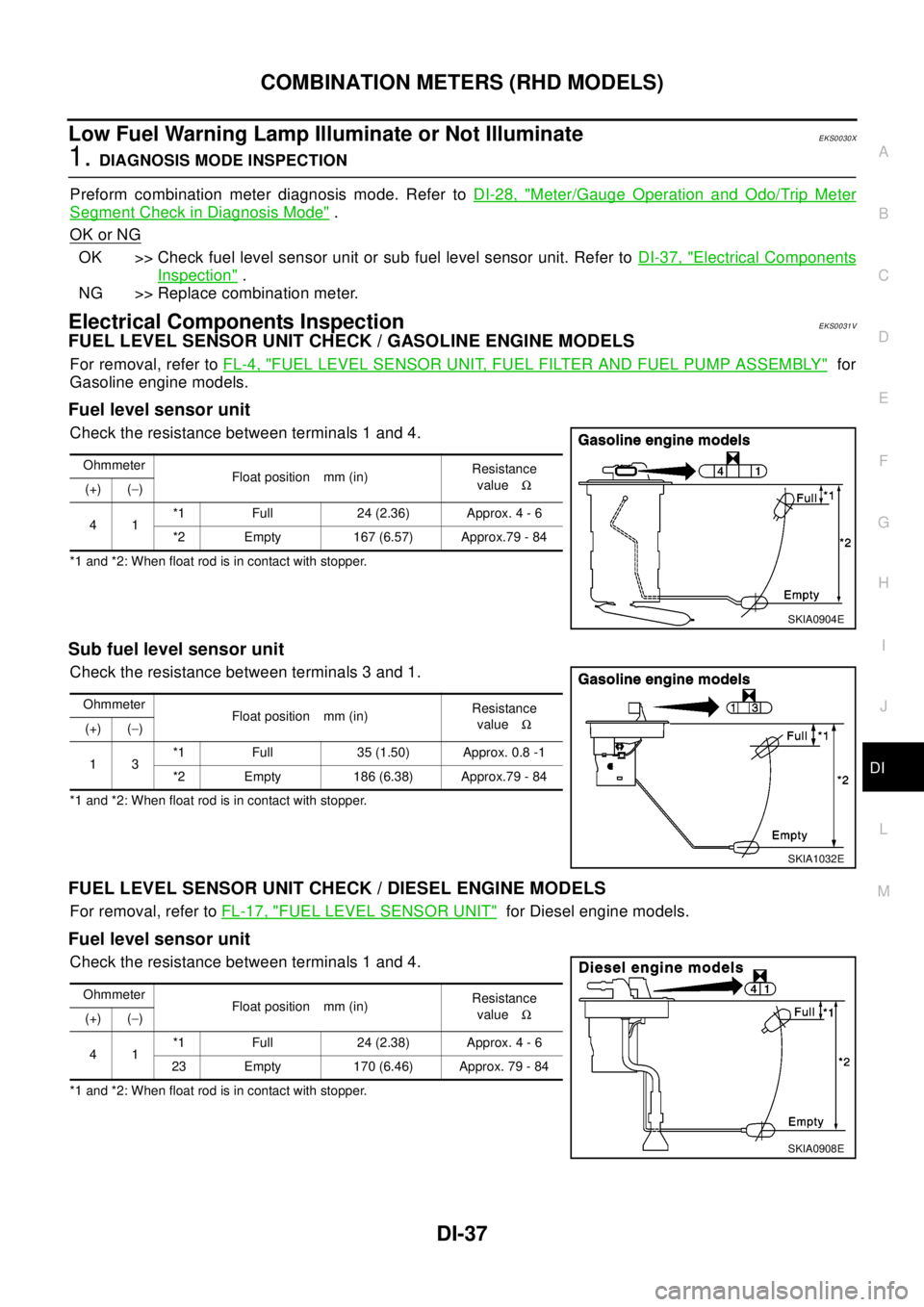

Electrical Components InspectionEKS0031V

FUEL LEVEL SENSOR UNIT CHECK / GASOLINE ENGINE MODELS

For removal, refer toFL-4, "FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY"for

Gasoline engine models.

Fuel level sensor unit

Check the resistance between terminals 1 and 4.

*1 and *2: When float rod is in contact with stopper.

Sub fuel level sensor unit

Check the resistance between terminals 3 and 1.

*1 and *2: When float rod is in contact with stopper.

FUEL LEVEL SENSOR UNIT CHECK / DIESEL ENGINE MODELS

For removal, refer toFL-17, "FUEL LEVEL SENSOR UNIT"for Diesel engine models.

Fuel level sensor unit

Check the resistance between terminals 1 and 4.

*1 and *2: When float rod is in contact with stopper.Ohmmeter

Float position mm (in)Resistance

valueW

(+) (-)

41*1 Full 24 (2.36) Approx. 4 - 6

*2 Empty 167 (6.57) Approx.79 - 84

SKIA0904E

Ohmmeter

Float position mm (in)Resistance

valueW

(+) (-)

13*1 Full 35 (1.50) Approx. 0.8 -1

*2 Empty 186 (6.38) Approx.79 - 84

SKIA1032E

Ohmmeter

Float position mm (in)Resistance

valueW

(+) (-)

41*1 Full 24 (2.38) Approx. 4 - 6

23 Empty 170 (6.46) Approx. 79 - 84

SKIA0908E

Page 1104 of 3066

DI-50

WARNING LAMPS

Electrical Components Inspection

EKS002HK

FUEL WARNING LAMP OPERATION CHECK

1. Turn ignition switch “OFF”.

2. Disconnect fuel level sensor unit harness connector B125.

3. Connect a resistor (80W) between fuel level sensor unit harness

connector terminal 1(G) and ground.

4. Turn ignition switch “ON”.

The fuel warning lamp should come on.

OIL PRESSURE SWITCH CHECK

Check the continuity between the terminals of oil pressure switch

and body ground.

DIODE CHECK

lCheck continuity using an ohmmeter.

lDiode is functioning properly if test results are as shown in the

figure at left.

lCheck diodes at the combination meter harness connector

instead of on the combination meter assembly. Refer toDI-40,

"Wiring Diagram—WARN—/LHDModels"orDI-45, "Wiring

Diagram—WARN—/RHDModels".

NOTE:

Specification may vary depending on the type of tester. Before

performing this inspection, be sure to refer to the instruction

manual for the tester to be used.

SKIA0993E

Oil pressure kPa (bar,

kg/cm2,psi)Continuity

Engine runningMore than 10 - 20 (0.10 -

0.20,0.1-0.2,1-3)No

Engine not runningLess than 10 - 20 (0.10 -

0.20,0.1-0.2,1-3)Ye s

MEL425F

SEL901F

Page 1115 of 3066

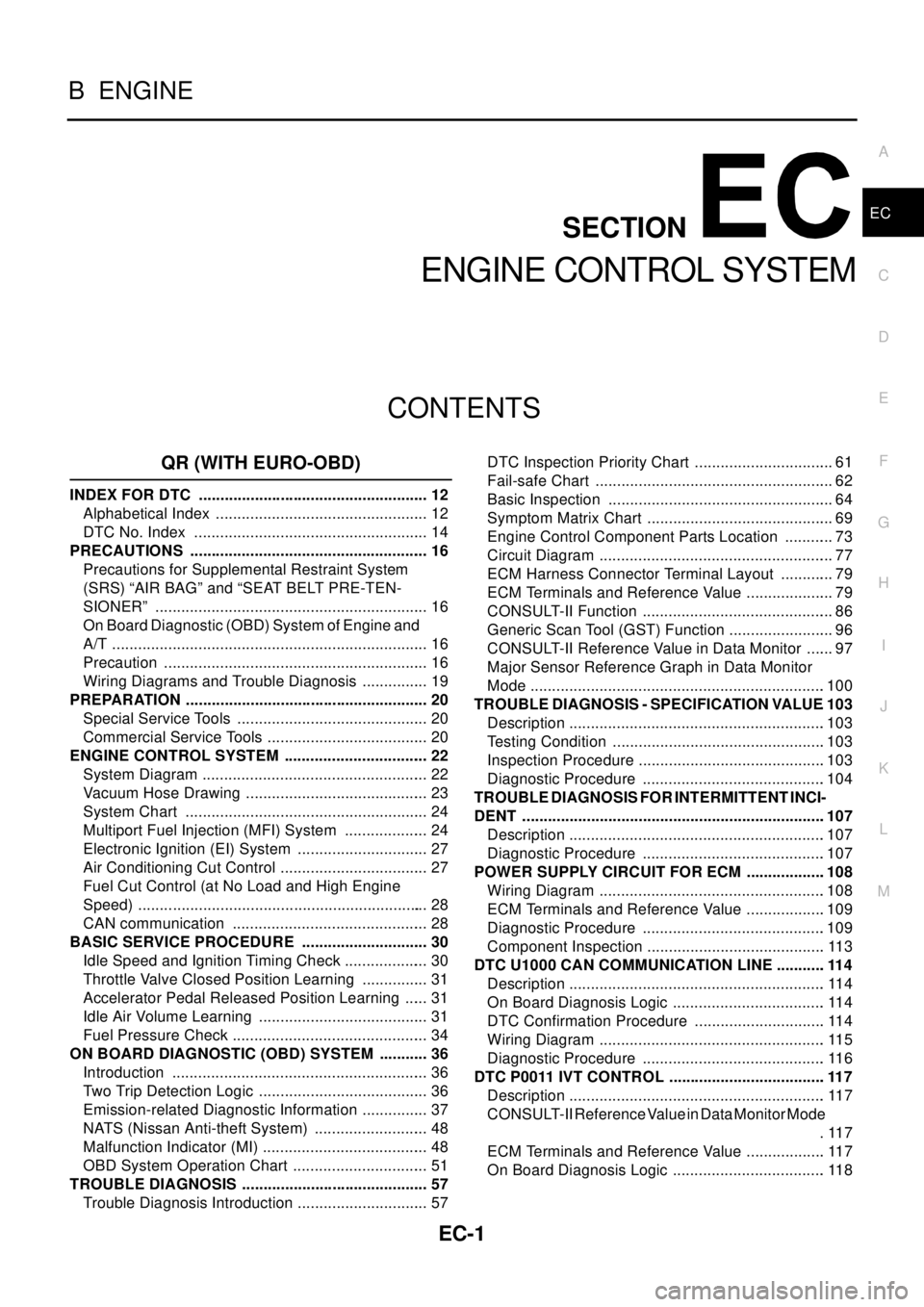

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

EC

ENGINE CONTROL SYSTEM

QR (WITH EURO-OBD)

INDEX FOR DTC ...................................................... 12

Alphabetical Index .................................................. 12

DTC No. Index ....................................................... 14

PRECAUTIONS ........................................................ 16

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 16

On Board Diagnostic (OBD) System of Engine and

A/T .......................................................................... 16

Precaution .............................................................. 16

Wiring Diagrams and Trouble Diagnosis ................ 19

PREPARATION ......................................................... 20

Special Service Tools ............................................. 20

Commercial Service Tools ...................................... 20

ENGINE CONTROL SYSTEM .................................. 22

System Diagram ..................................................... 22

Vacuum Hose Drawing ........................................... 23

System Chart ......................................................... 24

Multiport Fuel Injection (MFI) System .................... 24

Electronic Ignition (EI) System ............................... 27

Air Conditioning Cut Control ................................... 27

Fuel Cut Control (at No Load and High Engine

Speed) .................................................................... 28

CAN communication .............................................. 28

BASIC SERVICE PROCEDURE .............................. 30

Idle Speed and Ignition Timing Check .................... 30

Throttle Valve Closed Position Learning ................ 31

Accelerator Pedal Released Position Learning ...... 31

Idle Air Volume Learning ........................................ 31

Fuel Pressure Check .............................................. 34

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 36

Introduction ............................................................ 36

Two Trip Detection Logic ........................................ 36

Emission-related Diagnostic Information ................ 37

NATS (Nissan Anti-theft System) ........................... 48

Malfunction Indicator (MI) ....................................... 48

OBD System Operation Chart ................................ 51

TROUBLE DIAGNOSIS ............................................ 57

Trouble Diagnosis Introduction ............................... 57DTC Inspection Priority Chart ................................. 61

Fail-safe Chart ........................................................ 62

Basic Inspection ..................................................... 64

Symptom Matrix Chart ............................................ 69

Engine Control Component Parts Location ............ 73

Circuit Diagram ....................................................... 77

ECM Harness Connector Terminal Layout ............. 79

ECM Terminals and Reference Value ..................... 79

CONSULT-II Function ............................................. 86

Generic Scan Tool (GST) Function ......................... 96

CONSULT-II Reference Value in Data Monitor ....... 97

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................100

TROUBLE DIAGNOSIS - SPECIFICATION VALUE. 103

Description ............................................................103

Testing Condition ..................................................103

Inspection Procedure ............................................103

Diagnostic Procedure ...........................................104

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................107

Description ............................................................107

Diagnostic Procedure ...........................................107

POWER SUPPLY CIRCUIT FOR ECM ...................108

Wiring Diagram .....................................................108

ECM Terminals and Reference Value ...................109

Diagnostic Procedure ...........................................109

Component Inspection ..........................................113

DTC U1000 CAN COMMUNICATION LINE ............114

Description ............................................................114

On Board Diagnosis Logic ....................................114

DTC Confirmation Procedure ...............................114

Wiring Diagram .....................................................115

Diagnostic Procedure ...........................................116

DTC P0011 IVT CONTROL .....................................117

Description ............................................................117

CONSULT-II Reference Value in Data Monitor Mode

.117

ECM Terminals and Reference Value ...................117

On Board Diagnosis Logic ....................................118