engine OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1019 of 6000

6A–63

ENGINE MECHANICAL

Camshaft

Camshaft and Associated Parts

014RW040

Legend

(1) Camshaft Bracket Fixing Bolt

(2) Camshaft Bracket

(3) Camshaft Assembly Intake

(4) Camshaft Assembly Exhaust

(5) Pulley Fixing Bolt(6) Camshaft Drive Gear Pulley

(7) Retainer Fixing Bolt

(8) Retainer

(9) Camshaft Drive Gear

(10) Oil Seal

Disassembly

1. Remove fixing bolt (5) for camshaft drive gear pulley

using the 5–8840–2447–0 universal holder.

Page 1020 of 6000

6A–64

ENGINE MECHANICAL

014RW060

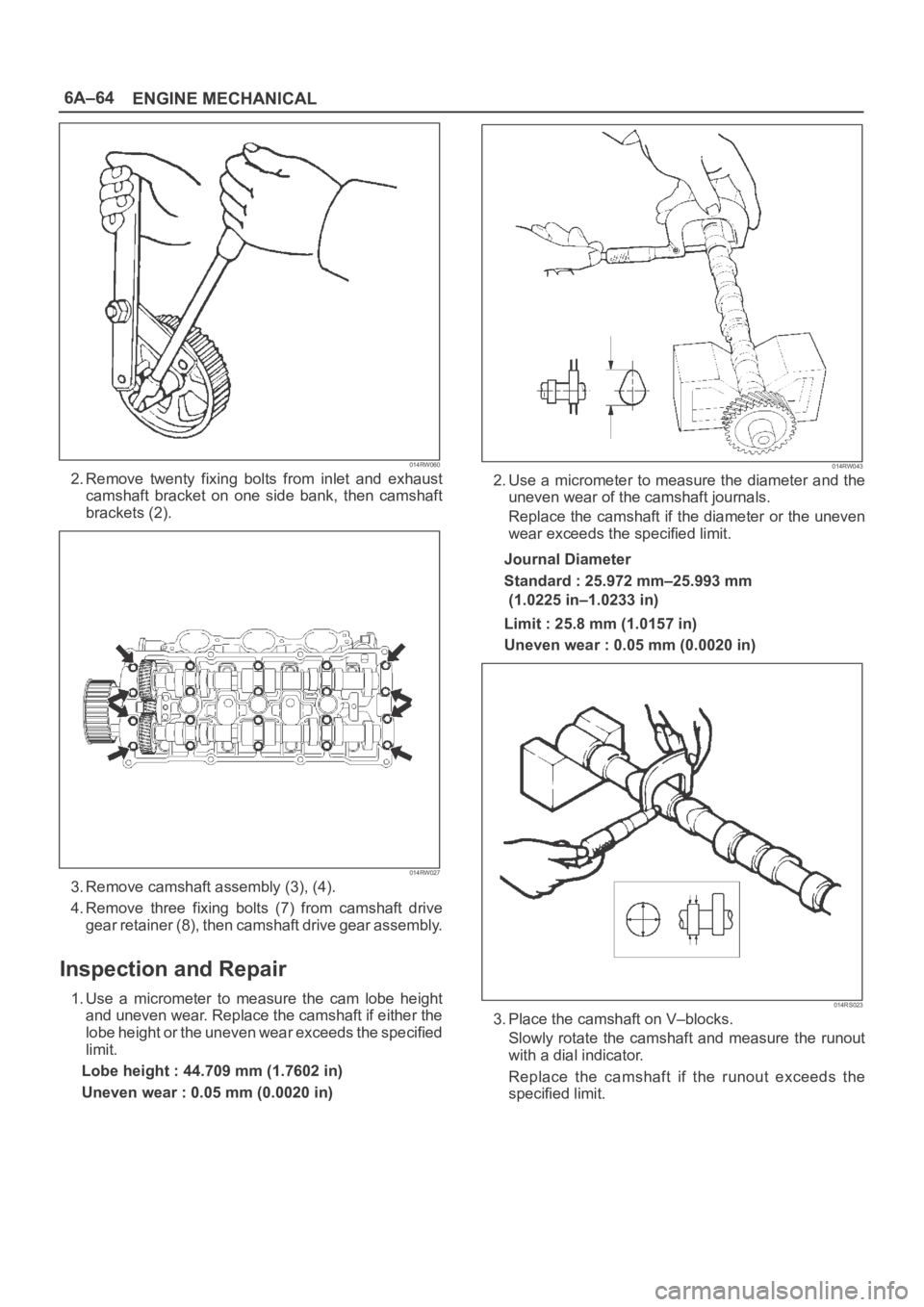

2. Remove twenty fixing bolts from inlet and exhaust

camshaft bracket on one side bank, then camshaft

brackets (2).

014RW027

3. Remove camshaft assembly (3), (4).

4. Remove three fixing bolts (7) from camshaft drive

gear retainer (8), then camshaft drive gear assembly.

Inspection and Repair

1. Use a micrometer to measure the cam lobe height

and uneven wear. Replace the camshaft if either the

lobe height or the uneven wear exceeds the specified

limit.

Lobe height : 44.709 mm (1.7602 in)

Uneven wear : 0.05 mm (0.0020 in)

014RW043

2. Use a micrometer to measure the diameter and the

uneven wear of the camshaft journals.

Replace the camshaft if the diameter or the uneven

wear exceeds the specified limit.

Journal Diameter

Standard : 25.972 mm–25.993 mm

(1.0225 in–1.0233 in)

Limit : 25.8 mm (1.0157 in)

Uneven wear : 0.05 mm (0.0020 in)

014RS023

3. Place the camshaft on V–blocks.

Slowly rotate the camshaft and measure the runout

with a dial indicator.

Replace the camshaft if the runout exceeds the

specified limit.

Page 1021 of 6000

6A–65

ENGINE MECHANICAL

Runout

Limit : 0.1 mm (0.0039 in)

014RW044

4. Measure the camshaft journal oil clearance.

1. Measure the camshaft bracket housing inside

diameter.

NOTE: Tighten camshaft bracket (2) to specified torque

before measuring the camshaft bracket inside diameter.

Torque : 10 Nꞏm (1.0 Kgꞏm/89 lb in)

014RW031

2. Subtract the camshaft outside diameter from the

camshaft bracket housing inside diameter.

Oil Clearance

Standard : 0.027 mm–0.078 mm

(0.0011 in–0.0031 in)

Limit : 0.11 mm (0.0043 in)

014RW037

5. Replace the cylinder head and/or camshaft if the

measured oil clearance exceeds the specified limit.

1. Carefully clean the camshaft journal, the

camshaft bracket, and the cylinder head.

2. Install camshaft assembly and camshaft brackets

(2), tighten twenty bolts (1) on one side bank to

the specified torque.

Torque: 10 Nꞏm (1.0 Kgꞏm/89 lb in)

014RW031

3. Measure the camshaft thrust clearance with a dial

indicator. Replace the camshaft and/or the

cylinder head if the camshaft thrust clearance

exceeds the specified limit.

Camshaft thrust Clearance

Standard : 0.03 mm–0.08 mm

(0.0012 in.–0.0031 in.)

Page 1022 of 6000

6A–66

ENGINE MECHANICAL

Limit : 0.12 mm (0.0047 mm)

014RW035

Reassembly

1. Install camshaft drive gear assembly and tighten

three bolts to specified torque.

Torque: 10 Nꞏm (1.0 Kgꞏm/89 lb in)

2. Tighten sub gear setting bolt.

1. Use 5–8840–2443–0 to turn sub gear to right

direction until the M5 bolt hole aligns between

camshaft driven gear and sub gear.

2. Tighten M5 bolt suitable torque for prevent

moving the sub gear.

014RW041

3. Install camshaft assembly and camshaft brackets,

tighten twenty bolts on one side bank to the specified

torque.

1. Apply engine oil to camshaft journal and bearing

surface of camshaft bracket.2. Align timing mark on intake camshaft (one dot for

right bank, two dots for left bank) and exhaust

camshaft (one dot for right bank, two dots for left

bank) to timing mark on camshaft drive gear (one

dot).

014RW020

Legend

(1) Intake Camshaft Timing Gear for Right Bank

(2) Intake Camshaft Timing Gear for Left Bank

(3) Exhaust Camshaft Timing Gear

(4) Discerning Mark

LI: Left Bank Intake

RI: Right Bank Intake

LE: Left Bank Exhaust

RE: Right Bank Exhaust

Page 1023 of 6000

6A–67

ENGINE MECHANICAL

014RW023

Legend

(1) Right Bank Camshaft Drive Gear

(2) Left Bank Camshaft Drive Gear

(3) Timing Mark on Drive Gear

(4) Dowel Pin

014RW024

Legend

(1) Right Bank

(2) Left Bank(3) Alignment Mark on Camshaft Drive Gear

(4) Alignment Mark on Camshaft

(5) Alignment Mark on Retainer

3. Tighten twenty bolts in numerical order on one

side bank as shown in the illustration.

Torque: 10 Nꞏm (1.0 Kgꞏm/89 lb in)

Page 1024 of 6000

6A–68

ENGINE MECHANICAL

014RW031

4. If the oil seal requires replacement, use the

5–8840–2445–0 to install the oil seal.

014RW034

5. Tighten bolt for camshaft drive gear pulley to the

specified torque using the 5–8840–2447–0 universal

holder.

Torque: 98 Nꞏm (10.0 Kgꞏm/72 lb ft)

014RW060

Page 1025 of 6000

6A–69

ENGINE MECHANICAL

Crankshaft

Crankshaft and Associated Parts

013RW009

Legend

(1) Cylinder Head Assembly

(2) Crankcase with Oil Pan

(3) Oil Pipe and O-Ring

(4) Oil Strainer and O-Ring

(5) Oil Pump Assembly

(6) Cylinder Block Side Bolts

(7) Oil Gallery(8) Piston and Connecting Rod Assembly

(9) Flywheel

(10) Rear Oil Seal Retainer and Oil Seal

(11) Main Bearing Cap

(12) Crankshaft

(13) Main Bearing Cap Fixing Bolts

(14) Oil Gallery Fixing Bolts

Disassembly

1. Remove cylinder head assembly (1). Refer to

“Cylinder Head” in this manual.

2. Remove crankcase with oil pan (2). Refer to “Oil Pan

and Crankcase” in this manual.CAUTION: Take care not to damage or deform the

sealing flange surface of crankcase.

3. Remove oil pipe and O-ring (3).

4. Remove oil strainer and O-ring (4).

5. Remove oil pump assembly (5).

6. Remove crankcase side bolts (6).

Page 1026 of 6000

6A–70

ENGINE MECHANICAL

7. Remove oil gallery (7).

8. Remove piston and connecting rod assembly (8).

Refer to “Piston, Piston Ring and Connecting Rod” in

this manual.

9. Remove flywheel (9).

10. Remove rear oil seal retainer (10).

11. Remove main bearing cap (11).

12. Remove crankshaft (12).

Inspection and Repair

1. Crankshaft

Set the dial indicator as shown in the illustration and

measure the crankshaft thrust clearance. If the thrust

clearance exceeds the specified limit, replace the

thrust bearings as a set.

Thrust Clearance

Standard : 0.06 mm–0.24 mm

(0.0024 in–0.0094 in)

Limit : 0.30 mm (0.0118 in)

015RS003

Main Bearing Clearance

1. Remove the bearing caps and measure the oil

clearance.

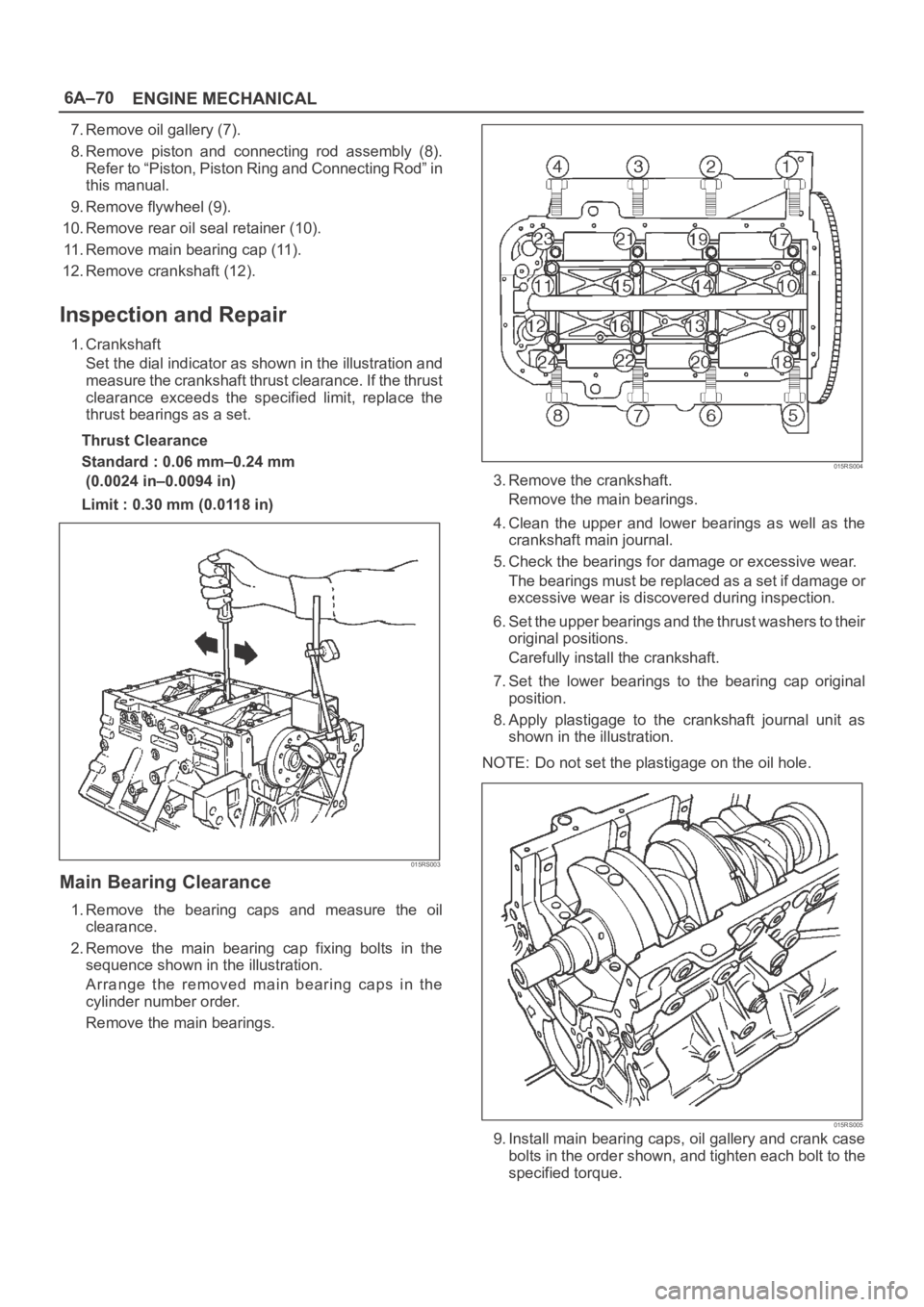

2. Remove the main bearing cap fixing bolts in the

sequence shown in the illustration.

Arrange the removed main bearing caps in the

cylinder number order.

Remove the main bearings.

015RS004

3. Remove the crankshaft.

Remove the main bearings.

4. Clean the upper and lower bearings as well as the

crankshaft main journal.

5. Check the bearings for damage or excessive wear.

The bearings must be replaced as a set if damage or

excessive wear is discovered during inspection.

6. Set the upper bearings and the thrust washers to their

original positions.

Carefully install the crankshaft.

7. Set the lower bearings to the bearing cap original

position.

8. Apply plastigage to the crankshaft journal unit as

shown in the illustration.

NOTE: Do not set the plastigage on the oil hole.

015RS005

9. Install main bearing caps, oil gallery and crank case

bolts in the order shown, and tighten each bolt to the

specified torque.

Page 1027 of 6000

6A–71

ENGINE MECHANICAL

NOTE: Do not apply engine oil to the crank case side

bolts.

Main bearing cap bolts.

Torque: 39 Nꞏm (4.0 Kgꞏm/29 lb ft)

Oil gallery fixing bolts.

Torque:

1st step: 29 Nꞏm (3.0 Kgꞏm/21 lb ft)

2nd step 55

65

Crank case side bolts

Torque : 39 Nꞏm (4.0 Kgꞏm/29 lb ft)

NOTE: Do not allow the crankshaft to rotate.

015RS006

10. Remove the main bearing caps in the sequence

shown in the illustration.

015RS004

11. Measure the plastigage width and determine the oil

clearance. If the oil clearance exceeds the specified

limit, replace the main bearings as a set and/or

replace the crankshaft.

Standard : 0.019 mm–0.043 mm

(0.0007 in–0.0017 in)Limit : 0.08 mm (0.0031 in)

015RS008

12. Clean the plastigage from the bearings and the

crankshaft.

Remove the crankshaft and the bearings.

Crankshaft (12) Inspection

Inspect the surface of the crankshaft journal and crank

pins for excessive wear and damage. Inspect the oil seal

fitting surfaces for excessive wear and damage. Inspect

the oil ports for obstructions.

Inspection and Repair

1. Carefully set the crankshaft on the V–blocks. Slowly

rotate the crankshaft and measure the runout. If the

crankshaft runout exceeds the specified limit, the

crankshaft must be replaced.

Runout : 0.04 mm (0.0016 in)

015RS007

Page 1028 of 6000

6A–72

ENGINE MECHANICAL

2. Measure the diameter and the uneven wear of main

journal and crank pin. If the crankshaft wear exceeds

the specified limit, crankshaft must be replaced.

Main journal diameter : 63.918 mm–63.933 mm

(2.5165 in–2.5170 in)

Crank pin diameter : 53.922 mm–53.937 mm

(2.1229 in.–2.1235 in.)

Uneven wear limit : 0.005 mm (0.0002 in)

015RS009

Crankshaft Bearing Selection

When installing new crankshaft bearings or replacing

bearings, refer to the selection table below. Select and

install the new crankshaft bearings, paying close

attention to the cylinder block journal hole.

1. Diameter size mark (1) and the crankshaft journal.

015RS010

2. Diameter size mark (1).

The diameter size marks are stamped on the No.1

crankshaft balancer as shown in the illustration.

015RS011

NOTE: Take care to ensure the bearings are positioned

correctly.

015RS012

Legend

(1) Number 1 and 4 main bearing upper and lower

(2) Number 2 and 3 main bearing upper

(3) Number 2 and 3 main bearing lower