check oil OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2698 of 6000

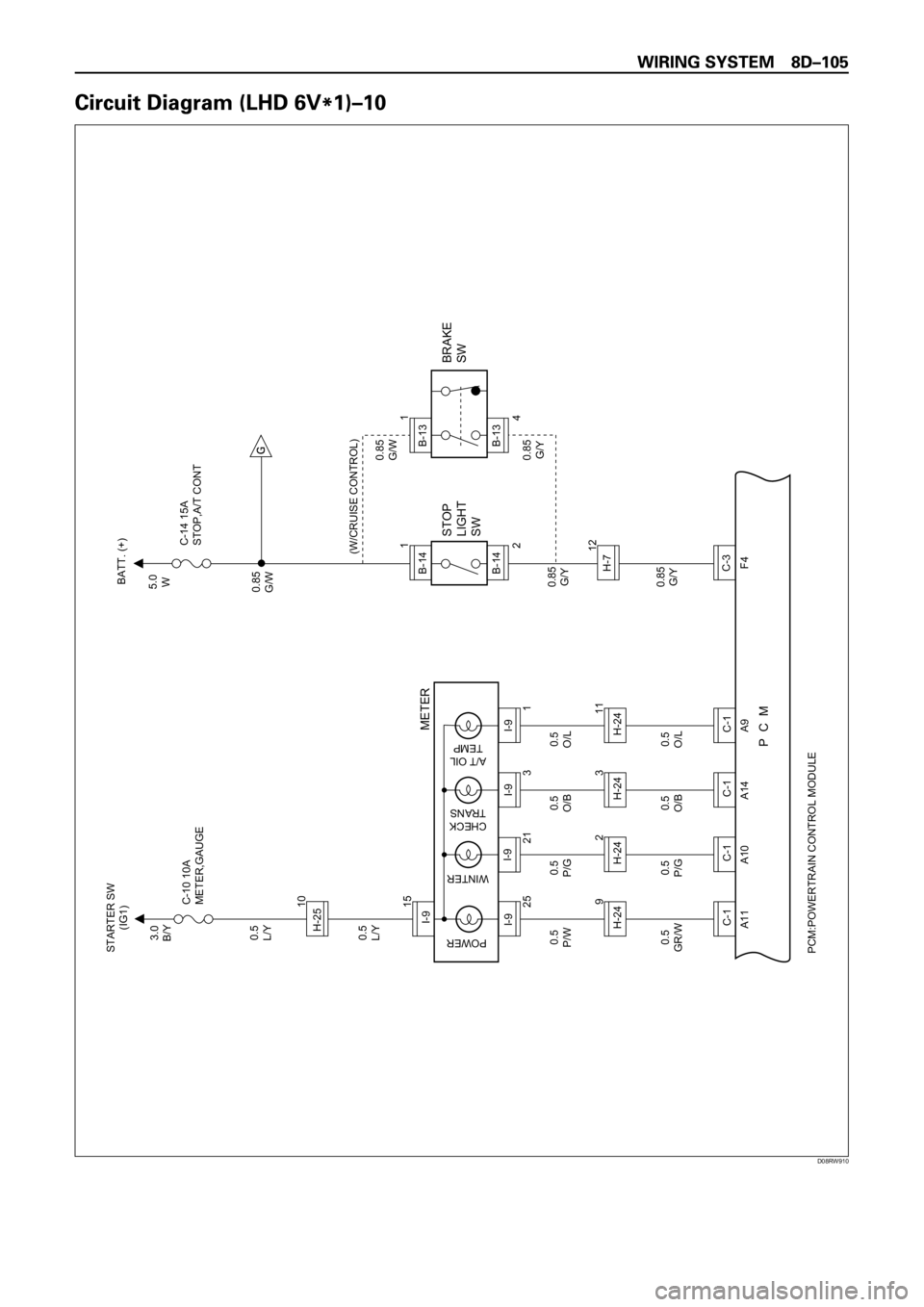

C-1

C-1

C-1

C-1

H-24I-9

H-24

H-24

H-24

A11 A10 A14 A9 F4

PCM:POWERTRAIN CONTROL MODULE

I-9H-25

I-9

I-9

I-9P C M0.5

O/L0.85

G/Y 0.85

G/Y0.85

G/W 0.85

G/W5.0

W

0.85

G/Y

0.5

O/B 0.5

P/G 0.5

GR/W0.5

O/L 0.5

O/B 0.5

P/G 0.5

L/Y0.5

L/Y3.0

B/Y

0.5

P/W

11 3 2 91

B-14H-7B-14C-3122 1

4 1

3 21 25 15 10C-10 10A

METER,GAUGE STARTER SW

(IG1)

METER

POWER

WINTER

CHECK

TRANS

A/T OIL

TEMP

B-13B-13

(W/CRUISE CONTROL)

STOP

LIGHT

SWBRAKE

SWC-14 15A

STOP,A/T CONT BATT. (+)

D08RW910

Page 3005 of 6000

D08RW723

B

C

D

J

E

5 18 15105

2 25

4 21

163

5 1

19 156

VOLT

METERC-10 10A

METER, GAUGE

CHECK

TRANS.A/T OIL

TEMP.

18

C-39 H-16I-9

PCM

(A13)PCM

(A11)PCM

(A10)PCM

(A14)PCM

(A9)

0.5

V0.5

P/W0.5

P/G0.5

O/B0.5

O/L 0.85

B/PH-26

I-9 0.5

L/Y0.5

L/Y0.5

L/Y3.0

B/Y STARTER SW

(IG1)

0.3

Y/G

0.85

B/P

FENDER-RH

I-10

H-25I-9

H-9I-9

H-9I-9

H-9I-9

H-9I-9

H-24 FUEL MIL POWER WINTER

METER

MIL:MALFUNCTION INDICATOR LIGHT

Page 3011 of 6000

D08RW 732

B

C

D

J

E

5 18 15104

2 29

4 28

166

5 3

21 266 C-10 10A

METER, GAUGE

CHECK

TRANS.A/T OIL

TEMP.

18

C-39 H-16I-10

PCM

(A13)PCM

(A11)PCM

(A10)PCM

(A14)PCM

(A9) 0.5

V0.5

P/W0.5

P/G0.5

O/B0.5

O/L 0.85

B/PH-26

I-9 0.5

L/Y0.5

L/Y0.5

L/Y3.0

B/Y STARTER SW

(IG1)

0.3

Y/G

0.85

B/P

FENDER-RH

I-10

H-25I-10

H-9I-9

H-9I-9

H-9I-9

H-9I-9

H-24 FUEL MIL POWER WINTER

METER

MIL:MALFUNCTION INDICATOR LIGHT

Page 3025 of 6000

D08RW925

B

C

D

E

3 193 5

9 25

2 21

3 3

111

19 15 10

VOLT

METERC-10 10A

METER, GAUGE

CHECK

TRANS.A/T OIL

TEMP.

18

C-39 H-16I-9

PCM

(A13)PCM

(A11)PCM

(A10)PCM

(A14)PCM

(A9)

0.5

V0.5

GR/W0.5

P/G0.5

O/B0.5

O/L 0.85

B/PH-25

I-9 0.5

L/Y0.5

L/Y0.5

L/Y3.0

B/Y STARTER SW

(IG1)

0.3

Y/G

0.85

B/P

FENDER-RH

I-10

H-25I-9

H-9I-9

H-24I-9

H-24I-9

H-24I-9

H-24 FUEL MIL POWER WINTER

METER

MIL:MALFUNCTION INDICATOR LIGHT

J

Page 3186 of 6000

METER AND GAUGE8E–9

Meter Assembly–Gasoline W/O TOD–2

Connector No. I–9

Te r m i n a lFunction

1A/T oil temp warning light

2Seat belt warning light

3Check trans warning light

4Brake warning light

5Check engine warning light

6Charge warning light

7Cigarette lighter illumination light

8Illumination controller

9Tachometer

10D position (A/T)

11—

12A/T shift indicator control unit

13—

142 position (A/T)

15Starter switch

16Cruise set indicator light

17Cruise main indicator light

184WD indicator light

19Ground (Gauge)

20—

21Winter drive indicator light

22Oil pressure warning light

23—

24Air bag warning light

25Power drive indicator light

26—

27—

28Turn signal indicator light (Left)

29—

30Ground

Connector No. I–10

Te r m i n a lFunction

1Turn signal indicator light (Right)

2L position (A/T)

3R position (A/T)

4Engine coolant temperature gauge

5Speedometer

6—

7—

8Battery (+)

9—

10Rear fog light

11P position (A/T)

12N position (A/T)

133 position (A/T)

14High-beam indicator light (–)

15High-beam indicator light (+)

16ABS indicator light

17—

18Fuel warning light

19Oil pressure gauge

20Fuel gauge

21—

22—

Page 3188 of 6000

METER AND GAUGE8E–11

Meter Assembly–Gasoline W/TOD–2

Connector No. I–9

Te r m i n a lFunction

1—

2Air bag warning light

3A/T oil temp warning light

4Charge warning light

5Check engine warning light

6Check trans warning light

7Brake warning light

8—

9Tachometer

10—

11Turn signal indicator light (Left)

12A/T shift indicator control unit

132 position (A/T)

14D position (A/T)

15Rear (TOD)

16Auto (TOD)

17Check (TOD)

18Cruise set indicator light

19Cruise main indicator light

20Oil pressure warning light

21Front “1” (TOD)

22Front “2” (TOD)

23Front “3” (TOD)

24Cigarette lighter illumination light

25Illumination controller

26Starter switch

27—

28Winter drive indicator light

29Power drive indicator light

30—

Connector No. I–10

Te r m i n a lFunction

1Turn signal indicator light (Right)

2L position (A/T)

3R position (A/T)

4Check engine warning light

5Speedometer

6—

7—

8Battery (+)

9Engine coolant temperature gauge

10Ground

11P position (A/T)

12N position (A/T)

133 position (A/T)

14High beam indicator light (–)

15High beam indicator light (+)

16ABS indicator light

17—

18Fuel warning light

19—

20Fuel gauge

21Ground (Gauge)

22—

Page 3442 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–5

1. Energy Reserve — The SDM maintains 24–Volt Loop

Reserve (24VLR) energy supply to provide

deployment energy when ignition voltage is lost in a

frontal crash.

2. Frontal Crash Detection — The SDM monitors

vehicle velocity changes to detect frontal crashes

which are severe enough to warrant deployment.

3. Air Bag Deployment — When a frontal crash of

sufficient force is detected, the SDM will cause

enough current to flow through the air bag assembly

to deploy the air bag.

4. Malfunction Detection — The SDM performs

diagnostic monitoring of SRS electrical components

and sets a diagnostic trouble code when a

malfunction is detected.

5. Frontal Crash Recording — The SDM records

information regarding SRS status during frontal

crash.

6. Malfunction Diagnosis — The SDM displays SRS

diagnostic trouble codes and system status

information through the use of a scan tool.

7. Driver Notification — The SDM warns the vehicle

driver of SRS malfunctions by controlling the “Air

Bag” warning lamp.

The SDM is connected to the SRS wiring harness by a

24–pin connector. This harness connector uses a

shorting clip across certain terminals in the contact area.

This shorting clip connects the “AIR BAG” warning lamp

to ground when the SDM harness connector is

disconnected or CPA (Connector Position Assurance) is

not inserted even if completely connected. This will

cause the “AIR BAG” warning lamp to come “ON” steady

whenever the ignition switch is at the ON or START

positions with the SDM disconnected.

827RW044

Legend

(1) SDM

(2) SRS Harness

(3) Connector Position Assurance

“Air Bag” Warning Lamp

Ignition voltage is applied to the “AIR BAG” warning lamp

when the ignition switch is at the ON or START positions.

The SDM controls the lamp by providing ground with a

lamp driver. The “AIR BAG” warning lamp is used in the

SRS to do the following:

1. Verify lamp and SDM operation by turn on 3.5

seconds and then turns “OFF” when the ignition

switch is first turned “ON”.

2. Warn the vehicle driver of SRS electrical system

malfunctions which could potentially affect the

operation of the SRS. These malfunctions could

result in nondeployment in case of a frontal crash or

deployment for conditions less severe than intended.

The “AIR BAG ” warning lamp is the key to driver

notification of SRS malfunctions. For proper lamp

operation, refer to the “SRS Diagnostic System Check” in

this section.

821RW037

SRS Coil Assembly

The SRS coil assembly consists of two current carrying

coils. This is attached to the steering column and allow

rotation of the steering wheel while maintaining

continuous contact of the driver deployment loop to the

driver air bag assembly.

There is a shorting clip on the yellow 2–pin connector near

the base of steering column which connects the SRS coil

to the SRS wiring harness.

The shorting clip shorts to the SRS coil and driver air bag

assembly when the yellow 2–pin connector is

disconnected. The circuit to the driver air bag assembly is

shorted in this way to help prevent unwanted deployment

of the air bag when servicing the steering column or other

SRS components.

Page 3445 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–8

the deployment loops, high resistance or opens in the

“Driver Side High”, “Driver Side Low”, “Passenger Side

High” and “Passenger Side Low” circuits and measures

the resistance of the inflator assembly consisting of 1)

Initiators, 2) SRS coil assembly (driver side only), 3)

Connectors and associated wiring.

Normal Operating Voltage Range

The voltage measured between the SDM “Ignition 1”

terminals and “Ground” terminals is between 9 and 16

volts.

Passenger Current Source

An output of the SDM which applies current into the

passenger air bag assembly circuit during the “Initiator

Assembly Resistance Test”.

Passenger Air Bag Assembly

An assembly located in the right side of the instrument

panel consisting of an inflatable bag, an inflator and an

initiator.

Scan Tool

An external computer used to read diagnostic information

from on–board computers via the data link connector.

SDM

Sensing and Diagnostic Module which provides reserve

energy to the deployment loops, deploys the air bags

when required and performs diagnostic monitoring of all

SRS components.

Serial Data

Information representing the status of the SRS.

SRS

Supplemental Restraint System.

SRS Coil Assembly

An assembly of two current–carrying coils in the driver

deployment loop that allows the rotation of the steering

wheel while maintaining the continuous contact of the

driver deployment loop to the driver air bag assembly.

SRS Wiring Harness

The wires and connectors that electrically connect the

components in the SRS.

“Turn–ON”

Test which the SDM performs on the SRS once during

each ignition cycle immediately after “Ignition 1” voltage

is applied to the SDM and before “Continuous

Monitoring”.

Diagnosis

WARNING: TO AVOID DEPLOYMENT WHEN

TROUBLESHOOTING THE SRS, DO NOT USE

ELECTRICAL TEST EQUIPMENT SUCH AS A

BATTERY–POWERED OR AC–POWERED

VOLTMETER, OHMMETER, ETC., OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN THAT

SPECIFIED IN THIS MANUAL. DO NOT USE A

NONPOWERED PROBE–TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PERSONAL

INJURY MAY RESULT.

Diagnostic Trouble Codes

The “SRS Diagnostic System Check” must always be the

starting point of any SRS diagnosis. The “SRS

Diagnostic System Check” checks for proper “AIR BAG”

warning lamp operation and checks for SRS diagnostic

trouble codes using the scan tool.

1. Current diagnostic trouble codes – Malfunctions that

are presently being detected. Current diagnostic

trouble codes are stored in RAM (Random Access

Memory).

2. History diagnostic trouble codes – All malfunctions

detected since the last time the history memory was

cleared. History diagnostic trouble codes are stored

in EEPROM.

Scan Tool Diagnostics

A scan tool is used to read current and history diagnostic

trouble codes and to clear all diagnostic trouble codes

after a repair is completed. The scan tool must be

updated to communicate with the SRS through a

replaceable cartridge before it can be used for SRS

diagnostics. To use the scan tool, connect it to the data

link connector and turn the ignition switch “ON”. The scan

tool reads serial data from the SDM “Serial Data” line

terminal “24” to the data link connector terminal “9”.

Use Of Special Tools

WARNING: TO AV O I D D E P L O Y M E N T W H E N

TROUBLESHOOTING THE SRS, DO NOT USE

ELECTRICAL TEST EQUIPMENT SUCH AS A

BATTERY–POWERED OR AC–POWERED

VOLTMETER, OHMMETER, ETC, OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN THAT

SPECIFIED IN THIS MANUAL. DO NOT USE A NON

POWERED PROBE–TYPE TESTER. INSTRUCTIONS

IN THIS MANUAL MUST BE FOLLOWED

CAREFULLY, OTHERWISE PERSONAL INJURY MAY

RESULT. YOU SHOULD BE FAMILIAR WITH THE

TOOLS LISTED IN THIS SECTION UNDER THE

HANDLING SRS SPECIAL TOOLS.

You should be able to measure voltage and resistance.

You should be familiar with proper use of a scan tool such

as the Tech 2 Diagnostic Computer, SRS

Driver/Passenger Load Tool 5–8840–2421–0, Connector

Test Adapter Kit 5–8840–0385–0, and the DVM (Digital

Multimeter) 5–8840–0285–0.

Page 3447 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–10

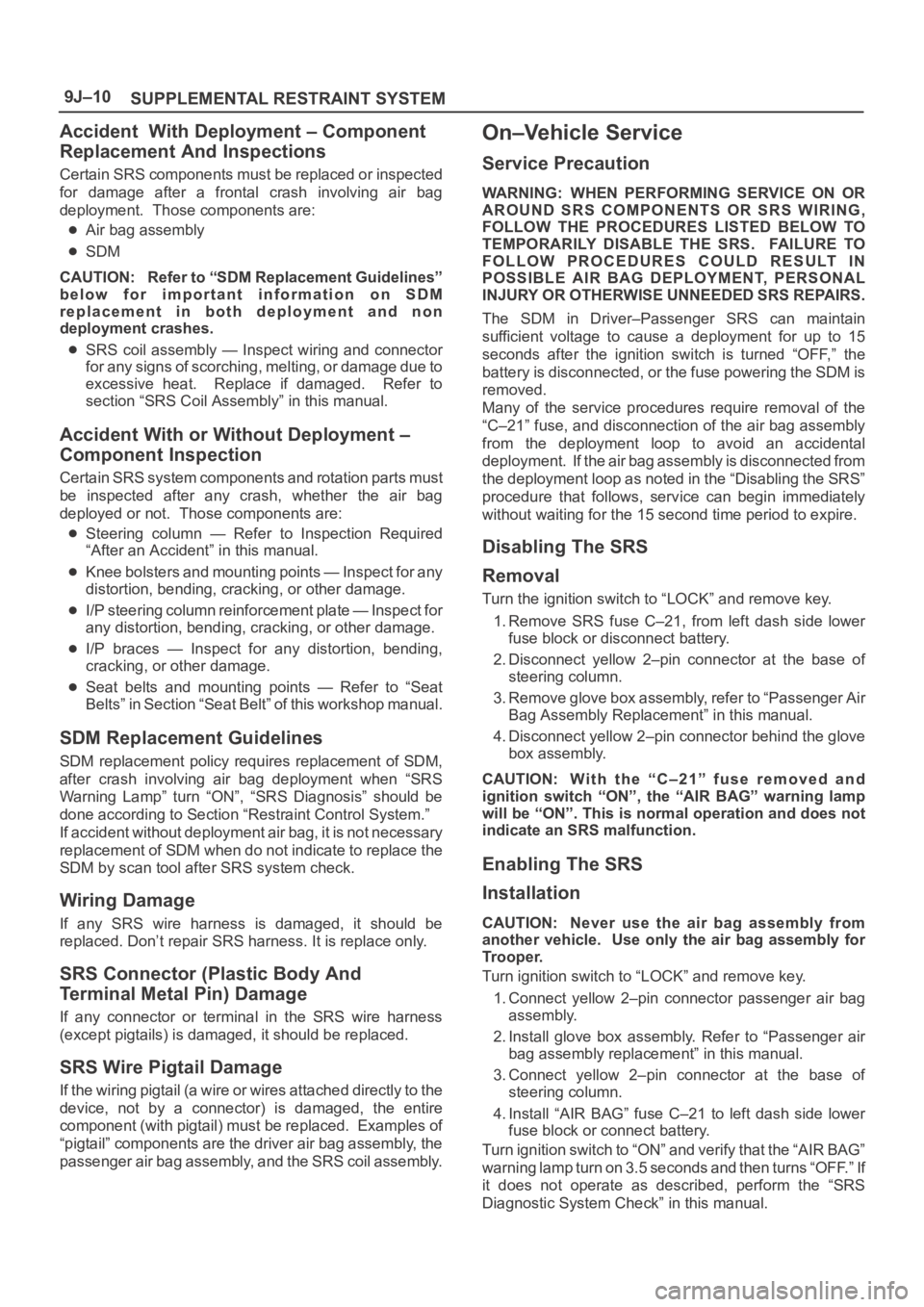

Accident With Deployment – Component

Replacement And Inspections

Certain SRS components must be replaced or inspected

for damage after a frontal crash involving air bag

deployment. Those components are:

Air bag assembly

SDM

CAUTION: Refer to “SDM Replacement Guidelines”

below for important information on SDM

replacement in both deployment and non

deployment crashes.

SRS coil assembly — Inspect wiring and connector

for any signs of scorching, melting, or damage due to

excessive heat. Replace if damaged. Refer to

section “SRS Coil Assembly” in this manual.

Accident With or Without Deployment –

Component Inspection

Certain SRS system components and rotation parts must

be inspected after any crash, whether the air bag

deployed or not. Those components are:

Steering column — Refer to Inspection Required

“After an Accident” in this manual.

Knee bolsters and mounting points — Inspect for any

distortion, bending, cracking, or other damage.

I/P steering column reinforcement plate — Inspect for

any distortion, bending, cracking, or other damage.

I/P braces — Inspect for any distortion, bending,

cracking, or other damage.

Seat belts and mounting points — Refer to “Seat

Belts” in Section “Seat Belt” of this workshop manual.

SDM Replacement Guidelines

SDM replacement policy requires replacement of SDM,

after crash involving air bag deployment when “SRS

Warning Lamp” turn “ON”, “SRS Diagnosis” should be

done according to Section “Restraint Control System.”

If accident without deployment air bag, it is not necessary

replacement of SDM when do not indicate to replace the

SDM by scan tool after SRS system check.

Wiring Damage

If any SRS wire harness is damaged, it should be

replaced. Don’t repair SRS harness. It is replace only.

SRS Connector (Plastic Body And

Terminal Metal Pin) Damage

If any connector or terminal in the SRS wire harness

(except pigtails) is damaged, it should be replaced.

SRS Wire Pigtail Damage

If the wiring pigtail (a wire or wires attached directly to the

device, not by a connector) is damaged, the entire

component (with pigtail) must be replaced. Examples of

“pigtail” components are the driver air bag assembly, the

passenger air bag assembly, and the SRS coil assembly.

On–Vehicle Service

Service Precaution

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND SRS COMPONENTS OR SRS WIRING,

FOLLOW THE PROCEDURES LISTED BELOW TO

TEMPORARILY DISABLE THE SRS. FAILURE TO

FOLLOW PROCEDURES COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY OR OTHERWISE UNNEEDED SRS REPAIRS.

The SDM in Driver–Passenger SRS can maintain

sufficient voltage to cause a deployment for up to 15

seconds after the ignition switch is turned “OFF,” the

battery is disconnected, or the fuse powering the SDM is

removed.

Many of the service procedures require removal of the

“C–21” fuse, and disconnection of the air bag assembly

from the deployment loop to avoid an accidental

deployment. If the air bag assembly is disconnected from

the deployment loop as noted in the “Disabling the SRS”

procedure that follows, service can begin immediately

without waiting for the 15 second time period to expire.

Disabling The SRS

Removal

Turn the ignition switch to “LOCK” and remove key.

1. Remove SRS fuse C–21, from left dash side lower

fuse block or disconnect battery.

2. Disconnect yellow 2–pin connector at the base of

steering column.

3. Remove glove box assembly, refer to “Passenger Air

Bag Assembly Replacement” in this manual.

4. Disconnect yellow 2–pin connector behind the glove

box assembly.

CAUTION: With the “C–21” fuse removed and

ignition switch “ON”, the “AIR BAG” warning lamp

will be “ON”. This is normal operation and does not

indicate an SRS malfunction.

Enabling The SRS

Installation

CAUTION: Never use the air bag assembly from

another vehicle. Use only the air bag assembly for

Trooper.

Turn ignition switch to “LOCK” and remove key.

1. Connect yellow 2–pin connector passenger air bag

assembly.

2. Install glove box assembly. Refer to “Passenger air

bag assembly replacement” in this manual.

3. Connect yellow 2–pin connector at the base of

steering column.

4. Install “AIR BAG” fuse C–21 to left dash side lower

fuse block or connect battery.

Turn ignition switch to “ON” and verify that the “AIR BAG”

warning lamp turn on 3.5 seconds and then turns “OFF.” If

it does not operate as described, perform the “SRS

Diagnostic System Check” in this manual.

Page 3467 of 6000

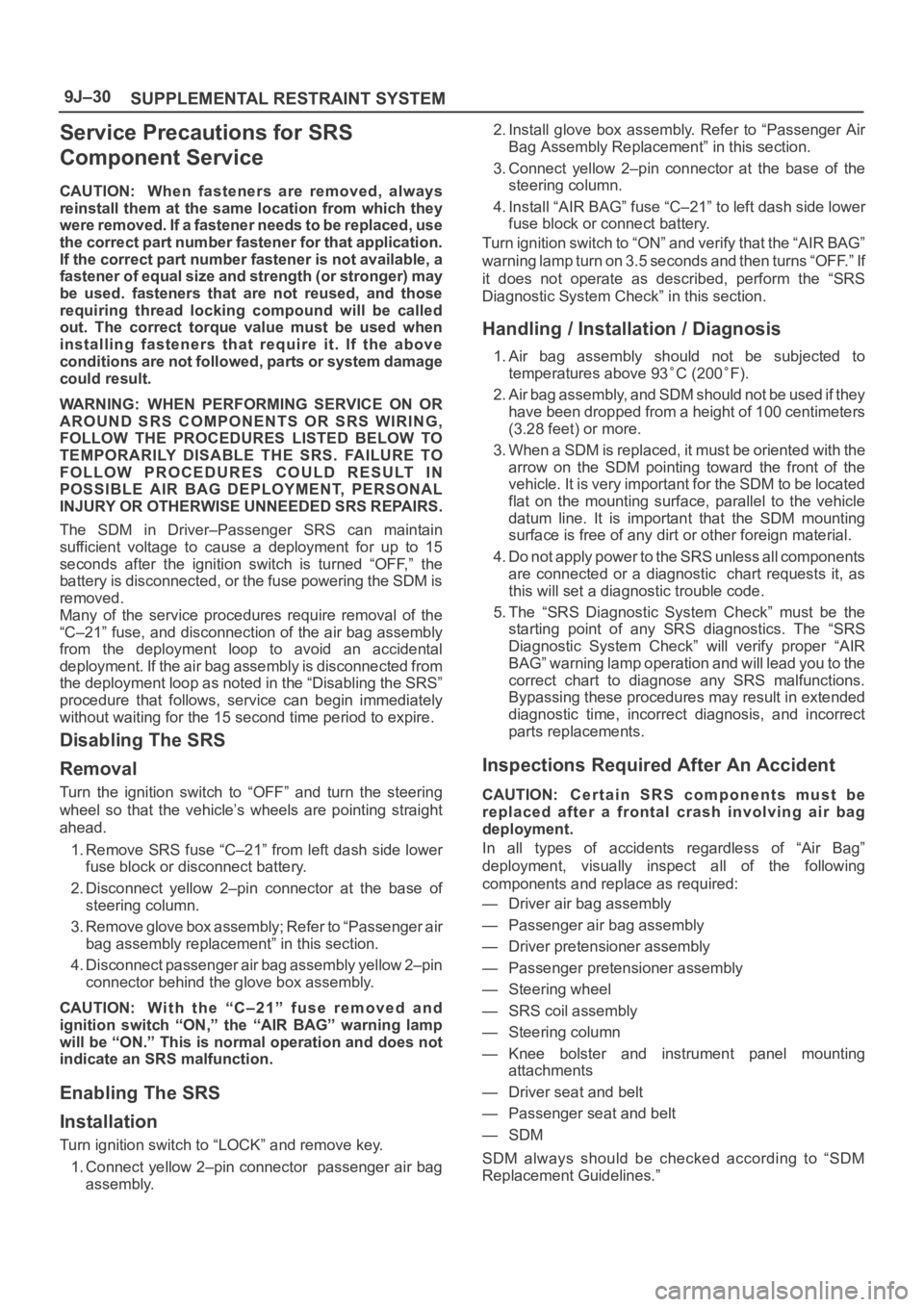

SUPPLEMENTAL RESTRAINT SYSTEM 9J–30

Service Precautions for SRS

Component Service

CAUTION: When fasteners are removed, always

reinstall them at the same location from which they

were removed. If a fastener needs to be replaced, use

the correct part number fastener for that application.

If the correct part number fastener is not available, a

fastener of equal size and strength (or stronger) may

be used. fasteners that are not reused, and those

requiring thread locking compound will be called

out. The correct torque value must be used when

installing fasteners that require it. If the above

conditions are not followed, parts or system damage

could result.

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND SRS COMPONENTS OR SRS WIRING,

FOLLOW THE PROCEDURES LISTED BELOW TO

TEMPORARILY DISABLE THE SRS. FAILURE TO

FOLLOW PROCEDURES COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY OR OTHERWISE UNNEEDED SRS REPAIRS.

The SDM in Driver–Passenger SRS can maintain

sufficient voltage to cause a deployment for up to 15

seconds after the ignition switch is turned “OFF,” the

battery is disconnected, or the fuse powering the SDM is

removed.

Many of the service procedures require removal of the

“C–21” fuse, and disconnection of the air bag assembly

from the deployment loop to avoid an accidental

deployment. If the air bag assembly is disconnected from

the deployment loop as noted in the “Disabling the SRS”

procedure that follows, service can begin immediately

without waiting for the 15 second time period to expire.

Disabling The SRS

Removal

Turn the ignition switch to “OFF” and turn the steering

wheel so that the vehicle’s wheels are pointing straight

ahead.

1. Remove SRS fuse “C–21” from left dash side lower

fuse block or disconnect battery.

2. Disconnect yellow 2–pin connector at the base of

steering column.

3 . R e m o v e g l o v e b o x a s s e m b l y ; R e f e r t o “ P a s s e n g e r a i r

bag assembly replacement” in this section.

4. Disconnect passenger air bag assembly yellow 2–pin

connector behind the glove box assembly.

CAUTION: W i t h t h e “ C – 2 1 ” f u s e r e m o v e d a n d

ignition switch “ON,” the “AIR BAG” warning lamp

will be “ON.” This is normal operation and does not

indicate an SRS malfunction.

Enabling The SRS

Installation

Turn ignition switch to “LOCK” and remove key.

1. Connect yellow 2–pin connector passenger air bag

assembly.2. Install glove box assembly. Refer to “Passenger Air

Bag Assembly Replacement” in this section.

3. Connect yellow 2–pin connector at the base of the

steering column.

4. Install “AIR BAG” fuse “C–21” to left dash side lower

fuse block or connect battery.

Turn ignition switch to “ON” and verify that the “AIR BAG”

warning lamp turn on 3.5 seconds and then turns “OFF.” If

it does not operate as described, perform the “SRS

Diagnostic System Check” in this section.

Handling / Installation / Diagnosis

1. Air bag assembly should not be subjected to

temperatures above 93

C (200F).

2. Air bag assembly, and SDM should not be used if they

have been dropped from a height of 100 centimeters

(3.28 feet) or more.

3. When a SDM is replaced, it must be oriented with the

arrow on the SDM pointing toward the front of the

vehicle. It is very important for the SDM to be located

flat on the mounting surface, parallel to the vehicle

datum line. It is important that the SDM mounting

surface is free of any dirt or other foreign material.

4. Do not apply power to the SRS unless all components

are connected or a diagnostic chart requests it, as

this will set a diagnostic trouble code.

5. The “SRS Diagnostic System Check” must be the

starting point of any SRS diagnostics. The “SRS

Diagnostic System Check” will verify proper “AIR

BAG” warning lamp operation and will lead you to the

correct chart to diagnose any SRS malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements.

Inspections Required After An Accident

CAUTION: C e r t a i n S R S c o m p o n e n t s m u s t b e

replaced after a frontal crash involving air bag

deployment.

In all types of accidents regardless of “Air Bag”

deployment, visually inspect all of the following

components and replace as required:

— Driver air bag assembly

— Passenger air bag assembly

— Driver pretensioner assembly

— Passenger pretensioner assembly

— Steering wheel

— SRS coil assembly

— Steering column

— Knee bolster and instrument panel mounting

attachments

— Driver seat and belt

— Passenger seat and belt

—SDM

SDM always should be checked according to “SDM

Replacement Guidelines.”