Front ach OPEL FRONTERA 1998 Manual PDF

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3290 of 6000

8F–95 BODY STRUCTURE

Installation

1. Install the moulding roof clips (1).

Install the clips on roof panel flange (2) to refer the

illustration.

645RW003

2. Install the roof end moulding (3).

Clean the body panel where the roof end moulding

is installed.

Install the roof end moulding and the rear air

deflector (2) so that the installation clearance

between them is within the specified values.

Securely fix it with the adhesive tape (4) and sealing

adhesive (5).

645RW001

3. Install the roof moulding (9).

Assemble the windshield side moulding upper clip

(8) to the roof panel with the clip positioning rib (6)

(oblique lines portion) attached to the roof panel

flange (7). Assemble the roof moulding (9) while

you attach the front edge portion of the roof molding

to the windshield side moulding (10).

645RW005

Page 3359 of 6000

8H–20SECURITY AND LOCKS

Power Door Lock System

General Description

The circuit consists of the door lock (& power window)

switch, door lock actuator for the front and rear door,

tailgate lock actuator and the door lock key switch. The

front door lock switch –LH is always provided with battery

voltage.

The key or the inside lock button on the both driver’s and

the front passenger’s door can activate the lock

mechanism of all the doors (including the tailgate).

When the driver’s door lock switch or the front

passenger’s door lock switch is turned on, current flows

for about one second to the door lock actuator of each

door connected in parallel with the front door lock (&

power window) switch –LH to activate the actuator to lock

and unlock the doors.

Front Door Lock Actuator Removal

1. Refer to the Front Door Lock Assembly removal

procedure in this section.

2. Remove the door lock actuator(1).

632RS021

632RS020

Front Door Lock Actuator Installation

To install, follow the removal steps in the reverse order.

Rear Door Lock Actuator Removal

1. Refer to the Rear Door Lock Assembly removal

procedure in this section.

2. Removal the door lock actuator(1).

632RS019

Page 3361 of 6000

8H–22SECURITY AND LOCKS

Anti-theft System

General Description

The circuit consists of the starter switch, anti-theft &

keyless entry control unit, anti-theft horn, front door and

tailgate key switch (detect and tamper switch), door lock

(& power window) switch, door lock actuator for each

door, engine hood switch, clutch start switch (M/T),

ANTI-THEFT indicator light and mode switch (A/T).

The system operates as follows: After locking the starter

switch and removing the starter key (this sets the alarm),

if the door is unlocked in any way other than with the

proper key, the headlights start flashing, the horn sounds,

and the starter circuit is disabled. (However, the engine

hood and all the doors must be locked and closed.)

Once the system has been placed in the warning or alarm

condition, it can be released only when the starter switch

is shifted from “OFF” to “ACC” by the starter key, or when

the lock of the front door or the tailgate is released (to

activate the detect switch) by the starter key.

Anti-theft & Keyless Entry Control

Unit Removal

1. Disconnect the battery ground cable.

2. Remove the front console assembly.

Refer to the Instrument Panel Assembly in Body

Structure section.

3. Remove the lower cluster assembly.

Refer to the Instrument Panel Assembly in Body

Structure section.

4. Disconnect the connector(2).

5. Remove four screws to remove the anti-theft &

keyless entry control unit with bracket(1).

825RW029

6. Remove two nuts from the anti-theft & keyless entry

control unit with bracket(3) to remove the anti-theft &

keyless entry controller(4).

825RW028

Anti-theft & Keyless Entry Control

Unit Installation

To install, follow the removal steps in the reverse order.

Anti-theft Indicator Removal

1. Disconnect the battery ground cable.

2. Remove the front console assembly(1).

Refer to the Instrument Panel Assembly in Body

Structure section.

3. Remove the lower cluster assembly(2).

Refer to the Instrument Panel Assembly in Body

Structure section.

4. Remove the instrument panel driver lower cover

assembly(3).

Refer to the Instrument Panel Assembly in Body

Structure section.

821RW024

Page 3374 of 6000

SUN ROOF/CONVERTIBLE TOP8I–7

5. Remove two sun roof frame complete assembly fixing

nuts (front side) and four fixing bolts (each side) from

the frame complete, and then remove the sun roof

frame complete assembly.

NOTE: Be sure to remove the frame complete while

supporting it.

Installation

1. Tighten the sun roof frame complete assembly fixing

bolts and nuts to the specified torque.

Torque: 10 Nꞏm(1.0 kgꞏm/87 lb in)2. After installing the frame complete, loosen the sun

roof glass fixing nuts and adjust the sun roof glass

setting position.

Refer to the Sun Roof Glass installation steps in this

section.

3. Install the sun roof drain hose.

4. Install the headlining.

Disassembled View

665RW033

Legend

(1) Sunshade

(2) Sun Roof Glass

(3) Sun Roof Motor(4) Sun Roof Drive Unit Assembly

(5) Outer Tube Fixing Screw

(6) Sun Roof Frame Assembly

(7) Sun Roof Deflector

Disassembly

1. Open the sun roof.

2. Remove the sun roof deflector fixing screws and then

remove the sun roof deflector.

3. Remove the sunshade.

Refer to the Sunshade in this section.

4. Close the sun roof, remove the decoration cover and

the fixing screws and then remove the sun roof glass.5. If the shims are used between the sun roof set plate

and the glass, note the number of the shims.

6. Disconnect the sun roof motor connector, remove the

sun roof fixing nuts and screws, and then remove the

sun roof motor.

Page 3408 of 6000

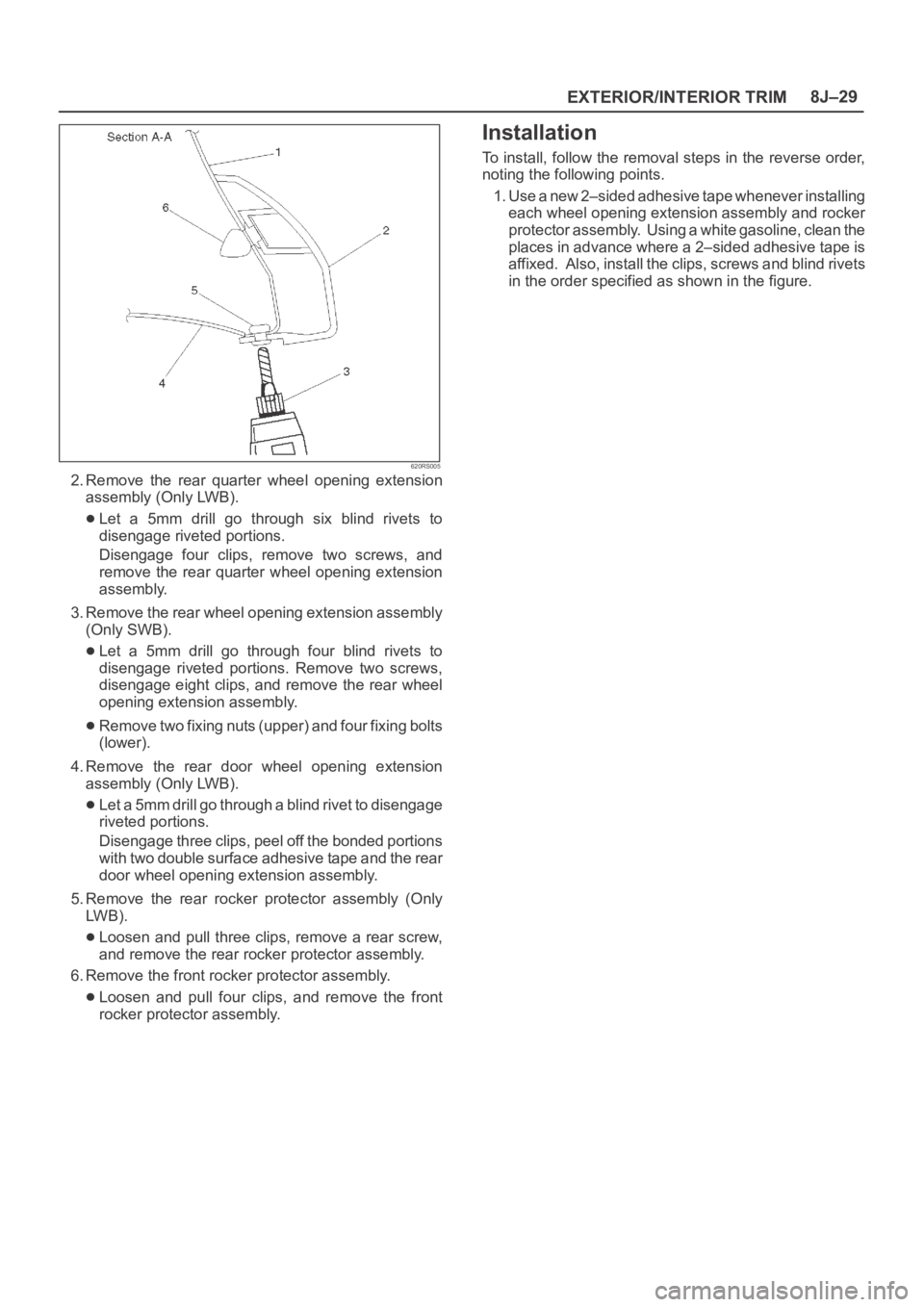

EXTERIOR/INTERIOR TRIM8J–29

620RS005

2. Remove the rear quarter wheel opening extension

assembly (Only LWB).

Let a 5mm drill go through six blind rivets to

disengage riveted portions.

Disengage four clips, remove two screws, and

remove the rear quarter wheel opening extension

assembly.

3. Remove the rear wheel opening extension assembly

(Only SWB).

Let a 5mm drill go through four blind rivets to

disengage riveted portions. Remove two screws,

disengage eight clips, and remove the rear wheel

opening extension assembly.

Remove two fixing nuts (upper) and four fixing bolts

(lower).

4. Remove the rear door wheel opening extension

assembly (Only LWB).

Let a 5mm drill go through a blind rivet to disengage

riveted portions.

Disengage three clips, peel off the bonded portions

with two double surface adhesive tape and the rear

door wheel opening extension assembly.

5. Remove the rear rocker protector assembly (Only

LW B ) .

Loosen and pull three clips, remove a rear screw,

and remove the rear rocker protector assembly.

6. Remove the front rocker protector assembly.

Loosen and pull four clips, and remove the front

rocker protector assembly.

Installation

To install, follow the removal steps in the reverse order,

noting the following points.

1. Use a new 2–sided adhesive tape whenever installing

each wheel opening extension assembly and rocker

protector assembly. Using a white gasoline, clean the

places in advance where a 2–sided adhesive tape is

affixed. Also, install the clips, screws and blind rivets

in the order specified as shown in the figure.

Page 3418 of 6000

EXTERIOR/INTERIOR TRIM8J–39

Power Window System

General Description

The circuit consists of the starter switch, (door lock &)

power window switch for each of the front windows,

p o w e r w i n d o w s w i t c h f o r r e a r w i n d o w s a n d p o w e r w i n d o w

motors.

When the starter switch is turned on, the battery voltage is

applied to each of the power window switches through the

circuit breaker and the power window relay on the circuit.

The “Down” switch of the driver’s power window switch

has a built-in function which can be operated by just

touching it.

Accordingly, the window will roll down automatically by

just setting the switch to the “AUTO” position.

When the driver’s power lock switch at the driver side is

depressed, the power source to the passenger’s power

window switches are shut off. So, even if these switches

are operated, the power window motor will not operate.

Power Window Switch Removal and

Installation

Driver Seat Side

Removal

1. Disconnect the battery ground cable.

2. Remove the switch(1).

Pull out the switch by pushing the spring with the tip

of a screwdriver.

Disconnect two connectors.

825RS052

Installation

To install, follow the removal steps in the reverse order.

Front Passenger Seat Side

Removal

1. Disconnect the battery ground cable.2. Remove the switch(1).

Pull out the switch by pushing the spring with the tip

of a screwdriver.

Disconnect the connector.

825RW046

Installation

To install, follow the removal steps in the reverse order.

Rear-Left and Right Sides

Removal

1. Disconnect the battery ground cable.

2. Remove the switch(1).

Pull out the switch by pushing the spring with the tip

of a screwdriver.

Disconnect the connector.

825RS057

Installation

To install, follow the removal steps in the reverse order.

Page 3441 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–4

SRS Component And Wiring Location View

810RW298

Legend

(1) Battery

(2) Relay & Fuse Box

(3) Passenger Air Bag Assembly

(4) SDM

(5) Meter Assembly

(6) SRS Coil Assembly

(7) Driver Air Bag Assembly(8) Starter Switch

(9) Fuse Box, C–21

(10) SRS Body Earth

(11) Body Harness Connector

(12) Instrument Harness Connector

(13) Engine Haness Connector

(14) Pretensioner, LH (If so equipped)

(15) Pretensioner, RH (If so equipped)

Component Description

SDM (Sensing and Diagnostic Module)

WARNING: DURING SERVICE PROCEDURES, BE

VERY CAREFUL WHEN HANDLING A SENSING AND

DIAGNOSTIC MODULE (SDM). NEVER STRIKE OR

JAR THE SDM. NEVER POWER UP THE SRS WHEN

THE SDM IS NOT RIGIDLY ATTACHED TO THE

VEHICLE. ALL SDM AND MOUNTING BRACKETFASTENERS MUST BE CAREFULLY TORQUED AND

THE ARROW MUST BE POINTED TOWARD THE

FRONT OF THE VEHICLE TO ENSURE PROPER

OPERATION OF THE SRS. THE SDM COULD BE

ACTIVATED WHEN POWERED WHILE NOT RIGIDLY

ATTACHED TO THE VEHICLE WHICH COULD CAUSE

DEPLOYMENT AND RESULT IN PERSONAL INJURY.

The Sensing and Diagnostic Module (SDM) is designed

to perform the following functions in the SRS:

Page 3442 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–5

1. Energy Reserve — The SDM maintains 24–Volt Loop

Reserve (24VLR) energy supply to provide

deployment energy when ignition voltage is lost in a

frontal crash.

2. Frontal Crash Detection — The SDM monitors

vehicle velocity changes to detect frontal crashes

which are severe enough to warrant deployment.

3. Air Bag Deployment — When a frontal crash of

sufficient force is detected, the SDM will cause

enough current to flow through the air bag assembly

to deploy the air bag.

4. Malfunction Detection — The SDM performs

diagnostic monitoring of SRS electrical components

and sets a diagnostic trouble code when a

malfunction is detected.

5. Frontal Crash Recording — The SDM records

information regarding SRS status during frontal

crash.

6. Malfunction Diagnosis — The SDM displays SRS

diagnostic trouble codes and system status

information through the use of a scan tool.

7. Driver Notification — The SDM warns the vehicle

driver of SRS malfunctions by controlling the “Air

Bag” warning lamp.

The SDM is connected to the SRS wiring harness by a

24–pin connector. This harness connector uses a

shorting clip across certain terminals in the contact area.

This shorting clip connects the “AIR BAG” warning lamp

to ground when the SDM harness connector is

disconnected or CPA (Connector Position Assurance) is

not inserted even if completely connected. This will

cause the “AIR BAG” warning lamp to come “ON” steady

whenever the ignition switch is at the ON or START

positions with the SDM disconnected.

827RW044

Legend

(1) SDM

(2) SRS Harness

(3) Connector Position Assurance

“Air Bag” Warning Lamp

Ignition voltage is applied to the “AIR BAG” warning lamp

when the ignition switch is at the ON or START positions.

The SDM controls the lamp by providing ground with a

lamp driver. The “AIR BAG” warning lamp is used in the

SRS to do the following:

1. Verify lamp and SDM operation by turn on 3.5

seconds and then turns “OFF” when the ignition

switch is first turned “ON”.

2. Warn the vehicle driver of SRS electrical system

malfunctions which could potentially affect the

operation of the SRS. These malfunctions could

result in nondeployment in case of a frontal crash or

deployment for conditions less severe than intended.

The “AIR BAG ” warning lamp is the key to driver

notification of SRS malfunctions. For proper lamp

operation, refer to the “SRS Diagnostic System Check” in

this section.

821RW037

SRS Coil Assembly

The SRS coil assembly consists of two current carrying

coils. This is attached to the steering column and allow

rotation of the steering wheel while maintaining

continuous contact of the driver deployment loop to the

driver air bag assembly.

There is a shorting clip on the yellow 2–pin connector near

the base of steering column which connects the SRS coil

to the SRS wiring harness.

The shorting clip shorts to the SRS coil and driver air bag

assembly when the yellow 2–pin connector is

disconnected. The circuit to the driver air bag assembly is

shorted in this way to help prevent unwanted deployment

of the air bag when servicing the steering column or other

SRS components.

Page 3444 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–7

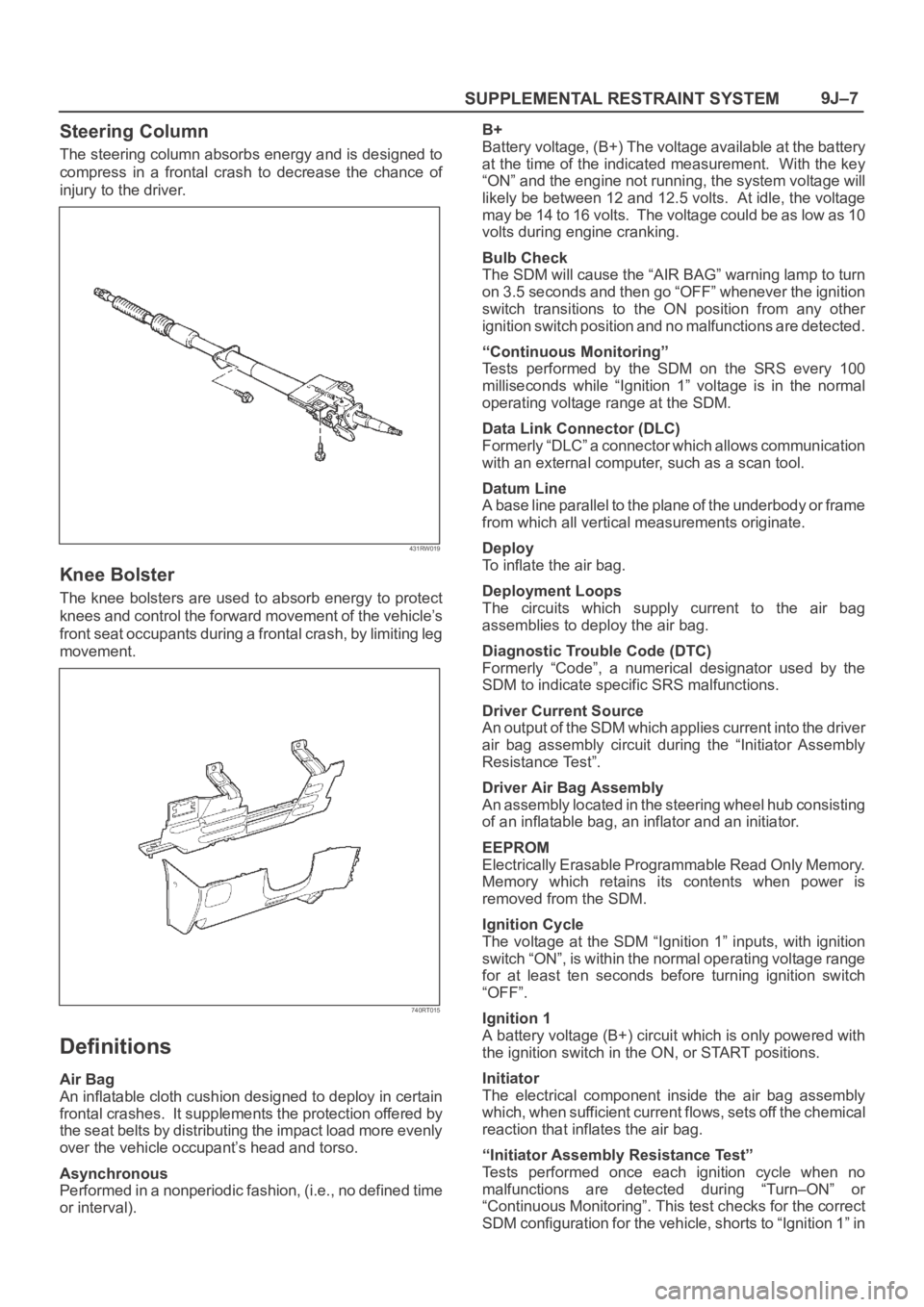

Steering Column

The steering column absorbs energy and is designed to

compress in a frontal crash to decrease the chance of

injury to the driver.

431RW019

Knee Bolster

The knee bolsters are used to absorb energy to protect

knees and control the forward movement of the vehicle’s

front seat occupants during a frontal crash, by limiting leg

movement.

740RT015

Definitions

Air Bag

An inflatable cloth cushion designed to deploy in certain

frontal crashes. It supplements the protection offered by

the seat belts by distributing the impact load more evenly

over the vehicle occupant’s head and torso.

Asynchronous

Performed in a nonperiodic fashion, (i.e., no defined time

or interval).B+

Battery voltage, (B+) The voltage available at the battery

at the time of the indicated measurement. With the key

“ON” and the engine not running, the system voltage will

likely be between 12 and 12.5 volts. At idle, the voltage

may be 14 to 16 volts. The voltage could be as low as 10

volts during engine cranking.

Bulb Check

The SDM will cause the “AIR BAG” warning lamp to turn

on 3.5 seconds and then go “OFF” whenever the ignition

switch transitions to the ON position from any other

ignition switch position and no malfunctions are detected.

“Continuous Monitoring”

Tests performed by the SDM on the SRS every 100

milliseconds while “Ignition 1” voltage is in the normal

operating voltage range at the SDM.

Data Link Connector (DLC)

Formerly “DLC” a connector which allows communication

with an external computer, such as a scan tool.

Datum Line

A base line parallel to the plane of the underbody or frame

from which all vertical measurements originate.

Deploy

To inflate the air bag.

Deployment Loops

The circuits which supply current to the air bag

assemblies to deploy the air bag.

Diagnostic Trouble Code (DTC)

Formerly “Code”, a numerical designator used by the

SDM to indicate specific SRS malfunctions.

Driver Current Source

An output of the SDM which applies current into the driver

air bag assembly circuit during the “Initiator Assembly

Resistance Test”.

Driver Air Bag Assembly

An assembly located in the steering wheel hub consisting

of an inflatable bag, an inflator and an initiator.

EEPROM

Electrically Erasable Programmable Read Only Memory.

Memory which retains its contents when power is

removed from the SDM.

Ignition Cycle

The voltage at the SDM “Ignition 1” inputs, with ignition

switch “ON”, is within the normal operating voltage range

for at least ten seconds before turning ignition switch

“OFF”.

Ignition 1

A battery voltage (B+) circuit which is only powered with

the ignition switch in the ON, or START positions.

Initiator

The electrical component inside the air bag assembly

which, when sufficient current flows, sets off the chemical

reaction that inflates the air bag.

“Initiator Assembly Resistance Test”

Tests performed once each ignition cycle when no

malfunctions are detected during “Turn–ON” or

“Continuous Monitoring”. This test checks for the correct

SDM configuration for the vehicle, shorts to “Ignition 1” in

Page 3447 of 6000

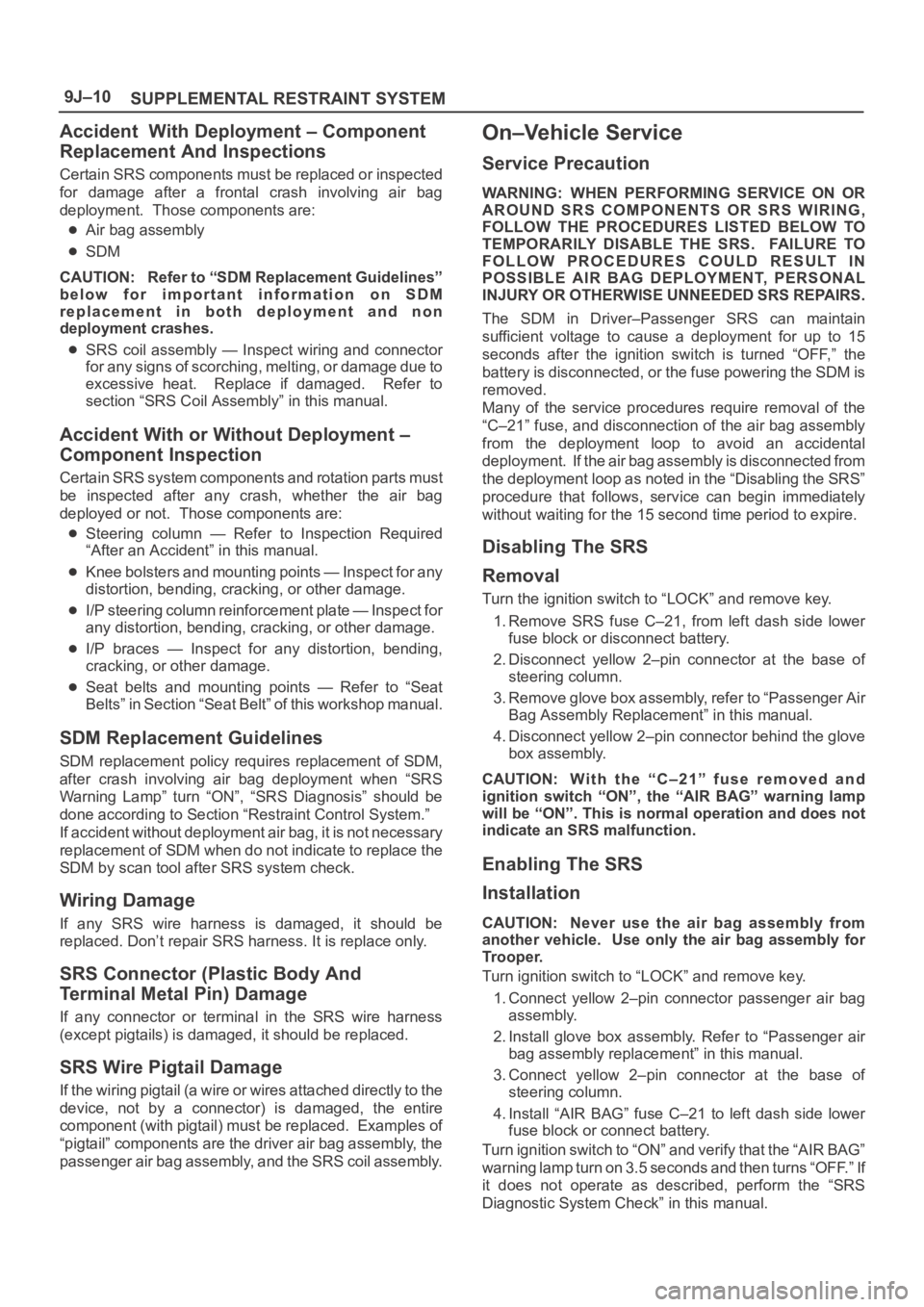

SUPPLEMENTAL RESTRAINT SYSTEM 9J–10

Accident With Deployment – Component

Replacement And Inspections

Certain SRS components must be replaced or inspected

for damage after a frontal crash involving air bag

deployment. Those components are:

Air bag assembly

SDM

CAUTION: Refer to “SDM Replacement Guidelines”

below for important information on SDM

replacement in both deployment and non

deployment crashes.

SRS coil assembly — Inspect wiring and connector

for any signs of scorching, melting, or damage due to

excessive heat. Replace if damaged. Refer to

section “SRS Coil Assembly” in this manual.

Accident With or Without Deployment –

Component Inspection

Certain SRS system components and rotation parts must

be inspected after any crash, whether the air bag

deployed or not. Those components are:

Steering column — Refer to Inspection Required

“After an Accident” in this manual.

Knee bolsters and mounting points — Inspect for any

distortion, bending, cracking, or other damage.

I/P steering column reinforcement plate — Inspect for

any distortion, bending, cracking, or other damage.

I/P braces — Inspect for any distortion, bending,

cracking, or other damage.

Seat belts and mounting points — Refer to “Seat

Belts” in Section “Seat Belt” of this workshop manual.

SDM Replacement Guidelines

SDM replacement policy requires replacement of SDM,

after crash involving air bag deployment when “SRS

Warning Lamp” turn “ON”, “SRS Diagnosis” should be

done according to Section “Restraint Control System.”

If accident without deployment air bag, it is not necessary

replacement of SDM when do not indicate to replace the

SDM by scan tool after SRS system check.

Wiring Damage

If any SRS wire harness is damaged, it should be

replaced. Don’t repair SRS harness. It is replace only.

SRS Connector (Plastic Body And

Terminal Metal Pin) Damage

If any connector or terminal in the SRS wire harness

(except pigtails) is damaged, it should be replaced.

SRS Wire Pigtail Damage

If the wiring pigtail (a wire or wires attached directly to the

device, not by a connector) is damaged, the entire

component (with pigtail) must be replaced. Examples of

“pigtail” components are the driver air bag assembly, the

passenger air bag assembly, and the SRS coil assembly.

On–Vehicle Service

Service Precaution

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND SRS COMPONENTS OR SRS WIRING,

FOLLOW THE PROCEDURES LISTED BELOW TO

TEMPORARILY DISABLE THE SRS. FAILURE TO

FOLLOW PROCEDURES COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY OR OTHERWISE UNNEEDED SRS REPAIRS.

The SDM in Driver–Passenger SRS can maintain

sufficient voltage to cause a deployment for up to 15

seconds after the ignition switch is turned “OFF,” the

battery is disconnected, or the fuse powering the SDM is

removed.

Many of the service procedures require removal of the

“C–21” fuse, and disconnection of the air bag assembly

from the deployment loop to avoid an accidental

deployment. If the air bag assembly is disconnected from

the deployment loop as noted in the “Disabling the SRS”

procedure that follows, service can begin immediately

without waiting for the 15 second time period to expire.

Disabling The SRS

Removal

Turn the ignition switch to “LOCK” and remove key.

1. Remove SRS fuse C–21, from left dash side lower

fuse block or disconnect battery.

2. Disconnect yellow 2–pin connector at the base of

steering column.

3. Remove glove box assembly, refer to “Passenger Air

Bag Assembly Replacement” in this manual.

4. Disconnect yellow 2–pin connector behind the glove

box assembly.

CAUTION: With the “C–21” fuse removed and

ignition switch “ON”, the “AIR BAG” warning lamp

will be “ON”. This is normal operation and does not

indicate an SRS malfunction.

Enabling The SRS

Installation

CAUTION: Never use the air bag assembly from

another vehicle. Use only the air bag assembly for

Trooper.

Turn ignition switch to “LOCK” and remove key.

1. Connect yellow 2–pin connector passenger air bag

assembly.

2. Install glove box assembly. Refer to “Passenger air

bag assembly replacement” in this manual.

3. Connect yellow 2–pin connector at the base of

steering column.

4. Install “AIR BAG” fuse C–21 to left dash side lower

fuse block or connect battery.

Turn ignition switch to “ON” and verify that the “AIR BAG”

warning lamp turn on 3.5 seconds and then turns “OFF.” If

it does not operate as described, perform the “SRS

Diagnostic System Check” in this manual.