Front ach OPEL FRONTERA 1998 Manual Online

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3449 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–12

Deployed Air Bag Assembly (Driver Side)

“You should wear gloves and glasses. After the air bag

assembly has been deployed, the surface of the air bag

may contain solid particulate. This solid particulate

c o n s i s t s p r i m a r i l y o f b y p r oducts of the chemical reaction,

Potassium Chloride and copper metal dust. Compounds

of Potassium Borate, Strontium Chloride, Copper

Chloride, and Ammonium Chloride may be found in

amounts of about 1% (each) of the total particulate.”

Deployed Pretensioner Seat Belt.

You should wear gloves and safety glasses. After the

pretensioner seat belt has been deployed, the surface of

the pretensioner seat belt cylinder may heating up.

Air Bag Assembly and/or Pretensioner

Seat Belt Scrapping Procedure.

During the cause of vehicle’s useful life, certain situations

may arise which will necessitate the disposal of a live air

bag and/or pretensioner seat belt. (This information

covers proper procedures for disposing of a live air bag

assembly and/or pretensioner seat belt.)

Before a live air bag assembly can be dispose off, it must

be deployed.

A live air bag assembly and/or pretensioner seat belt

must not be disposed of though normal refuse channels.

WARNING: FAILURE TO FOLLOW PROPER

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) AIR

BAG ASSEMBLY DISPOSAL PROCEDURES CAN

RESULT IN AIR BAG DEPLOYMENT WHICH MAY

CAUSE PERSONAL INJURY. AN UNDPLOYED AIR

BAG ASSEMBLY MUST NOT BE DISPOSED OF

THROUGH NORMAL REFUSE CHANNELS. THE

UNDEPLOYED AIR BAG ASSEMBLY CONTAINS

SUBSTANCES THAT CAN CAUSE SEVERE ILLNESS

OR PERSONAL INJURY IF THE SEALED CONTAINER

IS DAMAGED DURING DISPOSAL. DISPOSAL IN

ANY MANNER INCONSISTENT WITH PROPER

PROCEDURES MAY BE A VIOLATION OF LOCAL

LAW.

In situations which require deployment of a live air bag

assembly, deployment may be accomplished inside or

outside the vehicle. The method employed depends

upon the final disposition of the particular vehicle, as

noted in “Deployment Outside Vehicle” and “Deployment

Inside Vehicle” in this section.

Cautions About Air Bag Deployment And

Disposal

Failure to follow proper procedures could result in

erroneous air bag deployment which may cause personal

injury be sure to follow proper procedures.

1. Turn off (Lock) the ignition switch and disconnect the

minus terminal of the battery, then start the work 15 or

more sec later. (Air bag is designed to work by the

back-up power source even if the battery power

source is cut off at vehicle collision).

2. Be sure not to disassemble the air bag.

3. Do not give an impact to the air bag and bring the air

bag close to magnet. (The air bag could deploy

unexpectedly).4. Place the air bag with its trim cover up.

5. Do not let the air bag deploy directly on the floor. (The

air bag may be blown off 2

3 m (6.5 or 10 feet)).

6. Be sure to install the air bag firmly to a deployment

tool (fixing tool).

7. Set a battery 10 m (33 feet) or more away from the air

bag.

8. Before disconnecting air bag harness, ground the

worker by touching the vehicle outer panel with bare

hand.

9. When connecting or disconnecting the harness, do

not work just in front of the air bag.

10. As deployment gives rise to big sound, warn the

people around against it. Further, try to reduce the

sound by covering the steering wheel or tires, and

shut the vehicle windows in case of deployment

inside the vehicle.

11. As deployment generates smoke, select a well

ventilated place. (In case of deployment indoors,

avoid deployment just under a fire alarm, smoke

sensor, and fluorescent lamps).

12. Be careful not to inhale the smoke after deployment.

13. If part of the vehicle glass is damaged, cover the

vehicle with a car cover to prevent the glass from

braking at the time of deployment.

14. Do not touch the air bag immediately after

deployment, since it remains hot for 30 minutes.

15. Do not water the air bag immediately after

deployment.

16. Wear safety glasses and gloves throughout the work

and wash the glasses and gloves after the work.

17. Do not reuse the removed air bag for another vehicle.

(Deployment characteristic is different with vehicle

types).

Deployment Outside Vehicle (Driver Air

Bag Assembly)

Deployment outside the vehicle is proper when the

vehicle is to be returned to service. This includes, for

example, situations in which the vehicle will be returned to

useful service after a functionally or cosmetically deficient

air bag assembly is replaced. Deployment and disposal

of a malfunctioning air bag assembly is, of course, subject

to any required retention period.

For deployment of a live (undeployed) air bag assembly

outside the vehicle, the deployment procedure must be

followed exactly. Always wear safety glasses during this

deployment procedure until a deployed air bag assembly

is scrapped or until an undeployed air bag assembly is

shipped. Before performing the procedures you should

be familiar with servicing the SRS and with proper

handling of the air bag assembly. Procedures should be

read fully before they are performed.

The following procedure requires use of 5–8840–2468–0

SRS deployment harness with appropriate pigtail

adapter. Do not attempt procedure without

5–8840–2468–0 adapter.

WARNING: FAILURE TO FOLLOW PROCEDURES IN

THE ORDER LISTED MAY RESULT IN PERSONAL

INJURY. NEVER CONNECT DEPLOYMENT

Page 3457 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–20

13. Wash your hands with mild soap and water afterward.

NOTE: The remaining steps are to be followed in the

unlikely event that the air bag assembly did not deploy

after following the above procedures.

14. Ensure that the SRS deployment harness has been

disconnected from the power source and that its two

banana plugs have been shorted together by fully

seating one banana plug into the other.

827RW055

15. Disconnect the pigtail adapter from the air bag

assembly.

WARNING: WHEN STORING A LIVE AIR BAG

ASSEMBLY OR WHEN LEAVING A LIVE AIR BAG

ASSEMBLY UNATTENDED ON A BENCH OR OTHER

SURFACE, ALWAYS FACE THE BAG UP AND AWAY

FROM THE SURFACE. THIS IS NECESSARY SO

THAT A FREE SPACE IS PROVIDED TO ALLOW THE

AIR BAG TO EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. FAILURE TO FOLLOW

PROCEDURES MAY RESULT IN PERSONAL INJURY.

16. Temporarily store the air bag assembly with the bag

facing up, away from the surface upon which it rests.

066RW030

Deployment Inside Vehicle (Vehicle

Scrapping Procedure)

Deployment inside vehicle is proper when the vehicle is to

be destroyed or salvaged for component parts. This

includes, but is not limited to, the following situations:

1. The vehicle has completed its useful life.

2. The vehicle has been damaged beyond repair in a

nondeployment type accident.

3. The vehicle has been stripped or damaged beyond

repair in a theft.

4. The vehicle will be salvaged for component parts to

be used on a vehicle with a different Vehicle

Identification Number (VIN) as opposed to being

rebuilt as same VIN. Never use SRS components

from another vehicle.

WARNING: FAILURE TO FOLLOW PROPER SRS AIR

BAG ASSEMBLY DISPOSAL PROCEDURES CAN

RESULT IN AIR BAG DEPLOYMENT WHICH MAY

CAUSE PERSONAL INJURY. UNDEPLOYED AIR

BAG ASSEMBLIES MUST NOT BE DISPOSED OF

THROUGH NORMAL REFUSE CHANNELS. THE

UNDEPLOYED AIR BAG ASSEMBLY CONTAINS

SUBSTANCES THAT CAN CAUSE SEVERE ILLNESS

OR PERSONAL INJURY IF THE SEALED CONTAINER

IS DAMAGED DURING DISPOSAL. DISPOSAL IN

ANY MANNER INCONSISTENT WITH PROPER

PROCEDURES MAY BE A VIOLATION OF FEDERAL,

STATE AND/OR LOCAL LAWS.

1. Turn ignition switch to “LOCK,” remove key and put

on safety glasses.

2. Remove all loose objects from front seats.

3. Disconnect driver air bag assembly, yellow 2–pin

connector located at the base of the steering column.

4. Cut the driver air bag assembly yellow 2–pin harness

connector from the vehicle leaving at least 15 cm (six

inches) of wire at the connector.

5. Strip 13 mm (1/2 inch) of insulation from yellow –

green and yellow – black wire lead of the connector.

6. Cut two 900 cm (30 feet) deployment wires from 0.8

mm

(18 gauge) or thicker multi–strand wire. These

wires will be used to fabricate the driver deployment

harness.

7. Strip 13 mm (1/2 inch) of insulation from both ends of

the wires cut in the previous step.

8. Short the wires by twisting together one end from

each. Deployment wires shall remain shorted and not

be connected to a power source until the air bag is to

be deployed.

WARNING: FAILURE TO FOLLOW PROCEDURES IN

THE ORDER LISTED COULD RESULT IN PERSONAL

INJURY. NEVER CONNECT DEPLOYMENT WIRES

TO ANY POWER SOURCE BEFORE CONNECTING

DEPLOYMENT WIRES TO THE AIR BAG ASSEMBLY

LEADS. DEPLOYMENT WIRES SHALL REMAIN

SHORTED AND BE NOT CONNECTED TO A POWER

SOURCE UNTIL THE AIR BAG IS TO BE DEPLOYED.

THE AIR BAG ASSEMBLY WILL IMMEDIATELY

DEPLOY THE AIR BAG WHEN A POWER SOURCE IS

CONNECTED TO IT. WEAR SAFETY GLASSES

Page 3458 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–21

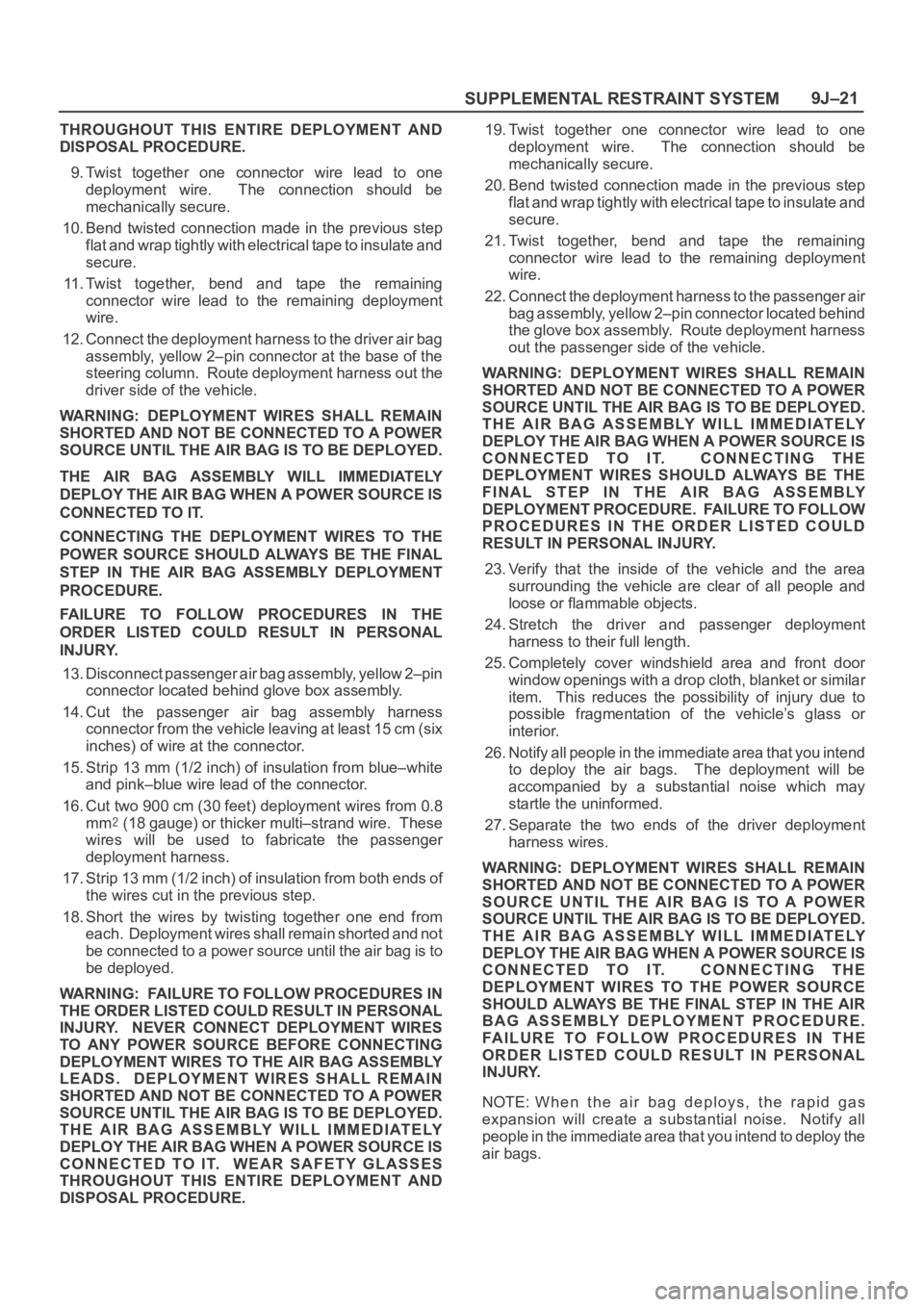

THROUGHOUT THIS ENTIRE DEPLOYMENT AND

DISPOSAL PROCEDURE.

9. Twist together one connector wire lead to one

deployment wire. The connection should be

mechanically secure.

10. Bend twisted connection made in the previous step

flat and wrap tightly with electrical tape to insulate and

secure.

11. Twist together, bend and tape the remaining

connector wire lead to the remaining deployment

wire.

12. Connect the deployment harness to the driver air bag

assembly, yellow 2–pin connector at the base of the

steering column. Route deployment harness out the

driver side of the vehicle.

WARNING: DEPLOYMENT WIRES SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE AIR BAG IS TO BE DEPLOYED.

THE AIR BAG ASSEMBLY WILL IMMEDIATELY

DEPLOY THE AIR BAG WHEN A POWER SOURCE IS

CONNECTED TO IT.

CONNECTING THE DEPLOYMENT WIRES TO THE

POWER SOURCE SHOULD ALWAYS BE THE FINAL

STEP IN THE AIR BAG ASSEMBLY DEPLOYMENT

PROCEDURE.

FAILURE TO FOLLOW PROCEDURES IN THE

ORDER LISTED COULD RESULT IN PERSONAL

INJURY.

13. Disconnect passenger air bag assembly, yellow 2–pin

connector located behind glove box assembly.

14. Cut the passenger air bag assembly harness

connector from the vehicle leaving at least 15 cm (six

inches) of wire at the connector.

15. Strip 13 mm (1/2 inch) of insulation from blue–white

and pink–blue wire lead of the connector.

16. Cut two 900 cm (30 feet) deployment wires from 0.8

mm

(18 gauge) or thicker multi–strand wire. These

wires will be used to fabricate the passenger

deployment harness.

17. Strip 13 mm (1/2 inch) of insulation from both ends of

the wires cut in the previous step.

18. Short the wires by twisting together one end from

each. Deployment wires shall remain shorted and not

be connected to a power source until the air bag is to

be deployed.

WARNING: FAILURE TO FOLLOW PROCEDURES IN

THE ORDER LISTED COULD RESULT IN PERSONAL

INJURY. NEVER CONNECT DEPLOYMENT WIRES

TO ANY POWER SOURCE BEFORE CONNECTING

DEPLOYMENT WIRES TO THE AIR BAG ASSEMBLY

LEADS. DEPLOYMENT WIRES SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE AIR BAG IS TO BE DEPLOYED.

THE AIR BAG ASSEMBLY WILL IMMEDIATELY

DEPLOY THE AIR BAG WHEN A POWER SOURCE IS

CONNECTED TO IT. WEAR SAFETY GLASSES

THROUGHOUT THIS ENTIRE DEPLOYMENT AND

DISPOSAL PROCEDURE.19. Twist together one connector wire lead to one

deployment wire. The connection should be

mechanically secure.

20. Bend twisted connection made in the previous step

flat and wrap tightly with electrical tape to insulate and

secure.

21. Twist together, bend and tape the remaining

connector wire lead to the remaining deployment

wire.

22. Connect the deployment harness to the passenger air

bag assembly, yellow 2–pin connector located behind

the glove box assembly. Route deployment harness

out the passenger side of the vehicle.

WARNING: DEPLOYMENT WIRES SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE AIR BAG IS TO BE DEPLOYED.

THE AIR BAG ASSEMBLY WILL IMMEDIATELY

DEPLOY THE AIR BAG WHEN A POWER SOURCE IS

CONNECTED TO IT. CONNECTING THE

DEPLOYMENT WIRES SHOULD ALWAYS BE THE

FINAL STEP IN THE AIR BAG ASSEMBLY

DEPLOYMENT PROCEDURE. FAILURE TO FOLLOW

PROCEDURES IN THE ORDER LISTED COULD

RESULT IN PERSONAL INJURY.

23. Verify that the inside of the vehicle and the area

surrounding the vehicle are clear of all people and

loose or flammable objects.

24. Stretch the driver and passenger deployment

harness to their full length.

25. Completely cover windshield area and front door

window openings with a drop cloth, blanket or similar

item. This reduces the possibility of injury due to

possible fragmentation of the vehicle’s glass or

interior.

26. Notify all people in the immediate area that you intend

to deploy the air bags. The deployment will be

accompanied by a substantial noise which may

startle the uninformed.

27. Separate the two ends of the driver deployment

harness wires.

WARNING: DEPLOYMENT WIRES SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE AIR BAG IS TO A POWER

SOURCE UNTIL THE AIR BAG IS TO BE DEPLOYED.

THE AIR BAG ASSEMBLY WILL IMMEDIATELY

DEPLOY THE AIR BAG WHEN A POWER SOURCE IS

CONNECTED TO IT. CONNECTING THE

DEPLOYMENT WIRES TO THE POWER SOURCE

SHOULD ALWAYS BE THE FINAL STEP IN THE AIR

BAG ASSEMBLY DEPLOYMENT PROCEDURE.

FAILURE TO FOLLOW PROCEDURES IN THE

ORDER LISTED COULD RESULT IN PERSONAL

INJURY.

NOTE: When the air bag deploys, the rapid gas

expansion will create a substantial noise. Notify all

people in the immediate area that you intend to deploy the

air bags.

Page 3467 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–30

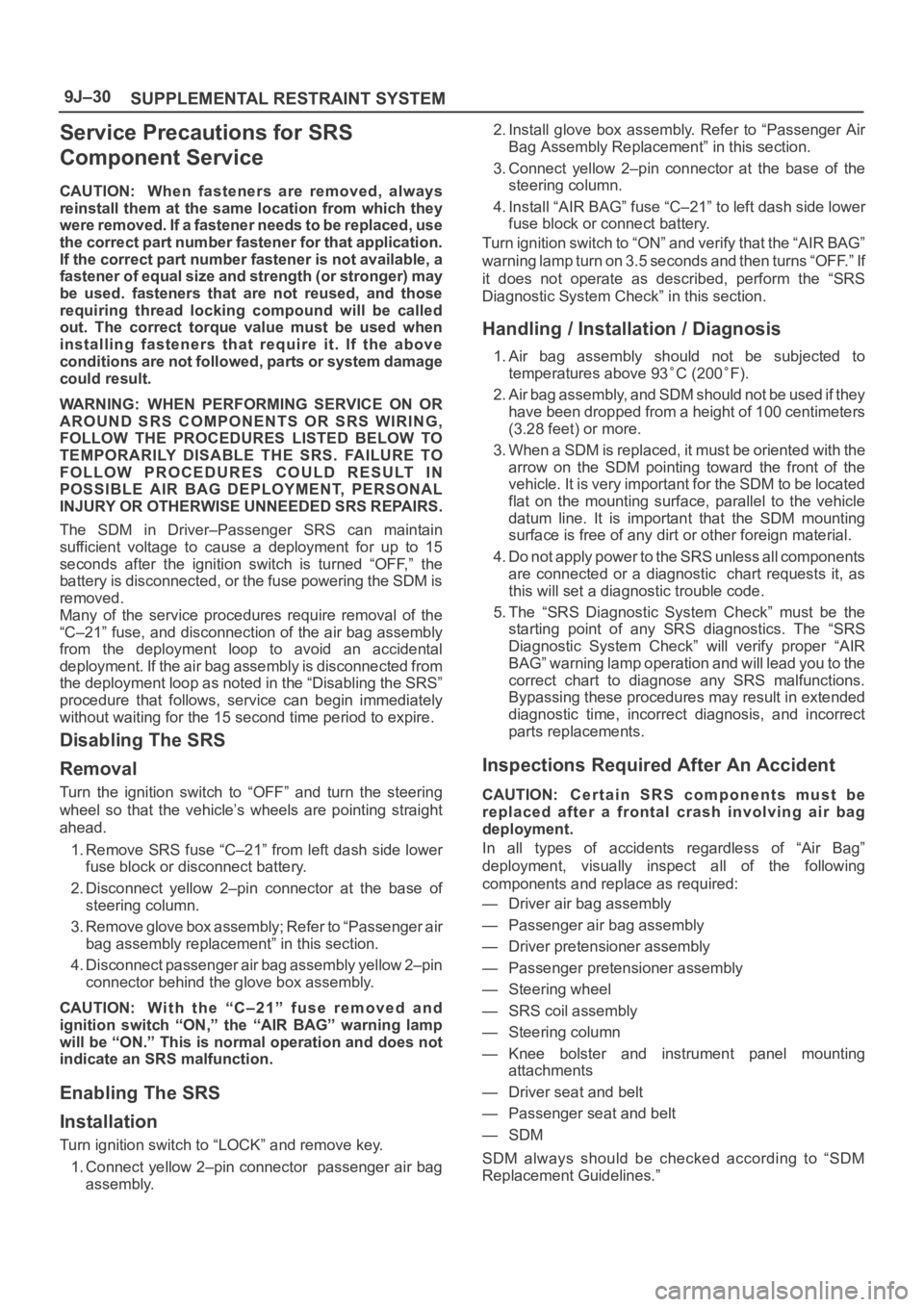

Service Precautions for SRS

Component Service

CAUTION: When fasteners are removed, always

reinstall them at the same location from which they

were removed. If a fastener needs to be replaced, use

the correct part number fastener for that application.

If the correct part number fastener is not available, a

fastener of equal size and strength (or stronger) may

be used. fasteners that are not reused, and those

requiring thread locking compound will be called

out. The correct torque value must be used when

installing fasteners that require it. If the above

conditions are not followed, parts or system damage

could result.

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND SRS COMPONENTS OR SRS WIRING,

FOLLOW THE PROCEDURES LISTED BELOW TO

TEMPORARILY DISABLE THE SRS. FAILURE TO

FOLLOW PROCEDURES COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY OR OTHERWISE UNNEEDED SRS REPAIRS.

The SDM in Driver–Passenger SRS can maintain

sufficient voltage to cause a deployment for up to 15

seconds after the ignition switch is turned “OFF,” the

battery is disconnected, or the fuse powering the SDM is

removed.

Many of the service procedures require removal of the

“C–21” fuse, and disconnection of the air bag assembly

from the deployment loop to avoid an accidental

deployment. If the air bag assembly is disconnected from

the deployment loop as noted in the “Disabling the SRS”

procedure that follows, service can begin immediately

without waiting for the 15 second time period to expire.

Disabling The SRS

Removal

Turn the ignition switch to “OFF” and turn the steering

wheel so that the vehicle’s wheels are pointing straight

ahead.

1. Remove SRS fuse “C–21” from left dash side lower

fuse block or disconnect battery.

2. Disconnect yellow 2–pin connector at the base of

steering column.

3 . R e m o v e g l o v e b o x a s s e m b l y ; R e f e r t o “ P a s s e n g e r a i r

bag assembly replacement” in this section.

4. Disconnect passenger air bag assembly yellow 2–pin

connector behind the glove box assembly.

CAUTION: W i t h t h e “ C – 2 1 ” f u s e r e m o v e d a n d

ignition switch “ON,” the “AIR BAG” warning lamp

will be “ON.” This is normal operation and does not

indicate an SRS malfunction.

Enabling The SRS

Installation

Turn ignition switch to “LOCK” and remove key.

1. Connect yellow 2–pin connector passenger air bag

assembly.2. Install glove box assembly. Refer to “Passenger Air

Bag Assembly Replacement” in this section.

3. Connect yellow 2–pin connector at the base of the

steering column.

4. Install “AIR BAG” fuse “C–21” to left dash side lower

fuse block or connect battery.

Turn ignition switch to “ON” and verify that the “AIR BAG”

warning lamp turn on 3.5 seconds and then turns “OFF.” If

it does not operate as described, perform the “SRS

Diagnostic System Check” in this section.

Handling / Installation / Diagnosis

1. Air bag assembly should not be subjected to

temperatures above 93

C (200F).

2. Air bag assembly, and SDM should not be used if they

have been dropped from a height of 100 centimeters

(3.28 feet) or more.

3. When a SDM is replaced, it must be oriented with the

arrow on the SDM pointing toward the front of the

vehicle. It is very important for the SDM to be located

flat on the mounting surface, parallel to the vehicle

datum line. It is important that the SDM mounting

surface is free of any dirt or other foreign material.

4. Do not apply power to the SRS unless all components

are connected or a diagnostic chart requests it, as

this will set a diagnostic trouble code.

5. The “SRS Diagnostic System Check” must be the

starting point of any SRS diagnostics. The “SRS

Diagnostic System Check” will verify proper “AIR

BAG” warning lamp operation and will lead you to the

correct chart to diagnose any SRS malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements.

Inspections Required After An Accident

CAUTION: C e r t a i n S R S c o m p o n e n t s m u s t b e

replaced after a frontal crash involving air bag

deployment.

In all types of accidents regardless of “Air Bag”

deployment, visually inspect all of the following

components and replace as required:

— Driver air bag assembly

— Passenger air bag assembly

— Driver pretensioner assembly

— Passenger pretensioner assembly

— Steering wheel

— SRS coil assembly

— Steering column

— Knee bolster and instrument panel mounting

attachments

— Driver seat and belt

— Passenger seat and belt

—SDM

SDM always should be checked according to “SDM

Replacement Guidelines.”

Page 3470 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–33

Sensing And Diagnostic Module (SDM)

Service Precautions

WARNING: DURING SERVICE PROCEDURES, BE

VERY CAREFUL WHEN HANDLING SDM. NEVER

STRIKE OR JAR SDM. UNDER SOME

CIRCUMSTANCES, IT COULD CAUSE

DEPLOYMENT AND RESULT IN PERSONAL INJURY

OR IMPROPER OPERATION OF THE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) . SDM

MOUNTING BRACKET BOLTS MUST BE

CAREFULLY TORQUED TO ASSURE PROPER

OPERATION. NEVER POWER UP THE SRS WHEN

SDM IS NOT RIGIDLY ATTACHED TO THE VEHICLE.

THE SDM COULD BE ACTIVATED WHEN POWERED

WHILE NOT RIGIDLY ATTACHED TO THE VEHICLE

WHICH COULD CAUSE DEPLOYMENT AND RESULT

IN PERSONAL INJURY.

WARNING: PROPER OPERATION OF THE SENSING

AND DIAGNOSTIC MODULE (SDM) REQUIRES THE

SDM TO BE RIGIDLY ATTACHED TO THE VEHICLE

STRUCTURE AND THAT THE ARROW ON THE

SENSOR BE POINTING TOWARD THE FRONT OF

THE VEHICLE.

SDM is specifically calibrated and is keyed to the SDM

location SRS wiring harness. Caution should be used to

ensure proper location of the SDM. The keying of the

SDM to its location and wiring harness connectors should

never be modified in the field.

Removal

1. Disable the SRS (Refer to “Disabling the SRS” in this

section).

2. Remove the transmission knob (for M/T) and transfer

lever knob.

3. Remove the front console assembly and disconnect

wiring harness connector.

4. Pull CPA (Connector Position Assurance) out and

push connector lock down to disconnect the SDM

harness connector.

5. Remove the three SDM fixing bolts and remove SDM.

827RW044

Legend

(1) SDM

(2) SRS Harness

(3) Connector Position Assurance

Installation

1. Install the SDM on bracket and fixing bolts and tighten

the fixing bolts to the specified torque.

Torque: 10 Nꞏm (1.0 Kgꞏm/87 Ib in)

2. Connect the SDM harness connector and after that,

put CPA into connector.

3. Install the front console.

4. Install the transmission knob (for M/T) and transfer

lever knob.

Page 3494 of 6000

9J1–7

RESTRAINT CONTROL SYSTEM

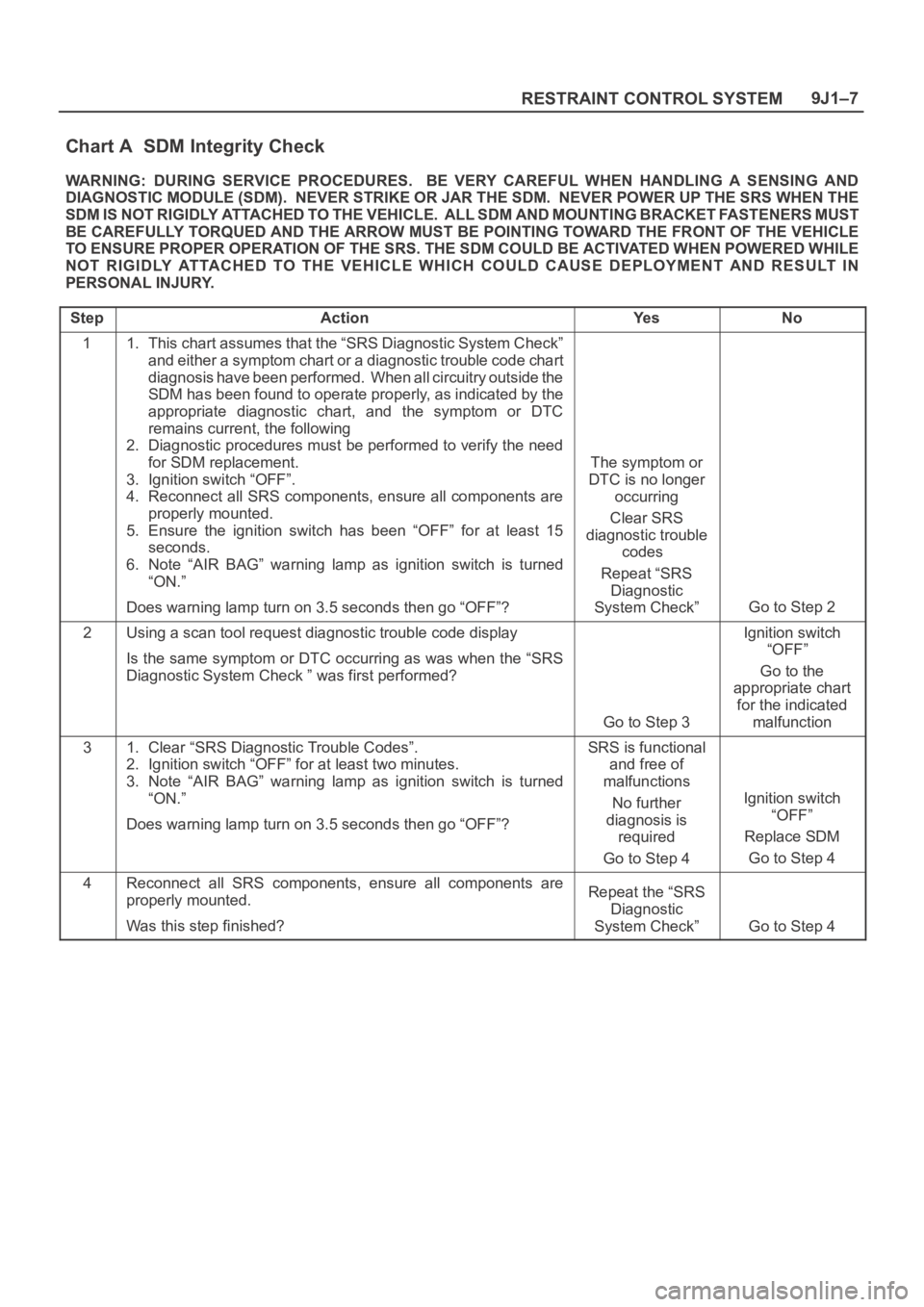

Chart A SDM Integrity Check

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SENSING AND

DIAGNOSTIC MODULE (SDM). NEVER STRIKE OR JAR THE SDM. NEVER POWER UP THE SRS WHEN THE

S D M I S N O T R I G I D LY AT TA C H E D T O T H E V E H I C L E . A L L S D M A N D M O U N T ING BRACKET FASTENERS MUST

BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE FRONT OF THE VEHICLE

TO ENSURE PROPER OPERATION OF THE SRS. THE SDM COULD BE ACTIVATED WHEN POWERED WHILE

NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD CAUSE DEPLOYMENT AND RESULT IN

PERSONAL INJURY.

Step

ActionYe sNo

11. This chart assumes that the “SRS Diagnostic System Check”

and either a symptom chart or a diagnostic trouble code chart

diagnosis have been performed. When all circuitry outside the

SDM has been found to operate properly, as indicated by the

appropriate diagnostic chart, and the symptom or DTC

remains current, the following

2. Diagnostic procedures must be performed to verify the need

for SDM replacement.

3. Ignition switch “OFF”.

4. Reconnect all SRS components, ensure all components are

properly mounted.

5. Ensure the ignition switch has been “OFF” for at least 15

seconds.

6. Note “AIR BAG” warning lamp as ignition switch is turned

“ON.”

Does warning lamp turn on 3.5 seconds then go “OFF”?

The symptom or

DTC is no longer

occurring

Clear SRS

diagnostic trouble

codes

Repeat “SRS

Diagnostic

System Check”

Go to Step 2

2Using a scan tool request diagnostic trouble code display

Is the same symptom or DTC occurring as was when the “SRS

Diagnostic System Check ” was first performed?

Go to Step 3

Ignition switch

“OFF”

Go to the

appropriate chart

for the indicated

malfunction

31. Clear “SRS Diagnostic Trouble Codes”.

2. Ignition switch “OFF” for at least two minutes.

3. Note “AIR BAG” warning lamp as ignition switch is turned

“ON.”

Does warning lamp turn on 3.5 seconds then go “OFF”?SRS is functional

and free of

malfunctions

No further

diagnosis is

required

Go to Step 4

Ignition switch

“OFF”

Replace SDM

Go to Step 4

4Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished?Repeat the “SRS

Diagnostic

System Check”

Go to Step 4

Page 3523 of 6000

RESTRAINT CONTROL SYSTEM 9J1–36

DTC 51 Air Bag Deployment Event Commanded

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SENSING AND

DIAGNOSTIC MODULE (SDM). NEVER STRIKE OR JAR THE SDM. NEVER POWER UP THE SRS WHEN THE

SDM IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SDM AND MOUNTING BRACKET FASTENERS MUST

BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE FRONT OF THE VEHICLE

TO ENSURE PROPER OPERATION OF THE SRS. THE SDM COULD BE ACTIVATED WHEN POWERED WHILE

NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD CAUSE DEPLOYMENT AND RESULT IN

PERSONAL INJURY.

Step

ActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Go to the “SRS

Diagnostic

System Check”

2Ignition switch “OFF.”

Have air bag assemblies deployed?Replace

components and

perform

inspections as

directed in

“repairs and

inspections

required after an

accident” in this

section

Clear diagnostic

trouble codes

Repeat “SRS

Diagnostic

System Check”

Go to Step 3

3Inspect front of vehicle and undercarriage for sings of impact.

Were signs of impact found?Replace

components and

perform

inspections as

directed in

“Repairs and

Inspections

Required After An

Accident” in this

section

Clear diagnostic

trouble codes

Repeat “SRS

Diagnostic

System Check”

Ignition switch

“OFF”

Replace SDM

Reconnect all

SRS system

components,

ensure all

components are

properly mounted

Repeat “SRS

Diagnostic

System Check”

Page 3525 of 6000

RESTRAINT CONTROL SYSTEM 9J1–38

DTC 53 Deployment Commanded WITH Deployment Loop Fault Or Energy Reserves Out

Of Range

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SENSING AND

DIAGNOSTIC MODULE (SDM). NEVER STRIKE OR JAR THE SDM. NEVER POWER UP THE SRS WHEN THE

SDM IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SDM AND MOUNTING BRACKET FASTENERS MUST

BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE FRONT OF THE VEHICLE

TO ENSURE PROPER OPERATION OF THE SRS. THE SDM COULD BE ACTIVATED WHEN POWERED WHILE

NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD CAUSE DEPLOYMENT AND RESULT IN

PERSONAL INJURY.

Step

ActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Go to the “SRS

Diagnostic

System Check”

2Ignition switch “OFF.”

Have air bag assembles deployed?Replace

components and

perform

inspections as

directed in

“Repairs And

Inspections

Required After An

Accident” in this

section

Clear diagnostic

trouble codes

Repeat the “SRS

Diagnostic

System Check”

Go to Step 3

3Inspect front of vehicle and undercarriage for signs of impact.

Were signs of impact found?Replace

components and

perform

inspections as

directed in

“Repairs And

Inspections

Required After An

Accident” in this

section

Clear diagnostic

trouble codes

Repeat “SRS

Diagnostic

System Check”

Ignition switch

“OFF”

Replace SDM

Reconnect all

SRS system

components,

ensure all

components are

properly mounted

Repeat the “SRS

Diagnostic

System Check”

Page 3529 of 6000

RESTRAINT CONTROL SYSTEM 9J1–42

DTC 71 Internal SDM Fault

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SENSING AND

DIAGNOSTIC MODULE (SDM). NEVER STRIKE OR JAR THE SDM. NEVER POWER UP THE SRS WHEN THE

SDM IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SDM AND MOUNTING BRACKET FASTENERS MUST

BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE FRONT OF THE VEHICLE

TO ENSURE PROPER OPERATION OF THE SRS. THE SDM COULD BE ACTIVATED WHEN POWERED WHILE

NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD CAUSE DEPLOYMENT AND RESULT IN

PERSONAL INJURY.

CAUTION: When DTC 19 or 25 has been set, it is necessary to replace the SDM. Setting DTC 19 and 25 or 51

or 53 will also cause DTC 71 to set. When a scan tool “CLEAR CODES” command is issued and the

malfunction is no longer present, DTC 51 or 53 and DTC 71 will remain current. Ensure that the short to voltage

condition DTC 19, 25 is repaired prior to installing a replacement SDM to avoid damaging the SDM.

Step

ActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Go to the “SRS

Diagnostic

System Check”

2Note SRS “Diagnostic System Check.”

IS DTC 19 OR 25 OR 51 OR 53 ALSO SET (CURRENT OR

HISTORY)? (REFER TO NOTICE ABOVE.)Go to DTC 19 if

DTC 19 is set

Go to DTC 25 if

DTC 25 is set

Go to DTC 51 if

DTC 51 is set

Go to DTC 53 if

DTC 53 is set

Ignition switch

“OFF”

Replace SDM

Repeat the “SRS

Diagnostic

System Check”

Page 3551 of 6000

RESTRAINT CONTROL SYSTEM 9J1–64

DTC 52 Deployment Event Commanded

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SENSING AND

DIAGNOSTIC MODULE (SDM). NEVER STRIKE OR JAR THE SDM. NEVER POWER UP THE PRETENSIONER

WHEN THE SDM IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SDM AND MOUNTING BRACKET

FASTENERS MUST BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE FRONT

OF THE VEHICLE TO ENSURE PROPER OPERATION OF THE PRETENSIONER. THE SDM COULD BE

ACTIVATED WHEN POWERED WHILE NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD CAUSE

DEPLOYMENT AND RESULT IN PERSONAL INJURY.

Step

ActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2.

Go to the “SRS

Diagnostic

System Check”

2Ignition switch “OFF.”

Have pretensioner assemblies deployed?Replace

components and

perform

inspections as

directed in

“repairs and

inspections

required after an

accident” in this

section

clear diagnostic

trouble codes

Repeat “SRS

Diagnostic

System Check”

Go to Step 3

3Inspect front of vehicle and undercarriage for sings of impact.

Were signs of impact found?Replace

components and

perform

inspections as

directed in

“Repairs and

Inspections

Required After An

Accident” in this

section

Clear diagnostic

trouble codes

Repeat “SRS

Diagnostic

System Check”

Ignition switch

“OFF”

Replace SDM

Reconnect all

SRS system

components,

ensure all

components are

properly mounted

Repeat “SRS

Diagnostic

System Check”