Front ach OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1822 of 6000

ENGINE MECHANICAL 6A – 89

3. Measure the oil clearance between the connecting

rod and the crankshaft.

1) Remove the connecting rod cap nuts and the

rod caps.

Arrange the removed rod caps in the cylinder

number order.

2) Clean the rod bearings and the crankshaft pins.

3) Carefully check the rod bearings.

If even one bearing is found to be damaged or

badly worn, the entire bearing assembly must be

replaced as a set. Reinstall the bearings in their

original positions.

Apply plastigage to the crank pin.

4) Reinstall the rod caps to their original positions.

5) Tighten the cap nuts in 2 steps, using angular

tightening method as shown in the following

specifications.

1st step: 29 Nꞏm (3.0 kgꞏm/22 lb ft)

2nd step: 45°– 60°NOTE: Do not allow the crankshaft to rotate

6) Remove the rod caps.

7) Measure the smallest width of the plastigage

and determine the oil clearance. If the oil

clearance exceeds the limit, replace the rod

bearings as a set.

8) Clean the plastigage from the bearings and the

crankshaft pins

Standard: 0.022 – 0.042 mm (0.0009 – 0.0017 in)

Limit: 0.100 mm (0.0039 in)

REASSEMBLY

1. Connecting Rod

2. Piston

3. Piston Pin

1) Apply a coat of engine oil to the piston pin and

the piston pin hole.

4. Piston Pin Snap Ring

1) Try to insert the piston pin into the piston pin

hole with normal finger pressure.

2) Weight each piston and connecting rod

assembly.

3) Select piston and connecting rod combinations

so that the weight variation of the different four

assemblies is held within the specified limits.

Variance in weight after assembly: Less than 3g

(0.1058 oz)

NOTE: When changing piston/connecting rod

combinations, do not change the piston/piston pin

combination.

4) Attach the piston to the connecting rod with the

piston front mark (2) and the connecting rod

front mark (3) on the same side.

014RW055

012RW075

014RW077

Page 1824 of 6000

ENGINE MECHANICAL 6A – 91

Legend

(1) 1st compressor ring gap

(2) 2nd compressor ring gap

(3) Oil ring gap

3) Insert the piston/connecting rod assemblies into

each cylinder with the piston ring compressor.

4) The front marks must be facing the front of the

engine.

Piston Ring Compressor : 5-8840-9018-0

7. Connecting Rod Bearing Cap

1) Apply engine oil to thread and seat of bearing

cap bolts.

2) Tighten the cap bolts in 2 steps, using angular

tightening method as shown in the following

specifications.

1st step: 29 Nꞏm (3.0 kgꞏm/22 lb ft)

2nd step: 45°– 60°

After tightening the cap bolts, check to see that

the crankshaft rotates smoothly.

8. Crank Case Assembly

1) Refer to “Crank Case” in this manual.

9. Cylinder Head Assembly

1) Refer to “Cylinder head” in this manual.

3

1

2

015RW083

Page 1888 of 6000

ENGINE ELECTRICAL 6D – 21

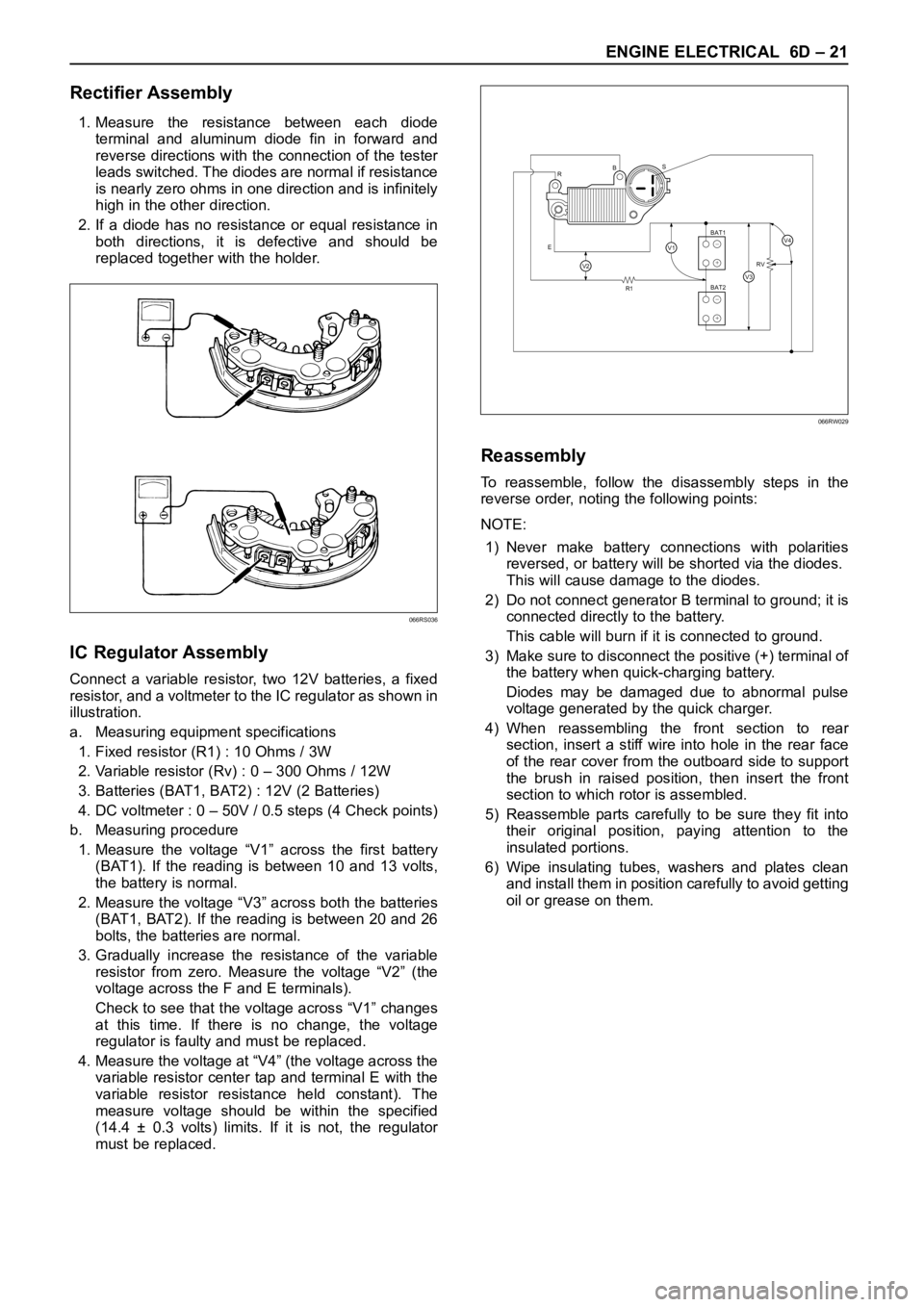

Rectifier Assembly

1. Measure the resistance between each diode

terminal and aluminum diode fin in forward and

reverse directions with the connection of the tester

leads switched. The diodes are normal if resistance

is nearly zero ohms in one direction and is infinitely

high in the other direction.

2. If a diode has no resistance or equal resistance in

both directions, it is defective and should be

replaced together with the holder.

IC Regulator Assembly

Connect a variable resistor, two 12V batteries, a fixed

resistor, and a voltmeter to the IC regulator as shown in

illustration.

a. Measuring equipment specifications

1. Fixed resistor (R1) : 10 Ohms / 3W

2. Variable resistor (Rv) : 0 – 300 Ohms / 12W

3. Batteries (BAT1, BAT2) : 12V (2 Batteries)

4. DC voltmeter : 0 – 50V / 0.5 steps (4 Check points)

b. Measuring procedure

1. Measure the voltage “V1” across the first battery

(BAT1). If the reading is between 10 and 13 volts,

the battery is normal.

2. Measure the voltage “V3” across both the batteries

(BAT1, BAT2). If the reading is between 20 and 26

bolts, the batteries are normal.

3. Gradually increase the resistance of the variable

resistor from zero. Measure the voltage “V2” (the

voltage across the F and E terminals).

Check to see that the voltage across “V1” changes

at this time. If there is no change, the voltage

regulator is faulty and must be replaced.

4. Measure the voltage at “V4” (the voltage across the

variable resistor center tap and terminal E with the

variable resistor resistance held constant). The

measure voltage should be within the specified

(14.4 ± 0.3 volts) limits. If it is not, the regulator

must be replaced.

Reassembly

To reassemble, follow the disassembly steps in the

reverse order, noting the following points:

NOTE:

1) Never make battery connections with polarities

reversed, or battery will be shorted via the diodes.

This will cause damage to the diodes.

2) Do not connect generator B terminal to ground; it is

connected directly to the battery.

This cable will burn if it is connected to ground.

3) Make sure to disconnect the positive (+) terminal of

the battery when quick-charging battery.

Diodes may be damaged due to abnormal pulse

voltage generated by the quick charger.

4) When reassembling the front section to rear

section, insert a stiff wire into hole in the rear face

of the rear cover from the outboard side to support

the brush in raised position, then insert the front

section to which rotor is assembled.

5) Reassemble parts carefully to be sure they fit into

their original position, paying attention to the

insulated portions.

6) Wipe insulating tubes, washers and plates clean

and install them in position carefully to avoid getting

oil or grease on them.

066RS036

R

EBS

R1RV

BAT2 BAT1

V2V3

V4V1+

−

+

−

066RW029

Page 1889 of 6000

6D – 22 ENGINE ELECTRICAL

1. Using a press with a socket wrench attached,

reassemble rotor and rear end cover assembly in

the front cover.2. Install pulley on the rotor.

Secure the pulley directly in the vise between two

copper plates, and tighten nut to the specified

torque.

Torque: 111 Nꞏm (82 lb ft)

066RS022

066RS010

MAIN DATA AND SPECIFICATIONS

General Specifications

Model LR190-750B LR-1100-731

Battery voltage V 12

Rated output A 90 100

Direction of rotation Clockwise

(as viewed from pulley side)

Rated rotation speed rpm 5,000

Maximum speed rpm 18,000

Page 1920 of 6000

6E–27 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Non-Emissions related

Dose not request illumination of any lamp

Stores a History DTC on the first trip with a fail

Stores Fail Record when test fails

Updates the Fail Record each time the diagnostic test

fails

Storing and Erasing Freeze Frame Data and Failure

Records

The data captured is called Freeze Frame data. The

Freeze Frame data is very similar to a single record of

operating conditions. Whenever the MIL is illuminated,

the corresponding record of operating conditions is

recorded to the Freeze Frame buffer.

Data from these faults take precedence over data

associated with any other fault. The Freeze Frame data

will not be erased unless the associated history DTC is

cleared.

Each time a diagnostic test reports a failure, the current

engine operating conditions are recorded in the

Failure

Records

buffer. A subsequent failure will update the

recorded operating conditions. The following operating

conditions for the diagnostic test which failed

typically

include the following parameters:

Engine Speed

Engine Load

Engine Coolant Temperature

Vehicle Speed

Intake Throttle Position

MAP

Injector Base Pulse Width

Loop Status

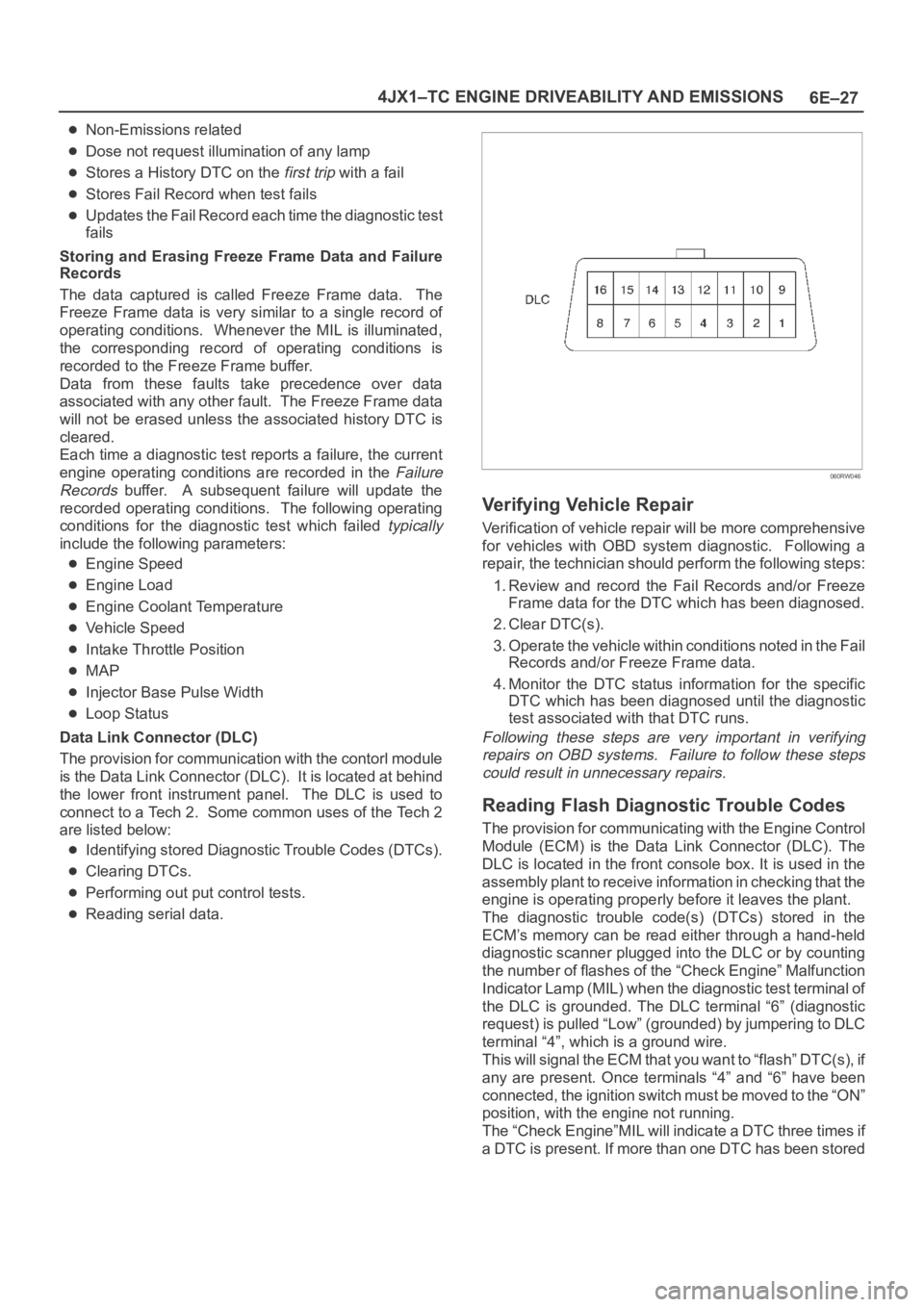

Data Link Connector (DLC)

The provision for communication with the contorl module

is the Data Link Connector (DLC). It is located at behind

the lower front instrument panel. The DLC is used to

connect to a Tech 2. Some common uses of the Tech 2

are listed below:

Identifying stored Diagnostic Trouble Codes (DTCs).

Clearing DTCs.

Performing out put control tests.

Reading serial data.

060RW046

Verifying Vehicle Repair

Verification of vehicle repair will be more comprehensive

for vehicles with OBD system diagnostic. Following a

repair, the technician should perform the following steps:

1. Review and record the Fail Records and/or Freeze

Frame data for the DTC which has been diagnosed.

2. Clear DTC(s).

3. Operate the vehicle within conditions noted in the Fail

Records and/or Freeze Frame data.

4. Monitor the DTC status information for the specific

DTC which has been diagnosed until the diagnostic

test associated with that DTC runs.

Following these steps are very important in verifying

repairs on OBD systems. Failure to follow these steps

could result in unnecessary repairs.

Reading Flash Diagnostic Trouble Codes

The provision for communicating with the Engine Control

Module (ECM) is the Data Link Connector (DLC). The

DLC is located in the front console box. It is used in the

assembly plant to receive information in checking that the

engine is operating properly before it leaves the plant.

The diagnostic trouble code(s) (DTCs) stored in the

ECM’s memory can be read either through a hand-held

diagnostic scanner plugged into the DLC or by counting

the number of flashes of the “Check Engine” Malfunction

Indicator Lamp (MIL) when the diagnostic test terminal of

the DLC is grounded. The DLC terminal “6” (diagnostic

request) is pulled “Low” (grounded) by jumpering to DLC

terminal “4”, which is a ground wire.

This will signal the ECM that you want to “flash” DTC(s), if

any are present. Once terminals “4” and “6” have been

connected, the ignition switch must be moved to the “ON”

position, with the engine not running.

The “Check Engine”MIL will indicate a DTC three times if

a DTC is present. If more than one DTC has been stored

Page 2137 of 6000

6G – 6 ENGINE LUBRICATION

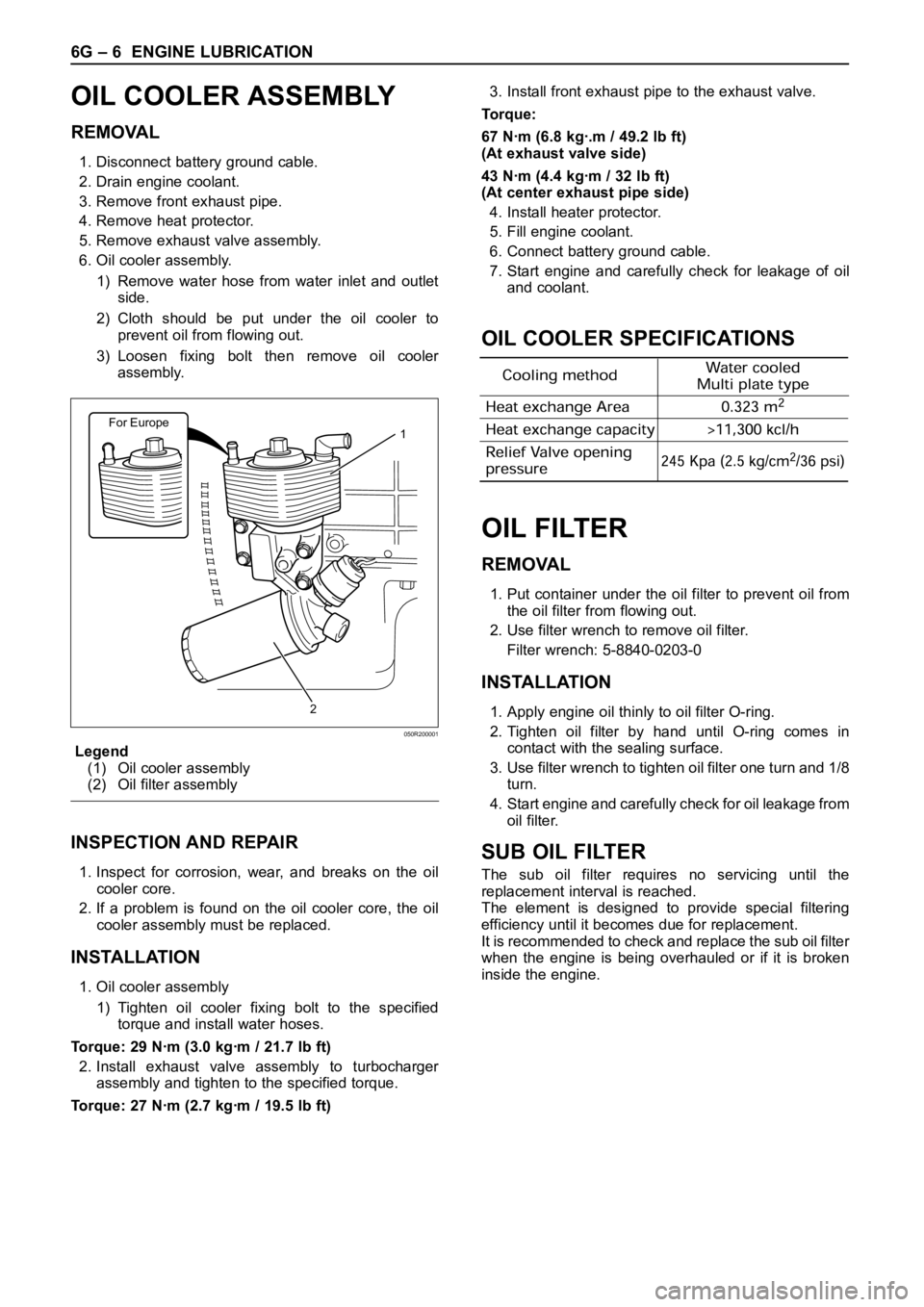

OIL COOLER ASSEMBLY

REMOVAL

1. Disconnect battery ground cable.

2. Drain engine coolant.

3. Remove front exhaust pipe.

4. Remove heat protector.

5. Remove exhaust valve assembly.

6. Oil cooler assembly.

1) Remove water hose from water inlet and outlet

side.

2) Cloth should be put under the oil cooler to

prevent oil from flowing out.

3) Loosen fixing bolt then remove oil cooler

assembly.

Legend

(1) Oil cooler assembly

(2) Oil filter assembly

INSPECTION AND REPAIR

1. Inspect for corrosion, wear, and breaks on the oil

cooler core.

2. If a problem is found on the oil cooler core, the oil

cooler assembly must be replaced.

INSTALLATION

1. Oil cooler assembly

1) Tighten oil cooler fixing bolt to the specified

torque and install water hoses.

Torque: 29 Nꞏm (3.0 kgꞏm / 21.7 lb ft)

2. Install exhaust valve assembly to turbocharger

assembly and tighten to the specified torque.

Torque: 27 Nꞏm (2.7 kgꞏm / 19.5 lb ft)3. Install front exhaust pipe to the exhaust valve.

Torque:

67 Nꞏm (6.8 kgꞏ.m / 49.2 lb ft)

(At exhaust valve side)

43 Nꞏm (4.4 kgꞏm / 32 lb ft)

(At center exhaust pipe side)

4. Install heater protector.

5. Fill engine coolant.

6. Connect battery ground cable.

7. Start engine and carefully check for leakage of oil

and coolant.

OIL COOLER SPECIFICATIONS

OIL FILTER

REMOVAL

1. Put container under the oil filter to prevent oil from

the oil filter from flowing out.

2. Use filter wrench to remove oil filter.

Filter wrench: 5-8840-0203-0

INSTALLATION

1. Apply engine oil thinly to oil filter O-ring.

2. Tighten oil filter by hand until O-ring comes in

contact with the sealing surface.

3. Use filter wrench to tighten oil filter one turn and 1/8

turn.

4. Start engine and carefully check for oil leakage from

oil filter.

SUB OIL FILTER

The sub oil filter requires no servicing until the

replacement interval is reached.

The element is designed to provide special filtering

efficiency until it becomes due for replacement.

It is recommended to check and replace the sub oil filter

when the engine is being overhauled or if it is broken

inside the engine.

For Europe1

2

050R200001

Page 2182 of 6000

7A–28

AUTOMATIC TRANSMISSION (4L30–E)

Removal

1. Disconnect battery ground cable.

2. Remove transfer control lever knob.

3. Remove front console.

Disconnect wiring harness connectors from front

console.

4. Disconnect shift lock cable (1) from the selector lever

assembly side.

256RW012

5. Disconnect shift control rod (2) from the selector lever

assembly side.

256RW013

6. Disconnect wiring harness connectors from the

selector lever assembly.

7. Remove selector lever assembly.

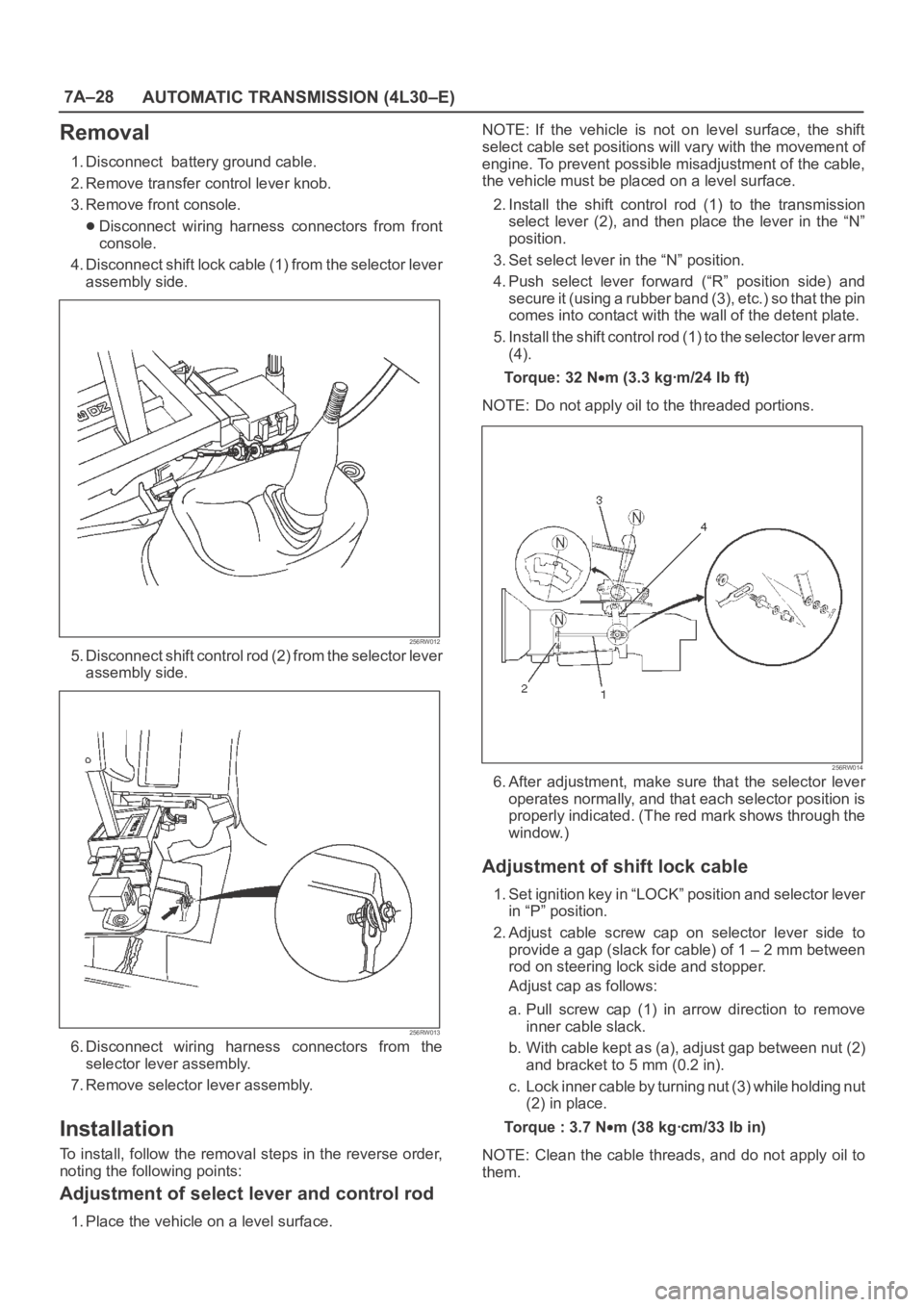

Installation

To install, follow the removal steps in the reverse order,

noting the following points:

Adjustment of select lever and control rod

1. Place the vehicle on a level surface.NOTE: If the vehicle is not on level surface, the shift

select cable set positions will vary with the movement of

engine. To prevent possible misadjustment of the cable,

the vehicle must be placed on a level surface.

2. Install the shift control rod (1) to the transmission

select lever (2), and then place the lever in the “N”

position.

3. Set select lever in the “N” position.

4. Push select lever forward (“R” position side) and

s e c u r e i t ( u s i n g a r u b b e r b a n d ( 3 ) , e t c . ) s o t h a t t h e p i n

comes into contact with the wall of the detent plate.

5. Install the shift control rod (1) to the selector lever arm

(4).

To r q u e : 3 2 N

m (3.3 kgꞏm/24 lb ft)

NOTE: Do not apply oil to the threaded portions.

256RW014

6. After adjustment, make sure that the selector lever

operates normally, and that each selector position is

properly indicated. (The red mark shows through the

window.)

Adjustment of shift lock cable

1. Set ignition key in “LOCK” position and selector lever

in “P” position.

2. Adjust cable screw cap on selector lever side to

provide a gap (slack for cable) of 1 – 2 mm between

rod on steering lock side and stopper.

Adjust cap as follows:

a. Pull screw cap (1) in arrow direction to remove

inner cable slack.

b. With cable kept as (a), adjust gap between nut (2)

and bracket to 5 mm (0.2 in).

c. Lock inner cable by turning nut (3) while holding nut

(2) in place.

Torque : 3.7 N

m (38 kgꞏcm/33 lb in)

NOTE: Clean the cable threads, and do not apply oil to

them.

Page 2347 of 6000

MANUAL TRANSMISSION7B–29

2. Using remover 5–8840–2551–0 (J–42795) and

attachment 5–8840–2560–0 (J–42988), remove

counter gear shaft center bearing.

NOTE: Be careful not to drop the counter gear, when

removing the bearing.

226RW199

3. Remove the counter gear from intermediate

plate.

226RW030

19. Disassemble the counter gear shaft assembly.

1. Using snap ring pliers, remove the counter gear

shaft front bearing snap ring.

226RW065

2. Using bearing separator 5–8840–0015–0

(J–22912–01) and a press, remove the bearing.

226RW200

Page 2368 of 6000

7B–50MANUAL TRANSMISSION

15. Inspect each gear radial clearance.

1. Mount the mainshaft through the aluminum plate

in a vise.

2. Using a dial indicator, measure the radial

clearance of each gear.

Gear

Standard Clearanse

1st0.020 – 0.073 mm (0.0008 – 0.0029 in)

2nd0.015 – 0.068 mm (0.0006 – 0.0027 in)

3rd0.015 – 0.068 mm (0.0006 – 0.0027 in)

226RW071

16. Install the counter gear shaft.

1. Check the new counter front bearing inner race

and the side race, as shown.

2. Using installer 5–8840–2556–0 (J–42800) and a

press, install the counter gear shaft front bearing.

226RW194

3. Select a snap ring that will allow minimum axial

play.

Mark

Thickness

A2.00–2.05mm (0.079–0.081in)

B2.05–2.10mm (0.081–0.083in)

C2.10–2.15mm (0.083–0.085in)

D2.15–2.20mm (0.085–0.087in)

E2.20–2.25mm (0.087–0.089in)

F2.25–2.30mm (0.089–0.091in)

226RW128

4. Using a snap ring expander, install the new snap

ring.

226RW129

Page 2381 of 6000

MANUAL TRANSMISSION7B–63

3. Stand the transmission by the wood blocks.

4. Using a plastic hammer, tap the transmission

case and attach it to the intermediate plate.

NOTE: Be careful not to add over force to bearing.

220RW022

5. Using a snap ring expander, install the front

bearing shaft snap ring (1) and counter gear shaft

bearing snap ring (2).

226RW004

6. Turn over the transmission.

35. Install the front cover.

1. Clean up the fitting surface.

2. Apply recommended liquid gasket (THREE

BOND 1281 or equivalent), as shown.NOTE:

Don’t dry the liquid gasket.

220RW025

3. Clean up and dry the bolts.

4. Apply thread sealant (THREE BOND 1344 or

equivalent) to the 8 bolts.

5. Using 8 bolts, install the front cover to the

transmission case.

Torque: 17 Nꞏm (1.7 kgꞏm/12 lb ft)

NOTE:

Tighten the all bolts evenly.

Be careful not to damage the oil seal.

220RW018