tire pressure OPEL GT-R 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 229 of 625

3G- 621973 OPEL SERVICE MANUAL

1. Clean rims thoroughly, using No. 3 coarse steel

wool to remove all oxidized rubber, soap solution,

etc. Remove rust with wire brush.2. Inspect butt weld and other areas of rim contactedby tire beads to make certain there is no groove or

high spot. Remove any groove or high spot by tiling

smooth.

3. Inspect valve stem and replace it if damaged.

Make certain that valve stem is properly installed to

provide an air tight joint.

4. Before mounting a tubeless tire on a wheel, mois-

ten a cloth with mounting compound or soap solu-

tion and wipe rim-seal ridges of both beads to remove

all foreign substances.

5. Moisten base of both beads with mounting com-

pound or soap solution to help beads snap into place

when tire is inflated. Start tire over rim flange at

point opposite valve stem.

6. Inflate tire until both beads are firmly seated

against rim flanges and temporarily over inflate.

Leak test wheel and tire assembly and if satisfactory,

reduce to recommended pressure.

SPECIFICATIONSWHEEL AND TIRE BALANCE

Wheel and tire balance is the equal distribution of the

weight of the wheel and tire assembly around the axis

of rotation. Wheel unbalance is the principal cause of

tramp and general car shake and roughness and con-

tributes somewhat to steering troubles.

The original balance of the tire and wheel assembly

may change as the tire wears. Severe acceleration,

severe brake applications, fast cornering and side slip

wear the tires out in spots and often upset the origi-

nal balance condition and make it desirable to rebal-

ance the tire and wheel as an assembly. Tire and

wheel assemblies should be rebalanced after punc-

tures are repaired.

Because of the speed at which cars are driven, it is

necessary to test the wheel and tire assembly for

dynamic balance. Dynamic balancing of a wheel and

tire assembly must be done on a machine designed to

indicate out-of-balance conditions while the wheel is

rotating on the car. Since procedures differ with dif-

ferent machines, the instructions of the equipment

manufacturer must be carefully followed.

General SpecificationsWheels

Opel 1900

- Manta and GT ,._......,,,._.................,...,,..............................~,,,.................... 5.J x 13

Tires

1900 - Manta __.......,,___.,...,,..,.....,,....,,...........,...,,.,,...,.........,,..................,....................... 165-13

GT . . . . . . . ..__........_..............,...,,........,,,...,,..........,....,..,,...,,........,..................,,,.....................165-13

Tire Size and Pressures (Pounds Per Square Inch

Cold)

ModelTire Size51.53.54.57

165-1357R.57L165-13

77

165-13Recommended(Standard

PressureInflation)

FrontRear24

PSI32PSI23

PSI26PSI

19PSI23

PSI

NOTE:

1.Tire inflation pressures may increase as much as 6 pounds per square inch

when hot.

2.For continuous high-speed operation (over 75 MPH), increase tire inflation

pressures 4 pounds per square inch over the recommended pressures up to a

maximum of 30 pounds per square inch cool for 4 ply rating tires. When the

4 psi pressure adjustment for sustained high speed with maximum vehicle load

Page 230 of 625

WHEELS AND TIRES36-63would require inflation pressures above the maximum allowable, speed must be

limited to 75 miles per hour.

3.Cool tire inflation pressure: After vehicle has been inoperative for 3 hours

or more, or driven less than one mile. Hot tire inflation pressure: After vehicle

has been driven

10 miles or more at 60-70 MPH.

4.Vehicles with luggage racks do not have a vehicle load limit greater than

specified.

5. When towing trailers, the allowable passenger and cargo load must be

reduced by an amount equal to the trailer tongue load on the trailer hitch.

Torque SpecificationWheelNuts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65lb.ft.

IFigure 3G-8 Wheel and Tire - Exploded View

Page 271 of 625

5B- 121973 OPEL SERVICE MANUAL

A = BRAKE ON

THE RUBBER FLUID SEAL TIGHTLY GRIPPING PISTON

IS DEFLECTED IN DIRECTION OF PISTON TRAVELAFRICTION PAD

BRAKE DISCRUBBER FLUID SEALBRAKE

IICALIPER

IPISTON

I

CE BETWEEN RUNNING CLEARAN

FRICTION PAD AND BRAKE DISC

B = BRAKE OFFBTHE PISTON IS RETRACTED BY THE AMOUNT OF

RUBBER FLUID SEAL DEFLECTION. THIS AMOUNT

IS EQUAL TO RUNNING CLEARANCE.SBZZ

Figure 58-22 Rubber Fluid Seal -Automatic Piston Retractiondraulic pressure, and the friction pads and pistonsmove away from the brake disc, leaving a small run-

ning clearance. The brake disc can now rotate freely.

The amount of brake travel is dependent upon the

amount of running clearance. For this reason therunout of the brake disc should be checked, besides

bleeding of the brake system and adjusting the rear

brake shoes, when the pedal free travel is too great.during braking, the rubber seals in the annular

grooves of the brake caliper bores deflect laterally in

the direction of piston movement. See Figure

5B-22,View (A). The seal remains deflected for the duration

of the braking operation. After braking, the caliper

bores are relieved of hydraulic pressure and the rub-

ber seals resume their normal position, thus pulling

or retracting the pistons. The distance traveled by

the pistons is equal to that of the running clearance

between brake disc and friction pads.

The running clearance between brake disc and

fric-tion pads is attained as follows: When the pistons in

the caliper halves are moved towards the brake discThe shifting of the pistons in the direction of the

brake disc due to friction pad wear has no effect on

the running clearance. The running clearance re-mains the same in all piston positions.

DIAGNOSIS

DISC BRAKE TROUBLE DIAGNOSIS

ConditionPulls

Possible Cause

I. Incorrect tire

pressures.Correction1. Inflate evenly on both sides to

the recommended pressures (see

Owner’s Manual).

Page 332 of 625

FUEL SYSTEM6C- 41

covered with sound deadening compound. See Fig-

ure

6C-10.7. Remove fuel tank vent hose and tiller hose. See

Figure 6C- 11.

8. Remove fuel tank attaching bolts and gauge wire

and remove tank.

Installation

1. Install tank and tighten attaching bolts.

2. Replace gauge wire. Install vent hose, making cer-

tain it is not kinked and seal vent hose hole in floor.

3. Install spare tire support attaching brackets, sup-

port panel, hold-down, and brackets.

4. Install spare tire and jack.

5. Install fuel line and rubber cap.

6. Connect battery.FUEL LINES. FUEL GAUGE TANK UNITS

All fuel lines are plastic and have an outside diameter

of

,240 inches. Unlike metal lines, plastic lines are

not flared.

When replacing a plastic line, place the line in hot

water to make it flexible. Using the old line as a

pattern, form the new line. Let the line cool com-

pletely, then route it in the same location as the old

line. To prevent chafing against the underbody, nine

(9) rubber grommets are placed at points on the line

between the fuel tank and the fuel pump. When re-

placing fuel gauge tank units, coat gasket on both

sides and first threads of attaching screws with seal-

ing compound.

CLEANING FUEL TANK

1. Remove fuel tank.

2. Empty fuel tank through filler neck.

3. Remove fuel gauge tank unit, together with suc-

tion tube and screen. Clean screen and blow out from

cover side. Flush fuel tank.

SPECIFICATIONSFuel Tank Capacity (Gallons)

Opel 1900 and Manta

....................................................................................................11.9GT

....................................................................................................................................13.2FuelGaugeType

........................................................................................................Electrical

Fuel Pump Type

......................................................................................................Mechanical

Fuel Pump Drive

..................................................................................Eccentric on Camshaft

Fuel Pump Pressure at 1950 (RPM)................................................................3.1 to 3.7 P.S.I.FuelFilter

............................................................................................................In-LineFilter

Page 485 of 625

7C.1241973 OPEL SERVICE MANUAL

14. Remove the downshift timing valve plug retain-

ing pin and remove downshift timing valve plug.

Remove the low speed downshift timing valve and

spring.

15. Remove the manual low and r&erse control

valve retaining pin. Remove the spring and the

manual low control valve and the reverse control

valve.

16. Remove the l-2 accumulator valve retaining pin

and remove the l-2 accumulator valve plug, l-2 ac-

cumulator valve and spring.

17. A clean work area which is free of dirt and dust

should be used to inspect, clean and install the valves

in the valve body. Handle valve components with

clean hands and tools. Since most valve failures are

caused initially by dirt or other foreign matter pre-

venting a valve from functioning properly, a

thorough cleaning of all the components with a

cleaning solvent is essential. Do not use paraffin toclean out the valve body passages and valve bore.

Compressed air may be used to blow out the pas-

sages.18. Inspect each valve for free movement in its re-

spective bore in

t.he valve body. If necessary, use

crocus cloth to remove small burrs on a valve. Do

not remove the sharp edges of the valves as these

edges perform a cleaning action within the bore.

19. Inspect the valve springs for distortion or col-

lapsed coils. Replace the entire valve body assembly

if any parts are damaged.

20. Inspect the transfer plate for dents or distortion.

Replace transfer plate if necessary.

21. Reassemble the valves, springs, plugs and retain-

ing pins in their proper location and order into the

valve body using a liberal amount of transmission

fluid. See the spring data chart which includes the

spring identification sizes in the event springs have

been disarranged.

LocationApplication

PumpPressureRegulator Valve....................................................

PumpPrimingValve

...........................................................

.............Valve Body1.2ShiftValve......................................................................

Valve Body2-3ShiftValve......................................................................

Valve BodyDetentPressureRegulatorValve......................................

Valve BodyHigh-Speed Timing Valve....................................................

Valve BodyLow-Speed

TimingValve....................................................

Valve BodyReverse and Low Control Valve

........................................

CSSDetentValve..........................................................................

Valve Body1-2 Accumulator Valve........................................................

Valve Body3-2Control

Valve..................................................................

Gov. BodySecondary

Governor Valve................................................

Valve BodyAccumulator Piston

..............................................................

CaseServo Return..........................................................................SHVOServoCushion

........................................................................

Clutch PackClutchReturn(All)................................................................ SPRING IDENTIFICATION CHART

FreeOuter

HeightDiameter

2.756

,7601.043

,3202.467

,7201.769

,7001.625,474

1.349

,4061.380,406

1.343

,4062.569

,6751.072

,5201.853

.4061.317

,4061.9171.224

2.2401.850

1.0391.267

1.050

,42422. Install spring and accumulator piston in valve

body.

23. Compress accumulator piston with C-clamp and

install retaining ring.

24. Install new valve body gasket.2. Inspect and clean oil passages with cleaning sol-

vent and air.

3. Check for good retention of band anchor pins.

25. Bolt the transfer plate and gasket to the valve

body. Torque to 6-8 lbs. ft.

Disassembly, Inspection and Reassembly of Case

1. Inspect case for damage. See Figure

7C-202.4. Inspect all threaded holes for thread damage.

5. Inspect detent valve and modulator valve bores for

scratches or scoring.

6. Inspect case bushing inside of case at rear. If

da-maged, remove bushing with remover and installer

tool J-23 130-3 and driver handle J-8092. See Figure

7C-203.

Page 486 of 625

AUTOMATIC TRANSMISSION 7C-1251. CASE VENT4.3RD CLUTCH7.SUCTION

2. CONVERTER OUT5MODULATOR8.LINE/3.2ND CLUTCH

6. BOOST9.REVERSEFigure 7C-202 Case Front View Oil Passage

Identification

7.

!nspect reaction sun gear drum bushing sleeve

inside case at rear for scoring. If necessary, replace

sleeve before installing rear case bushing.

8. Remove sleeve by grinding. Care must be used in

order that aluminum case is not damaged when

grinding sleeve.

9. Install new sleeve using installer tool J-23130-7

and driver handle J-8092.

10. Install new case bushing using remover and in-

staller tool J-23130-3 and driver handle J-8092.

Bushing should be installed flush with case at rear.

See Figure

7C-203.Figure 7C-2031. Drain Converter. If clutch disc material or

foreign matter has been found while draining con-

verter,

replace entire converter assembly as it can not be

cleaned properly.

2. Air check converter for leaks using converter

checking tool J-21369. Install tool and tighten. Ap-

ply 80 psi air pressure to tool. See Figure

7C-204.Figure 7C-204

3. Submerge in water and check for leaks.

4. Check converter hub surfaces for scoring or wear.

Installation of Selector Lever and Shaft1. Install new selector lever shaft oil seal in case.

Insert selector lever shaft through case from outside.

Care should be exercised so that oil seal is not da-

maged. See Figure

7C-206.2. Insert spring pin in case to secure selector lever

shaft.3. Guide selector lever over shaft and secure with

lock nut.

4. Insert parking

paw1 actuator rod from front of the

case and through hole in case at rear. See Figure 7C-

207.5. Install parking

paw1 actuator rod retaining ring.

Installation of Low Band1. Turn transmission case so that front of case is

upward.

Page 533 of 625

9B-24 1973 OPEL SERVICE MANUAL

Figure 9B-15 Compressor Assembly - GT Shown

Figure 3B-16 Condenser Assembly

condenser. The refrigerant vapor gives up its heat,

which is quickly and easily radiated into the sur-

rounding air through the large finned surfaces of the

condenser. In giving up its heat, the refrigerant vapor

condenses back into liquid which collects in a pool

at the bottom of the condenser.

As we have said before, when the refrigerant con-

denses into a liquid, it again is ready for boiling in the

evaporator. So, we can run a pipe from the condenser

back to the evaporator.

Main Units of the SystemThese three units then; the evaporator, the compres-

sor, and the condenser are the main working

parts of any typical air conditioning system. We have

the evaporator where the refrigerant boils andchanges into a vapor, absorbing heat as it does so. We

have the pump or compressor to put pressure on the

refrigerant so it can get rid of its heat. And we have

a condenser outside the car body to help discharge

the heat into the surrounding air.

Pressure and FlowThere is one more unit that co-operates with thesethree. It doesn’t do any real work, but it does act as

sort of a traffic officer in controlling the flow of the

refrigerant through the system. To get a better idea

of what this does. let’s first do a li,ttle exoerimentine

with an ordinary’ tire pump.

When we use a

t,ire pump to Sate an automobile

tire, we are creating pressure only because we are

“pushing” against the air already entrapped inside

the tire. If you question this, just try pumping up a

tire that has a large puncture in it. You could pump

all day, and still not be able to build up any pressure.

As fast as you would pump the air in, it would leak

out through the puncture.

Abou~t all you would be

doing would be circulating nice fresh air through the

tire.

1Jnless you have something lo push against - to

block the tlow of air

- you can’t create more than a

mere semblance of pressure.

The same situation holds true in an air conditioning

system. The compressor can pump refrigerant vapor

through the system, but unless it has something to

push against, it cannot build up pressure. All the

compressor would be doing would be to circulate the

vapor without increasing its

pres,sure.Yet we can’t just block the flow through the system

entirely. All we want to do is put pressure on the

refrigerant vapor so it will condense at normal tem-

peratures. What’s more, this

musi: be done some time

after the vapor leaves the evaporator and before it

returns again as a liquid. We can’t have high pressure

in the evaporator because that would slow down the

boiling of the refrigerant and thus penalize the re-

frigerating effect.

Controlling Pressure and FlowPressure and flow can be controlled with a float

valve, or with a pressure-regulating valve. They do

the same job, but in a different way.

Since the float valve type will give us a better idea of

pressure and flow control, let’s look at it first (Fig.

9B-17).It consists simply of a float that rides on the surface

of the liquid refrigerant. As the refrigerant liquid

boils and passes off as a vapor, naturally the liquid

level drops lower and lower. Correspondingly, the

float, because it rides on the surface of the refriger-

ant, also drops lower and lower as the liquid goes

down.By means of a simple system of mechanical linkage,

the downward movement of the float opens a valve

to let refrigerant in. The incoming liquid raises the

fluid level and, of course, the float rides up with it.

When the surface level of the refrigerant liquid re-

aches a desired height, the float: will have risen far

Page 535 of 625

98-26 1973 OPEL SERVICE MANUAL

greater than the opposing pressure in the power ele-

ment. Therefore, the valve remains closed. When the

compressor is started, it will reduce the pressure and

temperature of the refrigerant in the cooling coil to

a point where the vapor pressure in the power ele-

ment becomes the stronger. The seat then moves off

the orifice and liquid starts to flow through the valve

orifice into the cooling coil.

The purpose of the power element is to help deter-

mine the quantity of liquid that is being metered into

the cooling coil. As the temperature of the low pres-

sure line changes at the bulb, the pressure of

the

vapor in the power element changes, resulting in a

change of the position of the seat. For example, if the

cooling coil gets more liquid than is required, the

temperature of the low pressure line is reduced and

the resultant lowering of the bulb temperature

reduces the pressure of the vapor in the power ele-

ment, allowing the seat to move closer to the orifice.

This immediately reduces the amount of liquid leav-

ing the valve. Under normal operation, the power

element provides accurate control of the quantity of

refrigerant to the cooling coil.

To employ our tire pump analogy once more for

clarity, it is the same situation that would exist if you were inflating a tire with a very slow leak. Providing

you pumped the air into the tire as fast as it leaked

out, you would be able to maintain pressure even

though the air would merely be circulating through the tire and leaking out through the puncture.

To Sum Up

So far, we’ve discussed only what each unit in an air

conditioning system does. We’ve learned that the

evaporator is the unit in which liquid refrigerant

soaks up heat from the air, the compressor is a pump

for squeezing this heat out of the vapor, the con-

denser is a radiator for getting rid of the heat, and the

thermostatic expansion valve is a device for regulat-

ing the pressure on the refrigerant. Now, let’s

find

out how the temperature of the cooled air is con-

trolled.

METHOD OF TEMPERATURE CONTROL

To achieve temperature control, the compressor is

run intermittently, automatically turning on and off

as necessary to maintain proper temperature.

Thermostatic Switch

The compressor can be started and stopped au-

tomatically through the use of an electro-magnetic

clutch and a thermostat affected by variations of temperature.

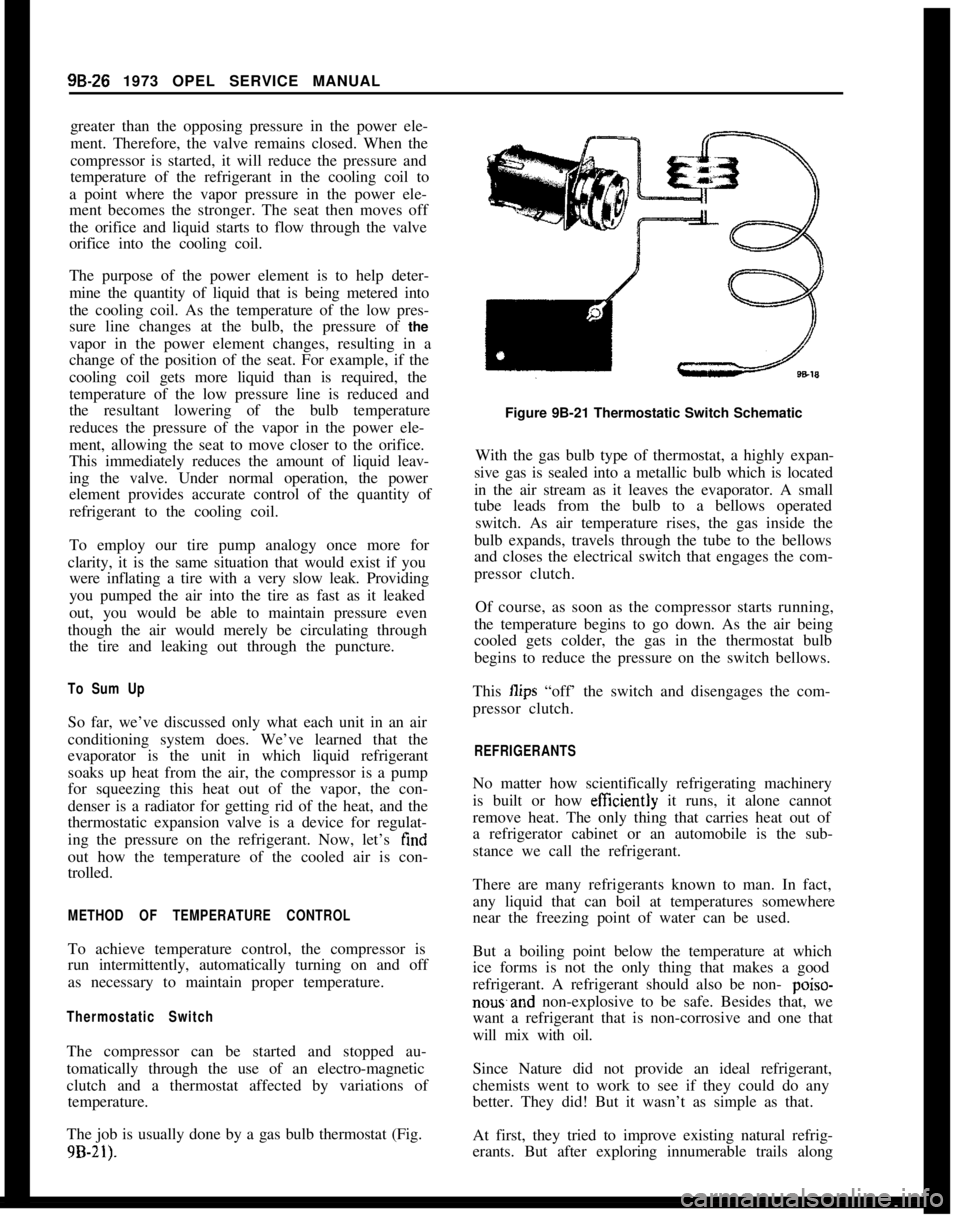

The job is usually done by a gas bulb thermostat (Fig.

9B-21).

Figure 9B-21 Thermostatic Switch Schematic

With the gas bulb type of thermostat, a highly expan-

sive gas is sealed into a metallic bulb which is located

in the air stream as it leaves the evaporator. A small

tube leads from the bulb to a bellows operated switch. As air temperature rises, the gas inside the

bulb expands, travels through the tube to the bellows

and closes the electrical switch that engages the com-

pressor clutch.

Of course, as soon as the compressor starts running,

the temperature begins to go down. As the air being

cooled gets colder, the gas in the thermostat bulb

begins to reduce the pressure on the switch bellows.

This

Ilips “off’ the switch and disengages the com-

pressor clutch.

REFRIGERANTS

No matter how scientifically refrigerating machinery

is built or how

efftciently it runs, it alone cannot

remove heat. The only thing that carries heat out of

a refrigerator cabinet or an automobile is the sub-

stance we call the refrigerant.

There are many refrigerants known to man. In fact,

any liquid that can boil at temperatures somewhere

near the freezing point of water can be used.

But a boiling point below the temperature at which

ice forms is not the only thing that makes a good

refrigerant. A refrigerant should also be non-

poiso-

nowand non-explosive to be safe. Besides that, we

want a refrigerant that is non-corrosive and one that

will mix with oil.

Since Nature did not provide an ideal refrigerant,

chemists went to work to see if they could do any

better. They did! But it wasn’t as simple as that.

At first, they tried to improve existing natural refrig-

erants. But after exploring innumerable trails along

Page 536 of 625

REFRIGERANT COMPONENTS ALL MODELS99.27that line, they still hadn’t gotten anywhere. So, they

started from scratch and juggled molecules around

to make an entirely new refrigerant. Eventually they

succeeded by remodeling the molecules in carbon

tetrachloride. This is the same fluid that is used in

fire extinguishers and dry-cleaners’ solvents.

From this fluid, the chemists removed two chlorine

atoms and replaced them with two fluorine atoms.

This newly-formed fluid carried the technical chemi-

cal name of dichlorodifluoromethane. Today, we

know it as Refrigerant-12 or R-12.

Fluorine is an extremely temperamental substance.

Under most conditions it is toxic and highly corro-

sive, and after is is manufactured, it has to be stored

in special containers because it will eat through glass

and will dissolve most metals in short order.

Despite its rambunctious character though, fluorine

is completely tamed when it is combined with the

other substances that go to make up the refrigerant.

Each is non-toxic, non-inflammable, non-explosive,

and non- poisonous; however, breathing large quan-

tities of R-12 should be avoided.

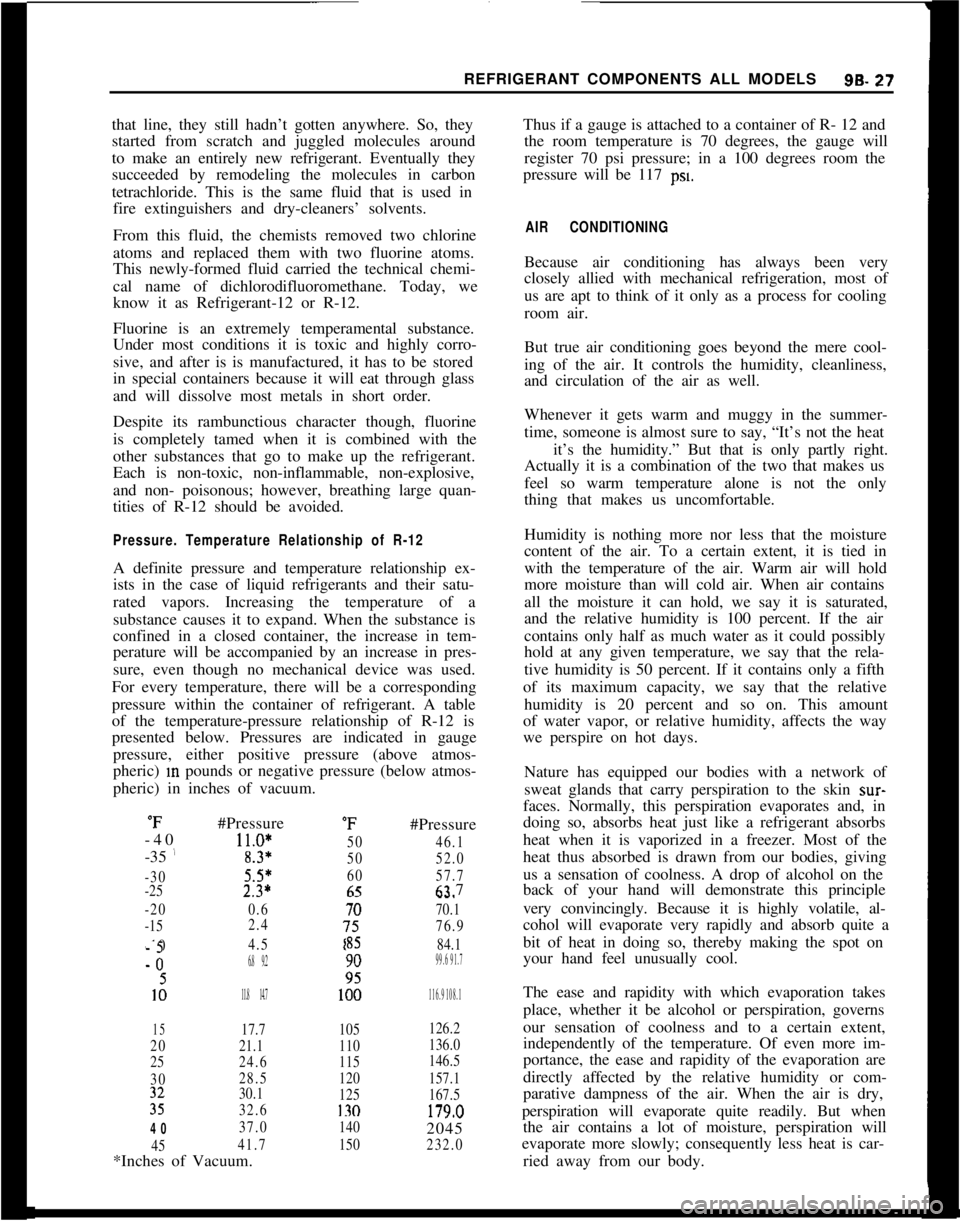

Pressure. Temperature Relationship of R-12A definite pressure and temperature relationship ex-

ists in the case of liquid refrigerants and their satu-

rated vapors. Increasing the temperature of a

substance causes it to expand. When the substance is

confined in a closed container, the increase in tem-

perature will be accompanied by an increase in pres-

sure, even though no mechanical device was used.

For every temperature, there will be a corresponding

pressure within the container of refrigerant. A table

of the temperature-pressure relationship of R-12 is

presented below. Pressures are indicated in gauge

pressure, either positive pressure (above atmos-

pheric) m pounds or negative pressure (below atmos-

pheric) in inches of vacuum.

“F-40

-35

i#Pressure

11.0*

8.3*

“F

50

50#Pressure

46.1

52.0

-30~

5.5*6057.7

-252.3*6s67 7__.

-200.6

io70.1

-152.4

76.9

-104.584.1

1;6.8 9.2tz99.6 91.71;

11.8 14.712116.9 108.1

1517.7105126.2

2021.1110136.0

2524.6115146.5

3028.5120157.1

;:

30.1

125167.5

32.6

131)179n

4037.0

4541.7*Inches of Vacuum.-. _.-

1402045

150232.0Thus if a gauge is attached to a container of R- 12 and

the room temperature is 70 degrees, the gauge will

register 70 psi pressure; in a 100 degrees room the

pressure will be 117

ps~

AIR CONDITIONINGBecause air conditioning has always been very

closely allied with mechanical refrigeration, most of

us are apt to think of it only as a process for cooling

room air.

But true air conditioning goes beyond the mere cool-

ing of the air. It controls the humidity, cleanliness,

and circulation of the air as well.

Whenever it gets warm and muggy in the summer-

time, someone is almost sure to say, “It’s not the heat

it’s the humidity.” But that is only partly right.

Actually it is a combination of the two that makes us

feel so warm temperature alone is not the only

thing that makes us uncomfortable.

Humidity is nothing more nor less that the moisture

content of the air. To a certain extent, it is tied in

with the temperature of the air. Warm air will hold

more moisture than will cold air. When air contains

all the moisture it can hold, we say it is saturated,

and the relative humidity is 100 percent. If the air

contains only half as much water as it could possibly

hold at any given temperature, we say that the rela-

tive humidity is 50 percent. If it contains only a fifth

of its maximum capacity, we say that the relative

humidity is 20 percent and so on. This amount

of water vapor, or relative humidity, affects the way

we perspire on hot days.

Nature has equipped our bodies with a network of

sweat glands that carry perspiration to the skin

sur-faces. Normally, this perspiration evaporates and, in

doing so, absorbs heat just like a refrigerant absorbs

heat when it is vaporized in a freezer. Most of the

heat thus absorbed is drawn from our bodies, giving

us a sensation of coolness. A drop of alcohol on the

back of your hand will demonstrate this principle

very convincingly. Because it is highly volatile, al-

cohol will evaporate very rapidly and absorb quite a

bit of heat in doing so, thereby making the spot on

your hand feel unusually cool.

The ease and rapidity with which evaporation takes

place, whether it be alcohol or perspiration, governs

our sensation of coolness and to a certain extent,

independently of the temperature. Of even more im-

portance, the ease and rapidity of the evaporation are

directly affected by the relative humidity or com-

parative dampness of the air. When the air is dry,

perspiration will evaporate quite readily. But when

the air contains a lot of moisture, perspiration will

evaporate more slowly; consequently less heat is car-

ried away from our body.

Page 538 of 625

REFRIGERANT COMPONENTS ALL MODELS99.29

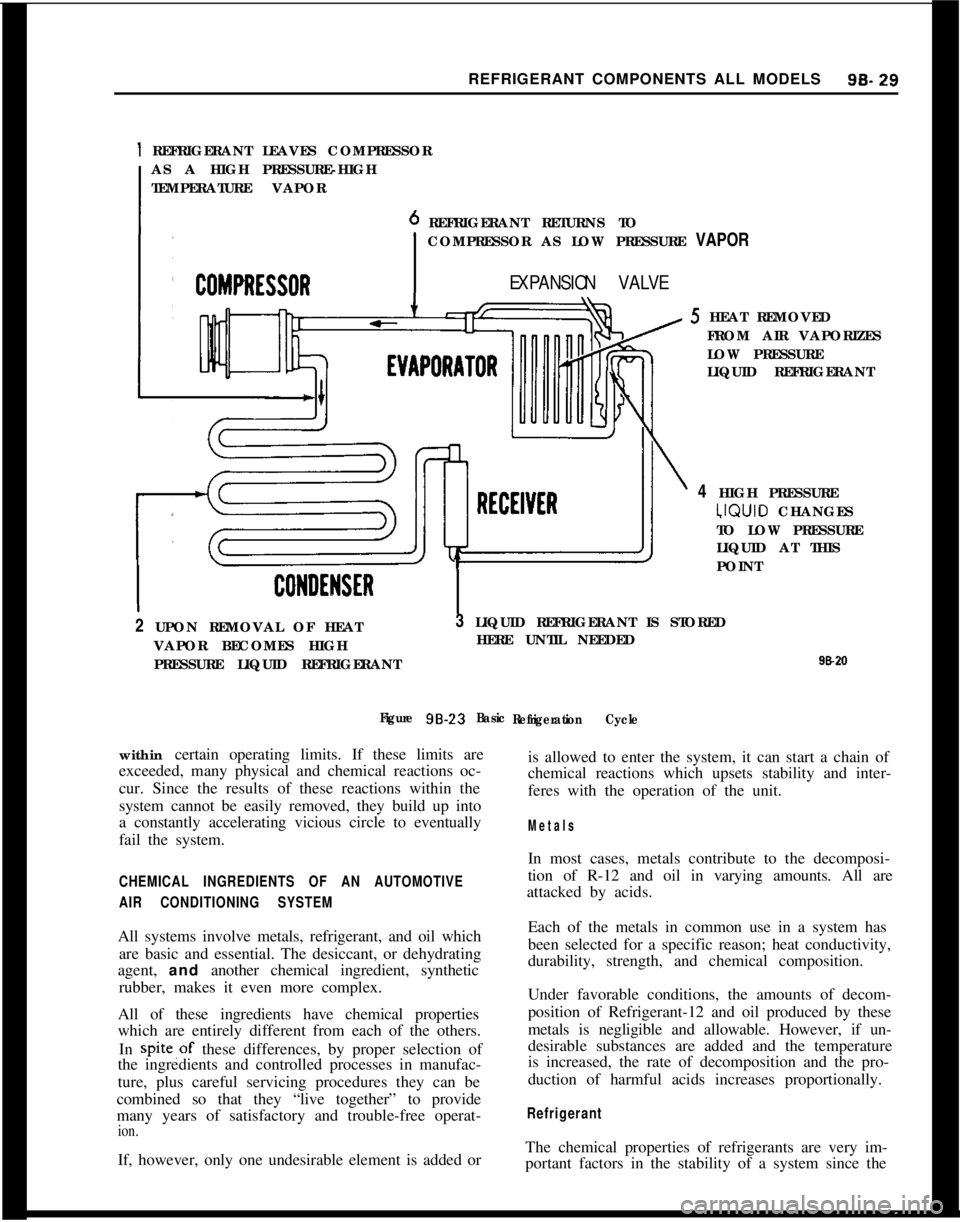

1 REFRIGERANT LEAVES COMPRESSOR

AS A HIGH PRESSURE-HIGH

TEMPERATURE VAPOR

REFRIGERANT RETURNS TO

COMPRESSOR AS LOW PRESSURE VAPOR

EXPANSION VALVE5 HEAT REMOVED

FROM AIR VAPORIZES

LOW PRESSURE

LIQUID REFRIGERANT

4 HIGH PRESSURE‘JQUID CHANGES

TO LOW PRESSURE

LIQUID AT THIS

POINT

2 UPON REMOVAL OF HEAT

VAPOR BECOMES HIGH

PRESSURE LIQUID REFRIGERANT3 LIQUID REFRIGERANT IS STORED

HERE UNTIL NEEDED

98*II

Figure 98-23

Basic

Refrigeration Cyclewithin certain operating limits. If these limits are

exceeded, many physical and chemical reactions oc-

cur. Since the results of these reactions within the

system cannot be easily removed, they build up into

a constantly accelerating vicious circle to eventually

fail the system.is allowed to enter the system, it can start a chain of

chemical reactions which upsets stability and inter-

feres with the operation of the unit.

Metals

CHEMICAL INGREDIENTS OF AN AUTOMOTIVE

AIR CONDITIONING SYSTEMAll systems involve metals, refrigerant, and oil which

are basic and essential. The desiccant, or dehydrating

agent, and another chemical ingredient, synthetic

rubber, makes it even more complex.

All of these ingredients have chemical properties

which are entirely different from each of the others.

In spite,of these differences, by proper selection of

the ingredients and controlled processes in manufac-

ture, plus careful servicing procedures they can be

combined so that they “live together” to provide

many years of satisfactory and trouble-free operat-

ion.If, however, only one undesirable element is added orIn most cases, metals contribute to the decomposi-

tion of R-12 and oil in varying amounts. All are

attacked by acids.

Each of the metals in common use in a system has

been selected for a specific reason; heat conductivity,

durability, strength, and chemical composition.

Under favorable conditions, the amounts of decom-

position of Refrigerant-12 and oil produced by these

metals is negligible and allowable. However, if un-

desirable substances are added and the temperature

is increased, the rate of decomposition and the pro-

duction of harmful acids increases proportionally.

RefrigerantThe chemical properties of refrigerants are very im-

portant factors in the stability of a system since the