OPEL GT-R 1973 Service Manual

Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 201 of 625

3D- 341973 OPEL SERVICE MANUALILOCK PLATE

7, @-, FLEXIBLE COUPLING NUTFLEXIBLE

COUPLING

-/BOLTPINION SHAFI

RUBBER BOOT

es+--RETAINER

ew O-RING

‘lNTERED METAL BUSHING 1y STEERING GEAR HOUSING @+ NEEDLE

BEARlNG

y-7RACK GUIDE BUSHING

RACK

he---THRUST SPRINGiRUBBERADJUSTER SCREW

BUSHING

ILOCK NUT

BOLT

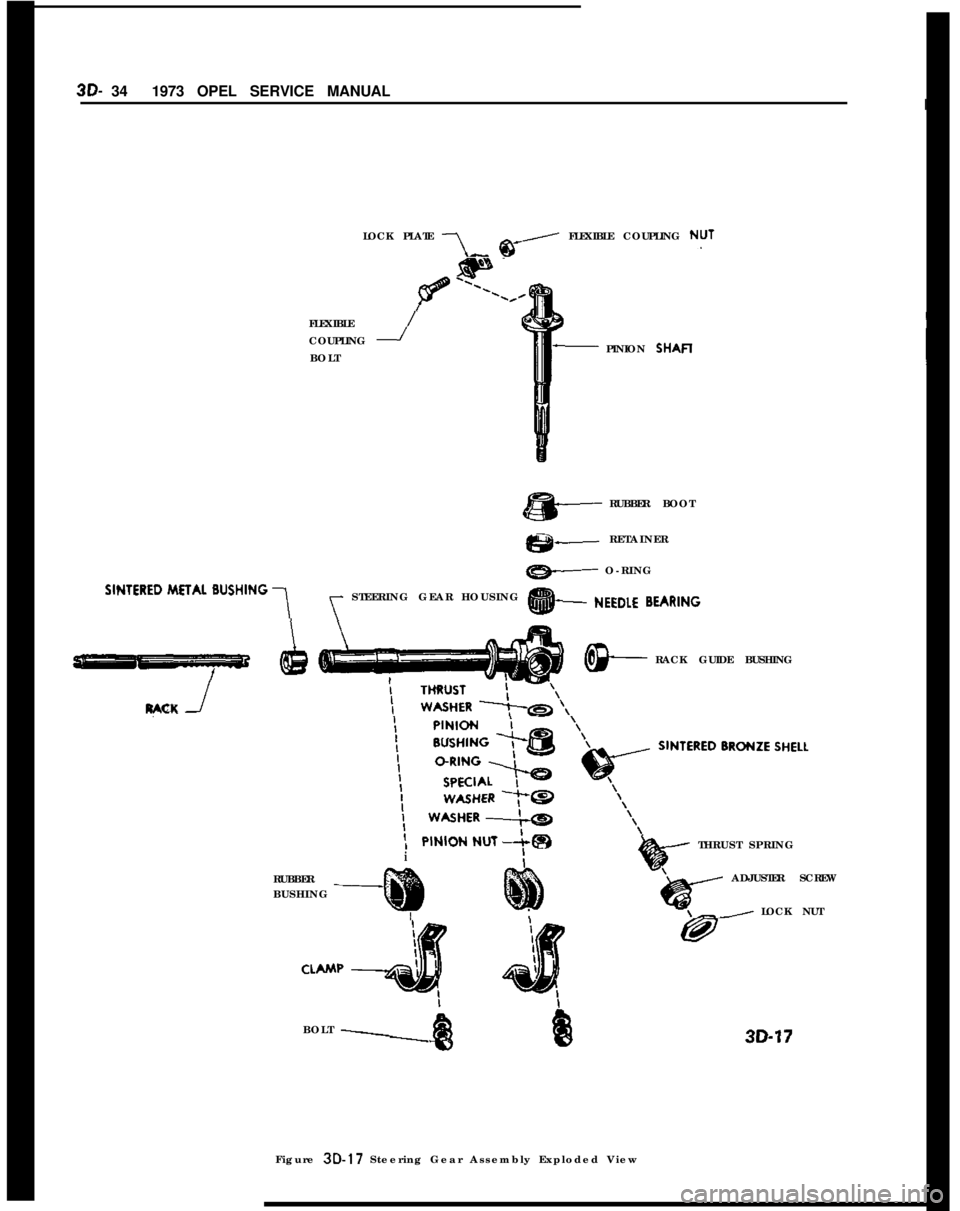

\Figure 3D-17 Steering Gear Assembly Exploded View30-17

Page 202 of 625

OPEL 1900 AND MANTA STEERING COLUMN ASSEMBLY 3E.35

II

OPEL 1900 AND MANTA STEERING COLUMN

ASSEMBLY

CONTENTS

SubjectPage No.

DESCRIPTION AND OPERATION:

Description and Operation of Directional Signal

Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Description

andOperationofHorn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Description of Steering Column Assembly

. . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

3E-353E-363E-36

Removal and Installation of Steering Column

Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RemovalandInstallationofSteeringWheel. . . . . . . . . . . .Disassembly and Reassembly of Direction Signal

Switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Disassembly and Reassembly of Steering and

Ignition Lock Cylinder, and Electrical Switch

from Mast Jacket Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Steering

ColumnSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3E-363E-383E-393E-403E-41

DESCRIPTION AND OPERATIONDESCRIPTION AND OPERATION OF

DIRECTIONAL SIGNAL LEVERhigh to low beam or vice versa. On all

19M) Rallye

cars, when switching from low to high beam posi-

tion, with the fog lamp instrument panel switch ON

The direction signal switch lever is a multi- purpose

lever controlling direction signals, passing signal and

headlight high and low beams. See Figure

3E-2.The dire&M signal lever is provided with a two-

step mechanism for operation of headlight high and

low beams, and passing signal (not in N.J.). With

headlights off, moving the lever repeatedly towards

steering wheel flashes headlights as a passing signal.

With headlights on, moving the lever repeatedly to-

wards steering wheel up to first stop also flashes

passing signal regardless whether or not the direction

signals are switched on. When the lever is moved up

to the second stop, the headlights are changed from

SE.2Figure

3E-2 Directional Signal Lever Position for

Headlamp Operation

Page 203 of 625

3E- 361973 OPEL SERVICE MANUAL

and ignition switch in RUN position, the fog lights

are automatically switched off. Direction signals

work in the normal manner; pushing the lever up for

right turn signal and pulling the lever down for left

turn signal.

DESCRIPTION AND OPERATION OF HORN

The horn button is located in the center part of the

steering wheel. The horn is actuated by pushing on

the ends of the spokes for the Opel 1900 - Manta and

by pushing on the center horn button on 57R, 57L,

and GT. The button is provided with a plug connec-

tion for each springloaded plunger. See Figure

3E-3.Figure

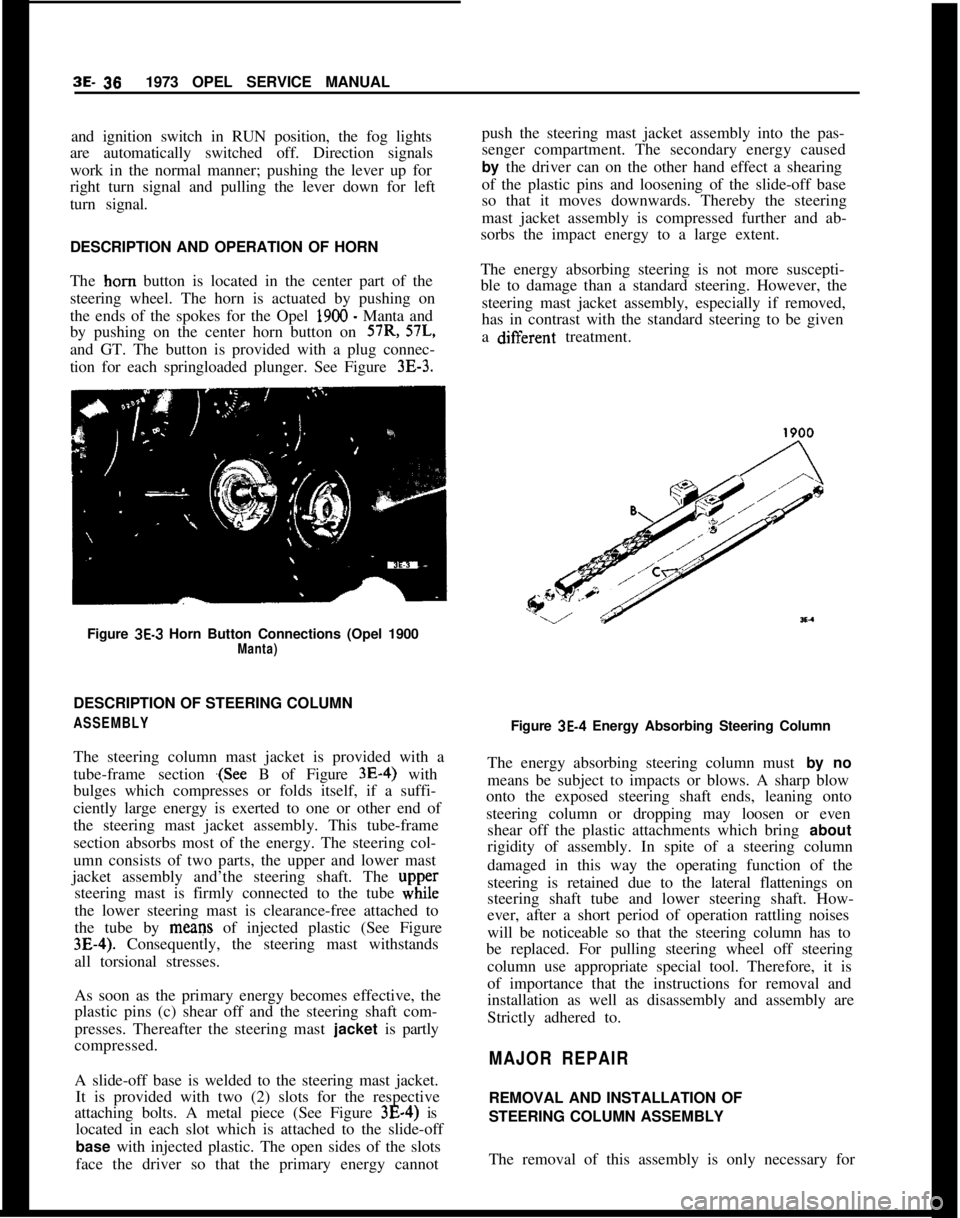

3E-3 Horn Button Connections (Opel 1900Manta)DESCRIPTION OF STEERING COLUMN

ASSEMBLYThe steering column mast jacket is provided with a

tube-frame section

.(See B of Figure 3E-4) with

bulges which compresses or folds itself, if a suffi-

ciently large energy is exerted to one or other end of

the steering mast jacket assembly. This tube-frame

section absorbs most of the energy. The steering col-

umn consists of two parts, the upper and lower mast

jacket assembly and’the steering shaft. The

upp,ersteering mast is firmly connected to the tube while

the lower steering mast is clearance-free attached to

the tube by means of injected plastic (See Figure

3E-4). Consequently, the steering mast withstands

all torsional stresses.

As soon as the primary energy becomes effective, the

plastic pins (c) shear off and the steering shaft com-

presses. Thereafter the steering mast jacket is partly

compressed.

A slide-off base is welded to the steering mast jacket.

It is provided with two (2) slots for the respective

attaching bolts. A metal piece (See Figure 3E-4) is

located in each slot which is attached to the slide-off

base with injected plastic. The open sides of the slots

face the driver so that the primary energy cannotpush the steering mast jacket assembly into the pas-

senger compartment. The secondary energy caused

by the driver can on the other hand effect a shearing

of the plastic pins and loosening of the slide-off base

so that it moves downwards. Thereby the steering

mast jacket assembly is compressed further and ab-

sorbs the impact energy to a large extent.

The energy absorbing steering is not more suscepti-

ble to damage than a standard steering. However, the

steering mast jacket assembly, especially if removed,

has in contrast with the standard steering to be given

a difierent treatment.

Figure

3E-4 Energy Absorbing Steering Column

The energy absorbing steering column must by no

means be subject to impacts or blows. A sharp blow

onto the exposed steering shaft ends, leaning onto

steering column or dropping may loosen or even

shear off the plastic attachments which bring about

rigidity of assembly. In spite of a steering column

damaged in this way the operating function of the

steering is retained due to the lateral flattenings on

steering shaft tube and lower steering shaft. How-

ever, after a short period of operation rattling noises

will be noticeable so that the steering column has to

be replaced. For pulling steering wheel off steering

column use appropriate special tool. Therefore, it is

of importance that the instructions for removal and

installation as well as disassembly and assembly are

Strictly adhered to.

MAJOR REPAIRREMOVAL AND INSTALLATION OF

STEERING COLUMN ASSEMBLY

The removal of this assembly is only necessary for

Page 204 of 625

OPEL 1900 AND MANTA STEERING COLUMN ASSEMBLY3E- 37

Figure 3E-5 Steering Column Assembly With Gear

replacement of steering column or steering ignition

lock parts.

Removal (Opel 1900 . Manta)1. Disconnect battery.

2. From underside of car, remove clamp screw of

upper steering mast out of universal joint flange. See

Figure

3E-6.Figure

3E-6 Upper Steering Mast Clamp Screw

3. Remove hex nut from steering mast jacket attach-

ment at front of dash panel. See Figure

3E-7.Figure

3E-7 - Steering Mast Jacket Attachment

4. Pull off signal switch, as well as steering and igni-

tion lock wire sets.

5. Unscrew slide-off base from underside of instru-

ment panel and remove steering column assembly

from car. See Figure

3E-8. Carefully put down as-

sembly. Avoid impacts and blows to steering column

assembly.

Figure

3E-8 - Slide-Off Base Attaching Nuts

Installation (Opel 1900. Manta)

CAUTION:

Fasteners are important attaching parts in

that they could affect the performance of

vital com-

Page 205 of 625

3E- 38 ,1973 OPEL SERVICE MANUAL

ponents and systems, and/or could result in major

repair expense. They must be replaced with one or

the same part number or with

an equivalent part if

replacement becomes necessary. Do not use a

re-

placement part of lesser quality or substitute design.

Torque

values must be used as specified during reas-

sembly to assure proper retention of these parts.On installation, make sure steering wheel spokes

point downwards and steering gear is in high point.

1. Carefully insert steering mast into universal joint

flange.

2. Loosely attach slide-off base attaching nuts at un-

derside of instrument panel.

3. Attach steering mast jacket at front of dash, using

a notched hex nut.

4. Torque nuts at slide-off base to II

lb.ft.5. Tighten screw at steering mast clamp to 22

lb.ft.6. Reconnect wires to directional signal switch and

ignition switch.

7. Reconnect battery.

REMOVAL AND INSTALLATION OF

STEERING WHEELThis procedure may be performed with the steering

column assembly either removed or installed in the

car.

Removal

1. Disconnect battery.

2. Pry off horn cap and remove wires from cap. See

Figure

3E-3.3. Bend lockplate tabs down and take off steering

shaft nut and lockplate.

4. Install steering wheel remover J-21686 as shown

in Figure

3E-9 and pull off steering wheel.

Installation1. Before installing steering wheel, lubricate return

pin and sliding area on directional signal switch re-

turn cams and horn contact ring.

2. Make sure that clamp bolt in steering shaft flange

is on top.

3. Make sure notch on steering shaft face is in hori-

zontal position.Figure

3E-9 Removing Steering Wheel

4. With the steering wheel centered, place the steer-

ing wheel onto the steering shaft.

5. Install steering wheel lockplate and nut. Torque to

11

lb.ft.

CAUTION:

This steering wheeI to steering shaft fas-

tener is an important attaching part in that it could

affect the

performance of vital components and sys-

tems, and/or could result in major repair expense. It

must be repked

with one of the same part number

or with an equivalent part if replacement becomes

necessary. Do not use a replacement part of lesser

quality or substitute design. Torque

values must be

used as specified during reassembly to assure proper

retention of this part.6. Bend lockplate tabs up, connect horn cap wires

and replace cable and cap.

7. Reconnect battery.

REMOVAL AND REPLACEMENT OF HORN

CONTACT RING

1. Remove steering wheel.

2. Cut off defective contact ring at wire.

3. Strip wire approximately

l/8”.4. Install new part and solder connection with resin

core solder.

5. Lubricate contact ring with lubriplate, or equiva-

lent.

6. Reinstall steering wheel.

Page 206 of 625

OPEL 1900 AND MANTA STEERING COLUMN ASSEMBLY3E- 39~~~A~SEMBLY AND ~EASBEMBL~ 0~

DIRECTIONAL SIGNAL SWITCHThis procedure may be performed with the steering

column assembly removed or installed in the car.

Disassembly (Opel 1900. Manta)

1. Remove steering wheel (see paragraph above).

2. Pull off signal switch and steering and ignition

lock wire set.

3. Pull directional signal lever out of seat. Lever is

held in place by a lock ball.

4. Unscrew lower half of signal switch housing cover.

See Figure

3E-10.Figure

3E-1 1 Removing Upper Part of Signal Switch

Housing Cover

Figure 3E-10 Lower Half of Signal Switch Housing

COVSr5. Remove hex nut from steering mast jacket attach-

ment at front of dash panel. See Figure

3E-7.6. Unscrew slide-off base from underside of instru-

ment panel and remove upper part of signal switch

housing cover. See Figure 3E-

11,7. Place a thick piece of wood onto front seat and let

down steering mast jacket assembly. When doing

this, the front seat must be in its front position.

8. Centerpunch tear-off bolt for steering and ignition

lock bracket attachment. Drill a. 12 in. (3mm) diam-

eter hole, using an angular-type drill and with a bolt

remover with left-hand twist screw out bolt. See Fig-

ure

3E-12.Figure

3E-12 Removing Tear-Off Bolt

9. Remove steering and ignition lock, as well as sig-

nal switch from steering mast jacket and

foosefyattach slide-off base below instrument panel.

Reassembly (Opel 1900 - Manta)

1 When replacing a new directional signal switch,

install new bearing and snap ring in switch assembly.

2. Install signal switch, as well as steering and igni-

tion lock, to steering mast jacket. To do this, screw

Page 207 of 625

3E- 40 1973 OPEL SERVICE MANUAL

on steering and ignition lock bracket using a new

tear-off bolt (hexagon head tears

ofD.

3. Disconnect slide-off base, install upper half of sig-

nal switch housing cover, and loosely reattach

slide-

off base.

4. Attach steering mast jacket at front of dash panel.

See Figure

3E-7.

5. Torque slide-off base attaching nuts to 11 lb.ft.

6. Install lower half of signal switch housing cover

and connect signal switch, as well as steering ignition

lock wire set.

7. Install steering wheel and torque nut to 11

Ib.ft.

Always use new lock plate.

DISASSEMBLY AND REASSEMBLY OF STEERING

AND IGNITION LOCK CYLINDER AND ELECTRICAL SWITCH FROM MAST JACKET

ASSEMBLY

Disassembly. GT

Disconnect the battery before proceeding.

1. Remove steering wheel.

2. Turn ignition switch to ON position.

3. Insert a suitable rod into stop pin hole on side of

steering and ignition lock (See Figure

3E-13) and

take out steering and ignition lock cylinder. 4. Remove two screws securing electrical switch to

steering and ignition lock housing and take out

switch.

Disassembly (Opel 1900 . Manta)

1. Rezmove steering wheel.

2. Unscrew split signal switch housing cover and

remove lower half. See Figure

3E-10.

3. Remove lock cylinder by pushing in lock spring of

the cylinder using a piece of wire. Cylinder must be

in the

” 1” position. See Figure 3E-14.

Figure 3E-14 Removing Lock Cylinder

Reassembly

1. On the GT reassemble electrical switch into steer-

ing and ignition

lock housing and rotate switch until:

(1) cam in lock housing recess fits into slotted hole

in rear of electrical switch, and (2) projection on

electrical switch fits into recess on lock housing.

2. On the Opel 1900

- Manta, insert lock cylinder in

the

P l* position into housing. Install lower half of

signal switch housing.

3. Reinstall steering wheel.

Figure 3E-13 Removing Ignition Lock Cylinder

Page 208 of 625

OPEL 1900 AND MANTA STEERING COLUMN ASSEMBLY3E- 41

SPECIFICATIONS

Steering Column Tightening Specifications

PartLocationToraue

1b.k.Nut

Steering Wheel Retaining (1900

- Manta) .._......._...,,....BoltSteering Column Flexible Coupling (1900 - Manta) ._.,

NutSlide Off Base Attaching (1 900 - Manta) ._..,,,,,,...._,,,,,..

NutMass Jacket (1 900

- Manta) .,............,,,............,,,,,.......,,,,,

screw

Steering Mast Clamp (1900

- Manta) .,.........,.._...............1122

10::

Page 209 of 625

3E- 421973 OPEL SERVICE MANUAL

GT STEERING COLUMN ASSEMBLY

CONTENTS

Subject

DESCRIPTION AND OPERATION:

DescriptionofSteeringColumn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

RemovalandInstallationofSteeringWheel. . . . . . . . . . . .Removal and Installation of Ignition Lock

Cylinder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removal and Installation of Steering Column

Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removal and Installation of Center Steering Shaft

Removal and Installation of Ignition Switch

and/or Steering Lock

.,~ ,........ ~ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removal and Installation of Upper Steering

Bearing and/or Directional Signal Switch

. . . . . . . . . . . .Removal and Installation of Steering Column

Lower Bearing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Steering Column Torques

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

3E-42

3E-44

3E-45

3E-45

3E-46

3E-46

3E-48

3E-49

3E-50

DESCRIPTION AND OPERATION

DESCRIPTION OF STEERING COLUMNThe Energy Abosrbing, Locking Steering .Column

assembly is used on the GT. This cohnnn is designed

to compress under impact. When an automobile is

being driven, the forward movement of the automo-

bile and the forward movement of the driver both

constitute a form of energy or force. When an au-

tomobile is involved in a frontal collision, the pri-

mary force (forward movement of the car) is

suddenly halted, while the secondary force (the

driver) continues its forward direction. A severe col-

lision generally involves these two forces

- the pri-

mary and the secondary forces. The secondaryjmpact occurs when the driver is thrust forward onto

the steering wheel and column.

The Energy Absorbing Column is designed to absorb

these primary and secondary forces to the extent thatthe severity of the secondary impact is reduced. Dur-

ing a collision, the steering column compresses and

thereby reduces its tendency to move rearward into

the driver’s compartment. A split second later when

the driver is thrown forward (the secondary impact)

his energy is also partially abosrbed by the compres-

sion characteristics of the column.

The Energy Absorbing, Locking Column assembly

may be easily disassembled and reassembled. The

serviceman should be aware that it is important that

only the specified screws, bolts and nuts be used as

designated during reassembly, and that they are

tightened to their specified torque. This precaution

will insure the energy absorbing action of the assem-

bly. Particular care should be exercised to avoid us-

ing overlength bolts as they may prevent a portion of

the assembly from compressing under impact.

Equally as important is correct torquing of all bolts

and nuts.

When the Energy Absorbing, Locking Column is

Page 210 of 625

GT STEERING COLUMN ASSEMBLY3E- 43

UPPER STEERING

COLUMN ASSEMBLY-\-AUPPER UNIVERSAL JOINT-

STEERING

-CENTER STEERING SHAFT

LOWER UNIVERSAL JOINT

Figure

3E-15 GT Steering Column Assembly

_--7FORCE

PRIMARY FORC

/FORCES

BEFORE

COLLISIONI ST STAGE

(PRIMARY COLLISION)2ND STAGE

(SECONDARY COLLISION)3E-16

Figure

3E-16 Reaction of Forces in a Collision