Peugeot 208 2015 Owner's Manual - RHD (UK, Australia)

Manufacturer: PEUGEOT, Model Year: 2015, Model line: 208, Model: Peugeot 208 2015Pages: 341, PDF Size: 38.75 MB

Page 201 of 341

199

208_en_Chap08_Informations-pratiques_ed01-2015

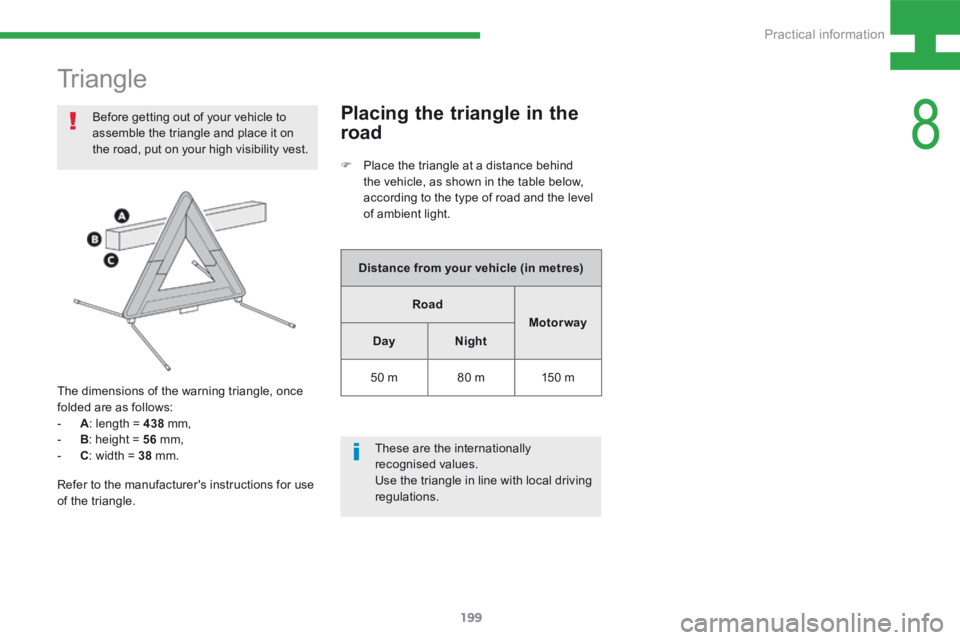

Triangle

Before getting out of your vehicle to

assemble the triangle and place it on

the road, put on your high visibility vest.

The dimensions of the warning triangle, once

folded are as follows:

- A: length = 438 mm,

- B: height = 56 mm,

- C: width = 38 mm. These are the internationally

recognised values.

Use the triangle in line with local driving

regulations.

Refer to the manufacturer's instructions for use

of the triangle.Placing the triangle in the

road

F

Place the triangle at a distance behind

the vehicle, as shown in the table below,

according to the type of road and the level

of ambient light.

Distance from your vehicle (in metres) Road Motor way

Day Night

50 m 80 m150 m

8

Practical information

Page 202 of 341

200

208_en_Chap08_Informations-pratiques_ed01-2015

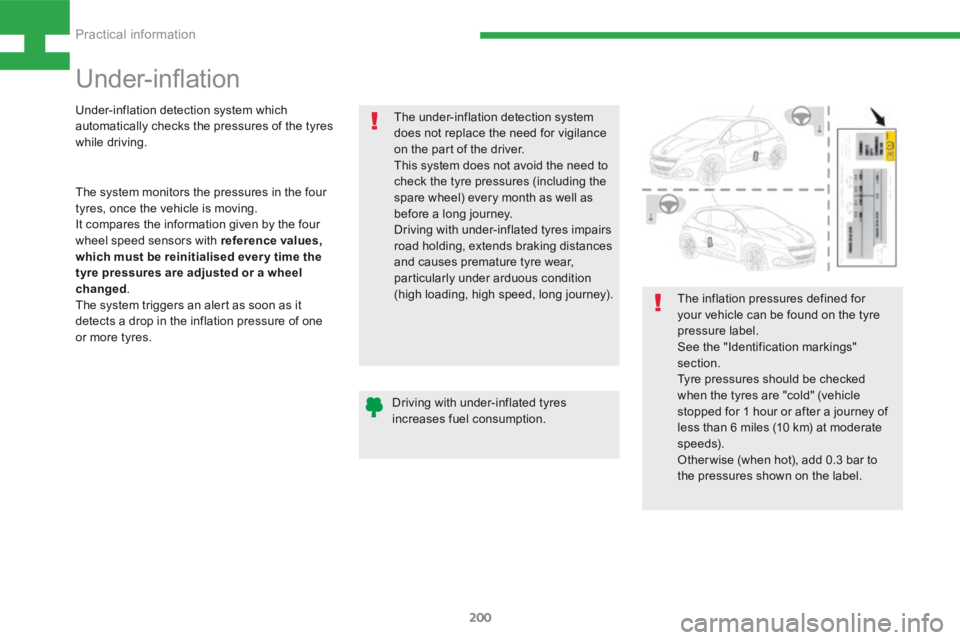

Under-inflation

The under-inflation detection system

does not replace the need for vigilance

on the part of the driver.

This system does not avoid the need to

check the tyre pressures (including the

spare wheel) every month as well as

before a long journey.

Driving with under-inflated tyres impairs

road holding, extends braking distances

and causes premature tyre wear,

particularly under arduous condition

(high loading, high speed, long journey).The inflation pressures defined for

your vehicle can be found on the tyre

pressure label.

See the "Identification markings"

section.

Tyre pressures should be checked

when the tyres are "cold" (vehicle

stopped for 1 hour or after a journey of

less than 6 miles (10 km) at moderate

speeds).

Other wise (when hot), add 0.3 bar to

the pressures shown on the label.

Driving with under-inflated tyres

increases fuel consumption.

Under-inflation detection system which

automatically checks the pressures of the tyres

while driving.

The system monitors the pressures in the four

tyres, once the vehicle is moving.

It compares the information given by the four

wheel speed sensors with reference values,

which must be reinitialised ever y time the

tyre pressures are adjusted or a wheel

changed

.

The system triggers an alert as soon as it

detects a drop in the inflation pressure of one

or more tyres.

Practical information

Page 203 of 341

201

208_en_Chap08_Informations-pratiques_ed01-2015

Under-inflation alert

The loss of pressure detected does not

always cause visible bulging of the tyre.

Do not satisfy yourself with just a visual

check.This is given by fixed illumination of

this warning lamp, accompanied by

an audible signal and, depending on

equipment, the display of a message.

F Reduce speed immediately, avoid

excessive steering movements and sudden

braking

F Stop the vehicle as soon as it is safe

to do so. F

In the event of a puncture, use the

temporary puncture repair kit or the spare

wheel (depending on equipment),

or

F if you have a compressor, such as the one

in the temporary puncture repair kit, check

the pressures of the four tyres when cold,

or

F if it is not possible to make this check

immediately, drive carefully at reduced

speed. The alert is maintained until the system

is reinitialised.

The under-inflation alert is only

dependable if the system has been

reinitialised with all four tyres inflated to

the correct pressures.

Snow chains

The system does not have to be

reinitialised after fitting or removing

snow chains.

8

Practical information

Page 204 of 341

202

208_en_Chap08_Informations-pratiques_ed01-2015

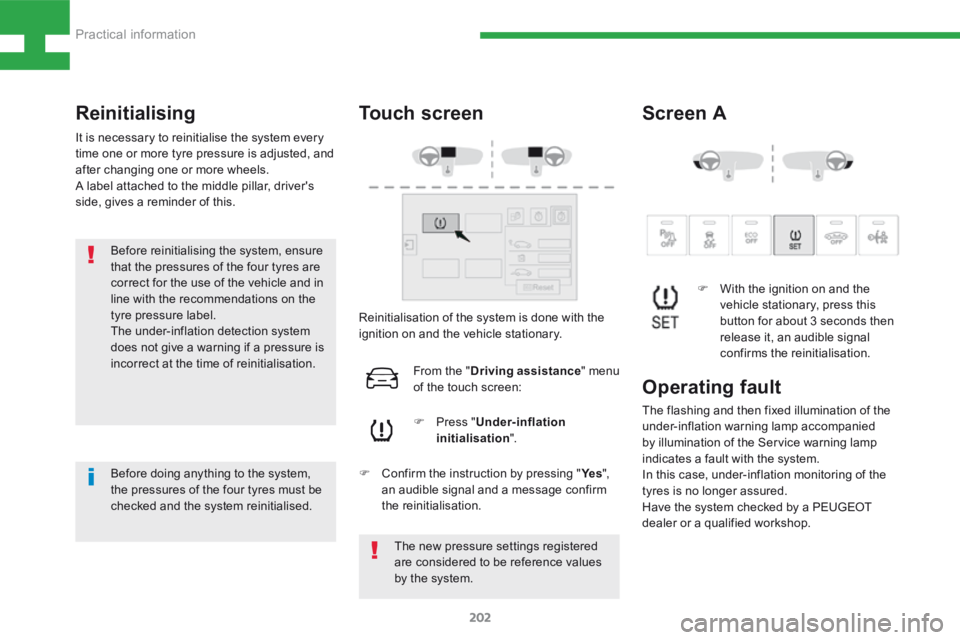

Reinitialising

It is necessary to reinitialise the system every

time one or more tyre pressure is adjusted, and

after changing one or more wheels.

A label attached to the middle pillar, driver's

side, gives a reminder of this.Before reinitialising the system, ensure

that the pressures of the four tyres are

correct for the use of the vehicle and in

line with the recommendations on the

tyre pressure label.

The under-inflation detection system

does not give a warning if a pressure is

incorrect at the time of reinitialisation. F

With the ignition on and the

vehicle stationary, press this

button for about 3 seconds then

release it, an audible signal

confirms the reinitialisation.

The new pressure settings registered

are considered to be reference values

by the system.

Reinitialisation of the system is done with the

ignition on and the vehicle stationary.

F Press " Under-inflation

initialisation ".

From the "

Driving assistance " menu

of the touch screen:

F Confirm the instruction by pressing " Ye s",

an audible signal and a message confirm

the reinitialisation.

Operating fault

The flashing and then fixed illumination of the

under-inflation warning lamp accompanied

by illumination of the Service warning lamp

indicates a fault with the system.

In this case, under-inflation monitoring of the

tyres is no longer assured.

Have the system checked by a PEUGEOT

dealer or a qualified workshop.

Touch screen Screen A

Before doing anything to the system,

the pressures of the four tyres must be

checked and the system reinitialised.

Practical information

Page 205 of 341

203

208_en_Chap08_Informations-pratiques_ed01-2015

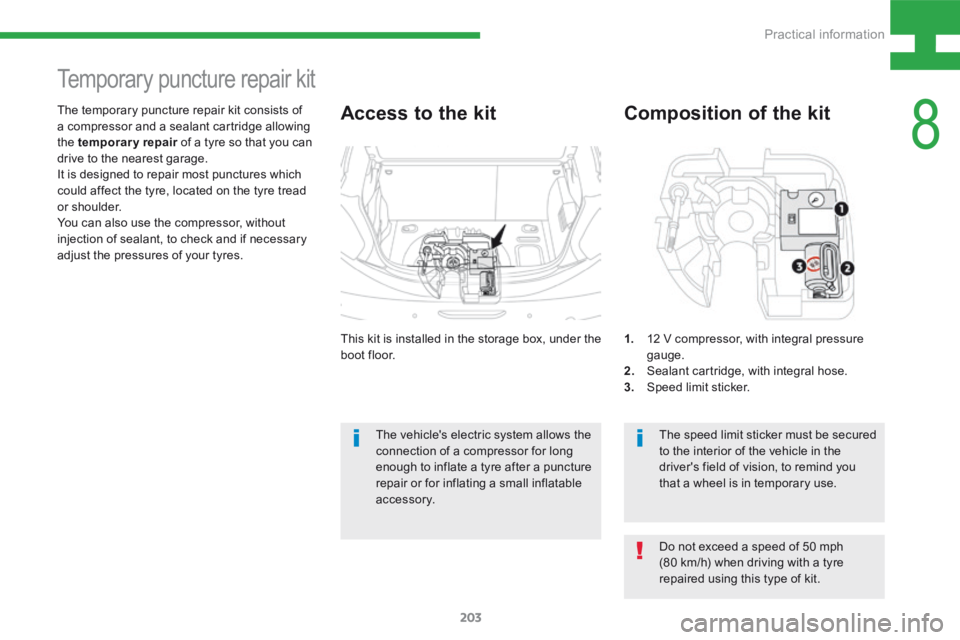

This kit is installed in the storage box, under the

boot floor.

The temporary puncture repair kit consists of

a compressor and a sealant cartridge allowing

the temporary repair

of a tyre so that you can

drive to the nearest garage.

It is designed to repair most punctures which

could affect the tyre, located on the tyre tread

or shoulder.

You can also use the compressor, without

injection of sealant, to check and if necessary

adjust the pressures of your tyres.

Temporary puncture repair kit

Access to the kit

1. 12 V compressor, with integral pressure

gauge.

2. Sealant cartridge, with integral hose.

3. Speed limit sticker.

The speed limit sticker must be secured

to the interior of the vehicle in the

driver's field of vision, to remind you

that a wheel is in temporary use.

The vehicle's electric system allows the

connection of a compressor for long

enough to inflate a tyre after a puncture

repair or for inflating a small inflatable

accessory.

Composition of the kit

Do not exceed a speed of 50 mph

(80 km/h) when driving with a tyre

repaired using this type of kit.

8

Practical information

Page 206 of 341

204

208_en_Chap08_Informations-pratiques_ed01-2015

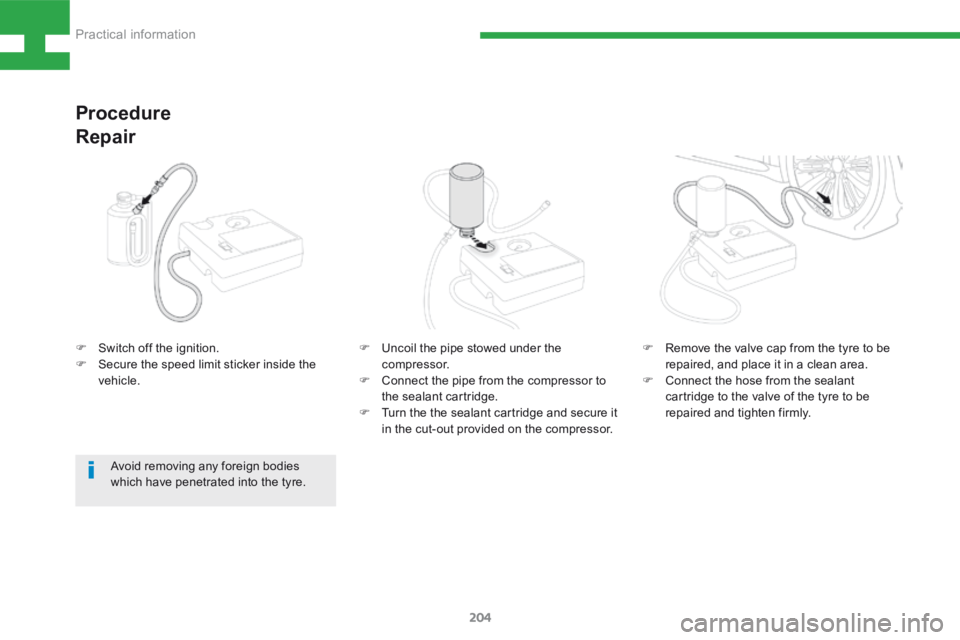

F Switch off the ignition.

F Secure the speed limit sticker inside the

vehicle.

Procedure

Repair

F Uncoil the pipe stowed under the

compressor.

F Connect the pipe from the compressor to

the sealant cartridge.

F Turn the the sealant cartridge and secure it

in the cut-out provided on the compressor.

Avoid removing any foreign bodies

which have penetrated into the tyre. F

Remove the valve cap from the tyre to be

repaired, and place it in a clean area.

F Connect the hose from the sealant

cartridge to the valve of the tyre to be

repaired and tighten firmly.

Practical information

Page 207 of 341

205

208_en_Chap08_Informations-pratiques_ed01-2015

Take care, the sealant product

is harmful (e.g. ethylene-glycol,

colophony...) if swallowed and causes

irritation to the eyes.

Keep this product out of the reach of

children.

The use-by date is marked on the

cartridge.

After use, do not discard the

cartridge by the roadside, take it to a

PEUGEOT dealer or an authorised

waste disposal site.

Don't forget to obtain a new sealant

cartridge, available from a PEUGEOT

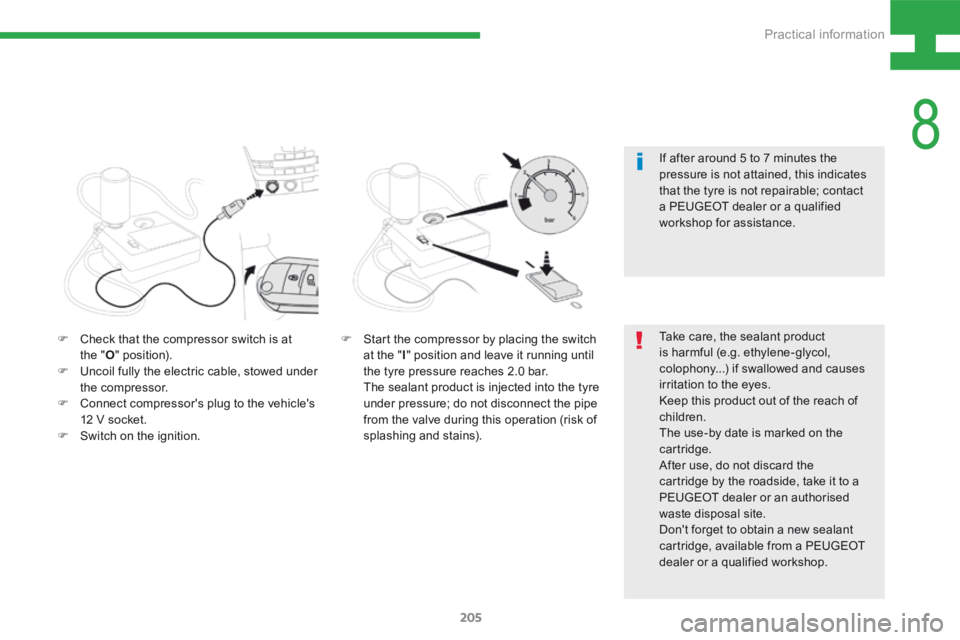

dealer or a qualified workshop. If after around 5 to 7 minutes the

pressure is not attained, this indicates

that the tyre is not repairable; contact

a PEUGEOT dealer or a qualified

workshop for assistance.

F Check that the compressor switch is at

the " O" position).

F Uncoil fully the electric cable, stowed under

the compressor.

F Connect compressor's plug to the vehicle's

12 V socket.

F Switch on the ignition. F

Start the compressor by placing the switch

at the " I" position and leave it running until

the tyre pressure reaches 2.0 bar.

The sealant product is injected into the tyre

under pressure; do not disconnect the pipe

from the valve during this operation (risk of

splashing and stains).

8

Practical information

Page 208 of 341

206

208_en_Chap08_Informations-pratiques_ed01-2015

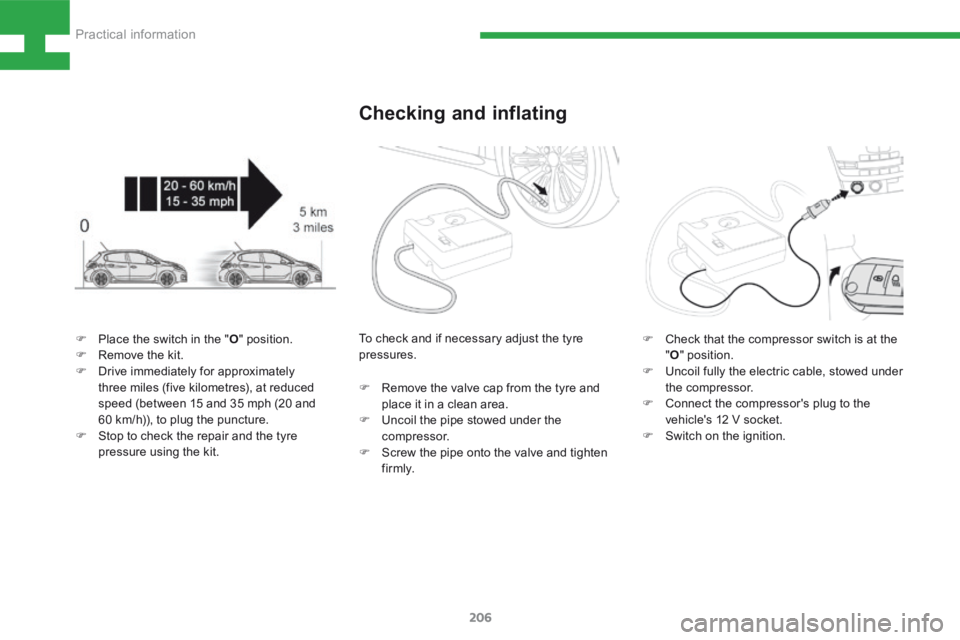

Checking and inflating

F Place the switch in the " O" position.

F Remove the kit.

F Drive immediately for approximately

three miles (five kilometres), at reduced

speed (between 15 and 35 mph (20 and

60 km/h)), to plug the puncture.

F Stop to check the repair and the tyre

pressure using the kit. To check and if necessary adjust the tyre

pressures.

F

Remove the valve cap from the tyre and

place it in a clean area.

F Uncoil the pipe stowed under the

compressor.

F Screw the pipe onto the valve and tighten

f i r m l y. F

Check that the compressor switch is at the

"O " position.

F Uncoil fully the electric cable, stowed under

the compressor.

F Connect the compressor's plug to the

vehicle's 12 V socket.

F Switch on the ignition.

Practical information

Page 209 of 341

207

208_en_Chap08_Informations-pratiques_ed01-2015

After using the kit, refer to the previous

pages to check the tyre pressures

and reinitialise the "Under-inflation

detection" function.

F

Start the compressor by placing the switch

at the " I" position and adjust the pressure

to the value shown on the vehicle's tyre

pressure label.

To deflate: press the black button on the

compressor pipe, at the valve connector.

F Once the correct pressure is reached, put

the switch to the " O" position.

F Remove the kit then stow it.

8

Practical information

Page 210 of 341

208

208_en_Chap08_Informations-pratiques_ed01-2015

Spare wheel

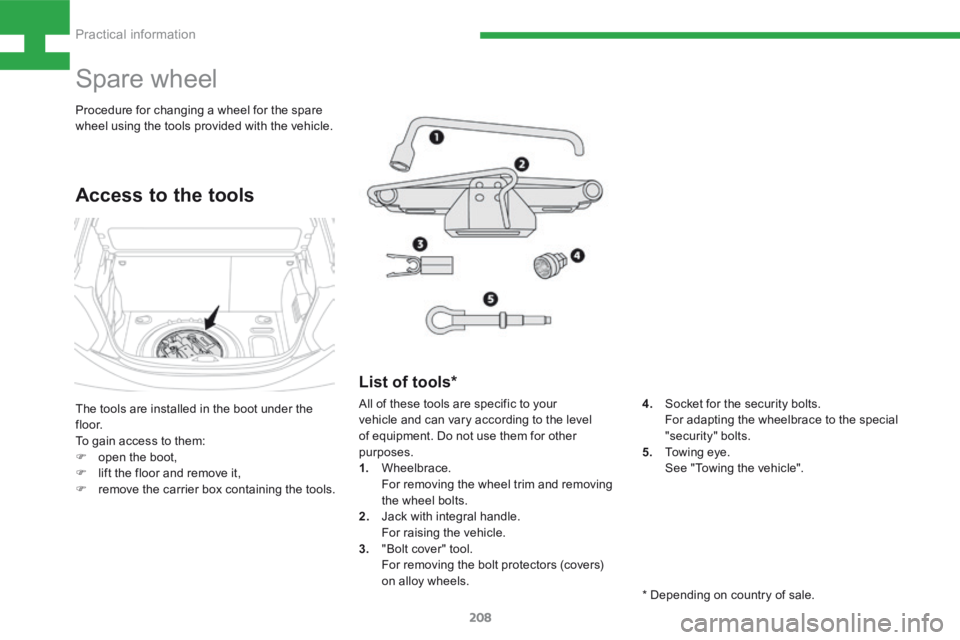

The tools are installed in the boot under the

f l o o r.

To gain access to them:

F open the boot,

F lift the floor and remove it,

F remove the carrier box containing the tools.

Access to the tools

List of tools*

4. Socket for the security bolts.

For adapting the wheelbrace to the special

"security" bolts.

5. Towing eye.

See "Towing the vehicle".

Procedure for changing a wheel for the spare

wheel using the tools provided with the vehicle.

All of these tools are specific to your

vehicle and can vary according to the level

of equipment. Do not use them for other

purposes.

1. Wheelbrace.

For removing the wheel trim and removing

the wheel bolts.

2. Jack with integral handle.

For raising the vehicle.

3. "Bolt cover" tool.

For removing the bolt protectors (covers)

on alloy wheels.

* Depending on country of sale.

Practical information