PEUGEOT PARTNER TEPEE 2020 Owners Manual

Manufacturer: PEUGEOT, Model Year: 2020, Model line: PARTNER TEPEE, Model: PEUGEOT PARTNER TEPEE 2020Pages: 216, PDF Size: 8.46 MB

Page 141 of 216

139

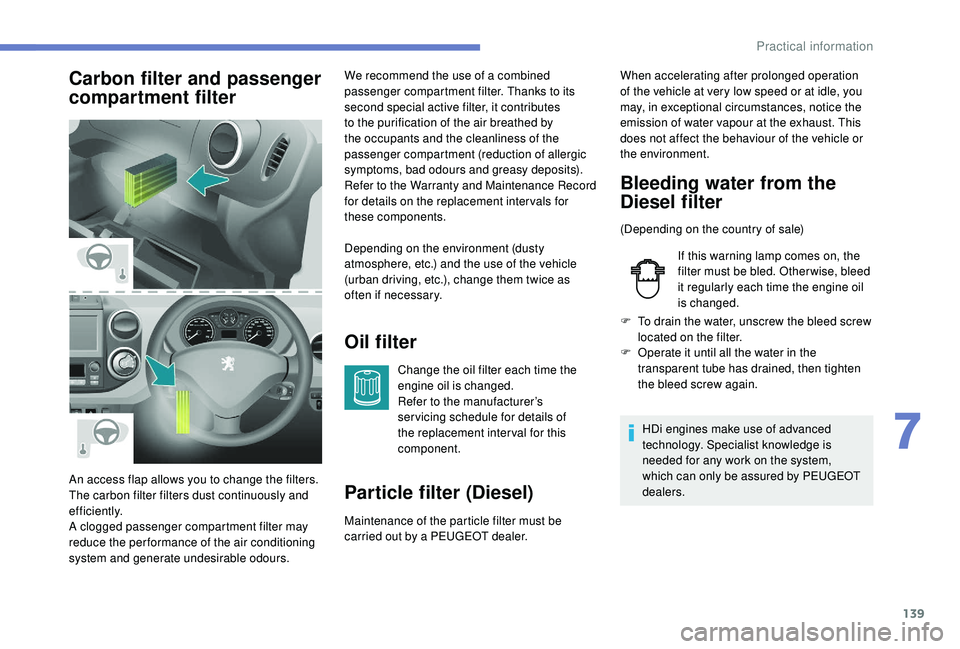

Carbon filter and passenger

compartment filterOil filter

Change the oil filter each time the

engine oil is changed.

Refer to the manufacturer’s

ser vicing schedule for details of

the replacement inter val for this

component.

Particle filter (Diesel)

Maintenance of the particle filter must be

carried out by a PEUGEOT dealer.

An access flap allows you to change the filters.

The carbon filter filters dust continuously and

ef f i c i e nt l y.

A clogged passenger compartment filter may

reduce the per formance of the air conditioning

system and generate undesirable odours. We recommend the use of a combined

passenger compartment filter. Thanks to its

second special active filter, it contributes

to the purification of the air breathed by

the occupants and the cleanliness of the

passenger compartment (reduction of allergic

symptoms, bad odours and greasy deposits).

Refer to the Warranty and Maintenance Record

for details on the replacement inter vals for

these components.

Depending on the environment (dusty

atmosphere, etc.) and the use of the vehicle

(urban driving, etc.), change them twice as

often if necessary.

Bleeding water from the

Diesel filter

(Depending on the country of sale)

If this warning lamp comes on, the

filter must be bled. Other wise, bleed

it regularly each time the engine oil

is changed.

F

T

o drain the water, unscrew the bleed screw

located on the filter.

F

O

perate it until all the water in the

transparent tube has drained, then tighten

the bleed screw again.

HDi engines make use of advanced

technology. Specialist knowledge is

needed for any work on the system,

which can only be assured by PEUGEOT

dealers.

When accelerating after prolonged operation

of the vehicle at very low speed or at idle, you

may, in exceptional circumstances, notice the

emission of water vapour at the exhaust. This

does not affect the behaviour of the vehicle or

the environment.

7

Practical information

Page 142 of 216

140

Manual gearbox

The gearbox does not require any

maintenance (no oil change).

Only use products recommended by

PEUGEOT or products of equivalent

quality and specification.

In order to optimise the operation of

components as important as those in the

braking system, PEUGEOT selects and

offers very specific products.

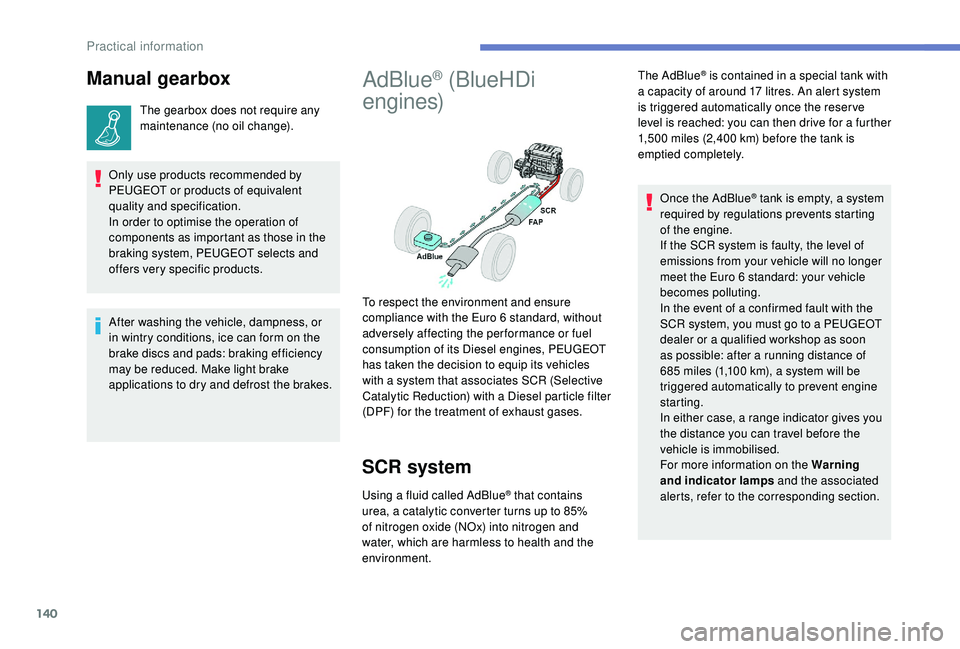

AdBlue® (BlueHDi

engines)

SCR system

Using a fluid called AdBlue® that contains

urea, a catalytic converter turns up to 85%

of nitrogen oxide (NOx) into nitrogen and

water, which are harmless to health and the

environment. The AdBlue

® is contained in a special tank with

a capacity of around 17 litres. An alert system

is triggered automatically once the reser ve

level is reached: you can then drive for a further

1,500

miles (2,400 km) before the tank is

emptied completely.

To respect the environment and ensure

compliance with the Euro 6 standard, without

adversely affecting the per formance or fuel

consumption of its Diesel engines, PEUGEOT

has taken the decision to equip its vehicles

with a system that associates SCR (Selective

Catalytic Reduction) with a Diesel particle filter

(DPF) for the treatment of exhaust gases. Once the AdBlue

® tank is empty, a system

r

equired by regulations prevents starting

of the engine.

If the SCR

system is faulty, the level of

emissions from your vehicle will no longer

meet the Euro 6 standard: your vehicle

becomes polluting.

In the event of a confirmed fault with the

SCR system, you must go to a PEUGEOT

dealer or a qualified workshop as soon

as possible: after a running distance of

685

miles (1,100

km), a system will be

triggered automatically to prevent engine

starting.

In either case, a range indicator gives you

the distance you can travel before the

vehicle is immobilised.

For more information on the Warning

and indicator lamps and the associated

alerts, refer to the corresponding section.

After washing the vehicle, dampness, or

in wintry conditions, ice can form on the

brake discs and pads: braking efficiency

may be reduced. Make light brake

applications to dry and defrost the brakes.

Practical information

Page 143 of 216

141

Freezing of AdBlue®

AdBlue® freezes at temperatures below

around -11°C.

The SCR system includes a heater for the

AdBlue

® tank, allowing you to continue

driving in all weather conditions.

Topping up with AdBlue®

Before topping up, please read the

following warnings carefully.

Precautions in use

In certain conditions (high ambient

temperature, for example), the risk of ammonia

being released cannot be discounted: do not

inhale the fluid. Ammonia vapour has an irritant

effect on mucous membranes (eyes, nose and

throat).

Keep AdBlue

® out of reach of children, in

its original container or bottle.

Never transfer AdBlue

® to another

container: it would lose its purity.

Use only AdBlue

® liquid that meets the

ISO

22241 standard.

AdBlue

® is a urea-based solution. This fluid is

non-flammable, colourless and odourless (kept

in a cool area).

In the event of contact with the skin, wash the

affected area with soap and running water. In

the event of contact with the eyes, immediately

rinse the eyes with large amounts of water

or with an eye wash solution for at least

15

minutes. If a burning sensation or irritation

persists, get medical attention.

If swallowed, immediately rinse the mouth with

clean water and then drink plenty of water.Never dilute AdBlue® with water.

Never pour AdBlue® into the Diesel fuel tank.

Containers or bottles are available from a

PEUGEOT dealer or a qualified workshop.

You can also visit a ser vice station

equipped with AdBlue pumps specially

designed for passenger vehicles and light

goods vehicles. Never top up from an AdBlue

® dispenser

reserved for heavy goods vehicles.

Recommendations on storage

AdBlue® freezes below around -11°C and

deteriorates above 25°C. It is recommended

that bottles or containers are stored in a cool

place and protected from direct sunlight.

Under these conditions, the fluid can be kept

for at least a year.

If the fluid has frozen, it can be used once

it has completely thawed out at ambient

temperature.

Never store bottles or containers of

AdBlue

® in your vehicle.

Do not dispose of AdBlue

® bottles or

containers in the household waste.

Place them in a container provided for

this purpose or take them to your dealer.

7

Practical information

Page 144 of 216

142

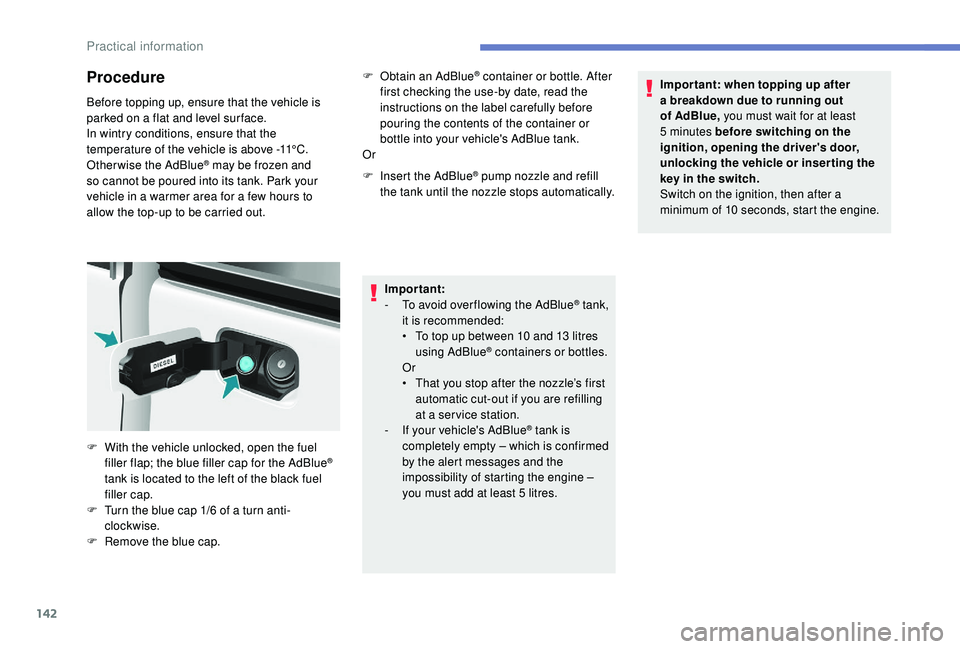

Procedure

Before topping up, ensure that the vehicle is

parked on a flat and level sur face.

In wintry conditions, ensure that the

temperature of the vehicle is above -11°C.

Otherwise the AdBlue

® may be frozen and

so cannot be poured into its tank. Park your

vehicle in a warmer area for a few hours to

allow the top-up to be carried out. F

O

btain an AdBlue

® container or bottle. After

first checking the use-by date, read the

instructions on the label carefully before

pouring the contents of the container or

bottle into your vehicle's AdBlue tank.

Or

F

I

nsert the AdBlue

® pump nozzle and refill

the tank until the nozzle stops automatically.

Important:

-

T

o avoid over flowing the AdBlue

® tank,

i

t is recommended:

•

T

o top up between 10 and 13

litres

using AdBlue

® containers or bottles.

Or

•

T

hat you stop after the nozzle’s first

automatic cut-out if you are refilling

at a ser vice station.

-

I

f your vehicle's AdBlue

® tank is

completely empty – which is confirmed

by the alert messages and the

impossibility of starting the engine –

you must add at least 5

litres. Impor tant: when topping up after

a breakdown due to running out

of AdBlue,

you must wait for at least

5 minutes before switching on the

ignition, opening the driver's door,

unlocking the vehicle or inser ting the

key in the switch.

Switch on the ignition, then after a

minimum of 10 seconds, start the engine.

F

W

ith the vehicle unlocked, open the fuel

filler flap; the blue filler cap for the AdBlue

®

tank is located to the left of the black fuel

filler cap.

F

T

urn the blue cap 1/6 of a turn anti-

clockwise.

F

R

emove the blue cap.

Practical information

Page 145 of 216

143

Temporary puncture

repair kit

The kit is located in a storage compartment

under the front seat.

Vehicles supplied with a temporary puncture

repair kit do not have a spare wheel or the

corresponding tools ( jack, wheelbrace, etc.).

The temporary puncture repair kit comprises a

compressor and a bottle of sealant.

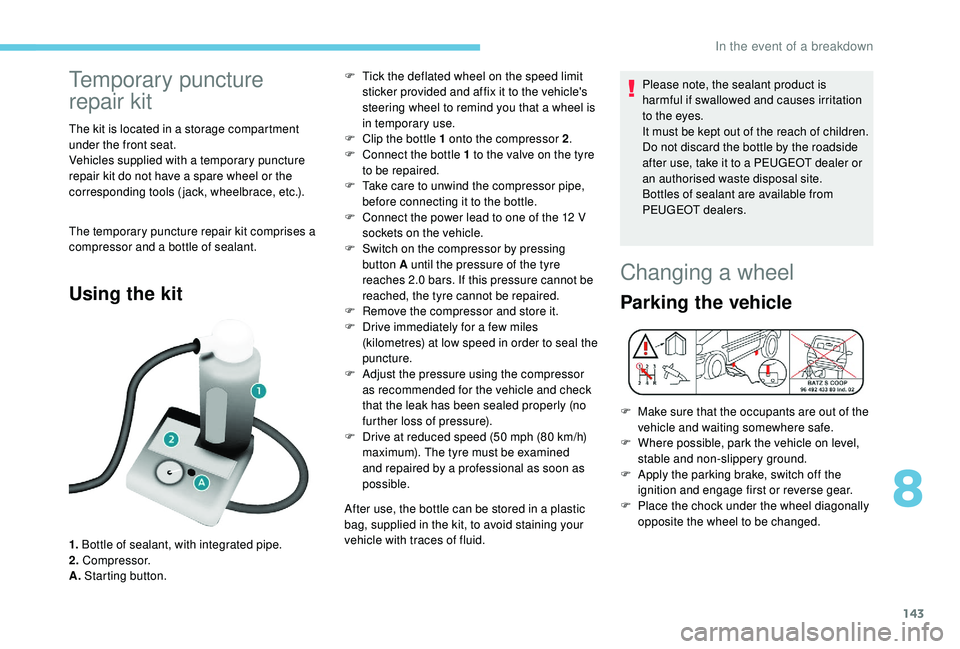

Using the kit

1. Bottle of sealant, with integrated pipe.

2. Compressor.

A. Starting button. F

T

ick the deflated wheel on the speed limit

sticker provided and affix it to the vehicle's

steering wheel to remind you that a wheel is

in temporary use.

F

C

lip the bottle 1 onto the compressor 2

.

F

C

onnect the bottle 1 to the valve on the tyre

to be repaired.

F

T

ake care to unwind the compressor pipe,

before connecting it to the bottle.

F

C

onnect the power lead to one of the 12 V

sockets on the vehicle.

F

S

witch on the compressor by pressing

button A until the pressure of the tyre

reaches 2.0 bars. If this pressure cannot be

reached, the tyre cannot be repaired.

F

R

emove the compressor and store it.

F

D

rive immediately for a few miles

(kilometres) at low speed in order to seal the

puncture.

F

A

djust the pressure using the compressor

as recommended for the vehicle and check

that the leak has been sealed properly (no

further loss of pressure).

F

D

rive at reduced speed (50 mph (80 km/h)

maximum). The tyre must be examined

and repaired by a professional as soon as

possible.

After use, the bottle can be stored in a plastic

bag, supplied in the kit, to avoid staining your

vehicle with traces of fluid. Please note, the sealant product is

harmful if swallowed and causes irritation

to the eyes.

It must be kept out of the reach of children.

Do not discard the bottle by the roadside

after use, take it to a PEUGEOT dealer or

an authorised waste disposal site.

Bottles of sealant are available from

PEUGEOT dealers.

Changing a wheel

Parking the vehicle

F Make sure that the occupants are out of the

vehicle and waiting somewhere safe.

F

W

here possible, park the vehicle on level,

stable and non-slippery ground.

F

A

pply the parking brake, switch off the

ignition and engage first or reverse gear.

F

P

lace the chock under the wheel diagonally

opposite the wheel to be changed.

8

In the event of a breakdown

Page 146 of 216

144

If the vehicle is equipped with a towbar, it is

sometimes necessary to raise the vehicle

slightly to make it easier to remove the spare

wheel from its carrier.

In certain ground conditions and/or when

transporting heavy loads, consult with a

PEUGEOT dealer or a qualified workshop.

The jack and the tool kit are specific to your

vehicle. Do not use them for any other purpose.

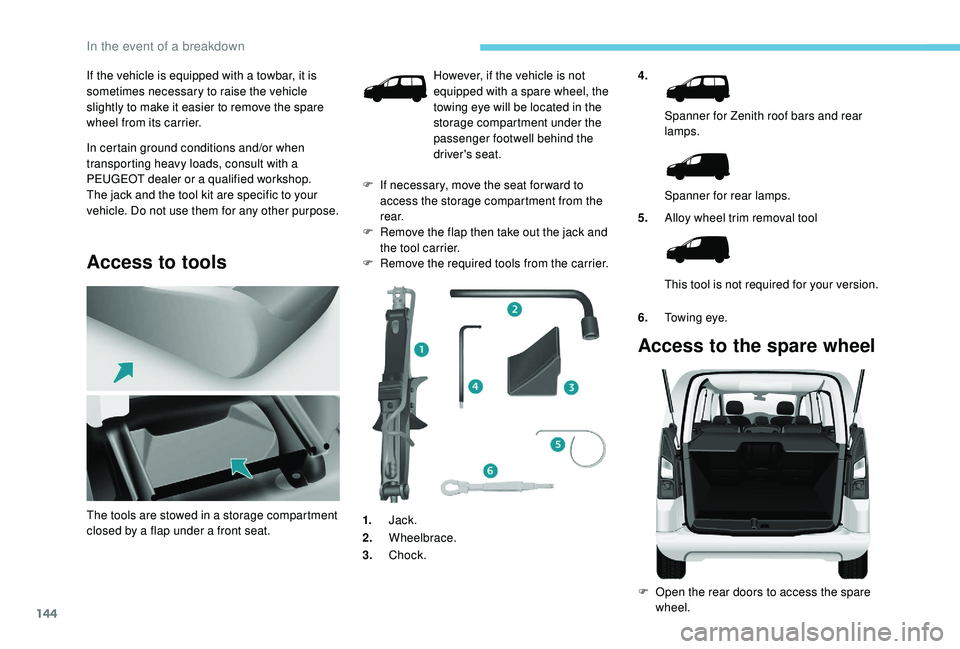

Access to tools

4.Spanner for Zenith roof bars and rear

lamps.

Spanner for rear lamps.

5. Alloy wheel trim removal tool

This tool is not required for your version.

6. Towing eye.

Access to the spare wheel

F Open the rear doors to access the spare

wheel.

The tools are stowed in a storage compartment

closed by a flap under a front seat. However, if the vehicle is not

equipped with a spare wheel, the

towing eye will be located in the

storage compartment under the

passenger footwell behind the

driver's seat.

F

I

f necessary, move the seat for ward to

access the storage compartment from the

r e a r.

F

R

emove the flap then take out the jack and

the tool carrier.

F

R

emove the required tools from the carrier.

1. Jack.

2. Wheelbrace.

3. Chock.

In the event of a breakdown

Page 147 of 216

145

F Detach the carrier from the hook and place the spare wheel near the wheel to be

changed.

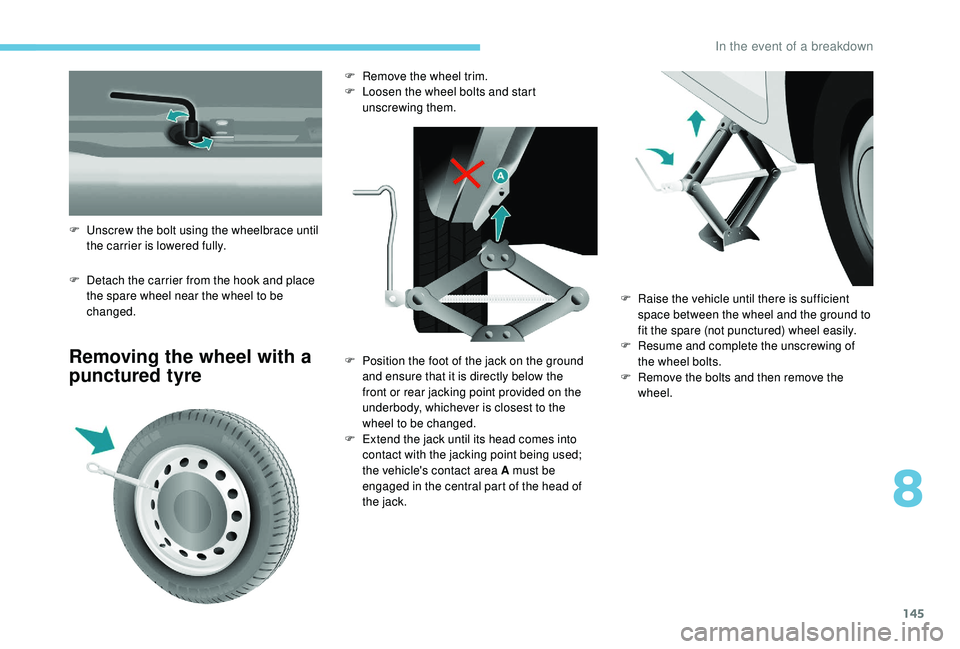

Removing the wheel with a

punctured tyre

F Unscrew the bolt using the wheelbrace until the carrier is lowered fully. F

R

emove the wheel trim.

F

L

oosen the wheel bolts and start

unscrewing them.

F

P

osition the foot of the jack on the ground

and ensure that it is directly below the

front or rear jacking point provided on the

underbody, whichever is closest to the

wheel to be changed.

F

E

xtend the jack until its head comes into

contact with the jacking point being used;

the vehicle's contact area A must be

engaged in the central part of the head of

the jack. F

Ra

ise the vehicle until there is sufficient

space between the wheel and the ground to

fit the spare (not punctured) wheel easily.

F

R

esume and complete the unscrewing of

the wheel bolts.

F

R

emove the bolts and then remove the

wheel.

8

In the event of a breakdown

Page 148 of 216

146

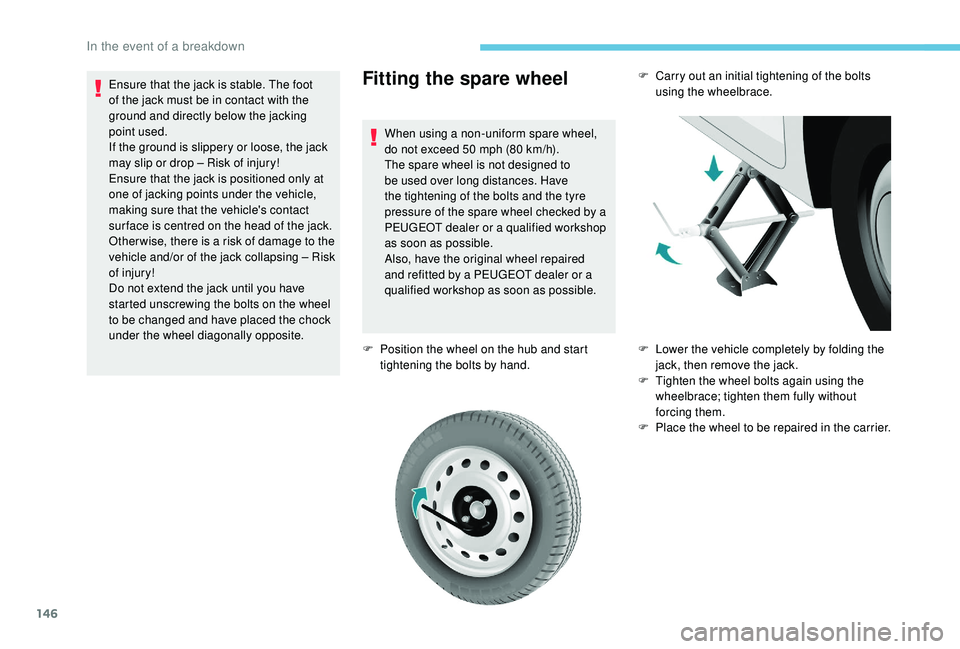

Fitting the spare wheel

When using a non-uniform spare wheel,

do not exceed 50 mph (80 km/h).

The spare wheel is not designed to

be used over long distances. Have

the tightening of the bolts and the tyre

pressure of the spare wheel checked by a

PEUGEOT dealer or a qualified workshop

as soon as possible.

Also, have the original wheel repaired

and refitted by a PEUGEOT dealer or a

qualified workshop as soon as possible.

F

P

osition the wheel on the hub and start

tightening the bolts by hand.

Ensure that the jack is stable. The foot

of the jack must be in contact with the

ground and directly below the jacking

point used.

If the ground is slippery or loose, the jack

may slip or drop – Risk of injury!

Ensure that the jack is positioned only at

one of jacking points under the vehicle,

making sure that the vehicle's contact

sur face is centred on the head of the jack.

Other wise, there is a risk of damage to the

vehicle and/or of the jack collapsing – Risk

of injury!

Do not extend the jack until you have

started unscrewing the bolts on the wheel

to be changed and have placed the chock

under the wheel diagonally opposite.

F

C

arry out an initial tightening of the bolts

using the wheelbrace.

F

L

ower the vehicle completely by folding the

jack, then remove the jack.

F

T

ighten the wheel bolts again using the

wheelbrace; tighten them fully without

forcing them.

F

P

lace the wheel to be repaired in the carrier.

In the event of a breakdown

Page 149 of 216

147

Never go underneath a vehicle that is

supported only by a jack (use an axle stand).

Never use an electric screwdriver instead of

the wheelbrace.

Refitting the repaired wheel

The wheel is refitted in the same way as the

spare wheel; do not forget to refit the wheel

trim.For more information on Identification

markings

, including the tyre label, refer to

the corresponding section.

For more information on Tyre under-

inflation detection , including

recommendations after changing a wheel

with a tyre under-inflation detection

sensor, refer to the corresponding section.

F

S

ecure the carrier on the hook, then raise

the carrier by tightening the bolt with the

wheelbrace.

F

T

ighten the bolt fully and check that the

wheel is held flat against the floor.

If not, repeat the procedure.

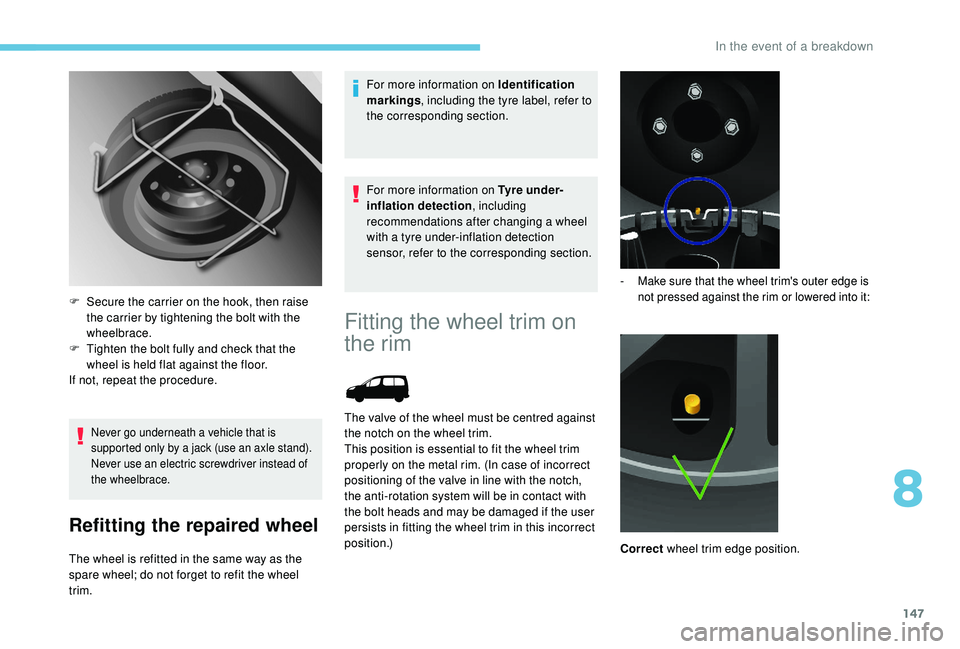

Fitting the wheel trim on

the rim

The valve of the wheel must be centred against

the notch on the wheel trim.

This position is essential to fit the wheel trim

properly on the metal rim. (In case of incorrect

positioning of the valve in line with the notch,

the anti-rotation system will be in contact with

the bolt heads and may be damaged if the user

persists in fitting the wheel trim in this incorrect

position.)

- Make sure that the wheel trim's outer edge is not pressed against the rim or lowered into it:

Correct wheel trim edge position.

8

In the event of a breakdown

Page 150 of 216

148

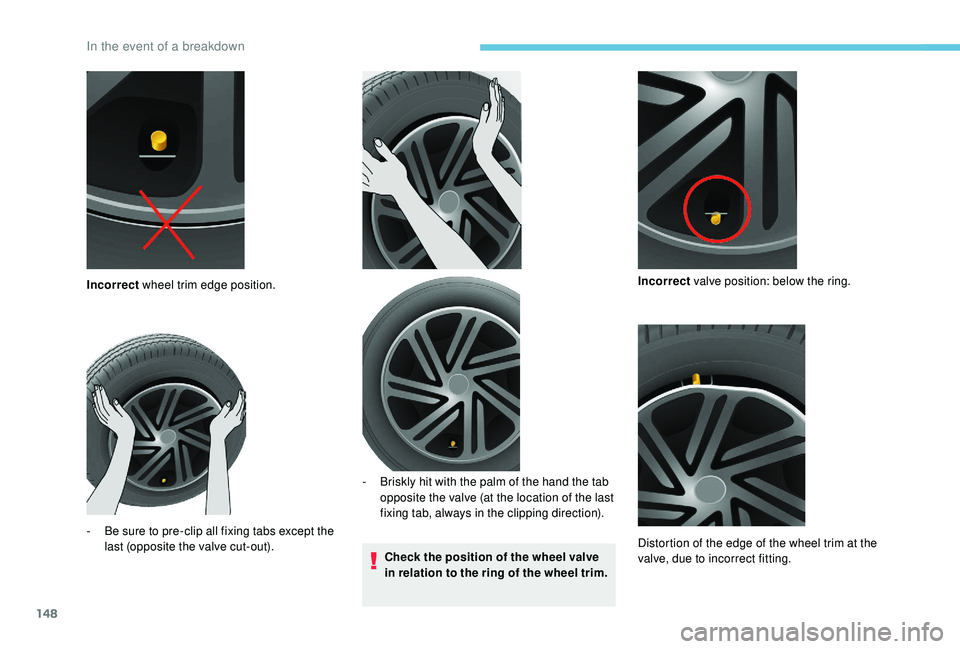

Check the position of the wheel valve

in relation to the ring of the wheel trim.

Incorrect

wheel trim edge position.

-

B

e sure to pre-clip all fixing tabs except the

last (opposite the valve cut-out). -

B

riskly hit with the palm of the hand the tab

opposite the valve (at the location of the last

fixing tab, always in the clipping direction). Incorrect

valve position: below the ring.

Distortion of the edge of the wheel trim at the

valve, due to incorrect fitting.

In the event of a breakdown