PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1411 of 1825

(Continued from previous page)

If the Speedometer reads correctly, refer to

Vehicle Speed Sensor, Section

8A-33 for fur-

ther diagnosis.

If the Speedometer reads incorrectly, check

LT GRN (537) wire and the Instrument Clus-

ter Printed Circuit for opens. Replace the

Speedometer Assembly if the wire and

Printed Circuit are good (see Section

8C).

O: UPSHIFT INDICATOR WIRE TEST

Disconnect ECM connector C207. Put the Igni-

tion Switch in RUN and measure the voltage at

terminal

H (see section 8A-21 or 22).

If battery voltage is present, see section

6E

for ECM diagnosis.

If battery voltage is not present, check the

TANIBLK (422) wire for an open or short to

Ground.

CIRCUIT OPERATION

The operation of an indicator is explained in

the operation of the circuit it is apart of. See the

circuit referred to for a complete description of

that indicator and the other components that

work with it. Only the gages and indicators that

do not appear in other schematics are described

in this section.

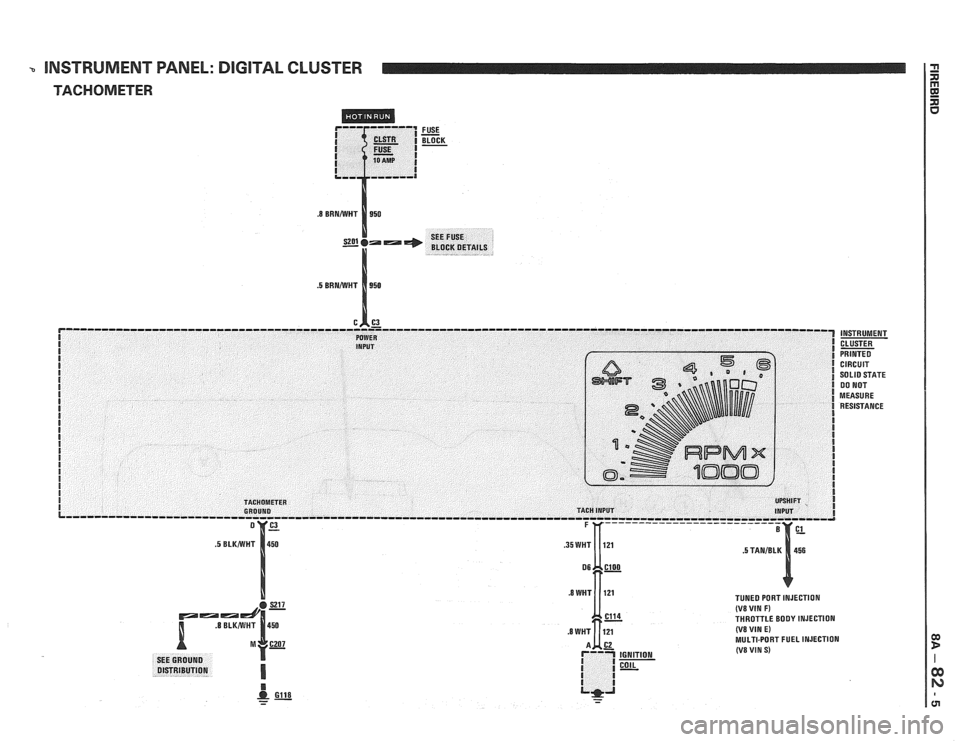

Tachometer

The Tachometer displays engine speed in

rpm. Voltage pulses are taken from the Ignition

System and sent to the Tachometer. Solid State

circuits process these pulses into a signal that

drives the pointer of the meter. The Tachometer

responds to the frequency of the voltage pulses.

These pulses increase with engine speed.

Fuel Gage

The pointer of the Fuel Gage is moved by the

magnetic field of two coils. The coils are at right

angles to each other. Battery voltage is applied

to the E coil and the circuit divides at the

opposite end of this coil. One path continues to

ground through the F coil. Another goes to

ground through the variable resistor of the Fuel

Gage Sender Unit.

When the tank is low, the resistance of the

Fuel Gage Sender is low. A large flow of current

passes through the E coil and the Fuel Gage

Sender resistor. This moves the pointer

towards E on the scale. When the tank is

full,

the sender resistance is high. More current

flows through the F coil, moving the pointer

toward F on the scale.

With two coils operating the pointer, the Fuel

Gage is not affected by changes in the voltage

of the system.

011 Pressure Gage

The engine oil pressure is displayed by the Oil

Pressure Gage. The pointer of the gage is

moved by two coils, and its operation is similar

to that of the Fuel Gage. The

Oil Pressure Sender is connected to the

junction of the two coils.

It has low resistance

when the oil pressure is low, and 90 ohms

resistance when the oil pressure is high. This

changing resistance changes the current flow

through the coils. The magnetic fields of the

coils move the pointer to indicate high or low

coolant temperature.

Voltmeter

The Voltmeter measures the electrical sys-

tem voltage with the Ignition Switch in RUN,

BULB TEST, or START. With the engine

stopped, the Voltmeter indicates battery condi-

tion. With the engine

running, the Voltmeter

indicates Charging System operation.

Coolant Temperature Gage

The Coolant Temperature Gage is also oper-

ated by two coils. Battery voltage is applied to

both coils. One is grounded directly

and the

other is grounded through the Coolant Tem-

perature Sender. This has 54 ohms resistance at

260

OF, 130 "C (hot coolant) and its resistance

becomes greater at lower temperatures. It is

appr~ximately 1284 ohms at 100 OF (40 '6). This

causes the current through the sender and one

coil to vary as the coolant temperature charges

and this moves the pointer.

Page 1412 of 1825

INSTRUMENT PANEL: GAGES CLUSTER

Speedorneter and Odometers

The Speedometer is operated by an electronic

circuit. The Vehicle Speed Sensor (VSS),

located in the transmission, generates an AC

voltage whose frequency is proportional to the

speed of the vehicle. This goes to the Vehicle

Speed Sensor Buffer and then to the Speedom-

eter circuit board in the Instrument Cluster.

The Solid State circuit drives the pointer of the

Speedometer. There is no speedometer cable

in

the vehicle.

The same speed signal from the Vehicle Speed

Buffer is processed by the Speedometer circuit

board to drive the Odometers. They are oper-

ated by a motor that responds to pulses from

the Speedometer circuit.

UpshiN Indicator

With Manual Transmission, the indicator

lights when the car should be shifted to the next

higher gear for better fuel economy. Battery

voltage is applied to one side of the bulb. The

other side of the bulb is switched to ground by

the ECM which uses engine data to compute an

efficient shift point.

Page 1413 of 1825

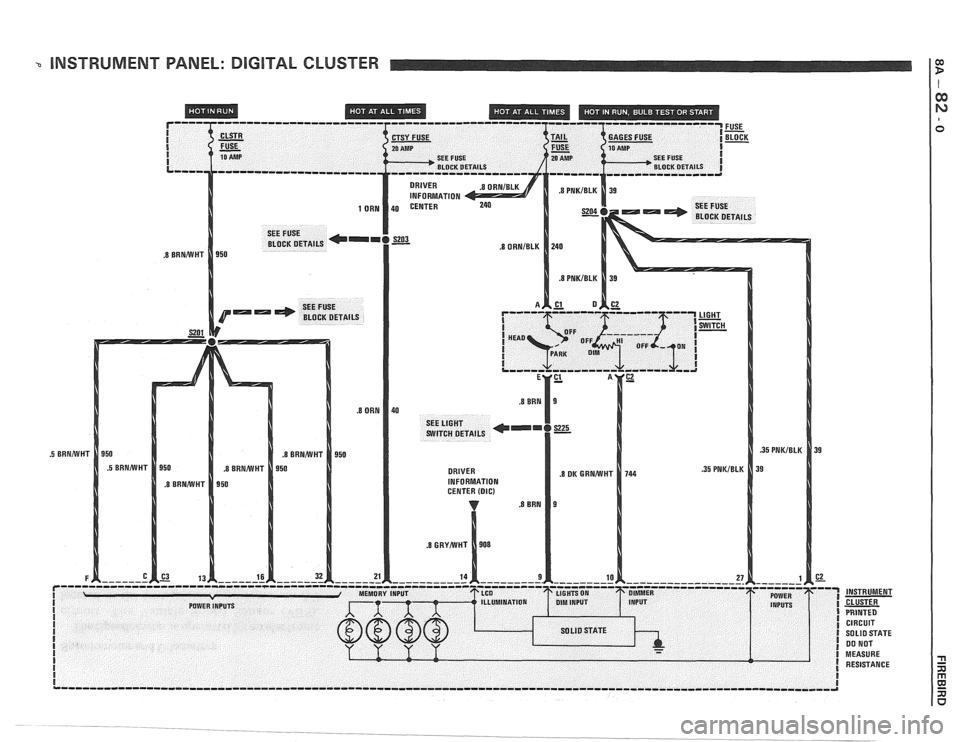

INSTRUMENT PANEL: DIGITAL CLUSTER

I

I

I I SEE FUSE 20 AMP SEE FUSE I

BLOCK DETAILS

CIRCUIT SOLID STATE 00 NOT

MEASURE RESISTANCE

Page 1414 of 1825

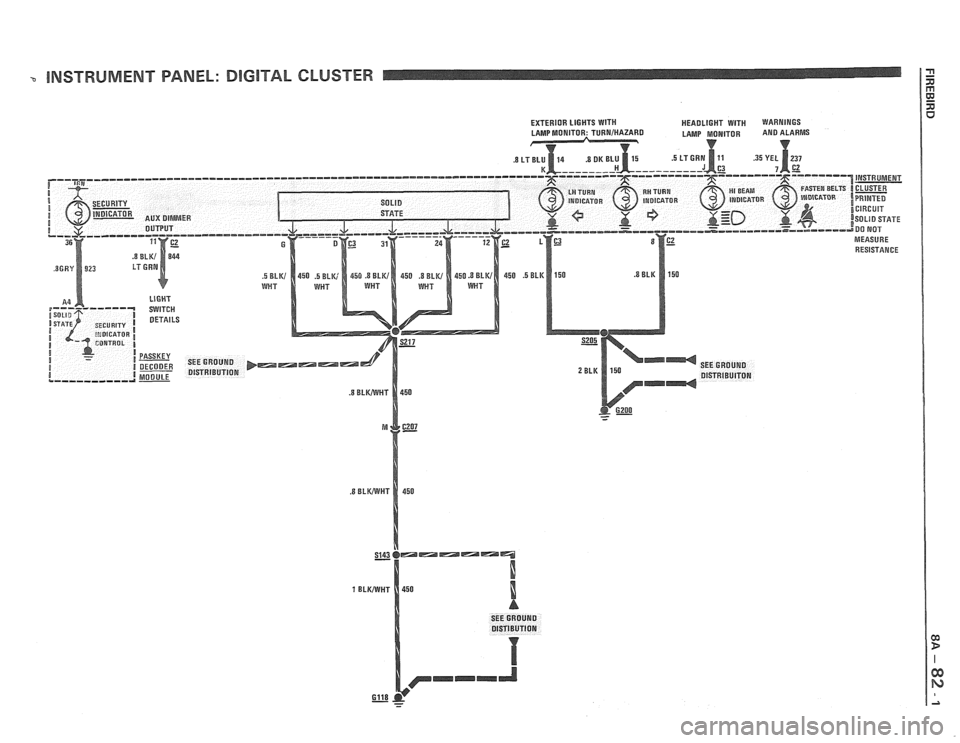

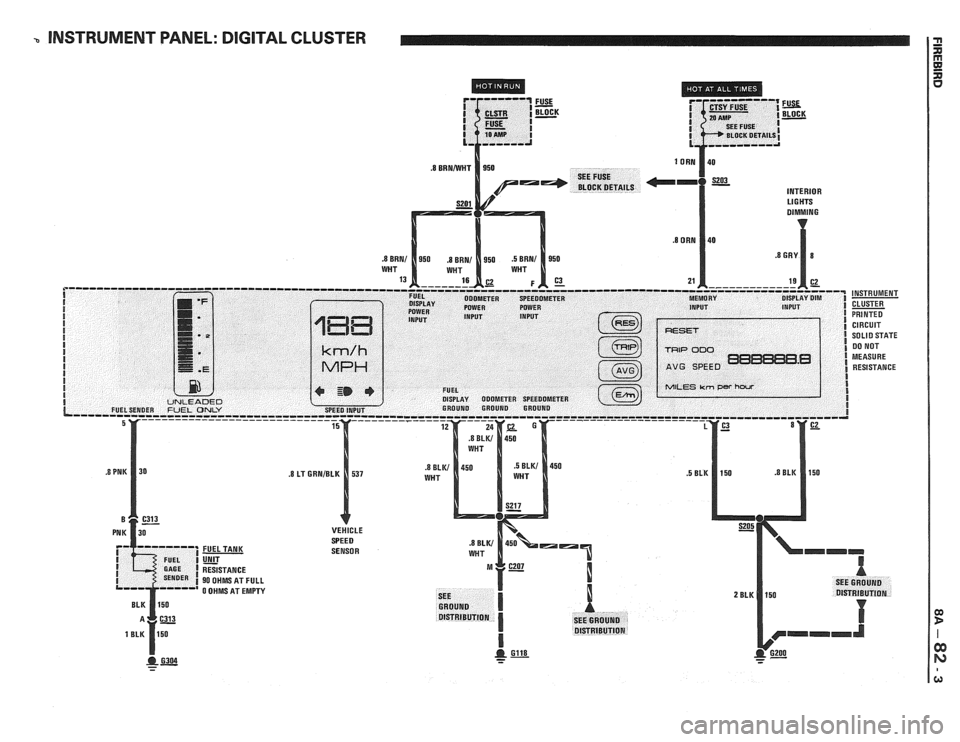

- INSTRUMENT PANEL: DlGlTAL CLUSTER

SEE GROUND

Gll8 - - -

Page 1415 of 1825

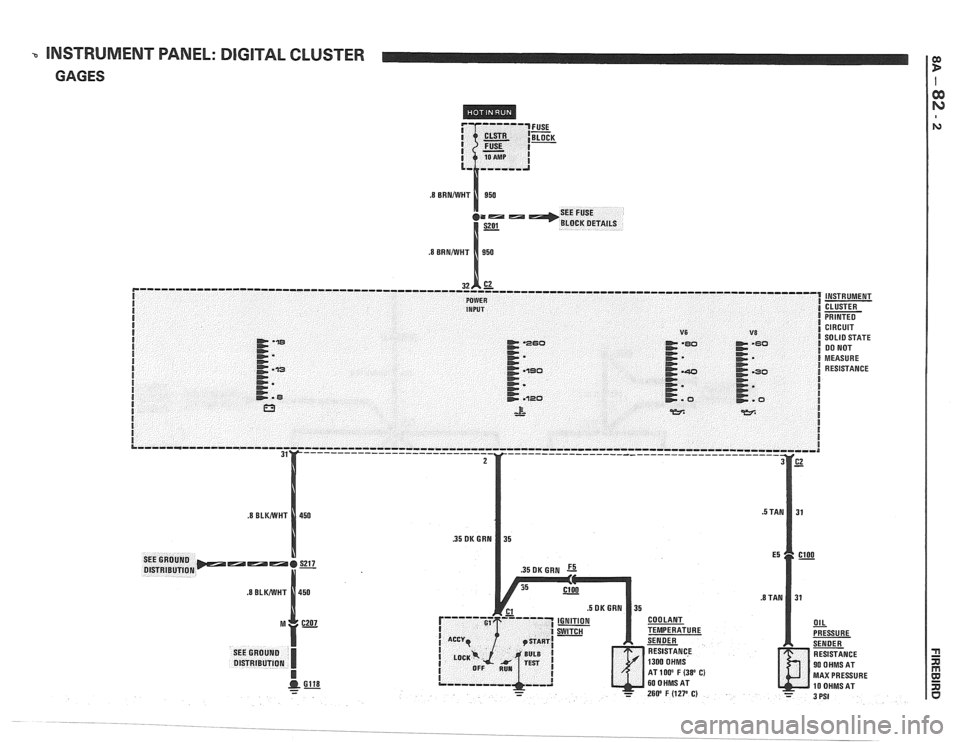

INSTRUMENT PANEL: DIGITAL CLUSTER

GAGES

MAX PRESSURE

Page 1416 of 1825

b INSTRUMENT PANEL: DIGITAL CLUSTER

INTERIOR Ll G HTS

SENSOR

- - -

Page 1417 of 1825

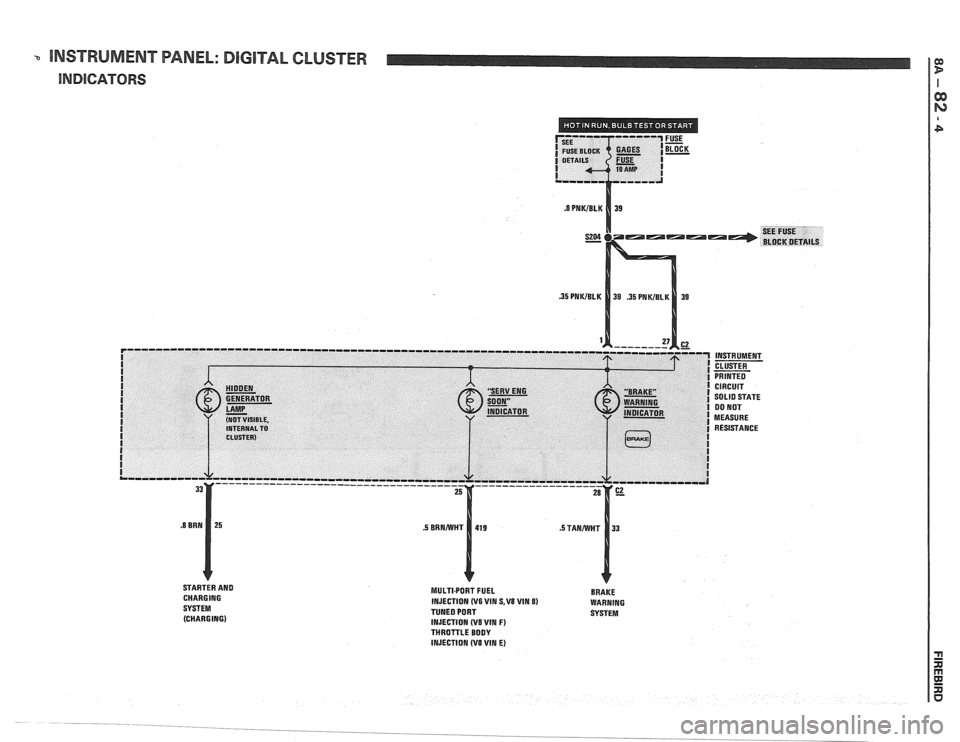

-. INSTRUMENT PANEL: DIGlTAL CLUSTER

INDICATORS

STARTER AND

CHARGING

SYSTEM (CHARGING) MULTIPORT FUEL BRAKE

INJECTION (V6 WIN S,V8 VIM 8) WARNING

TUNED PORT SYSTEM

INJECTION

(V8 VIN F) THROTTLE BODY

INJECTION (V8 WIN E)

Page 1418 of 1825

3 INSTRUMENT PANEL: DIGITAL CLUSTER

TACHOMETER

FUSE - BLOCK -

INSTRUMENT

CLUSTER

PRINTED CIRCUIT

SO

LID STATE 00 NOT

MEASURE RESISTANCE

TUNED PORT INJECTION (V8 VIN F) THROTTLE BODY INJECTION (VB VIN E) MULTI-PORT FUEL INJECTION (V8 VIN S)

Page 1419 of 1825

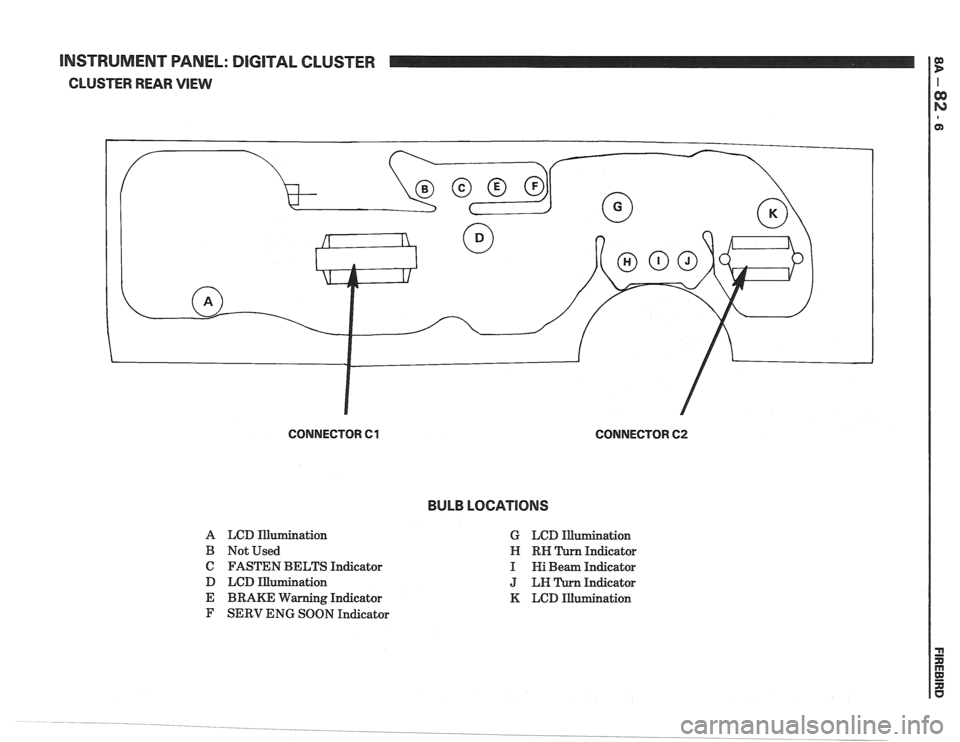

[NSTRUMENT WNEL: DIGITAL CLUSTER

CLUSTER REAR VlEW

CONNECTOR 61 CONNECTOR 62

BULB LOCATIONS

A LCD Illurnination

B Not Used

C FASTEN BELTS Indicator

D LCD Illumination

E BRAKE Warning Indicator

F SERV ENG SOON Indicator G

LCD Illumination

Indicator

Indicator

Indicator

K LCD Illumination

Page 1420 of 1825

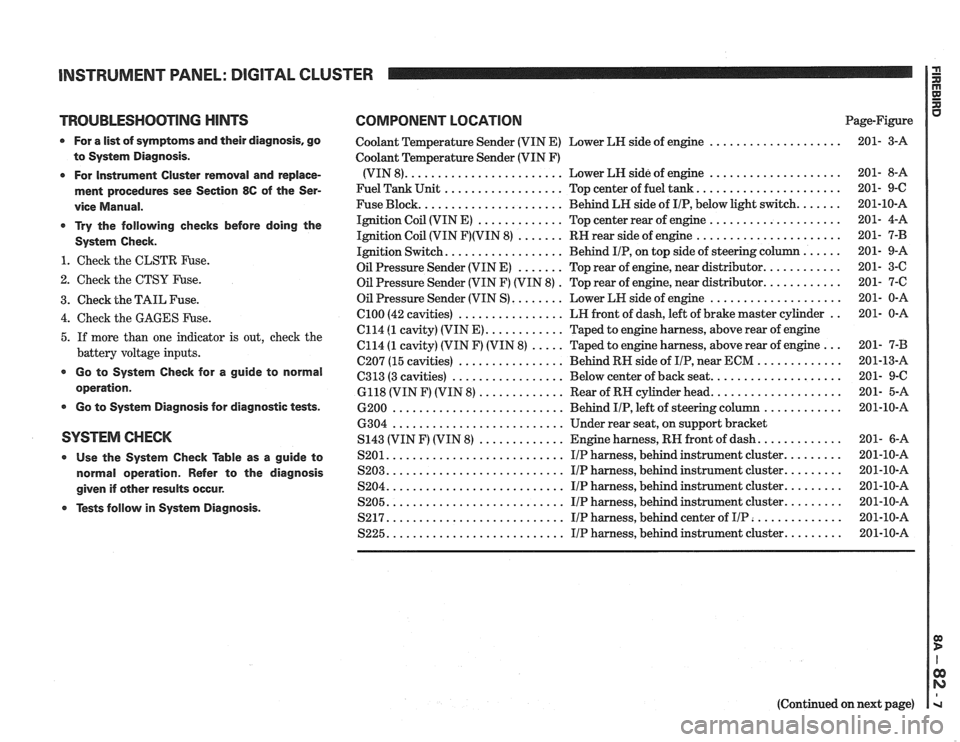

INSTRUMENT PANEL: DIGITAL CLUSTER a

TROUBLESHOOTING HINTS COMPONENT LOCATION u Page-Figure

0 For a list of symptoms and their diagnosis. go

to System Diagnosis

.

0 For Instrument Cluster removal and replace-

ment procedures see Section

86 of the Ser-

vice Manual

.

* Try the following checks before doing the

System Check

.

1 . Check the CLSTR Fuse .

2 . Check the CTSY Fuse .

3 . Check the TAIL Fuse .

Coolant Temperature Sender (VIN E) Lower LH side of engine ....................

Coolant Temperature Sender (VIN F)

(VIN 8)

........................ Lower LH side of engine ....................

Fuel Tank Unit .................. Top center of fuel tank ......................

Fuse Block ...................... Behind LH side of IIP. below light switch .......

Ignition Coil (VIN E) ............. Top center rear of engine ....................

Ignition Coil (VIN F)(VIN 8) ....... RH rear side of engine ......................

Ignition Switch .................. Behind IIP. on top side of steering column ......

Oil Pressure Sender (VIN E) ....... Top rear of engine. near distributor ............

Oil Pressure Sender (VIN F) (VIN 8) . Top rear of engine. near distributor ............

Oil Pressure Sender (VIN S) ........ Lower LH side of engine ....................

................ .. 4 . Check the GAGES Fuse . el00 (42 cavities) LH

front of dash. left of brake master cylinder 201- 0-A

C114

(1 cavity) (VIN E) ............ Taped to engine harness. above rear of engine

5 . If more than one indicator is out. check the C114 (1 cavity) (VIN F) (VIN 8) ..... Taped to engine harness. above rear of engine ... 201- 7-B

battery voltage inputs . . C207 (15 cavities) ................ Behind RH side of IIP near ECM ............. 201-13-A

................. .................... * Go to System Check for a guide to C313 (3 cavities) Below

center of back seat 201- 9-C operation . 6118 (VIN F) (VIN 8) ............. Rear of RH cylinder head .................... 201- 5-A

0 Go to System Diagnosis for diagnostic tests . 6200 .......................... Behind IIP. left of steering column ............ 201-10-A

6304

.......................... Under rear seat. on support bracket

SYSTEM CHECK S143 (VIN F) (VIN 8) ............. Engine harness. RH front of dash ............. 201- 6-A

0 Use the System Check able as a guide to S201 ........................... IIP harness. behind instrument cluster ......... 201-10-A

normal operation . Refer to the diagnosis S203 ........................... I/P harness. behind instrument cluster ......... 201-10-A

........................... ......... given if other results occur . S204 IIP harness. behind instrument cluster 201-10-A

........................... ......... Tests follow in System Diagnosis . S205 IIP harness. behind instrument cluster 201-10-A

S217 ........................... IIP harness. behind center of IIP .............. 201-10-A

S225 ........................... IIP harness. behind instrument cluster ......... 201-10-A

(Continued on next page)