PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 771 of 1825

6E3-C6-2 2.8L (WIN 5) DRIVEABILITY AND EMISSIONS

When the solenoid is de-energized, the pressurized

air from the air pump is allowed to enter the decel

timing chamber. This places sufficient pressure on

the metering valve diaphragm to overcome spring

tension, closing the

valve,causing air to divert to the

silencer.

At higher engine speeds, excess air is exhausted to

the silencer through the pressure relief valve. (Figure

C6-1)

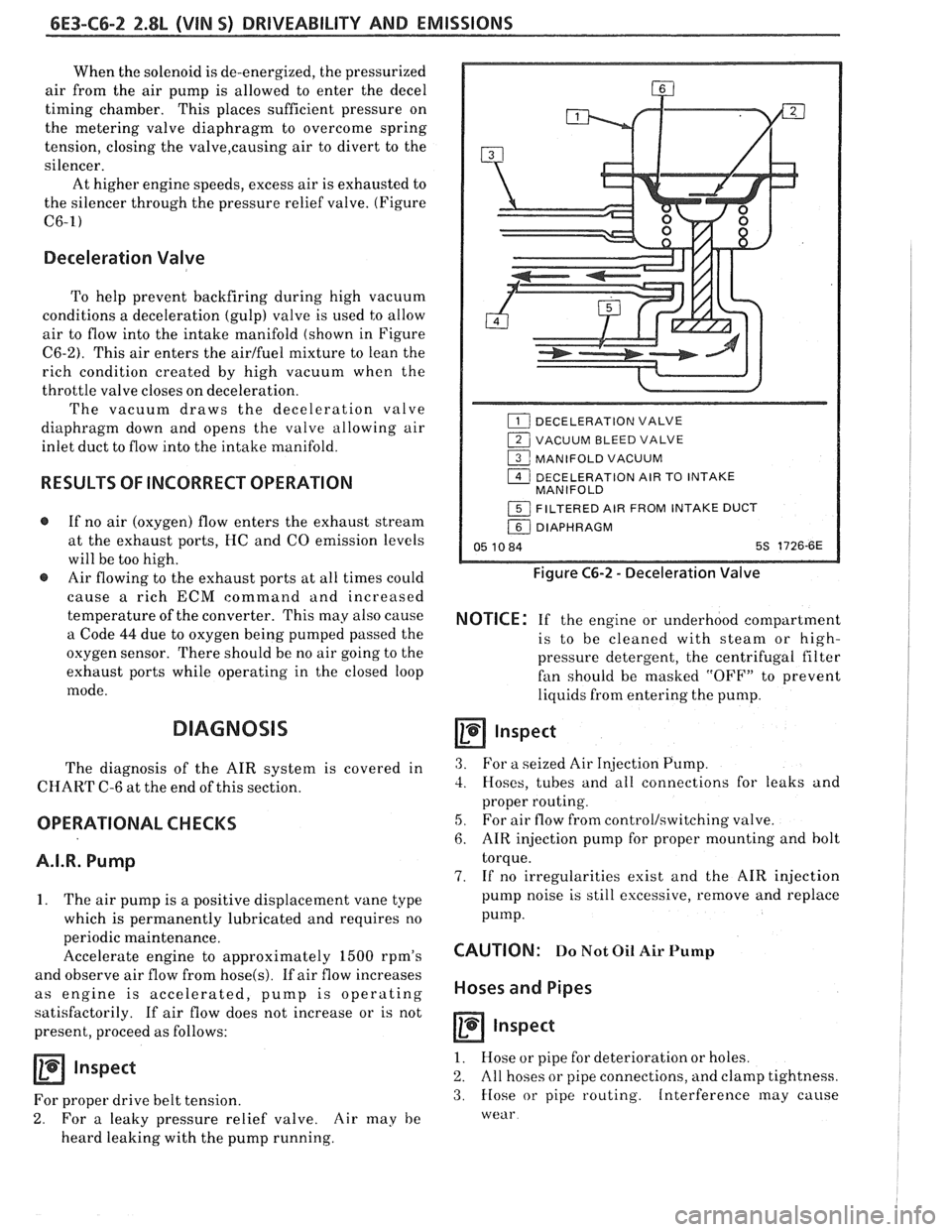

Deceleration Valve

To help prevent backfiring during high vacuum

conditions a deceleration (gulp) valve is used to allow

air to flow into the intake manifold (shown in Figure

C6-2). This air enters the airlfuel mixture to lean the

rich condition created by high vacuum when the

throttle valve closes on deceleration.

The vacuum draws the deceleration valve

diaphragm down and opens the valve allowing air

inlet duct to flow into the intake manifold.

RESULTS OF INCORRECT OPERATION

@ If no air (oxygen) flow enters the exhaust stream

at the exhaust ports, HC and

CO emission levels

will be too high.

@ Air flowing to the exhaust ports at all times could

cause

a rich ECM command and increased

temperature of the converter. This may also cause

a Code

44 due to oxygen being pumped passed the

oxygen sensor. There should be no air going to the

exhaust ports while operating in the closed loop

mode.

DIAGNOSIS

The diagnosis of the AIR system is covered in

CHART C-6 at the end of this section.

OPERATIONAL CHECKS

A.I.R. Pump

1. The air pump is a positive displacement vane type

which is permanently lubricated and requires no

periodic maintenance.

Accelerate engine to approximately

1500 rpm's

and observe air flow from

hose(s). If air flow increases

as engine is accelerated, pump is operating

satisfactorily. If air flow does not increase or is not

present, proceed as follows:

Inspect

For proper drive belt tension.

2. For a leaky pressure relief valve. Air may he

heard leaking with the pump running.

DECELERATION VALVE

1 VACUUM BLEED VALVE

1 MANIFOLD VACUUM

1 DECELERATION AIR TO INTAKE

MANIFOLD

1 FILTERED AIR FROM INTAKE DUCT

/ DIAPHRAGM

05 10 84 5s 1726-6E

Figure C6-2 - Deceleration Valve

NOTICE: If the engine or underhood compartment

is to he cleaned with

steam or high-

pressure detergent, the centrifugal filter

fan should be masked "OFF7' to prevent

liquids from entering the pump.

Inspect

3. For a seized Air Injection Pump.

3. Hoses, tubes and all connections for leaks and

proper routing.

5, For air flow from controllswitching valve.

6. AIR injection pump for proper mounting and bolt

torque.

7. If no irregularities exist and the AIR injection

pump noise is still excessive, remove and replace

pump.

CAUTION: Do Not Oil Air Pump

Hoses and Pipes

Inspect

1. Hose or pipe for deterioration or holes.

2. All hoses or pipe connections, and clamp tightness.

3. Hose or pipe routing. Interference may cause

wear

Page 772 of 1825

DRIVEABILITY AND EMISSIONS 2.8L (WIN 5) 6E3-C6-3

4. If a leak is suspected on the pressure side of the

system or if

a hose or pipe has been disconnected

on the pressure side, the connections should be

checked for leaks with a soapy water solution.

With the pump running, bubbles will form if

a

leak exists.

Deceleration Valve

1. Connect tachometer, start engine and allow idle to

stabilize.

2. With the engine running at specified idle speed,

remove the small deceleration valve signal hose

from the manifold vacuum source.

3. Reconnect the signal hose and listen for air flow

through the ventilation pipe and into the

deceleration valve. There should also be a

noticeable speed drop when the signal hose is

reconnected.

4. If the air flow does not continue for at least one

second or the engine speed does not drop

noticeably, check the deceleration valve hoses for

restrictions or leaks.

5. If no restrictions or leaks are found, replace the

deceleration valve.

Check Valve

Inspect

1. A check valve should be inspected whenever the

hose is disconnected form

a check valve or

whenever check valve failure is suspected.

(A

pump that had become inoperative and had shown

indications of having exhaust gases in the pump

would indicate check valve failure).

2. Blow through the check valve (toward the exhaust

manifold) then attempt to suck back through the

check valve. Flow should only be in one

direction(towax-d the exhaust manifold). Replace

valve which does not operate properly.

ON-CAR SERVICE

DRIVE BELT

Remove or Disconnect

1. Inspect drive belt for ware, cracks or deterioration

and replace if required. When installing new belt,

it must be seated and fully secured in grooves of

A/C compressor, AIR pump, generator, and

crankshaft pulleys.

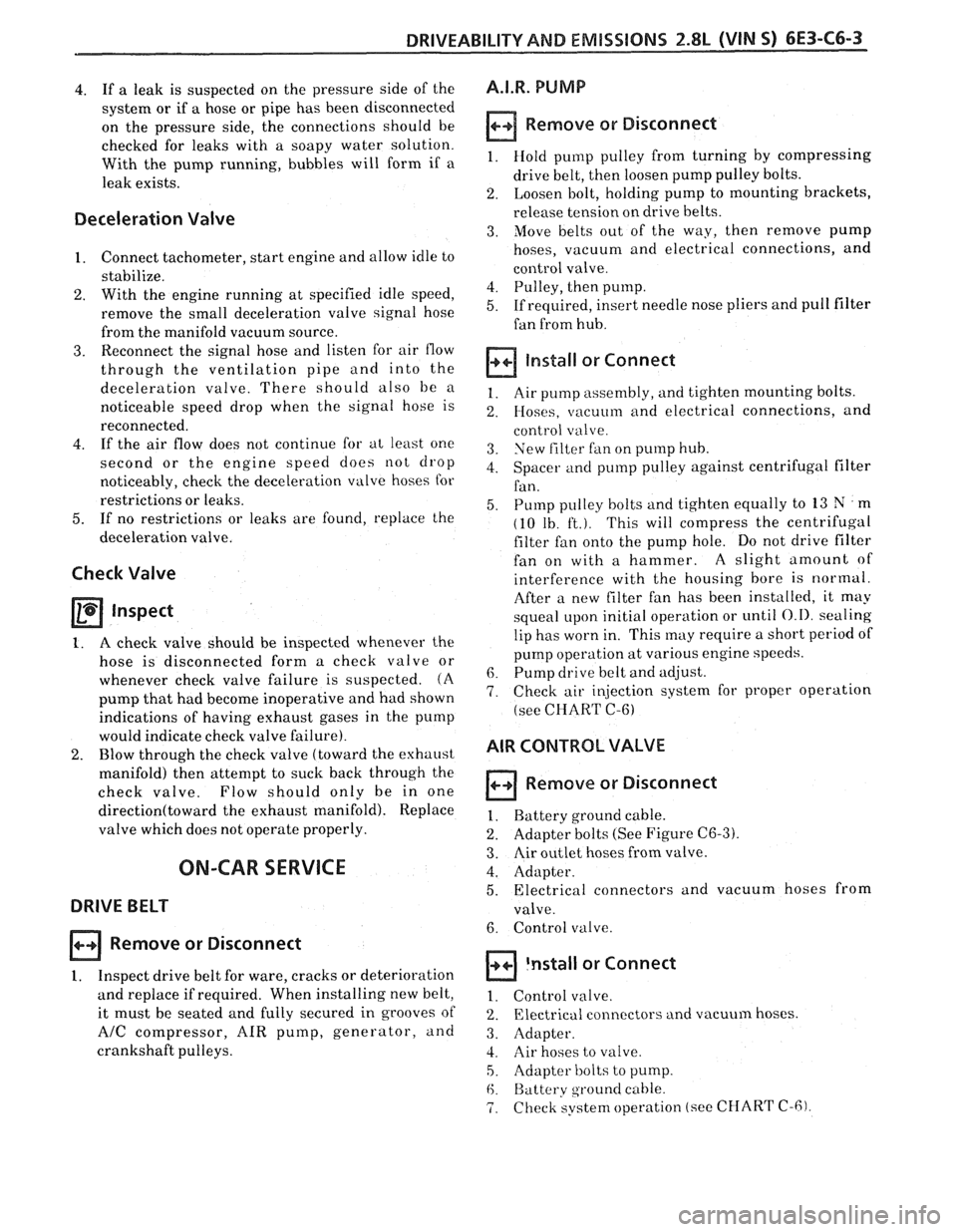

A.I.R. PUMP

Remove or Disconnect

1. Hold pump pulley from turning by compressing

drive belt, then loosen pump pulley bolts.

2. Loosen bolt, holding pump to mounting brackets,

release tension on drive belts.

3. Move belts out of the way, then remove pump

hoses, vacuum and electrical connections, and

control valve.

4. Pulley, then pump.

5. If required, insert needle nose pliers and pull filter

fan from hub.

Install or Connect

1. Air pump assembly, and tighten mounting bolts.

2. I-loses, vacuum and electrical connections, and

control valve

3. New

filter

fan on pump hub.

4. Spacer and pump pulley against centrifugal filter

fan.

5. Pump pulley bolts and tighten equally to 13 N m

(10 lb.

ft.). This will compress the centrifugal

filter fan onto the pump hole. Do not drive filter

fan on with a hammer. A slight amount of

interference with the housing bore is normal.

After a new filter fan has been installed, it

ma?;

squeal upon initial operation or until 0.11, sealing

lip has worn in. This

may require a short period of

purnp operation at various engine speeds.

6. Pump drive belt and adjust.

a Lon 7. Check air injection system for proper oper t'

(see CHART C-6)

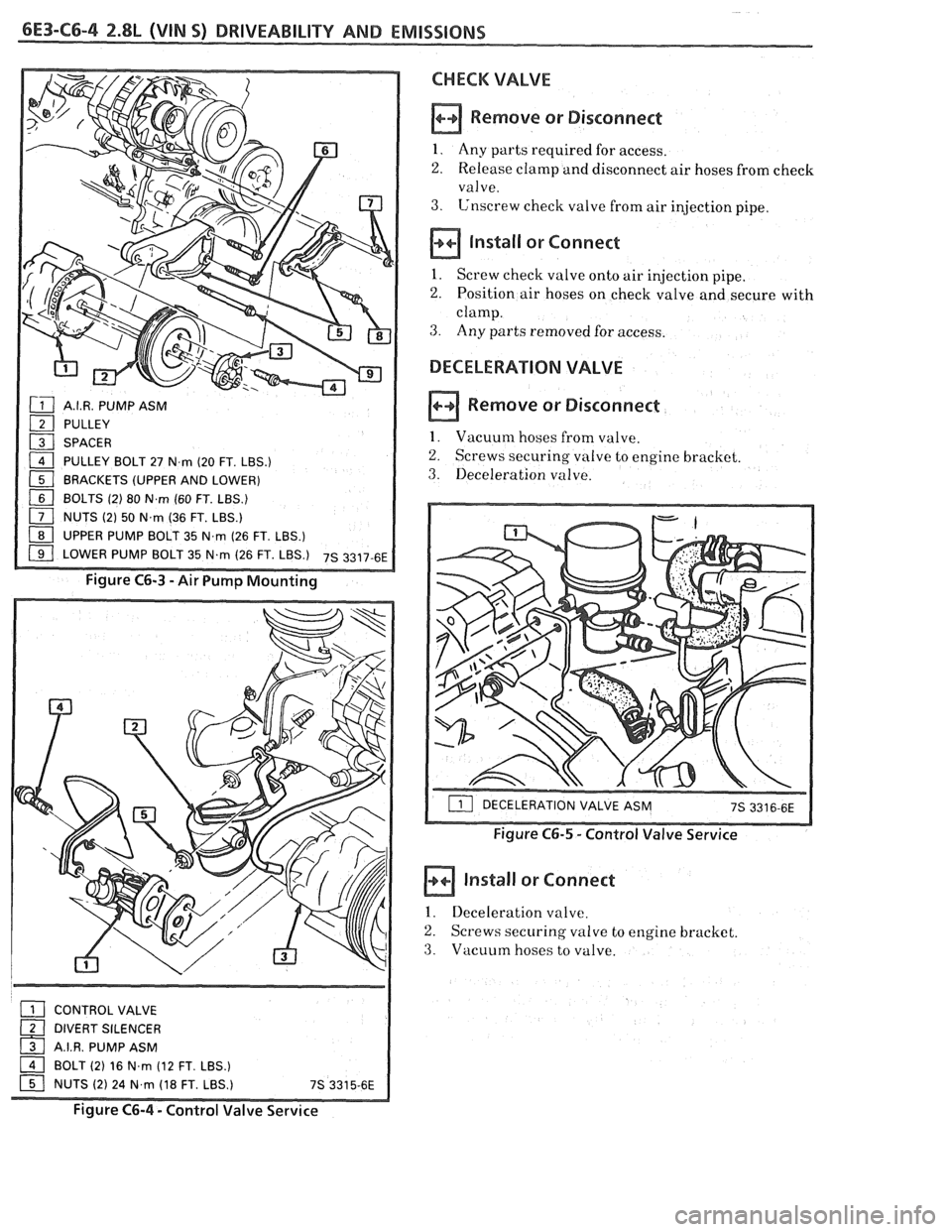

AIR CONTROL VALVE

Remove or Disconnect

1. Battery ground cable.

2. Adapter bolts (See Figure C6-3).

3. Air outlet hoses from valve.

4. Adapter.

5. Electrical connectors and vacuum hoses from

valve. ve.

6. Control

va 1

Install or Connect

1. Control valve.

2. Electrical connectors and vacuum hoses.

3. Adapter.

4. Air hoses to valve.

5. Adapter bolts to pump.

6 Batterv ground crtble.

7. Check system operation (see CHART C-6)

Page 773 of 1825

6E3-C6-4 2.8L (WIN S) DRIVEABILITY AND EMlSDlONS

A.I.R. PUMP ASM

PULLEY

SPACER

PULLEY BOLT 27 N

rn (20 FT. LBS.)

BRACKETS (UPPER AND LOWER)

[ BOLTS (2) 80 Nm (60 FT. LBS.)

NUTS (2) 50 N.rn (36 FT. LBS.)

( UPPER PUMP BOLT 35 N,rn (26 FT. LBS.)

( LOWER PUMP BOLT 35 N.rn (26 FT. LBS.) 7s 3317-6E

Figure C6-3 -Air Pump Mounting

CONTROL VALVE

( DIVERT SILENCER

1 A.I.R. PUMP ASM

CHECK VALVE

Remove or Disconnect

1. Any parts required for access.

2. Release clamp and disconnect air hoses from check

valve.

3. Unscrew check valve from air injection pipe.

install or Connect

1. Screw check valve onto air injection pipe.

2. Position air hoses on check valve and secure with

clamp.

3. Any parts removed for access.

DECELERATION VALVE

Remove or Disconnect

1. Vacuum hoses from valve.

2. Screws securing valve to engine bracket.

3. Deceleration valve.

Figure C6-5 - Control Valve Service

Install or Connect

1. Deceleration valve.

2. Screws securing valve to engine bracket.

3. Vacuum hoses to valve.

1 BOLT (2) 16 N.rn (12 FT. LBS.)

1 NUTS (2) 24 N.rn (18 FT. LBS.) 7s 3315-6E

Figure C6-4 - Control Valve Service

Page 774 of 1825

DRIVEABILITY AND EMISSIONS 2.8L (VIN 0) 6E3-C6-5

PART NAME CROUP

Bracket. AIR Inj Pump Supt (RR) .........

Bracket. AIR Inj Pump (Frt) .............

Bracket. Dclr Vlv ....................

Gasket. AIR Cont Vlv ..................

IIose. AIR 111j Cont Vlv .................

........ Ilose. Clcase Vent Pipe to Dclr Vlv

Pipe . AIR 1n.j Ctltc Conv Chk Vlv .........

Pipe . AIR Inj Cont Vlv .................

Pulley. AIR tnj Pump .................

Punlp. AIR Ini .......................

Silencer. AIR Inj Corit Vlv ..............

Valve. AIR Inj Cont ...................

Valve. AIR I11j Eng Ckik ................

Valve. Ilclr ..........................

Page 775 of 1825

6E3-C6-6 2.8L (VIN S) DRlVEABlLlTY AND EMISSIONS

AIR SOLENOID

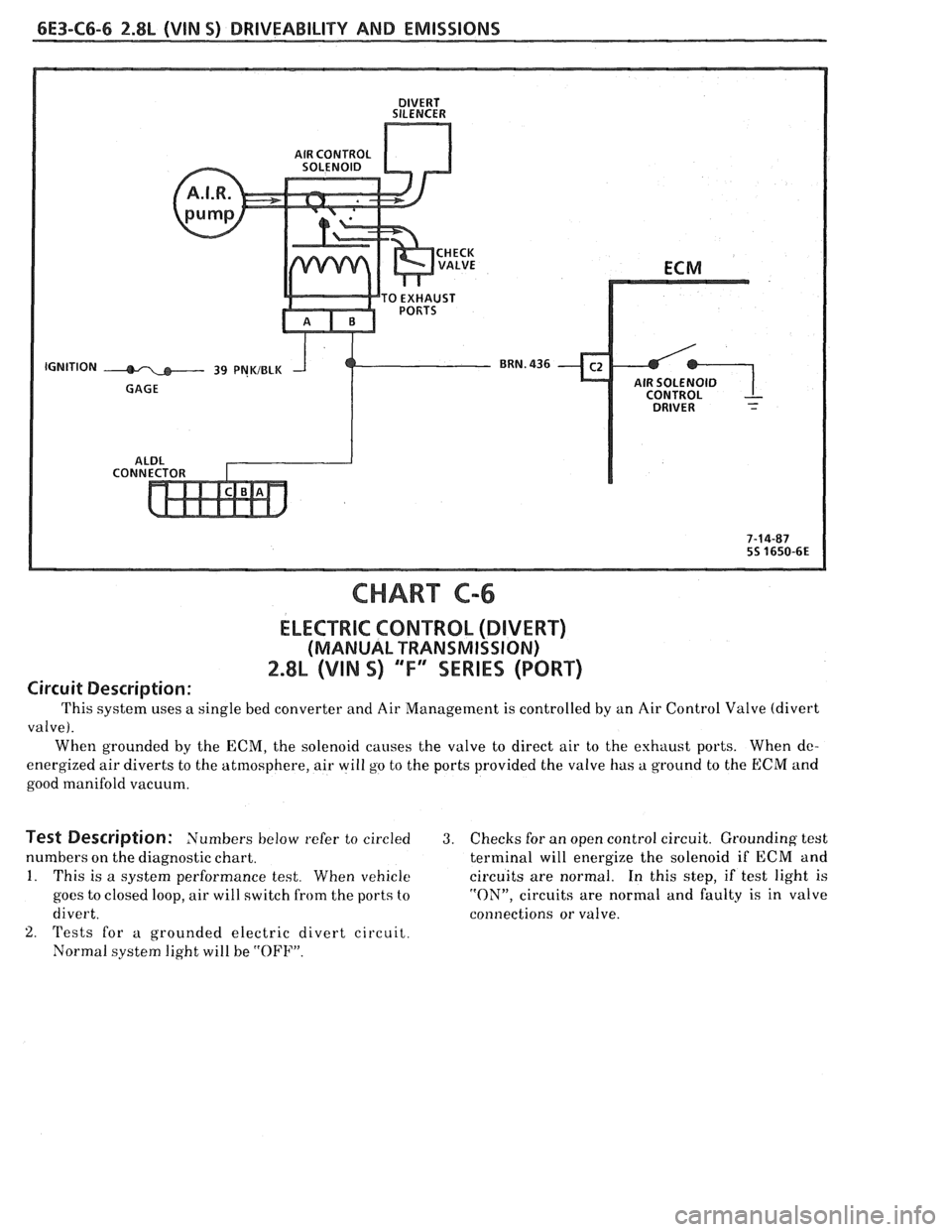

CHART C-6

ELECTRIC CONTROL (DIVERT)

(MANUAL TRANSMISSION)

2.8L (VIN S) "'F" SERIES (PORT)

Circuit Description:

This system uses a single bed converter and Air Management is controlled by an Air Control Valve (divert

valve).

When grounded by the ECM, the solenoid causes the valve to direct air to the exhaust ports. When

dc-

energized air diverts to the atmosphere, air will go to the ports provided the valve has a ground to the ECM and

good manifold vacuum.

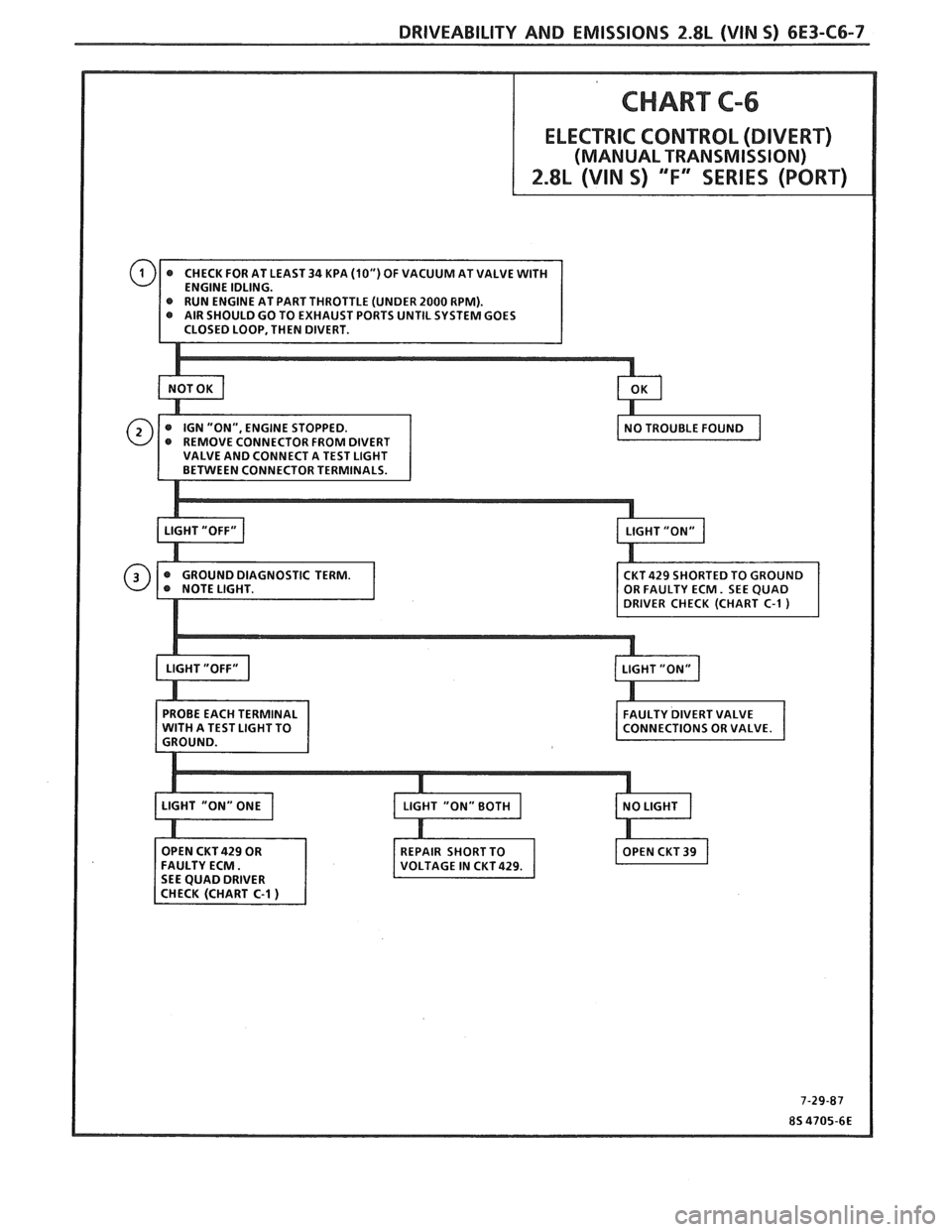

Test Description: Numbers below refer to circled 3. Checks for an open control circuit. Grounding test

numbers on the diagnostic chart. terminal will energize the solenoid if ECM and

1. This is a system performance test. When vehicle circuits are normal. In this step, if test light is

goes to closed loop, air will switch from the ports to "ON", circuits are normal and faulty is in valve

divert. connections or valve.

2. 'rests for a grounded electric divert circuit.

Normal system light will be

"OFF".

Page 776 of 1825

DRIVEABILITY AND EMISSIONS 2.8L (VIM 5) 6E3-C6-7

LE (UNDER 2000 RPM).

PORTS UNTIL SYSTEM GOES

Page 777 of 1825

6E3-C6-8 2.8L (WIN S) DRIVEABILITY AND EMISSIONS

BLANK

Page 778 of 1825

DRIVEABILITY AND EMISSIONS 2.8L (VIN 5) 6E3-C7-1

SECTION C7

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

CONTENTS

GENERAL DESCRIPTION ................ C7-1

PURPOSE

......................... C7-1

OPERATION

....................... C7-1

ELECTRONIC VACUUM REGULATOR

VALVE

........................... C7-1

PORT EGR VALVE

................... C7-2

EGR VALVE IDENTIFICATION..

......... C7-2

RESULTS OF INCORRECT OPERATION

... C7-2

DIAGNOSIS

......................... C7-3

GENERAL DESCRIPTION

PURPOSE

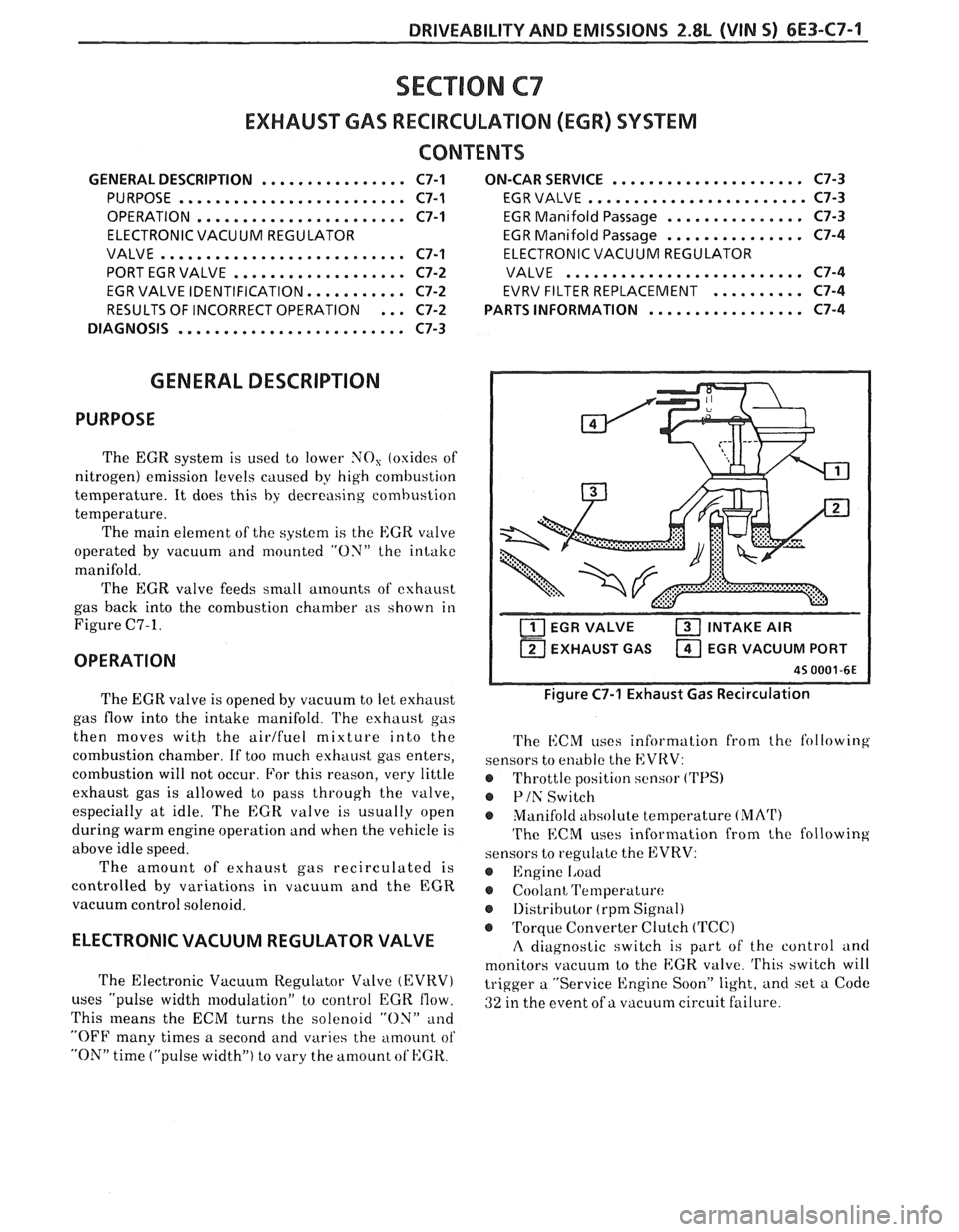

The EGR system is used to lower NO, (oxides of

nitrogen) emission levels caused by high combustion

temperature. It does this

by decreasing combustion

temperature.

The main element of the system is the

EGR valve

operated by vacuum and mounted

"ON" the intake

manifold.

The EGR valve feeds small

amounts of exhaust

gas back into the combustion chamber as shown in

Figure C7-1.

OPERATION

..................... ON-CAR SERVICE C7-3

EGR VALVE

........................ C7-3

EGR Manifold Passage

............... C7-3

EGR Manifold Passage

............... C7-4

ELECTRONIC VACUUM REGULATOR

VALVE

.......................... C7-4

EVRV FILTER REPLACEMENT

.......... C7-4

................. PARTS INFORMATION C7-4

EGR VALVE INTAKE AIR

1 EXHAUST GAS EGR VACUUM PORT I

The EGR valve is opened by vacuum to let exhaust

gas flow into the intake manifold.

l'he exhaust gas

then moves

witb the airlfuel mixture into the

combustion chamber. If too much exhaust gas enters,

combustion will not occur. For this reason, very little

exhaust gas is allowed to pass through the valve,

especially at idle. The

EGR valve is usually open

during warm engine operation and when the vehicle is

above idle speed.

The amount of exhaust gas recirculated is

controlled by variations in vacuum and the EGR

vacuum control solenoid.

ELECTRONIC VACUUM REGULATOR VALVE

The Electronic Vacuum Regulator Valve (EVRV)

uses "pulse width modulation" to control EGK flow.

This

means the ECM turns the solenoid "ON" and

"OFF many times a second and varies the amount of

"ON" time ("pulse width") to vary the amount ot'HGK.

Figure C7-1 Exhaust Gas Recirculation

The i1:CM uses information from the following

sensors to enable the EVRV:

@ Throttle position sensor ('I'PS)

@ Plh' Switch

Manifold

ahsolute temperature (MArI')

The ECM uses information from the following

sensors to regulate the EVRV:

@ Engine 1,oad

Coolant Temperature

@ 1)istributor (rpm Signal)

@ Torque Converter Clutch (TCC)

A diagnostic switch is part of the control and

monitors vacuum to the

EGK. valve. 'I'his switch will

trigger a "Service Engine Soon" light, and set a Code

ai ure. 32 in the event of a vacuum circuit f 'I

Page 779 of 1825

EXHAUST GAS VALVE OPEN

INTAKE AIR

171 VALVE CLOSED

VACUUM PORT

/ SPRING 4s 05366E

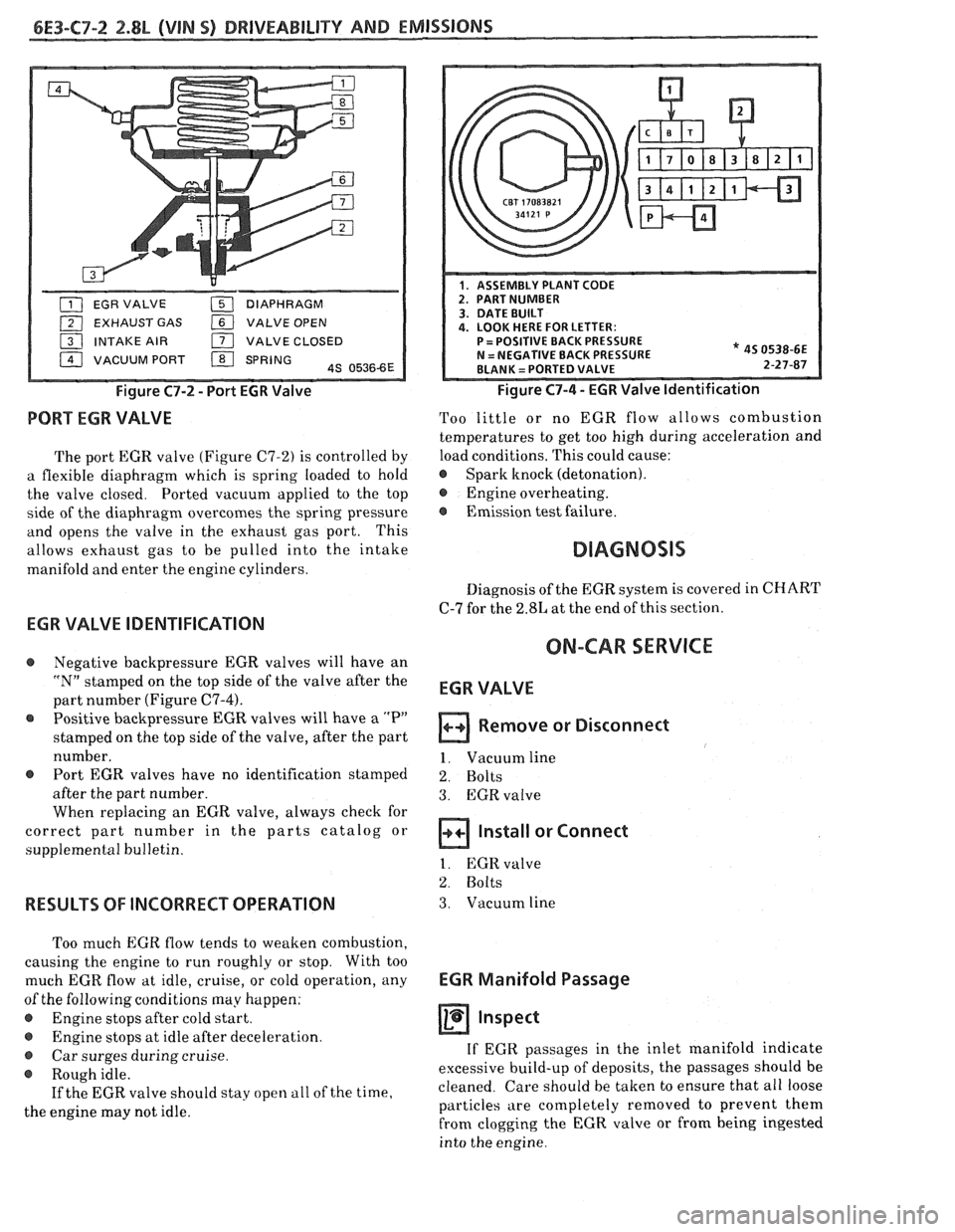

Figure C7-2 - Port EGR Valve

PORT EGR VALVE

The port EGR valve (Figure C7-2) is controlled by

a flexible diaphragm which is spring loaded to hold

the valve closed. Ported vacuum applied to the top

side of the diaphragm overcomes the spring pressure

and opens the valve in the exhaust gas port. This

allows exhaust gas to be pulled into the intake

manifold and enter the engine cylinders.

* 45 0538-6E 2-27-87

Figure C7-4 - EGR Valve Identification

Too little or no EGR flow allows combustion

temperatures to get too high during acceleration and

load conditions. This could cause:

@ Spark knock (detonation).

@ Engine overheating.

@ Emission test failure.

Diagnosis of the EGR system is covered in CHART

C-7 for the 2.8L at the end of this section.

EGR VALVE IDENTIFICATION

ON-CAR SERVICE @ Negative backpressure EGR valves will have an

"N" stamped on the top side of the valve after the

part number (Figure

C7-4).

Positive backpressure EGR valves will have a "P"

stamped on the top side of the valve, after the part

number.

@ Port EGR valves have no identification stamped

after the part number.

When replacing an EGR valve, always check for

correct part number in the parts catalog or

supplemental bulletin.

RESULTS OF INCORRECT OPERATION

Too much EGR flow tends to weaken combustion,

causing the engine to run roughly or stop. With too

much EGR flow at idle, cruise, or cold operation, any

of the following conditions may happen:

@ Engine stops after cold start.

e Engine stops at idle after deceleration.

@ Car surges during cruise.

@ Rough idle.

If the EGR valve should stay open

a11 of the time,

the engine may not idle.

EGR VALVE

Remove or Disconnect

1. Vacuum line

2. Bolts

3. EGRvalve

Install or Connect

1. EGR valve

2. Bolts

3. Vacuum line

EGR Manifold Passage

Inspect

If EGR passages in the inlet manifold indicate

excessive build-up of deposits, the passages should be

cleaned. Care should be taken to ensure that all loose

particles are completely removed to prevent them

from clogging the EGR valve or from being ingested

into the engine.

Page 780 of 1825

DRIVEABILITY AND EMISSIONS 2.8L (VIM 5) 6E3-C7-3

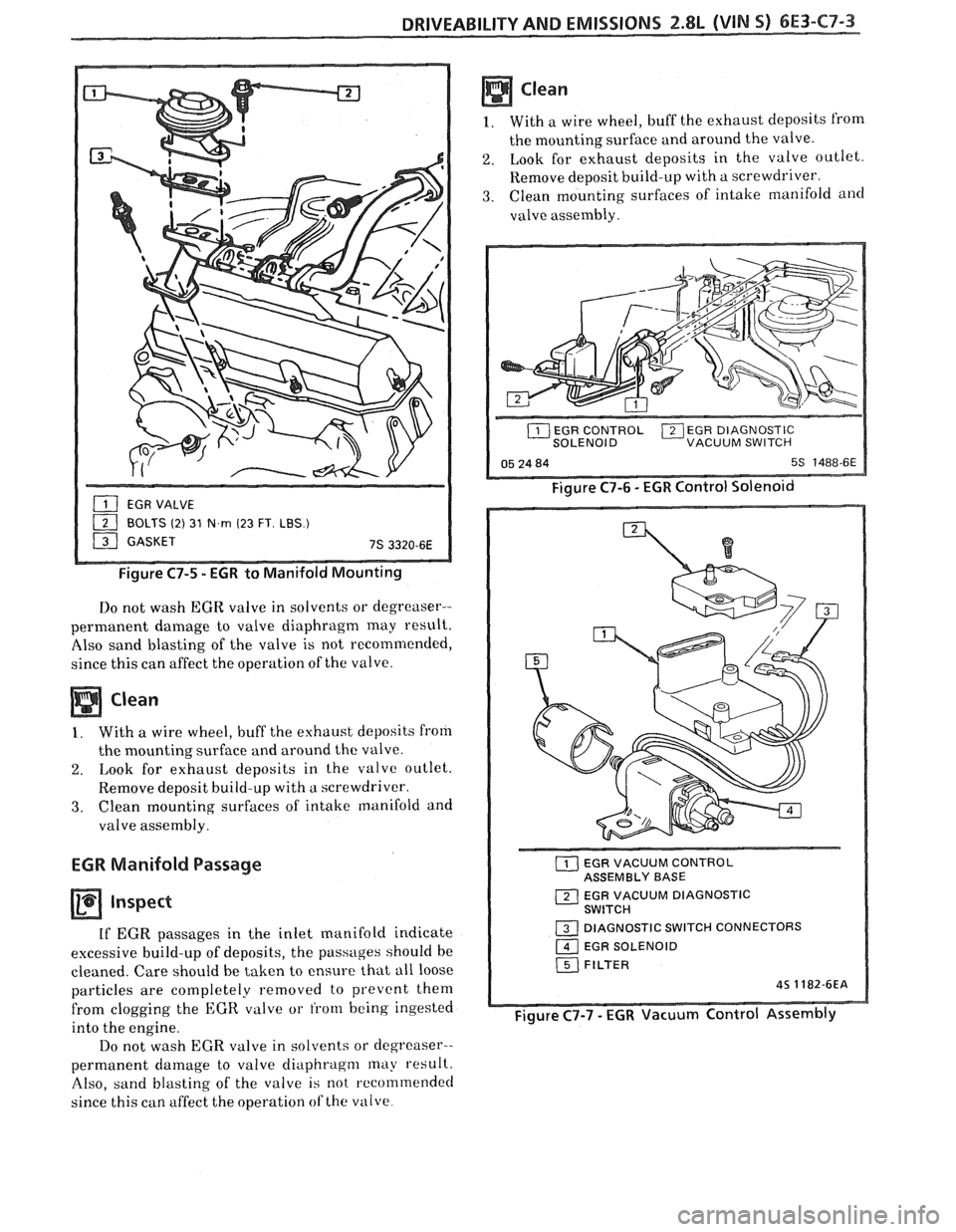

- Figure C7-5 - EGR to Manifold Mounting

Do not wash EGR valve in solvents or degreaser--

permanent damage to valve diaphragm

may result.

Also sand blasting of the valve is not recommended,

since this can affect the operation of the valve.

1. With a wire wheel, buff the exhaust deposits fro111

the mounting surface and around the valve.

2. Look for exhaust deposits in the valve outlet.

Remove deposit build-up with a screwdriver.

3. Clean mounting surfaces of intake manifold and

valve assembly.

EGR Manifold Passage

a Inspect

If EGR passages in the inlet manifold indicate

excessive build-up of deposits, the passages should be

cleaned. Care should be taken to ensure that

a11 loose

particles are completely removed to prevent them

from clogging the

EGR valve or from being ingested

into the engine.

Do not wash

EGR valve in solvents or clegrcaser--

permanent damage to valve diaphragm may result.

Also, sand blasting of the valve is

not 1.ccomrnendec1

since this can affect the operation of the villve

Clean

1. With a wire wheel, buff the exhaust deposits from

the mounting surface and around the valve.

2. Look for exhaust deposits in the valve outlet.

Remove deposit build-up with a screwdriver.

3. Clean mounting surfaces of intake manifold and

valve assembly.

EGR CONTROL ~EGR DIAGNOSTIC SOLENOID VACUUM SWITCH

Figure C7-6 - EGR Control Solenoid

( EGR VACUUM CONTROL

ASSEMBLY BASE

( EGR VACUUM DIAGNOSTIC SWITCH

1 DIAGNOSTIC SWITCH CONNECTORS

1 EGR SOLENOID

FILTER

45 1182-6EA

Figure C7-7 - EGR Vacuum Control Assembly