diagram RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 4 of 208

Page

Cooling

Specifications

Filling and bleeding

Testing

Diagram

Water pump

Exhaust

General

Exhaust pipe assembly

Fuel tank

Tank

Sender unit

Pump and sender unit assembly

Engine suspension

Suspended engine mountings19-1

19-2

19-3

19-4

19-7

19-12

19-15

19-17

19-29

19-30

19-32 COOLING - EXHAUST - FUEL TANK -

ENGINE SUSPENSION

19

16-1

16-7 STARTING - CHARGING

Alternator

Starter

16

IGNITION - INJECTION

Ignition

Static ignition

Plugs

Injection

General

Location of components

Centralised coolant temperature

management

Injection fault warning light

Immobiliser function

Computer configuration depending

on gearbox type17

14-1

14-2

14-7

14-11 ANTIPOLLUTION

Test for the presence of lead

Fuel vapour rebreathing

Oil vapour rebreathing

Exhaust gas recirculation

(EGR)

14

17-17

17-18

17-19

17-20

17-22 IGNITION - INJECTION

(continued)

Injection/air conditioning

programming

Idle speed correction

Adaptive idle speed

correction

Richness regulation

Adaptive richness correction

17

Page

17-1

17-3

17-4

17-8

17-13

17-14

17-15

17-16

Contents

Page 15 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

Insert a wooden block between the gearbox and

the sub-frame.

Diagram showing the holes drilled in tool Mot.

1040-01 (dimensions in mm).

10

Disconnect the gear control:

- at the position of the gearbox output lever af-

ter releasing the gaiter,

- at the level of the gear lever after removing

the central heat shield.

Pull the control lever (2) towards the rear of the

vehicle.

10621R

Fit tool Mot. 1379 onto the sub-frame and take

the weight off the right-hand engine mounting,

using the threaded rod (1).

10267R1

93912R2

Fix tool Mot. 1040-01 underneath the sub-frame,

having first fitted the shims Mot. 1379 onto this

tool.

92442-1R2

D7F engine

10-11

Page 18 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

Front sub-frame mounting bolt 6.2

Rear sub-frame mounting bolt 10.5

Mounting bolt for front right suspended

engine mounting cover on engine 6.2

Mounting nut for front right suspended

engine mounting cover 4.4

Mounting nut for rubber engine mounting pad

on front left-hand side member support 6.2

Shock absorber base bolt 18

Brake caliper mounting bolt 4

Steering shaft yoke bolt 3

Wheel bolt 9

TIGHTENING TORQUES (in daN.m)

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Drain:

- the cooling circuit through the bottom hose

of the radiator,

- the gearbox and the engine if necessary.

Remove:

- the bonnet,

- the front wheels,

- the tie-rods between sub-frame and body,- the mounting bolts (1); pull away the brake

calipers as shown in the diagram below and

attach them to the suspension springs,

12994R1

- the shock absorber base bolts, E7J engine

SPECIAL TOOLING REQUIRED

Mot. 1040-01 Dummy sub-frame for removing

and refitting engine and

transmission assembly

Mot. 1159 Tool for maintaining engine on

sub-frame

Mot. 1202

Mot. 1448

Mot. 1311-06 Tool for removing fuel pipe

Hose clip pliers

10-14

Page 19 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

13085R

- the exhaust heat shield and the gear control

on the lever and gearbox sides,

12988R

- the exhaust pipe clamp between the catalytic

converter and the expansion chamber,

- the earth strap on the gearbox,

- the front bumper,

- the air intake pipe from the air filter,

- the injection computer support after dis-

connecting the 55 track connector and that of

the impact switch.

13088R2

Disconnect:

- the wiring connections and the hoses on the

thermostat support,

- the hoses on the expansion bottle,

- the brake servo pipe,

- the heater hoses (there are two types of as-

sembly to be disconnected, as shown in the

diagrams below),

13084R

E7J engine

10-15

Page 23 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

SPECIAL TOOLING REQUIRED

Mot. 1040-01 Dummy sub-frame for removing -

refitting the engine and

transmission assembly

Mot. 1159 Tool for maintaining engine on

sub-frame

Mot. 1202

Mot. 1448

Mot. 1311-06 Tool for removing fuel pipe

Front sub-frame mounting bolt 6.2

Rear sub-frame mounting bolt 10.5

Mounting bolt for front right suspended engine

mounting cover on engine 6.2

Mounting nut for front right suspended engine

mounting cover 4.4

Mounting nut for rubber engine mounting

pad on front left side member support 6.2

Shock absorber base bolt 18

Brake caliper mounting bolt 4

Steering shaft yoke bolt 3

Wheel bolt 9

TIGHTENING TORQUES (in daN.m)

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Drain:

- the cooling circuit through the bottom hose

of the radiator,

- the gearbox and the engine if necessary.

Remove:

- the bonnet,

- the front wheels,

- the tie-rods between sub-frame and body,- the mounting bolts (1); pull away the brake

calipers as shown in the diagram below and

attach them to the suspension springs,

12994R1

- the shock absorber base bolts, F8Q engine

Hose clip pliers

10-19

Page 25 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

Remove the computer support.

13088R1

Disconnect:

- the hoses on the expansion bottle,

- the brake servo pipe,

- the heater hoses (there are two types of as-

sembly to be disconnected, as shown in the

diagrams below),

13085R

F8Q engine

11734R

For the locking of the quick release unions, refer

to the diagrams below:

11733R

10-21

Page 32 of 208

ENGINE AND ENGINE PERIPHERALS

Sump

10

REFITTING

Clean the sump.

E7J engine

Apply an approximately 3 mm wide bead of

RHODORSEAL 5661 as shown in the diagram be-

low.

E7J / F8Q

engines

99179S

Do not forget to replace the two half-moon gas-

kets on each side of the sump.

F8Q engine

Fit a new after-sales gasket.

Refitting is the reverse of removal.

10-28

Page 60 of 208

TOP AND FRONT OF ENGINE

Cylinder head gasket

11

13083-1R1

To release the quick release unions, refer to the

following diagrams.

11734R

F8Q Engine

11-25

Page 128 of 208

ANTIPOLLUTION

Fuel vapour rebreathing

14

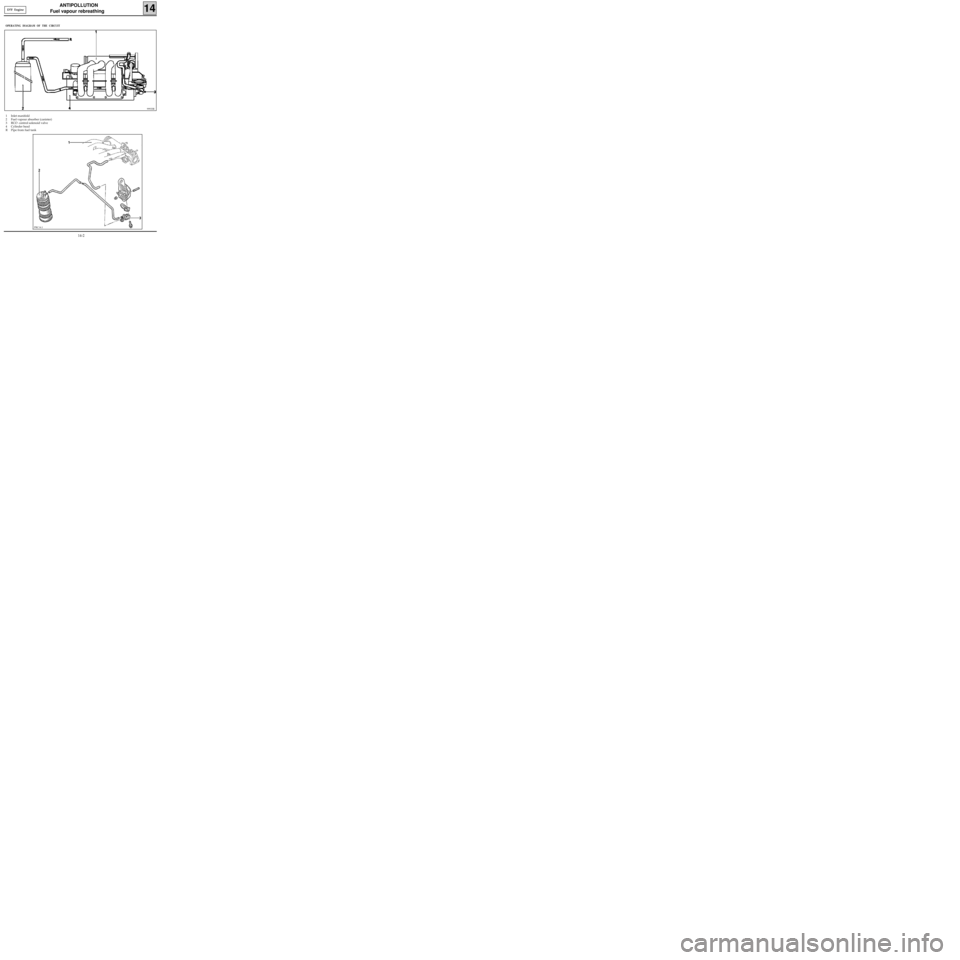

OPERATING DIAGRAM OF THE CIRCUIT

1 Inlet manifold

2 Fuel vapour absorber (canister)

3 RCO control solenoid valve

4 Cylinder head

R Pipe from fuel tank

99933R

PRC14.1

D7F Engine

14-2

Page 129 of 208

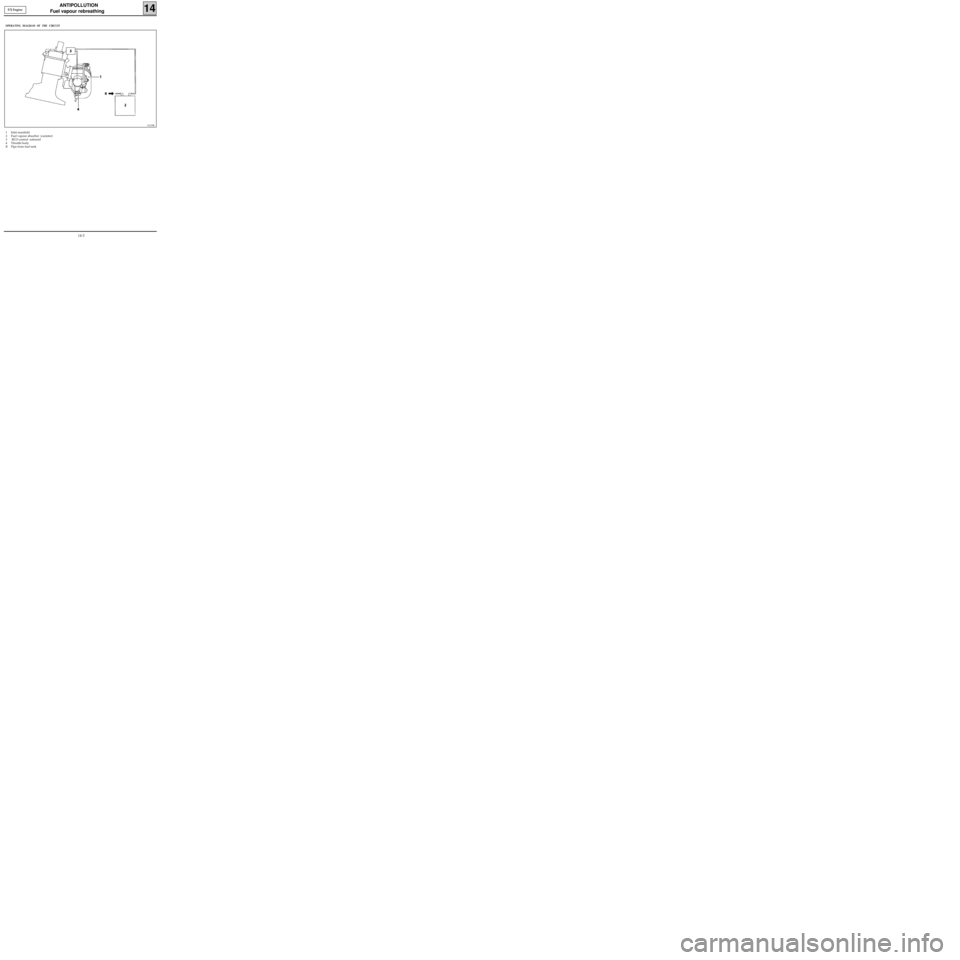

ANTIPOLLUTION

Fuel vapour rebreathing

14E7J Engine

OPERATING DIAGRAM OF THE CIRCUIT

1 Inlet manifold

2 Fuel vapour absorber (canister)

3 RCO control solenoid

4 Throttle body

R Pipe from fuel tank

13123R

14-3