ignition RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 109 of 208

DIESEL EQUIPMENT

Computer configuration

13

PROGRAMMING THE FULL LOAD POSITION

Switch the ignition off.

Replace the computer.

Carry out the programming of the full load position; in order to do this :

Switch the ignition on.

Connect the

XR25.

Set the selector to S8.

Enter code

Enter code

When the display flashes "PF", press the accelerator pedal down as far as it will go.

The programming is complete when

the screen displays the following

wording: D

34

G31*

Bargraph N.12 on the right hand side should now be extinguished.

Switch the ignition off.

DPCN LUCAS injection computers are configured before sale to "with air conditioning". If the vehicle is not

fitted with an air conditioning system, use command G50*4* on the

XR25 to carry out the "no air conditio-

ning " programming.

DPCN LUCAS "injection computers are configured before sale to "with power assisted steering " (power as-

sisted steering with pump assembly). If the vehicle is not fitted with a power assisted steering pump as-

sembly, use command G50*9* on the

XR25 to carry out the "no power assisted steering pump assembly"

programming.then

13-29

Page 112 of 208

DIESEL EQUIPMENT

Injection warning light

13

OPERATING PRINCIPLE OF THE DIESEL INJECTION WARNING LIGHT ON THE INSTRUMENT PANEL

On switching on the ignition, the diesel injection fault warning light is illuminated. It extinguishes as the en-

gine begins to run.

•Fault in a component of the injection assembly

Faults in the following components may cause the warning light to illuminate :

- injector with sensor

- advance solenoid valve,

- engine speed sensor ,

- load lever potentiometer,

- pre-postheating (according to version).

13-32

Page 113 of 208

DIESEL EQUIPMENT

Pre-postheating control

13

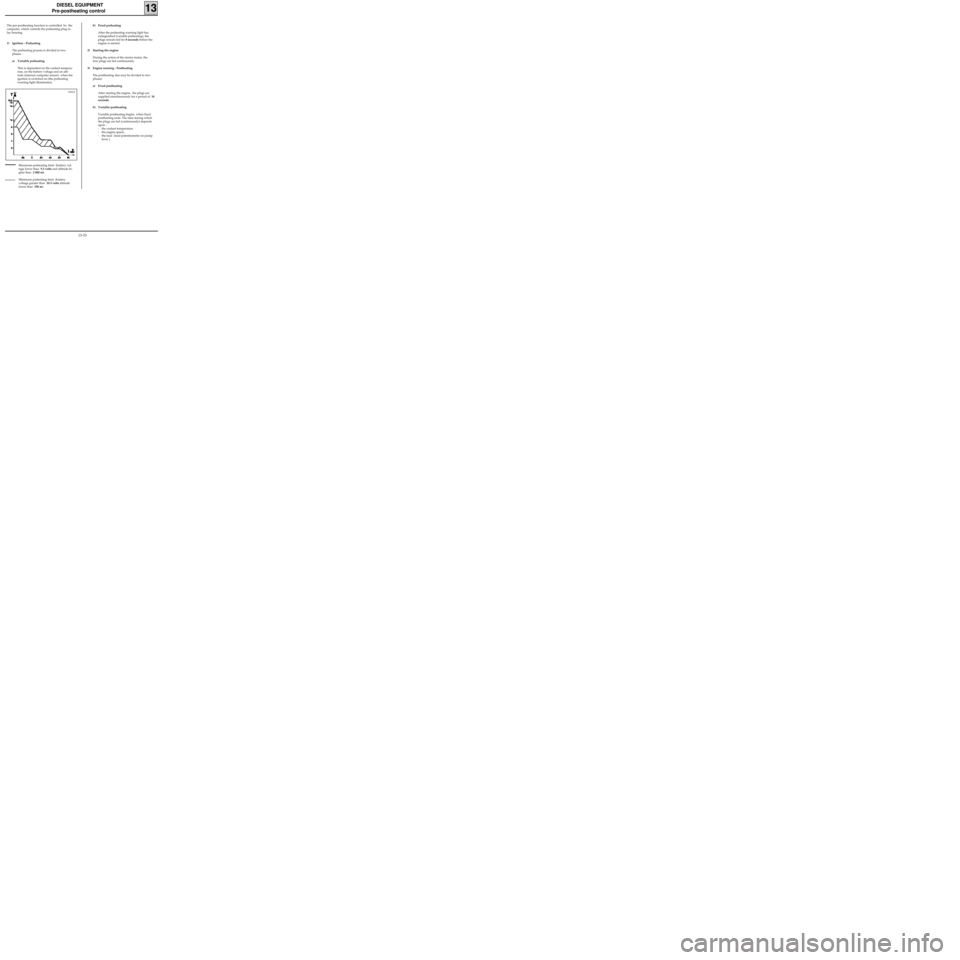

The pre-postheating function is controlled by the

computer, which controls the preheating plug re-

lay housing.

1) Ignition - Preheating

The preheating process is divided in two

phases :

a) Variable preheating

This is dependent on the coolant tempera-

ture, on the battery voltage and on alti-

tude (internal computer sensor) when the

ignition is switched on (the preheating

warning light illuminates).b) Fixed preheating

After the preheating warning light has

extinguished (variable preheating), the

plugs remain fed for 8 seconds before the

engine is started.

2) Starting the engine

During the action of the starter motor, the

four plugs are fed continuously.

3) Engine running - Postheating

The postheating also may be divided in two

phases:

a) Fixed postheating

After starting the engine, the plugs are

supplied simultaneously for a period of 10

seconds.

b) Variable postheating

Variable postheating begins when fixed

postheating ends. The time during which

the plugs are fed (continuously) depends

upon :

- the coolant temperature

- the engine speed ,

- the load (load potentiometer on pump

lever ).

Maximum preheating limit (battery vol-

tage lower than 9.3 volts and altitude hi-

gher than 2 000 m).

Minimum preheating limit (battery

voltage greater than 10.5 volts altitude

lower than 350 m).

13041S

13-33

Page 115 of 208

DIESEL EQUIPMENT

Fast idle speed control

13

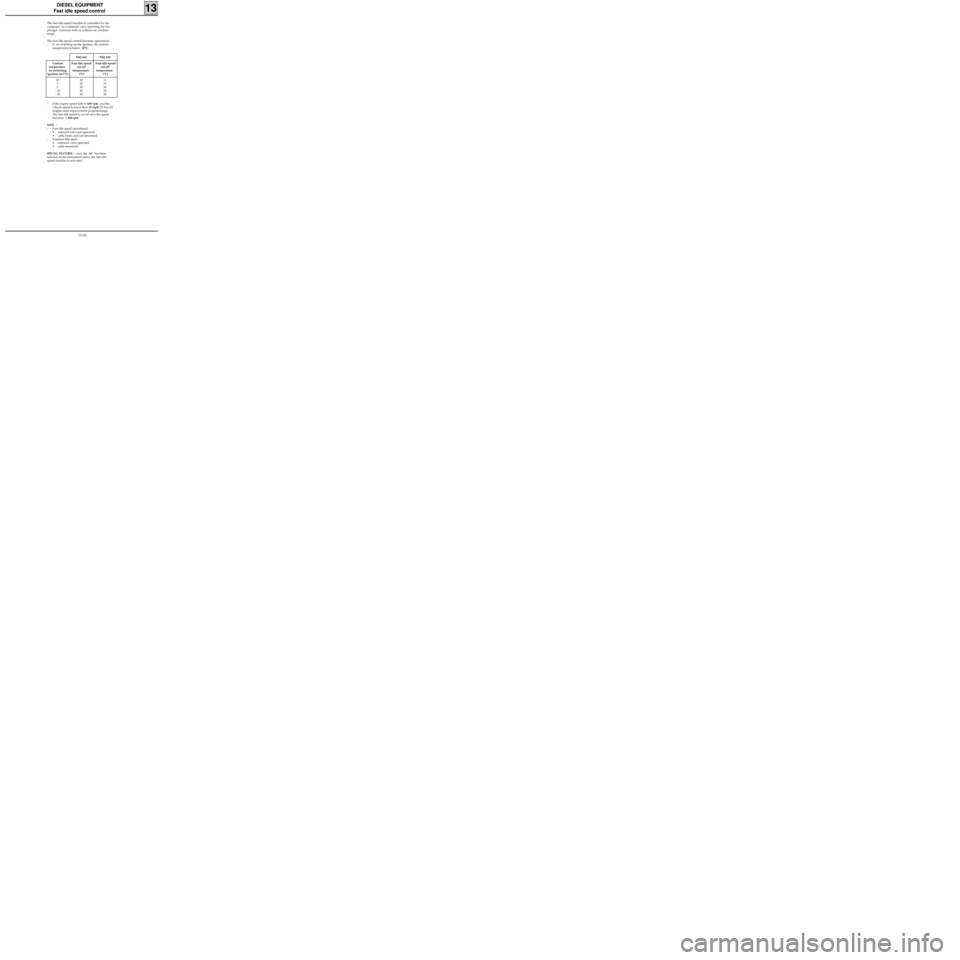

- if the engine speed falls to 650 rpm and the

vehicle speed is lower than 15 mph (25 km/h)

(engine start improvement programming).

The fast idle speed is cut off once the speed

becomes > 850 rpm

NOTE :

- Fast idle speed operational :

• solenoid valve not operated,

• cable loose, and not tensioned.

- Nominal idle sped :

• solenoid valve operated

• cable tensioned

SPECIAL FEATURES : once the AC has been

selected on the instrument panel, the fast idle

speed function is activated. The fast idle speed function is controlled by the

computer via a solenoid valve operating the dia-

phragm (versions with or without air conditio-

ning).

The fast idle speed control becomes operational :

- if, on switching on the ignition, the coolant

temperature is below 10°C,

Coolant

temperature

on switching

ignition on (°C)Fast idle speed

cut-off

temperature

(°C) Fast idle speed

cut-off

temperature

(°C)

10

5

0

- 10

- 2020

20

30

40

5011

15

20

25

30

F8Q 662F8Q 630

13-35

Page 118 of 208

DIESEL EQUIPMENT

Defect modes

13

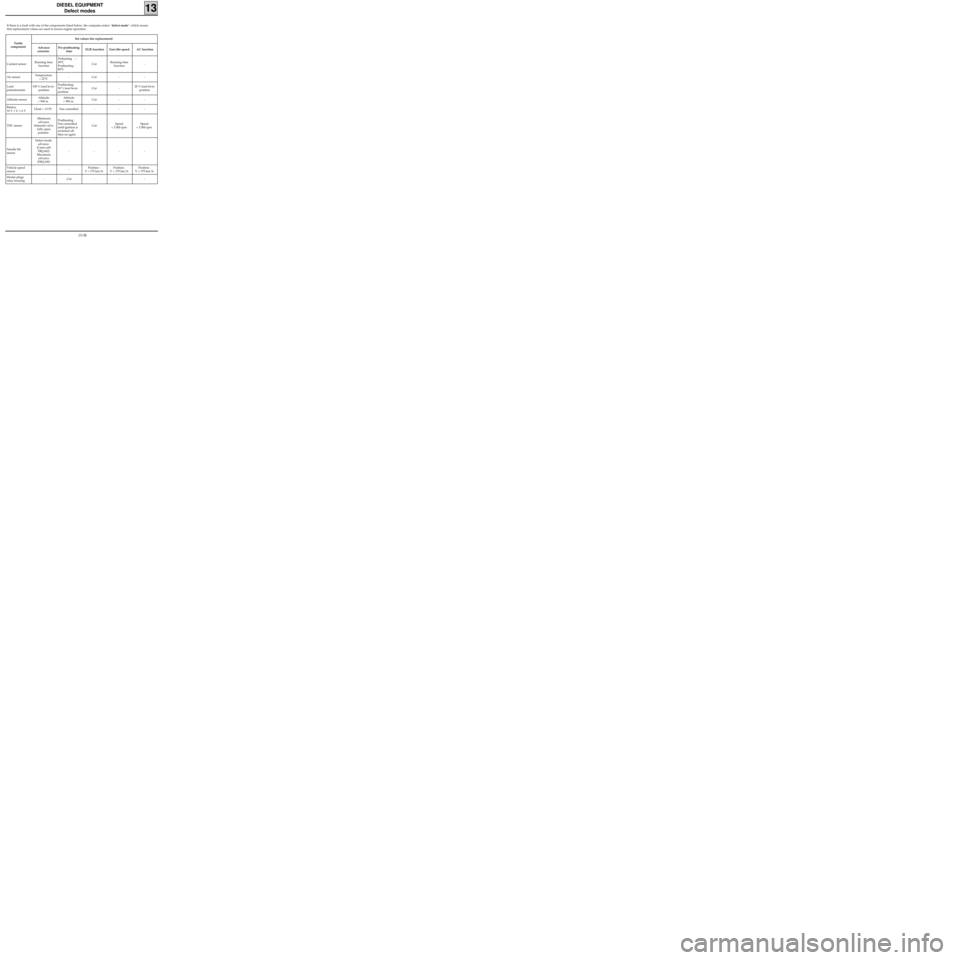

If there is a fault with one of the components listed below, the computer enters "defect mode", which means

that replacement values are used to ensure engine operation.

Faulty

componentSet values (for replacement)

Advance

corrector Pre-postheating

timeEGR function Fast idle speed AC function

Coolant sensorRunning time

functionPreheating : -

30°C

Postheating :

80°CCutRunning time

function-

Air sensorTemperature

= 22°C- Cut - -

Load

potentiometer100 % load lever

positionPostheating:

30 % load lever

position Cut - 20 % load lever

position

Altitude sensorAltitude

= 900 mAltitude

= 900 mCut - -

Battery

16 V < U < 6 VUbatt = 13.5V Not controlled - - -

TDC sensorMinimum

advance

Solenoid valve

fully open

position Postheating :

Not controlled

until ignition is

switched off

then on againCutSpeed

= 2 000 rpmSpeed

= 2 000 rpm

Needle lift

sensorDefect mode

advance

(Carto soft

F8Q 662)

Maximum

advance

(F8Q 630)----

Vehicle speed

sensor--Position :

V = 175 km/hPosition :

V = 175 km/hPosition :

V = 175 km/h

Heater plugs

relay housing- Cut - - -

13-38

Page 131 of 208

ANTIPOLLUTION

Fuel vapour rebreathing

14

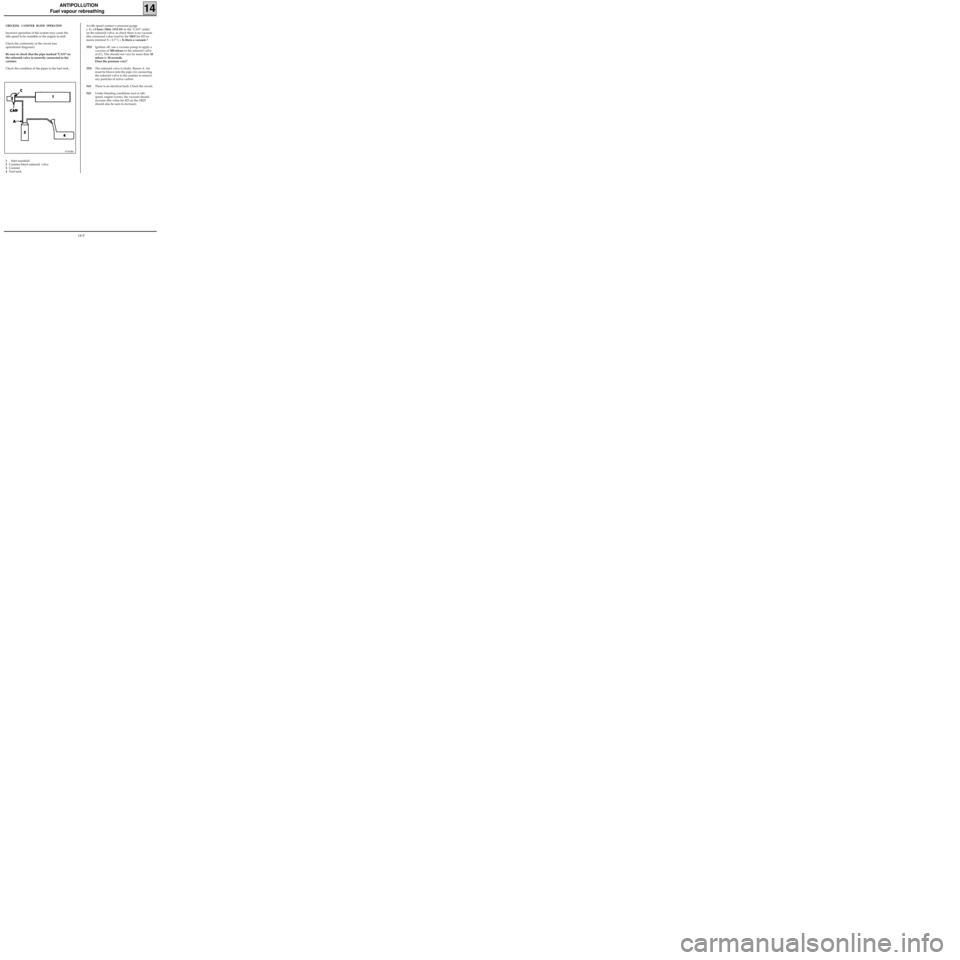

CHECKING CANISTER BLEED OPERATION

Incorrect operation of the system may cause the

idle speed to be unstable or the engine to stall.

Check the conformity of the circuit (see

operational diagrams)

Be sure to check that the pipe marked "CAN" on

the solenoid valve is correctly connected to the

canister.

Check the condition of the pipes to the fuel tank.

97393R6

1Inlet manifold

2Canister bleed solenoid valve

3Canister

4Fuel tankAt idle speed connect a pressure gauge

(- 3 ; +3 bars) (Mot. 1311-01) to the "CAN" outlet

on the solenoid valve, to check there is no vacuum

(the command value read by the

XR25 for #23 re-

mains minimal X = 0.7 % ). Is there a vacuum ?

YESIgnition off, use a vacuum pump to apply a

vacuum of 500 mbars to the solenoid valve

at (C). This should not vary by more than 10

mbars in 30 seconds.

Does the pressure vary?

YESThe solenoid valve is faulty. Renew it. Air

must be blown into the pipe (A) connecting

the solenoid valve to the canister to remove

any particles of active carbon.

NOThere is an electrical fault. Check the circuit.

NOUnder bleeding conditions (not at idle

speed, engine warm), the vacuum should

increase (the value for #23 on the XR25

should also be seen to increase).

14-5

Page 141 of 208

STARTING - CHARGING

Alternator

16

OPERATION - FAULT FINDING

These vehicles are equipped with alternators with

internal ventilation and integral regulator, also

with a warning light on the instrument panel

which has the following functions :

- when the ignition is switched on, the light illu-

minates

- when the engine is started the light extin-

guishes,

- if the light illuminates whilst the engine is

running there is a "charging "fault.

LOOKING FOR FAULTS

The warning light does not illuminate when the

ignition is switched on.

Check:

- all electrical connections are good.

- the bulb has not blown. (Earth the circuit and

the bulb should illuminate).

The warning light illuminates when the engine is

running.

This indicates a charging fault which could be

caused by :

- the alternator drive belt being broken or the

charging wiring being cut,

- internal alternator damage (rotor, stator,

diodes or brush),

- a regulator fault,

- excess voltage.The customer complains of a lack of charge and

the warning light is operating correctly.

If the regulated voltage is less than 13.5 V, check

the alternator. The fault could be caused by :

- a diode which has been damaged,

- a phase which is cut,

- contaminated or worn tracks.

Checking the voltage

Connect a voltmeter across the battery terminals

and read the battery voltage.

Start the engine and increase the engine speed

until the needle registers a stable regulated

voltage.

This voltage should be between 13.5 V and 14.8 V.

Connect as many consumers as possible, the

regulated voltage should be between 13.5 V and

14.8 V.

IMPORTANT: if arc welding work is to be carried

out on the vehicle, the battery and regulator

must be disconnected.

16-2

Page 142 of 208

STARTING - CHARGING

Alternator

16

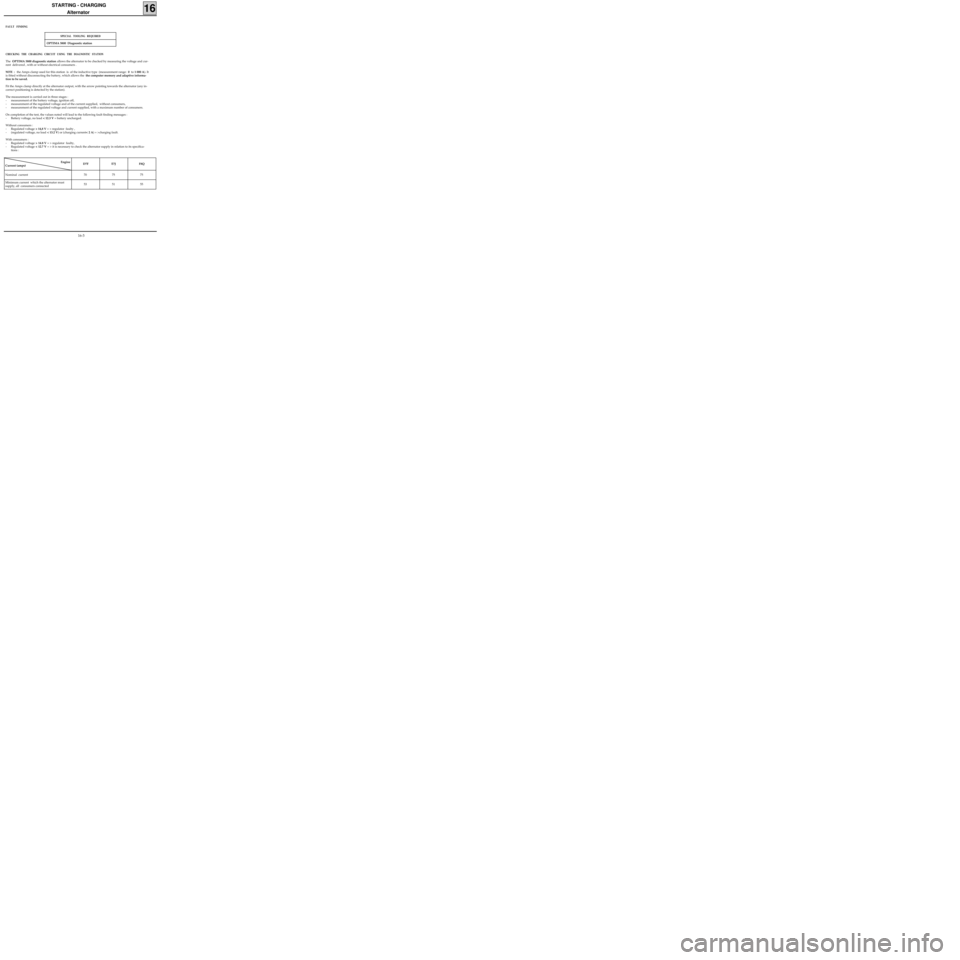

OPTIMA 5800 Diagnostic station

CHECKING THE CHARGING CIRCUIT USING THE DIAGNOSTIC STATION

The OPTIMA 5800 diagnostic station allows the alternator to be checked by measuring the voltage and cur-

rent delivered , with or without electrical consumers .

NOTE : the Amps clamp used for this station is of the inductive type (measurement range: 0 to 1 000 A). It

is fitted without disconnecting the battery, which allows the the computer memory and adaptive informa-

tion to be saved.

Fit the Amps clamp directly at the alternator output, with the arrow pointing towards the alternator (any in-

correct positioning is detected by the station).

The measurement is carried out in three stages :

- measurement of the battery voltage, ignition off,

- measurement of the regulated voltage and of the current supplied, without consumers,

- measurement of the regulated voltage and current supplied, with a maximum number of consumers.

On completion of the test, the values noted will lead to the following fault finding messages :

- Battery voltage, no load < 12.3 V = battery uncharged.

Without consumers :

- Regulated voltage > 14,8 V = > regulator faulty ,

- (regulated voltage, no load < 13.2 V) or (charging current< 2 A) = >charging fault.

With consumers :

- Regulated voltage > 14.8 V = > regulator faulty,

- Regulated voltage < 12.7 V = > it is necessary to check the alternator supply in relation to its specifica-

tions :

Engine

Current (amps)D7F E7J F8Q

Nominal current 70 75 75

Minimum current which the alternator must

supply, all consumers connected 53 51 55

FAULT FINDING

SPECIAL TOOLING REQUIRED

16-3

Page 147 of 208

STARTING - CHARGING

Starter motor

16

OPTIMA 5800 Diagnostic station

CHECKING THE STARTER MOTOR USING THE DIAGNOSTIC STATION

Checking of the starter motor is carried out using the OPTIMA 5800, by measuring the battery voltage and

the current absorbed in the engine starting phase. The following operation faults may be highlighted :

- a fault in the battery ( the voltage falls during the starting phase),

- locking of the starter motor (the current absorbed is too high),

- a fault in the engine starter gear (the current absorbed is too low).

In order to carry out the measurement, it is necessary to stop the vehicle from starting :

- for D7F and E7J engines : disconnect the engine speed sensor (located on the clutch housing ,

- for

F8Q engines : disconnect the pump electrical solenoid and isolate the terminal.

NOTE :

- an open circuit on the engine speed sensor or the ignition creates a fault memorised by the injection

computer, this fault must then be erased from the memory using the

XR25 (see "Injection" section),

- if the engine is fitted with an immobiliser, it is sufficient to lock the doors using the remote control.

FAULT FINDING

SPECIAL TOOLING REQUIRED

16-8

Page 151 of 208

IGNITION

Semi-static ignition

17

PRESENTATION

The system comprises:

- the injection computer (the ignition power

stage is integrated into the computer),

- two dual output coils, (for the

D7F engine,

these are moulded into one),

- four spark plugs,

- an anti-interference condenser (4).

DESCRIPTION - OPERATING PRINCIPLE

COMPUTER

The injection computer (120), depending on the

information received from various sensors, but

principally depending on the engine speed and

load, determines:

- the number of degrees of advance to be used

and consequently the ignition point,

- which cylinders are at TDC and consequently

the ignition coil to be operated.

The spark is created at the two cylinders at TDC by

cutting the earth to the coil concerned.

COILS (1)

There are two coils. They are of the dual output

type (they cannot be separated in the

D7F en-

gine ).

They are controlled separately by the computer.

They create two sparks simultaneously.

Both coils are connected to an anti-interference

condenser.

99931-1R2

D7F Engine

E7J Engine

13242R

Special features of the E7J engine

The coil at (2) has a black electrical connector. It

creates a spark simultaneously at cylinders 1 and

4. It is controlled by track 28 of the injection

computer.

The coil at (3) has a grey electrical connector . It

creates a spark simultaneously at cylinders 2 and

3. It is controlled by track 29 of the injection

computer.

17-1