check engine RENAULT KANGOO 1997 KC / 1.G Foult Finding - Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 363

Page 255 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

55 tracks

Engine warm, at idle speed, after fan assembly has operated at least once(air

conditioning not selected)NOTES

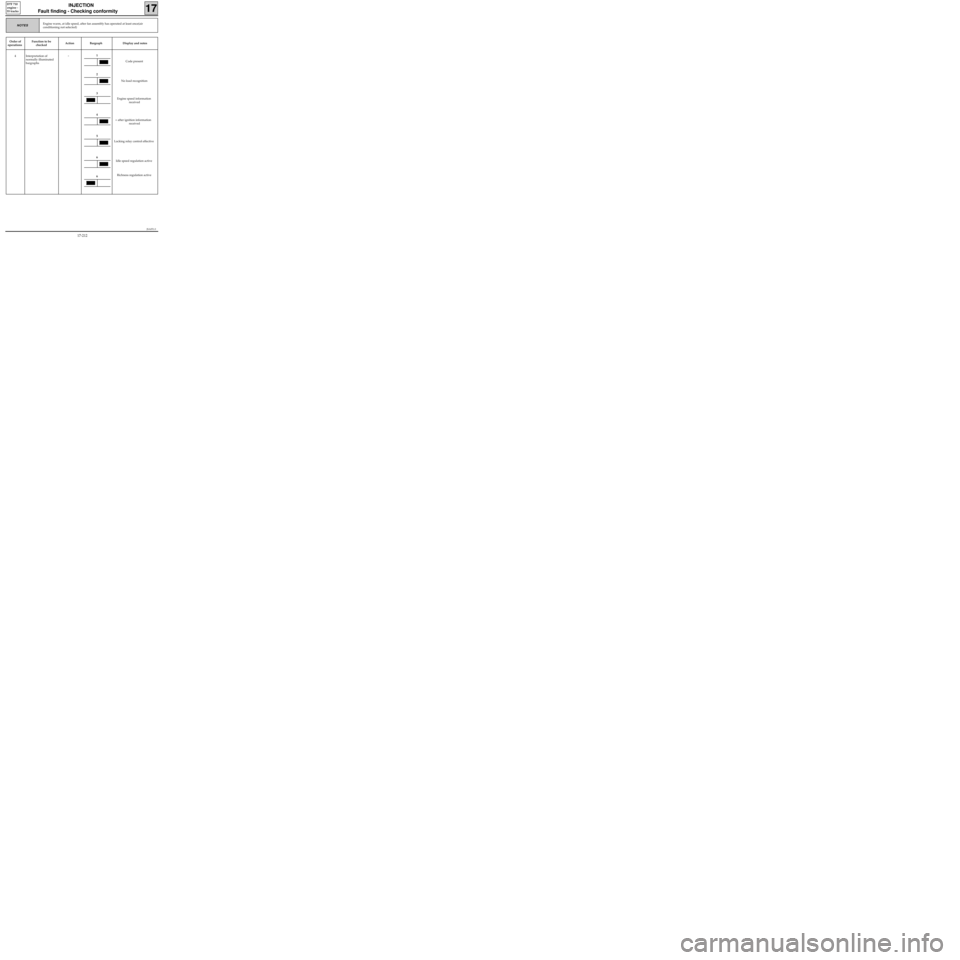

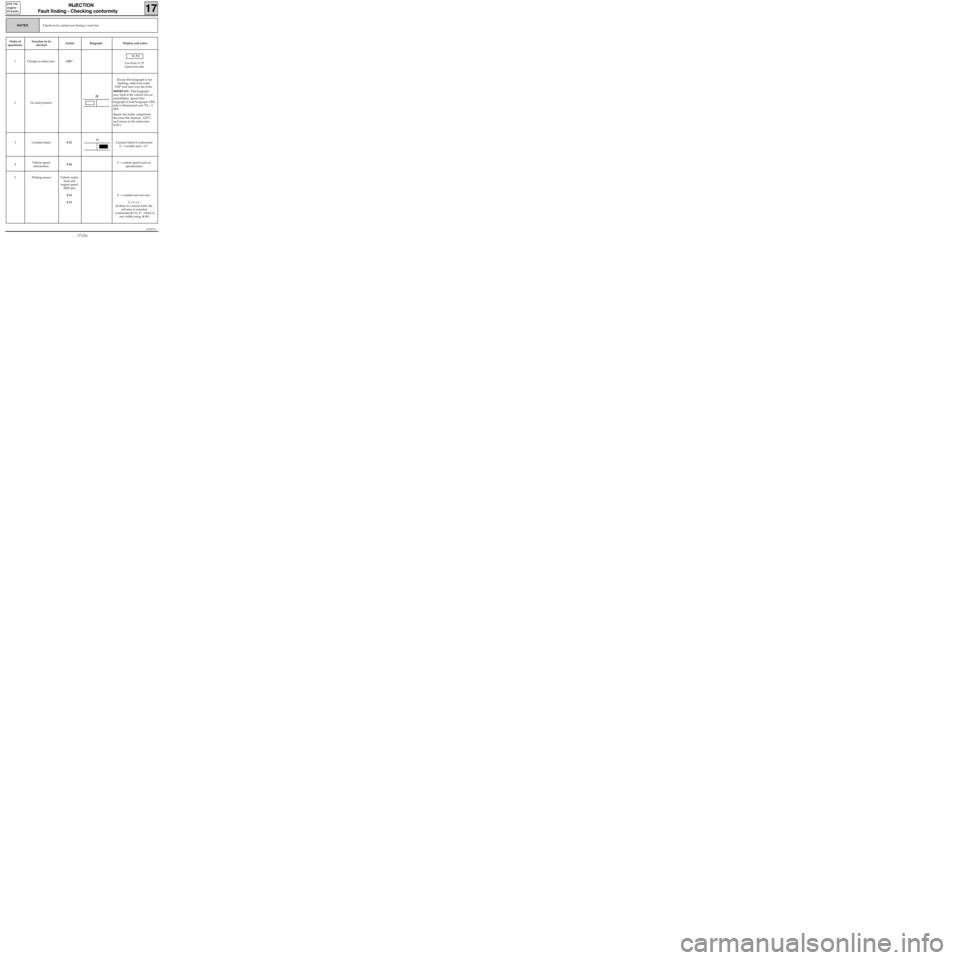

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

4 Interpretation of

normally illuminated

bargraphs

-

Code present

No load recognition

Engine speed information

received

+ after ignition information

received

Locking relay control effective

Idle speed regulation active

Richness regulation active1

2

5

4

6

6

3

17-212

Page 256 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

55 tracks

Engine warm, at idle speed, after fan assembly has operated at least once (air

conditioning not selected)NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

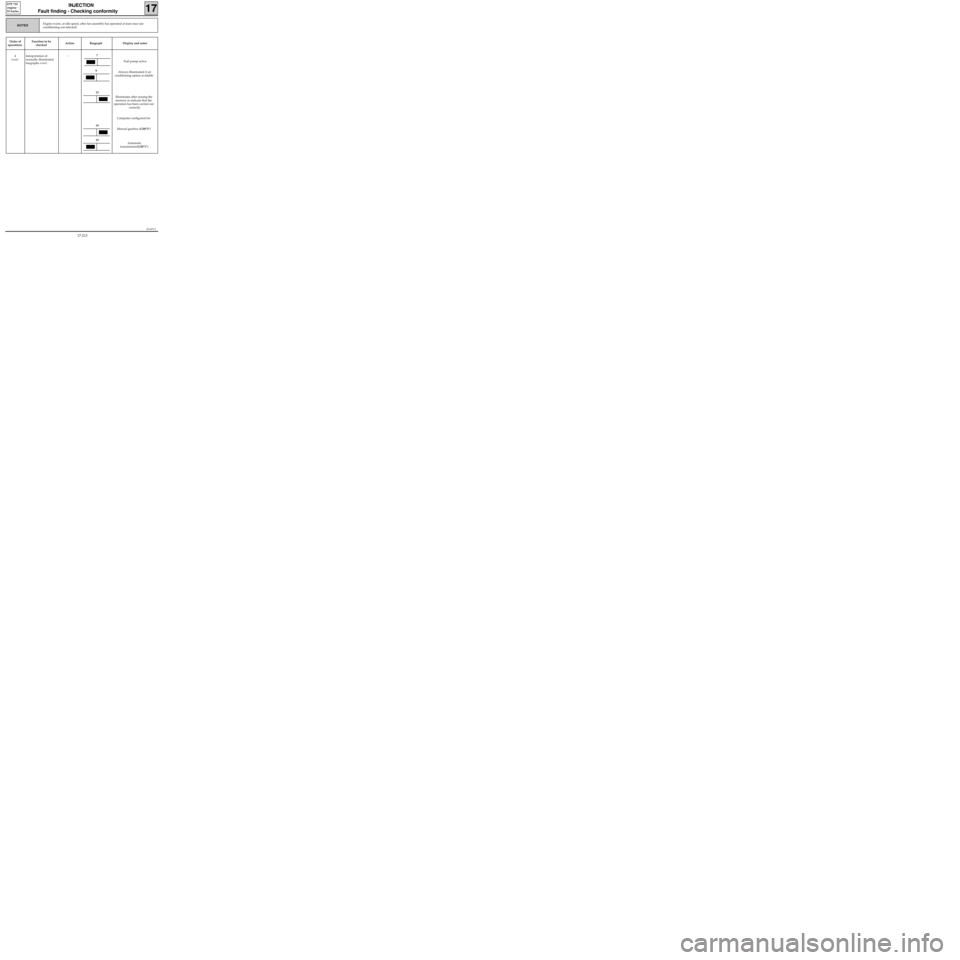

4

(cont)Interpretation of

normally illuminated

bargraphs (cont)

-

Fuel pump active

Always illuminated if air

conditioning option available

Illuminates after erasing the

memory to indicate that the

operation has been carried out

correctly

Computer configured for:

Manual gearbox (G50*2*)

Automatic

transmission(G50*1*)

7

19

9

19

12

17-213

Page 257 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

55 tracks

NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

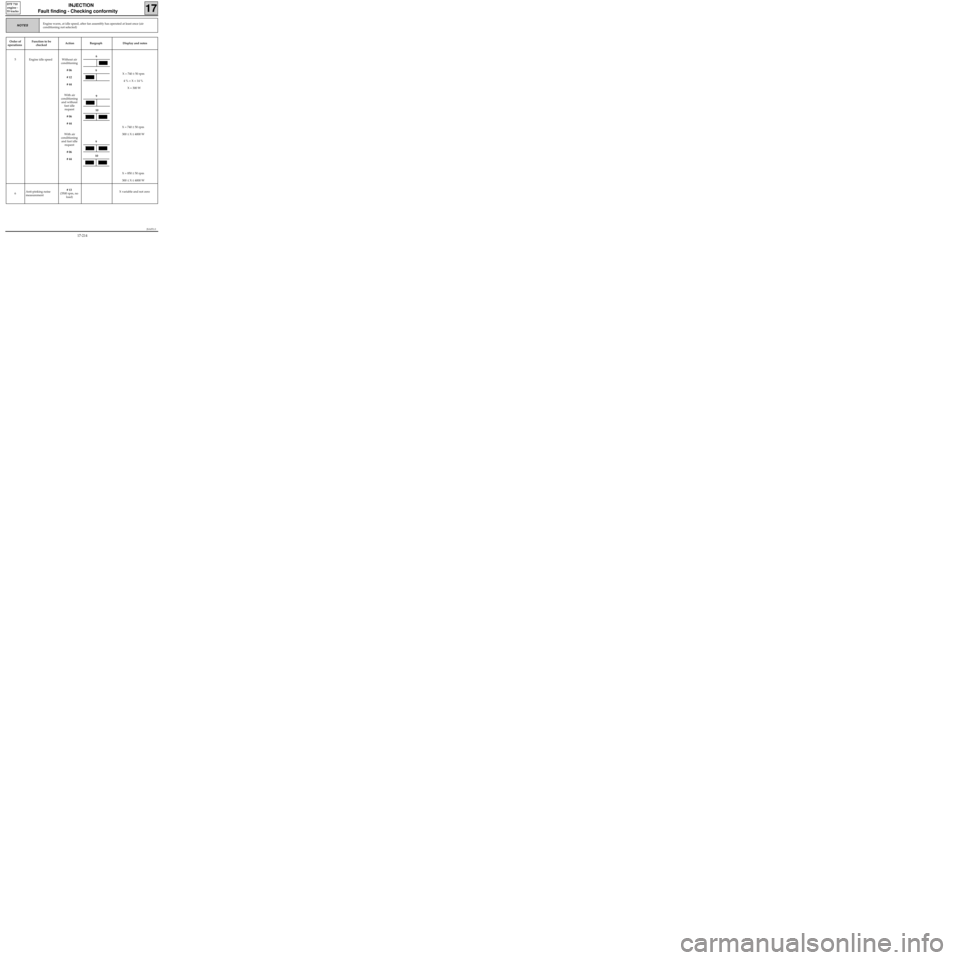

5 Engine idle speed Without air

conditioning

# 06

# 12

# 44

With air

conditioning

and without

fast idle

request

# 06

# 44

With air

conditioning

and fast idle

request

# 06

# 44X = 740 ± 50 rpm

4 % < X < 14 %

X ≈ 300 W

X = 740 ± 50 rpm

300 ≤ X ≤ 4000 W

X = 850 ± 50 rpm

300 ≤ X ≤ 4000 W

6Anti-pinking noise

measurement# 13

(3500 rpm, no

load) X variable and not zero

Engine warm, at idle speed, after fan assembly has operated at least once (air

conditioning not selected)

6

9

9

10

9

10

17-214

Page 258 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

55 tracks

NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

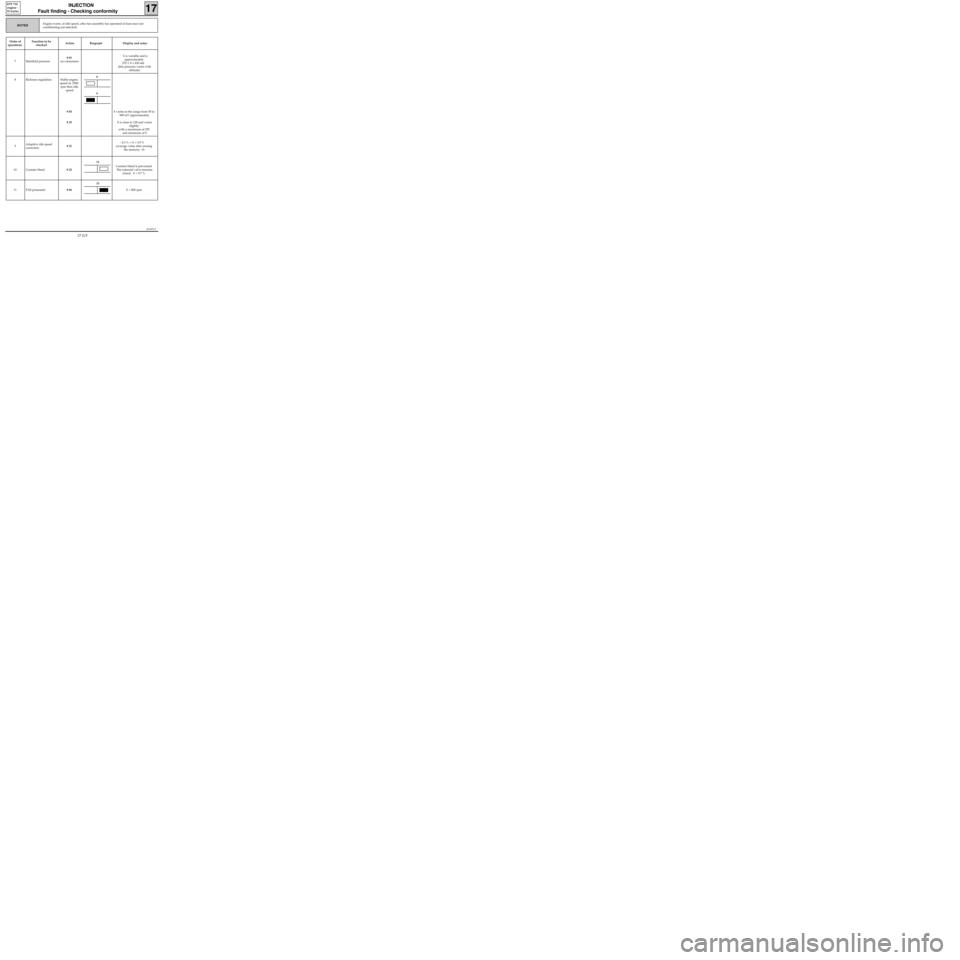

7 Manifold pressure# 01

no consumers X is variable and is

approximately

270 ≤ X ≤ 430 mb

(this pressure varies with

altitude)

8 Richness regulation Stable engine

speed of 2500

rpm then idle

speed

# 05

# 35X varies in the range from 50 to

900 mV approximately

X is close to 128 and varies

slightly

with a maximum of 255

and minimum of 0

9Adaptive idle speed

correction# 21- 4.3 % < X < 3.9 %

(average value after erasing

the memory : 0)

10 Canister bleed# 23Canister bleed is prevented.

The solenoid valve remains

closed. X = 0.7 %

11 PAS pressostat# 06X = 800 rpm

Engine warm, at idle speed, after fan assembly has operated at least once (air

conditioning not selected)

6

6

11

13

17-215

Page 259 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

55 tracks

Checks to be carried out during a road test.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

1 Change to status testG01*

10.NJ

Use fiche n° 27

status test side

2 No fault presentEnsure this bargraph is not

flashing, otherwise enter

G02* and turn over the fiche.

IMPORTANT: This bargraph

may flash if the vehicle has no

immobiliser. Ignore this

bargraph if fault bargraph 2 RH

side is illuminated and *22 = 2

dEF.

Repair the faulty component

the erase the memory (G0**)

and return to the status test

(G01*)

3 Canister bleed# 23Canister bleed is authorised

X = variable and > 0.7

4Vehicle speed

information# 18X = vehicle speed read on

speedometer

5 Pinking sensor Vehicle under

load and

engine speed

2000 rpm

# 13

# 15X = variable and not zero

0 ≤ X ≤ 6

(if there is a sensor fault, the

advance is retarded

systematically by 4° , which is

not visible using # 15)

11

20

17-216

Page 260 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

55 tracks

Checks to be carried out during a road test.NOTES

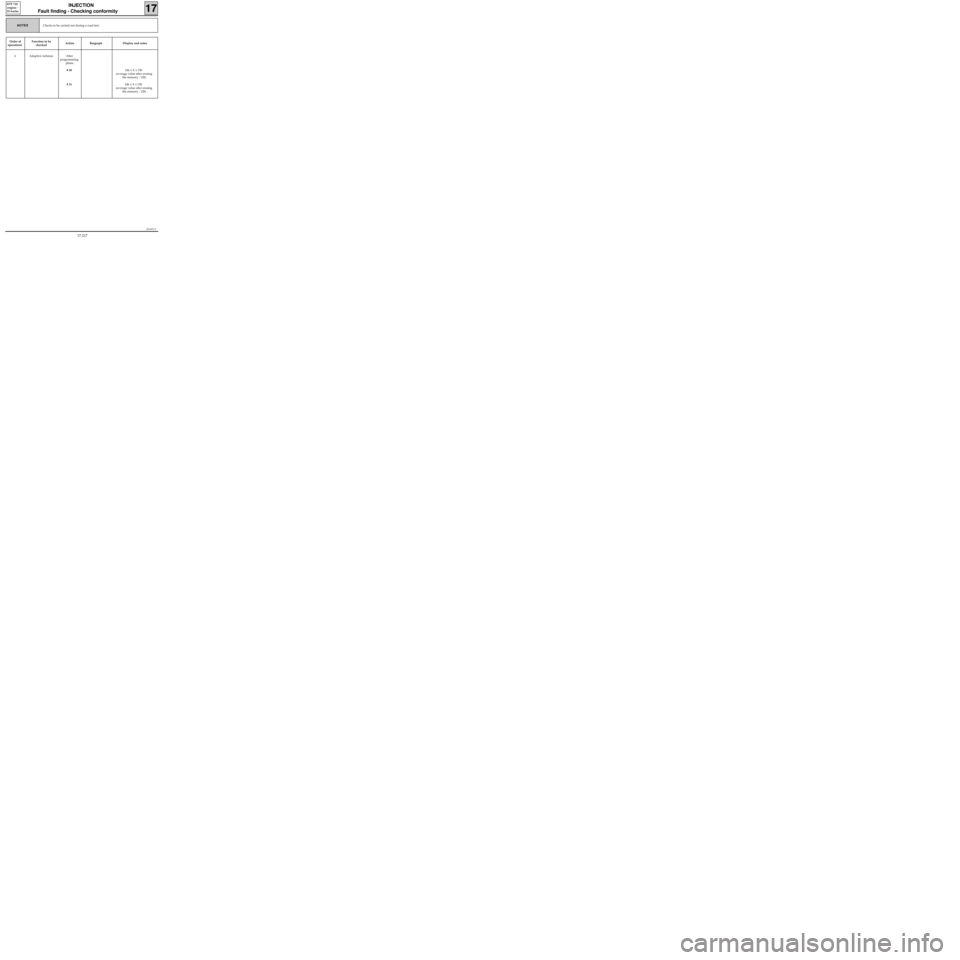

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

6 Adaptive richness After

programming

phase

# 30

# 31 106 ≤ X ≤ 150

(average value after erasing

the memory : 128)

106 ≤ X ≤ 150

(average value after erasing

the memory : 128)

17-217

Page 266 of 363

B76531.0

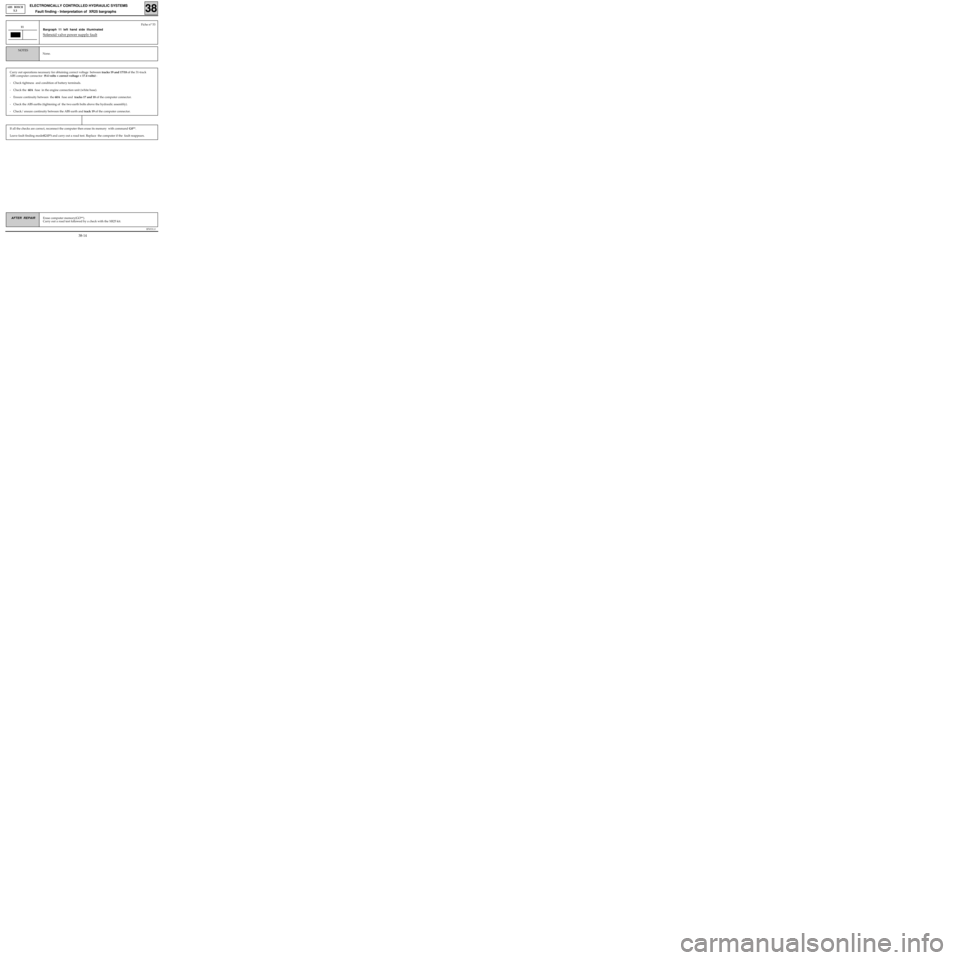

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEMS

Fault finding - Interpretation of XR25 bargraphs

38

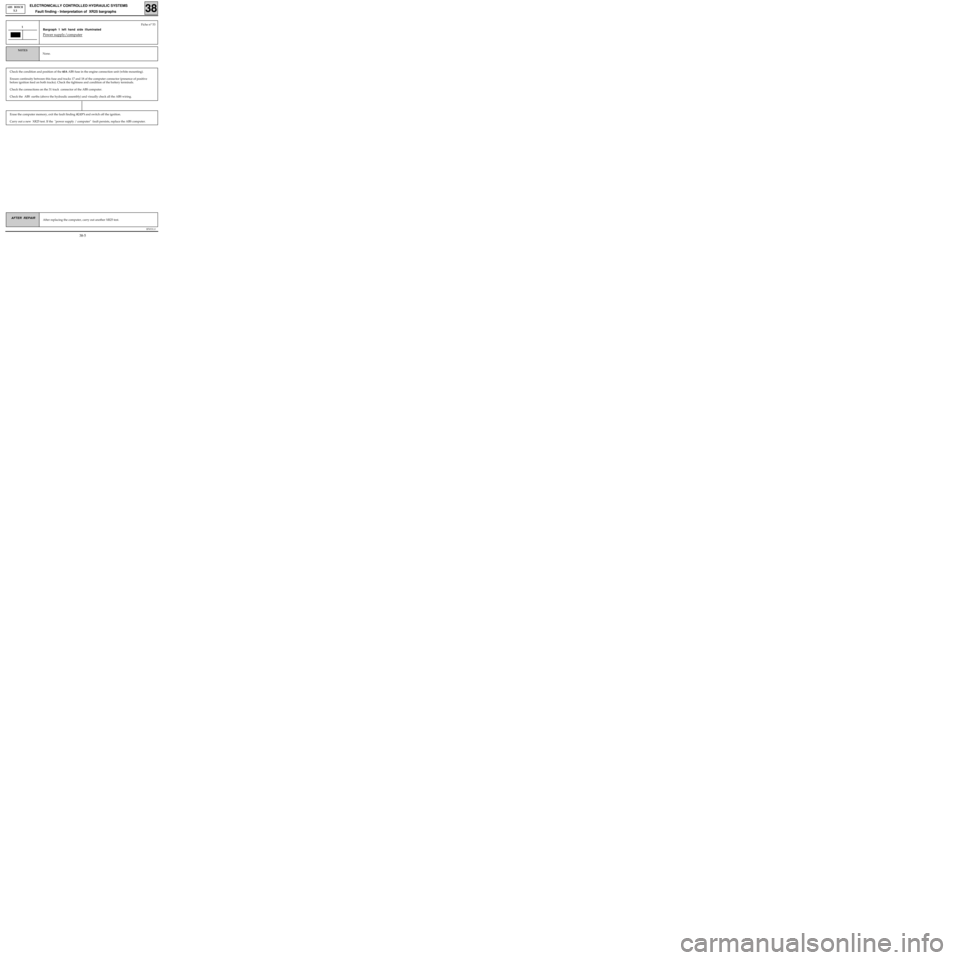

ABS BOSCH

5.3

After replacing the computer, carry out another XR25 test.AFTER REPAIR

Bargraph 1 left hand side illuminated

Power supply/computer

1

None.

NOTES

Fiche n° 53

Erase the computer memory, exit the fault finding (G13*) and switch off the ignition.

Carry out a new XR25 test. If the "power supply / computer" fault persists, replace the ABS computer.

Check the condition and position of the 60A ABS fuse in the engine connection unit (white mounting).

Ensure continuity between this fuse and tracks 17 and 18 of the computer connector (presence of positive

before ignition feed on both tracks). Check the tightness and condition of the battery terminals.

Check the connections on the 31 track connector of the ABS computer.

Check the ABS earths (above the hydraulic assembly) and visually check all the ABS wiring.

38-5

Page 267 of 363

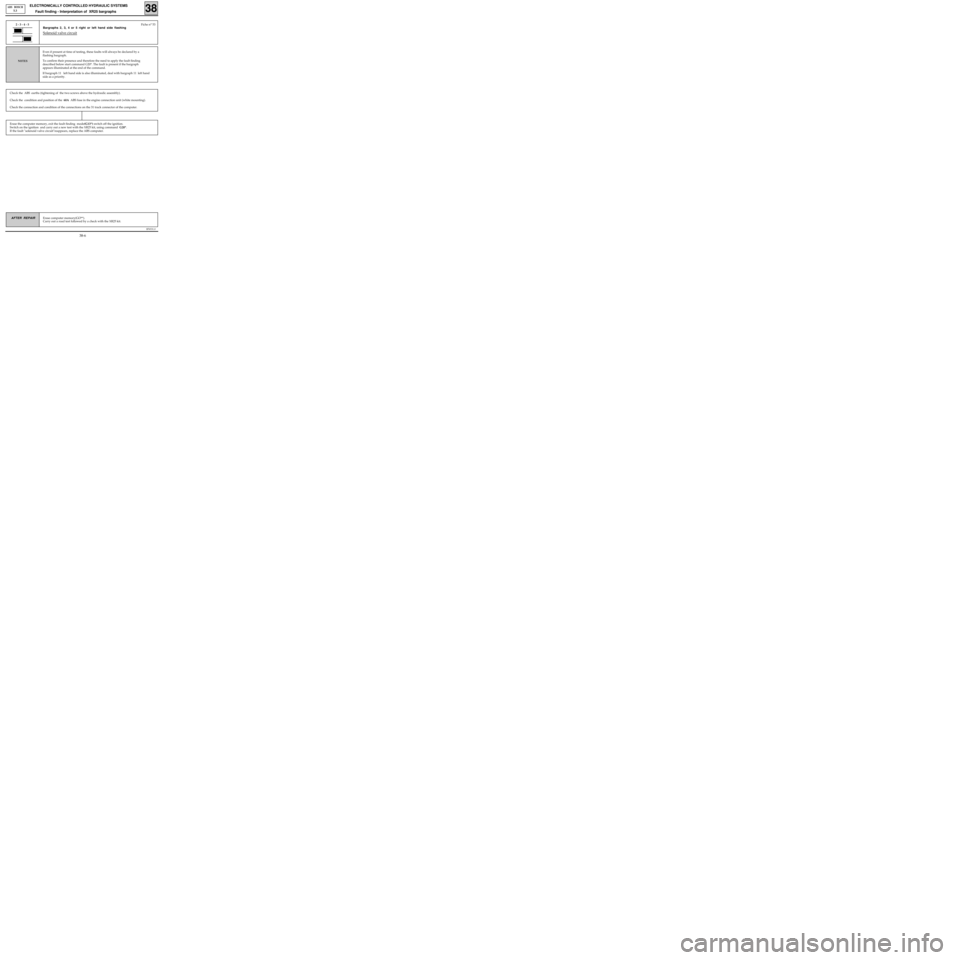

B76531.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEMS

Fault finding - Interpretation of XR25 bargraphs

38

ABS BOSCH

5.3

Erase computer memory(GO**).

Carry out a road test followed by a check with the XR25 kit.AFTER REPAIR

Bargraphs 2, 3, 4 or 5 right or left hand side flashing

Solenoid valve circuit

Even if present at time of testing, these faults will always be declared by a

flashing bargraph.

To confirm their presence and therefore the need to apply the fault finding

described below start command G20*. The fault is present if the bargraph

appears illuminated at the end of the command.

If bargraph 11 left hand side is also illuminated, deal with bargraph 11 left hand

side as a priority.

NOTES

Fiche n° 532 - 3 - 4 - 5

Check the ABS earths (tightening of the two screws above the hydraulic assembly).

Check the condition and position of the 60A ABS fuse in the engine connection unit (white mounting).

Check the connection and condition of the connections on the 31 track connector of the computer.

Erase the computer memory, exit the fault finding mode(G13*) switch off the ignition.

Switch on the ignition and carry out a new test with the XR25 kit, using command G20*.

If the fault "solenoid valve circuit"reappears, replace the ABS computer.

38-6

Page 275 of 363

B76531.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEMS

Fault finding - Interpretation of XR25 bargraphs

38

ABS BOSCH

5.3

Erase computer memory(GO**).

Carry out a road test followed by a check with the XR25 kit.AFTER REPAIR

Bargraph 11 left hand side illuminated

Solenoid valve power supply fault

11Fiche n° 53

If all the checks are correct, reconnect the computer then erase its memory with command G0**.

Leave fault finding mode(G13*) and carry out a road test. Replace the computer if the fault reappears.

Carry out operations necessary for obtaining correct voltage between tracks 19 and 17/18 of the 31-track

ABS computer connector (9.4 volts < correct voltage < 17.4 volts) :

- Check tightness and condition of battery terminals.

- Check the 60A fuse in the engine connection unit (white base).

- Ensure continuity between the 60A fuse and tracks 17 and 18 of the computer connector.

- Check the ABS earths (tightening of the two earth bolts above the hydraulic assembly).

- Check/ ensure continuity between the ABS earth and track 19 of the computer connector.

None.

NOTES

38-14

Page 281 of 363

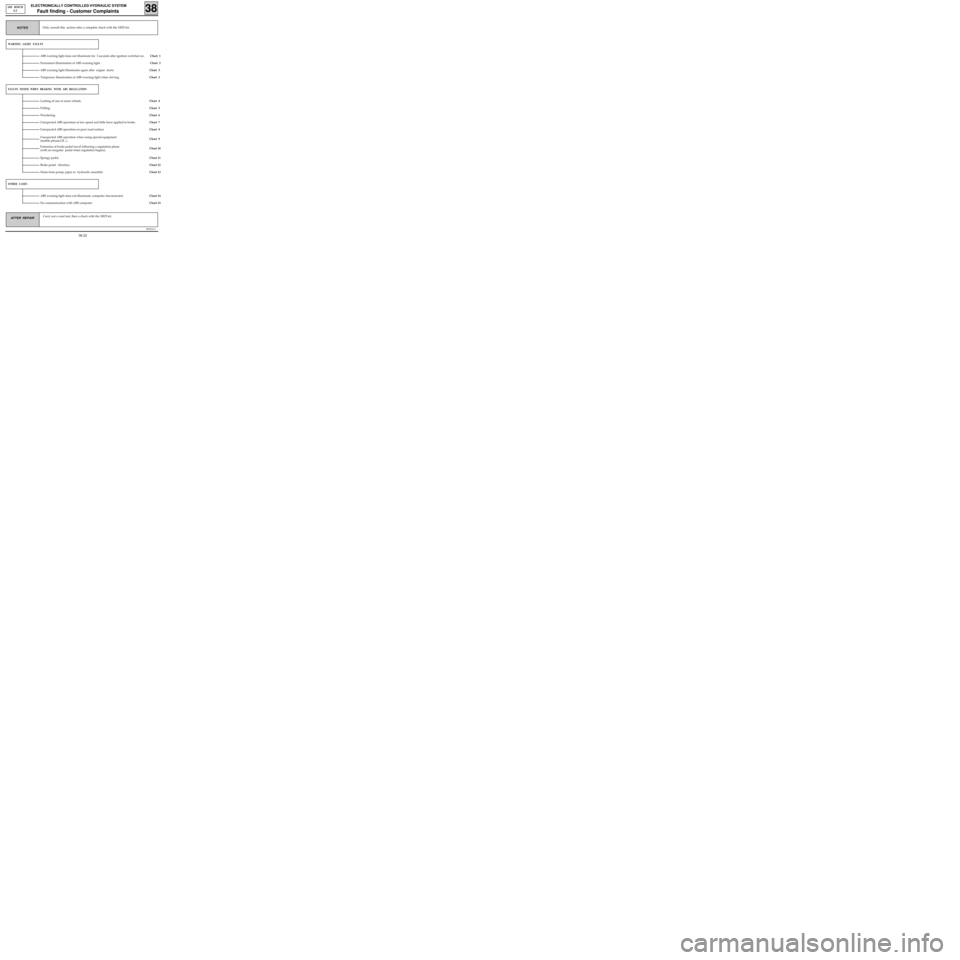

B76531.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Customer Complaints38

ABS BOSCH

5.3

AFTER REPAIR Carry out a road test, then a check with the XR25 kit.

WARNING LIGHT FAULTS

ABS warning light does not illuminate for 3 seconds after ignition switched on. Chart 1

Chart 2 Permanent illumination of ABS warning light .

Chart 3

FAULTS NOTED WHEN BRAKING WITH ABS REGULATION

Locking of one or more wheels.Chart 4

Pulling.

Chart 6 Wandering.

Chart 7

Unexpected ABS operation when using special equipment

(mobile phone,CB...).

Chart 9

OTHER CASES

ABS warning light does not illuminate, computer disconnected.Chart 14

No communication with ABS computer.

Chart 15 Only consult this section after a complete check with the XR25 kit.

NOTES

ABS warning light illuminates again after engine starts.

Unexpected ABS operation at low speed and little force applied to brake.

Unexpected ABS operation on poor road surface.

Extension of brake pedal travel following a regulation phase

(with an irregular pedal when regulation begins).

Chart 5

Chart 8

Chart 10

Spongy pedal.

Brake pedal vibration.

Noise from pump, pipes or hydraulic assembly .

Chart 11

Chart 12

Chart 13 Chart 3 Temporary illumination of ABS warning light when driving.

38-20