air condition RENAULT KANGOO 1997 KC / 1.G Foult Finding - Injection Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 363

Page 132 of 363

Connect the bornier in place of the computer and check the insulation and continuity of the line:

Computer 22 C Oxygen sensor

Repair if necessary.

JSA051.0

INJECTION

Fault finding - Interpretation of XR25 bargraphs17

D7F 710

engine -

35 tracks

Turn the engine, switch the ignition on and erase the computer memory using

G0**. Try to start the engine. Switch the ignition on, then deal with the other

faults. Remember to carry out a status and parameter check.AFTER REPAIR

Bargraph 3 RH side illuminated or flashingFiche n° 27 side 1/2

OXYGEN SENSOR CIRCUIT

XR25 aid:CO, CC- or CC+line 22

CO line 4

3

If BG 3RH is flashing, increase the engine speed to 2500 rpm for 5 minutes

If BG 3RH becomes permanently illuminated, deal with the fault.

NOTES

Check the connection and the condition of the connector on the oxygen sensor.

Check, ignition on during the timed phase, for :

-earth on track B of the oxygen sensor,

-+ 12 V after the fuel pump relay on track A of the oxygen sensor.

Repair if necessary.

Check for the presence of earth on track 4 on the injection computer.

Repair if necessary.

The fault persists. Replace the oxygen sensor.

The fault persists! Replace the injection computer.

IMPORTANT: The computer has probably been damaged by an electric shock. The cause of the damage

must be found before fitting a new computer.

17-87

Page 136 of 363

Connect the bornier in place of the computer and check the insulation,

continuity and that there is no interference resistance on the line:

Computer 13 B Target sensor

Computer 31 A Target sensor

Repair if necessary.

JSA051.0

INJECTION

Fault finding - Interpretation of XR25 bargraphs17

D7F 710

engine -

35 tracks

Erase the computer memory using G0**.

Try to start the engine. Switch the ignition on, then deal with the other faults.

Remember to carry out a status and parameter check.AFTER REPAIR

Bargraph 5 RH side illuminated or flashingFiche n° 27 side 1/2

FLYWHEEL SIGNAL CIRCUIT

XR25 aid:*25 = CO.0 =>CO or CC- line 13 or 31

*25 = CC.0 =

>CC- line 13 or 31 on the computer

*25 = In =

>sensor incorrectly connected

5

Try to illuminate BG 5RH when the starter is activated.

BG 5RH often seen to flash if *25 = dEF as its permanent illumination is very quick.

In certain cases, BG 5RH may illuminate then extinguish.

NOTES

Check the resistance of the target sensor.

Replace the sensor if necessary.*25 = CO.0

*25 = CC.0

Check the condition of the flywheel, especially if it has been removed.

The fault persists! Replace the injection computer.

IMPORTANT: The computer has probably been damaged by an electric shock.

The cause of the damage must be found before fitting a new

computer.

Check the target sensor has been correctly connected (the sensor connector must

not be inverted).

Repair if necessary.*25 = In

The fault persists! Replace the sensor.

17-91

Page 142 of 363

Connect the bornier in place of the computer and check the insulation and continuity of the line:

Computer 19 6 Instrument panel

Repair.

JSA051.0

INJECTION

Fault finding - Interpretation of XR25 bargraphs17

D7F 710

engine -

35 tracks

Erase the computer memory using G0**.

Try to start the engine. Switch the ignition on, then deal with the other faults.

Remember to carry out a status and parameter check.AFTER REPAIR

Bargraph 12 LH side illuminatedFiche n° 27 side 1/2

FAULT WARNING LIGHT CIRCUIT

XR25 aid:CO, CC- or CC+ line 19 of the computer

12

NoneNOTES

Check the condition of the warning light and its feed.

Repair if necessary.

17-97

Page 158 of 363

Check the insulation, continuity and that there is no interference resistance on the electrical line :

Computer 13 B Flywheel signal sensor

Computer 31 A Flywheel signal sensor

Repair.

JSA051.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

35 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 5

Fiche n° 27

TDC DETECTION

XR25 aid:Status BG 3LH, incorrect illumination

No fault bargraphs should be illuminated.

When the starter motor is activated.NOTES

Check the resistance of the TDC sensor.

Replace the sensor if necessary.

Check the sensor is correctly mounted.

Repair if necessary.

Check the condition of the target (if it has been removed).

Repair if necessary.

17-113

Page 172 of 363

Connect the bornier in place of the computer and check the insulation and continuity of the line:

Computer 19 6 Instrument panel

Repair.

JSA051.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

35 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 18

Fiche n° 27

FAULT WARNING LIGHT CIRCUIT

XR25 aid:None

No fault bargraphs should be illuminated.NOTES

Check the condition of the warning light and its feed.

Repair if necessary.

17-127

Page 175 of 363

JSA051.0

INJECTION

Fault finding - Fault charts

17

D7F 710

engine -

35 tracks

AFTER REPAIR

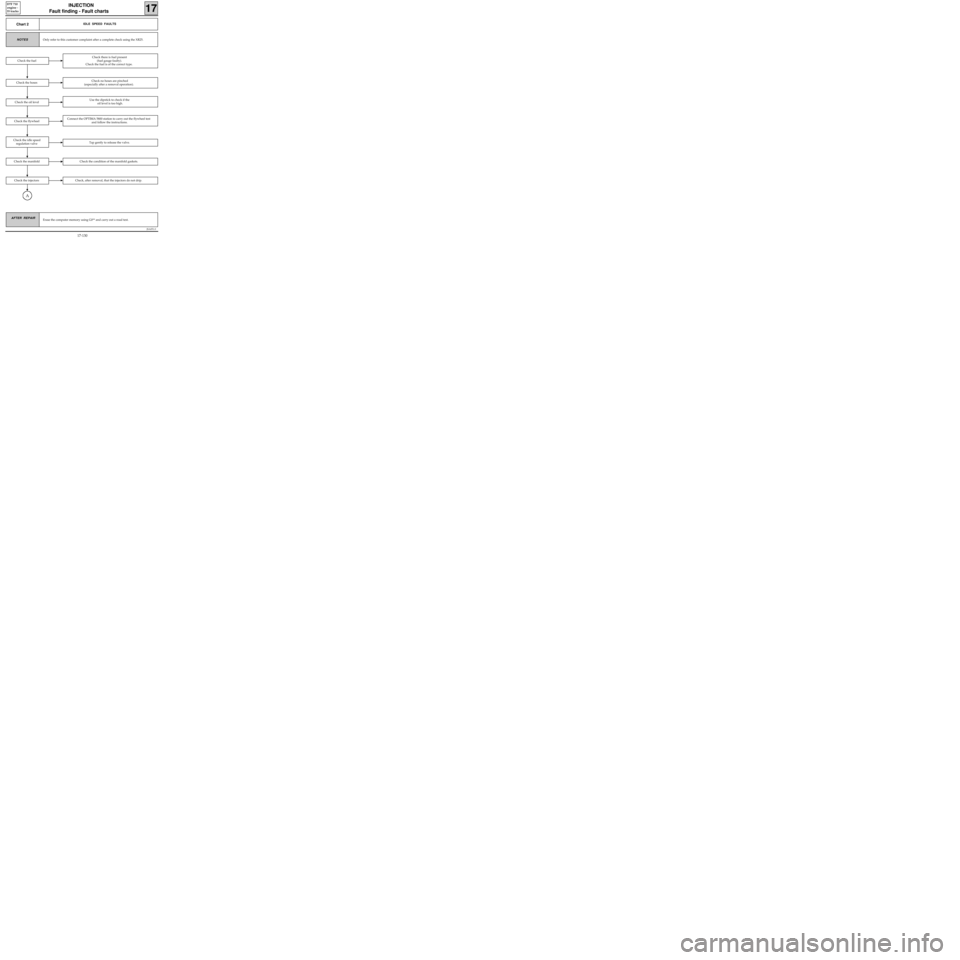

Chart 2IDLE SPEED FAULTS

Only refer to this customer complaint after a complete check using the XR25.NOTES

Erase the computer memory using G0** and carry out a road test.

Check there is fuel present

(fuel gauge faulty).

Check the fuel is of the correct type.

Check the hosesCheck no hoses are pinched

(especially after a removal operation).

Check the oil levelUse the dipstick to check if the

oil level is too high.

Check the fuel

Check the flywheelConnect the OPTIMA 5800 station to carry out the flywheel test

and follow the instructions.

Check the idle speed

regulation valveTap gently to release the valve.

Check the manifoldCheck the condition of the manifold gaskets.

Check the injectorsCheck, after removal, that the injectors do not drip.

A

17-130

Page 177 of 363

JSA051.0

INJECTION

Fault finding - Fault charts

17

D7F 710

engine -

35 tracks

AFTER REPAIRErase the computer memory using G0** and carry out a road test.

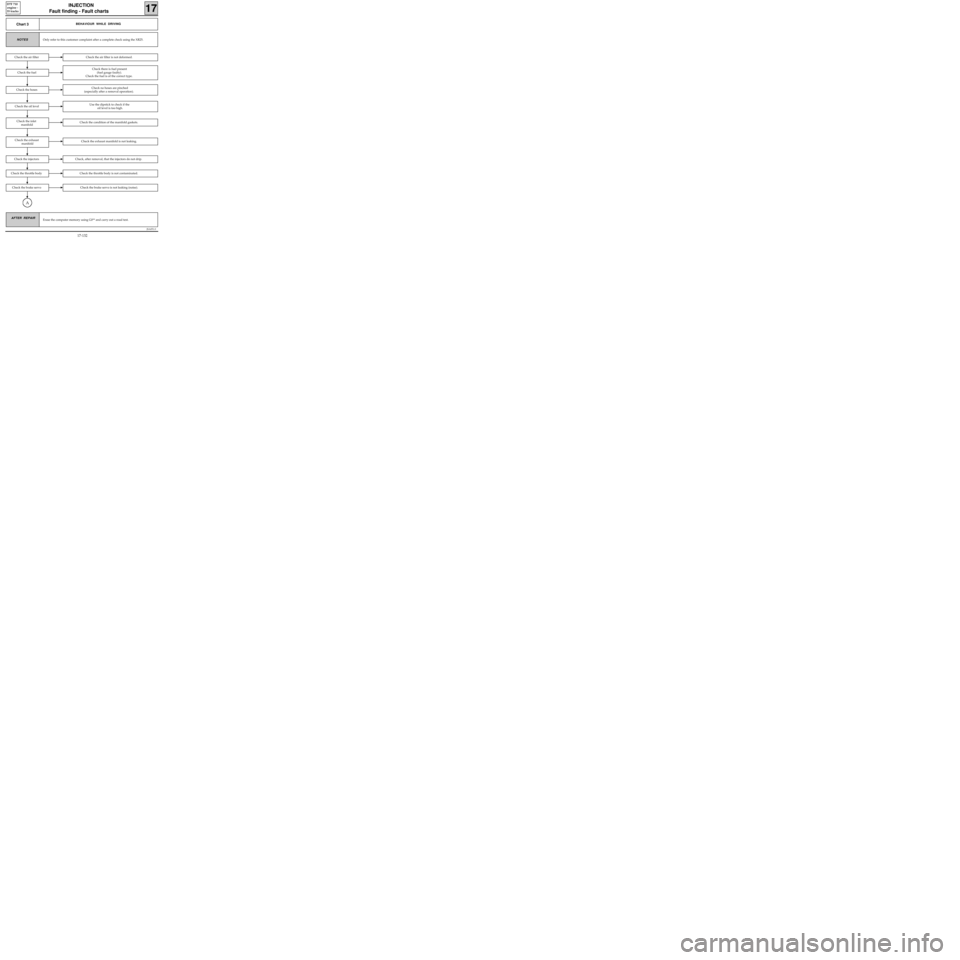

Chart 3BEHAVIOUR WHILE DRIVING

Only refer to this customer complaint after a complete check using the XR25.NOTES

Check the air filter is not deformed.

Check the fuel

Check there is fuel present

(fuel gauge faulty).

Check the fuel is of the correct type.

Check the hosesCheck no hoses are pinched

(especially after a removal operation).

Check the air filter

Check the oil levelUse the dipstick to check if the

oil level is too high.

Check the condition of the manifold gaskets.Check the inlet

manifold

Check the exhaust manifold is not leaking.Check the exhaust

manifold

Check, after removal, that the injectors do not drip.Check the injectors

Check the throttle body is not contaminated.Check the throttle body

Check the brake servo is not leaking (noise).Check the brake servo

A

17-132

Page 192 of 363

JSA052.0

INJECTION

Fault finding - Introduction

17

D7F 710

engine -

55 tracks

DESCRIPTION OF THE FAULT-FINDING PHASES

The process described below is to be carried out in all cases of faults.

XR25 FAULT-CHECKING

This phase is the essential starting point for any intervention on the vehicle.

There are several constraints to the treatment of the bargraphs :

- A priority in the order of treatment when several bargraphs are illuminated.

- The interpretation of a bargraph depending on whether it is constantly illuminated or flashing .

1 - Order of priority

A series of illuminated bargraphs corresponding to the sensors with the same 12 V or having the same

earth, indicates a fault in this source. These priorities are dealt with in the "NOTES" section of the

fault-finding of the bargraph concerned.

2 - Input / output fault bargraphs

a) Illuminated :

The fault is present : treat the fault following the method described in the "INTERPRETATION OF XR25

BARGRAPHS" section.

b) Flashing :

Note the bargraphs displayed on the XR25.

Erase the memory of the computer and attempt to re-illuminate the bargraph: ignition on, idle speed

(or at starter speed) or by means of a road test (the "NOTES" section in the fault finding for the

bargraph concerned may help to determine the conditions under which the bargraph will illuminate).

If the bargraph has re-illuminated (fixed or flashing) :

The fault is present once again. In this case, treat the fault bargraph.

If the bargraph has not re-illuminated, check :

- the electrical lines which correspond to the flashing fault,

- the connectors of these lines (for rust, bent pins...).

- the resistance of the component found to be faulty.

- the cleanliness of the wires (insulation melted or cut, friction..).

NOTE : If the customer complaint does not correspond to the fault bargraph which is flashing

(example : Air temperature sensor fault bargraph flashing, but no customer complaint) ignore

this memorised fault and erase it.

3 - No bargraphs illuminated

If no bargraphs are illuminated on the XR25, carry out a status and parameter check. This may help in

detecting a problem.

17-149

Page 193 of 363

JSA052.0

INJECTION

Fault finding - Introduction

17

D7F 710

engine -

55 tracks

XR25 CHECKING STATUSES AND PARAMETERS

The status and parameter check is aimed at checking the statuses and parameters which do not illuminate

any fault bargraphs if they are outside of permitted tolerance values . This phase allows :

- Faults to be found without the illumination of fault bargraphs which may correspond to a customer

complaint (example : absence of no load information causing an unstable idle speed).

- The correct operation of the injection to be checked and the risk of faults appearing shortly after the

repair to be eliminated.

This section contains fault-finding for statuses and parameters, under their test conditions

(example : fault finding for # 01 ignition on and fault finding for # 01 engine running).

If a status does not operate normally or a parameter is outside of permitted tolerance values, consult the

fault-finding page indicated in the "Fault-finding" column.

XR25 CHECK CORRECT

If the XR25 check is correct, but the customer complaint persists, the problem must be dealt with through

customer complaints.

Treatment of customer complaints

This section has fault charts, which suggest a series of possible causes of the problem.

These lines of enquiry must only be used in the following cases :

- No fault bargraph appears on the XR25.

- No faults are detected during the checking of statuses and parameters.

- The vehicle is not operating correctly

POST-REPAIR CHECK

This operation is a simple check of the repair (by a command, or by an XR25 command mode ...).

This makes it possible to check that the system upon which the intervention has been carried out is correct

electrically.

It is an introduction to the road test.

ROAD TEST

A road test is essential in order to guarantee the correct operation of the vehicle and to test the quality of the

repair. Its role is to make sure that no faults occur (or will occur) when driving.

In order to be significant, the road test is subject to special driving conditions.

17-150

Page 194 of 363

JSA052.0

INJECTION

Fault finding - Introduction

17

D7F 710

engine -

55 tracks

Driving conditions for programming the adaptive variables:

During the road test, the engine speed must be stabilised for a few moments between:

260 < # 01 < 385 mbars

then 385 < # 01 < 510 mbars

then 510 < # 01 < 635 mbars

then is 635 < # 01 < 760 mbars

then 760 < # 01 < 970 mbars

Do not exceed an engine speed of 4400 rpm

The engine must be warm (coolant temperature > 75 °C).

For this test, start from a fairly low engine speed, in 3rd or 4th gear, and apply progressive acceleration to

stabilise at the pressure required for 10 seconds in each zone.

The test must then be continued by driving normally, in a varied manner for 3 to 6 miles (5 to 10 km).

17-151