air condition RENAULT KANGOO 1997 KC / 1.G Foult Finding - Injection Manual Online

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 363

Page 284 of 363

B76531.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault chart 38

ABS BOSCH

5.3

AFTER REPAIR Carry out a road test, then a check with the XR25 kit.

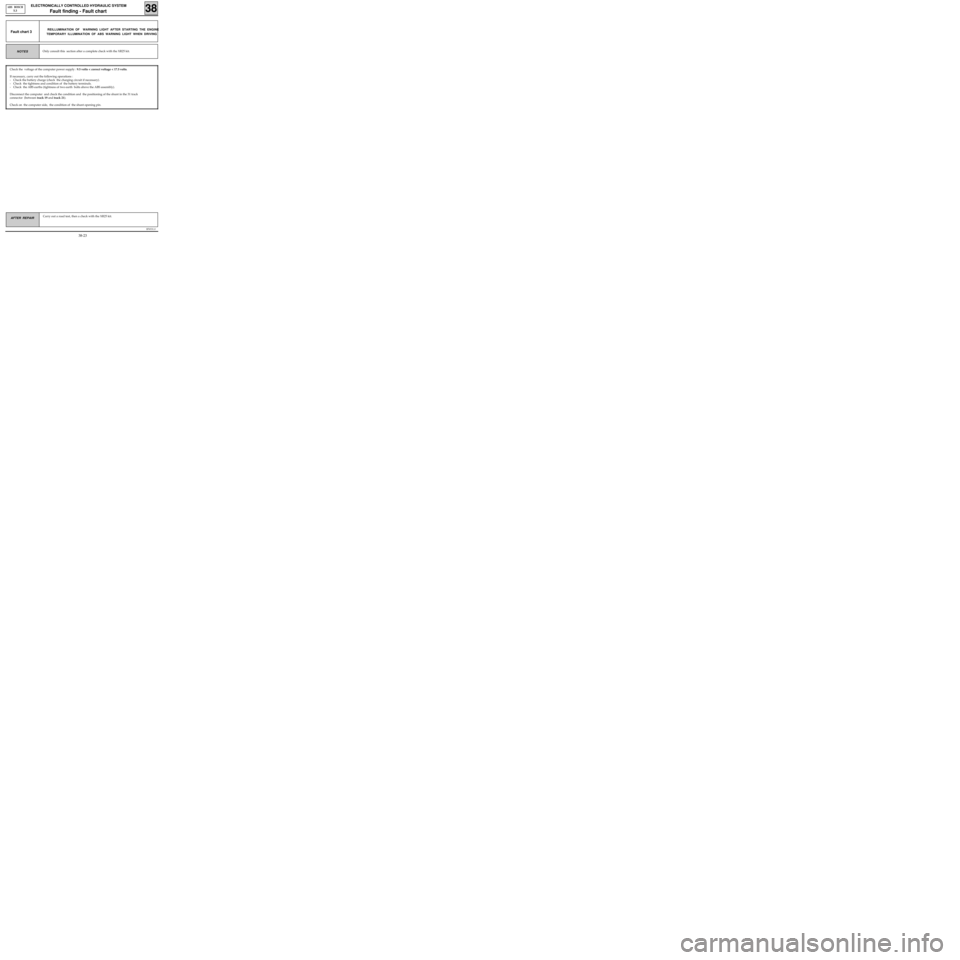

REILLUMINATION OF WARNING LIGHT AFTER STARTING THE ENGINE

TEMPORARY ILLUMINATION OF ABS WARNING LIGHT WHEN DRIVINGFault chart 3

Check the voltage of the computer power supply : 9.5 volts < correct voltage < 17.5 volts.

If necessary, carry out the following operations :

- Check the battery charge (check the charging circuit if necessary).

- Check the tightness and condition of the battery terminals.

- Check the ABS earths (tightness of two earth bolts above the ABS assembly).

Disconnect the computer and check the condition and the positioning of the shunt in the 31 track

connector (between track 19 and track 21).

Check on the computer side, the condition of the shunt opening pin.

Only consult this section after a complete check with the XR25 kit.NOTES

38-23

Page 285 of 363

B76531.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault chart 38

ABS BOSCH

5.3

AFTER REPAIR Carry out a road test, then a check with the XR25 kit.

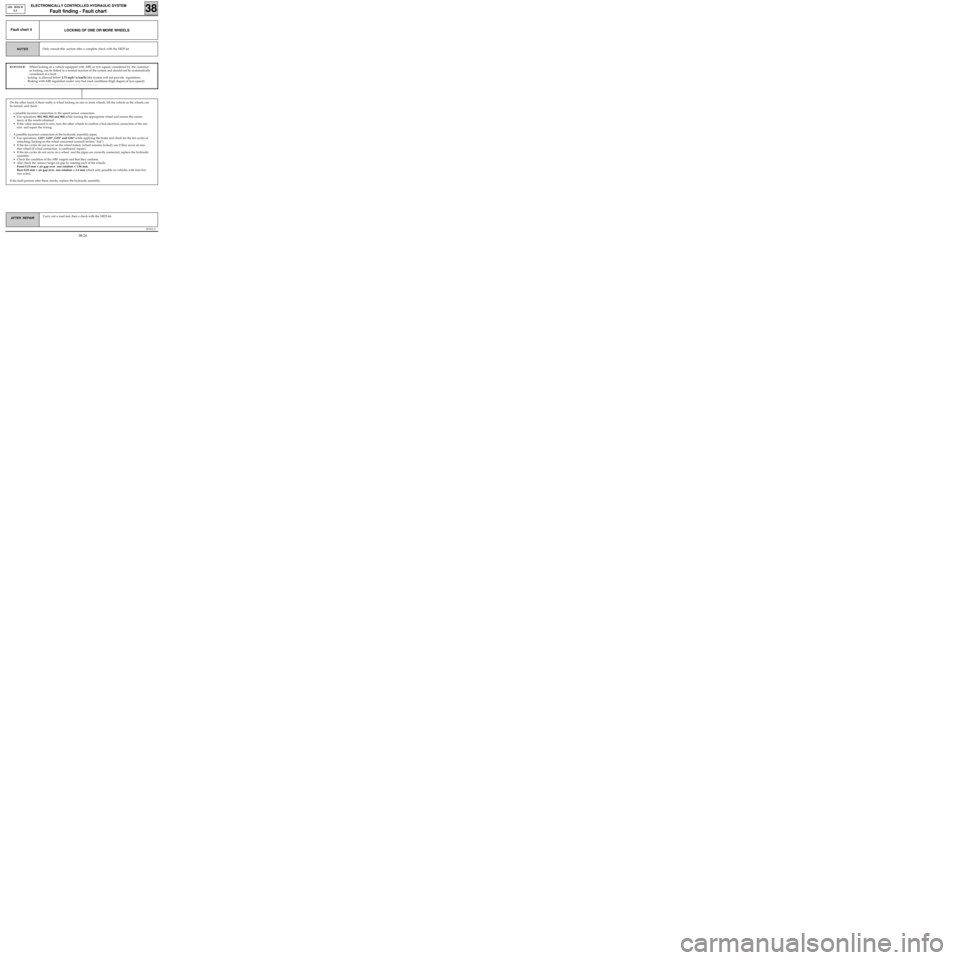

LOCKING OF ONE OR MORE WHEELSFault chart 4

REMINDER:Wheel locking on a vehicle equipped with ABS, or tyre squeal, considered by the customer

as locking, can be linked to a normal reaction of the system and should not be systematically

considered as a fault :

- locking is allowed below 3.75 mph ( 6 km/h) (the system will not provide regulation).

- Braking with ABS regulation under very bad road conditions (high degree of tyre squeal).

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Only consult this section after a complete check with the XR25 kit.NOTES

On the other hand, if there really is wheel locking on one or more wheels, lift the vehicle so the wheels can

be turned, and check :

- a possible incorrect connection in the speed sensor connection.

• Use operations #01, #02, #03 and #04 while turning the appropriate wheel and ensure the consis-

tency of the results obtained .

• If the value measured is zero, turn the other wheels to confirm a bad electrical connection of the sen-

sors and repair the wiring.

- A possible incorrect connection of the hydraulic assembly pipes.

• Use operations G03*, G04*, G05* and G06* while applying the brake and check for the ten cycles of

unlocking/locking on the wheel concerned (consult section "Aid").

• If the ten cycles do not occur on the wheel tested, (wheel remains locked), see if they occur on ano-

ther wheel (if a bad connection is confirmed: repair).

• If the ten cycles do not occur on a wheel and the pipes are correctly connected, replace the hydraulic

assembly.

• Check the condition of the ABS targets and that they conform.

• Also check the sensor/target air gap by rotating each of the wheels :

Front 0.13 mm < air gap over one rotation < 1.96 mm.

Rear 0.03 mm < air gap over one rotation < 2.4 mm (check only possible on vehicles with four-bar

rear axles).

If the fault persists after these checks, replace the hydraulic assembly.

38-24

Page 286 of 363

B76531.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault chart 38

ABS BOSCH

5.3

AFTER REPAIR Carry out a road test, then a check with the XR25 kit.

yes

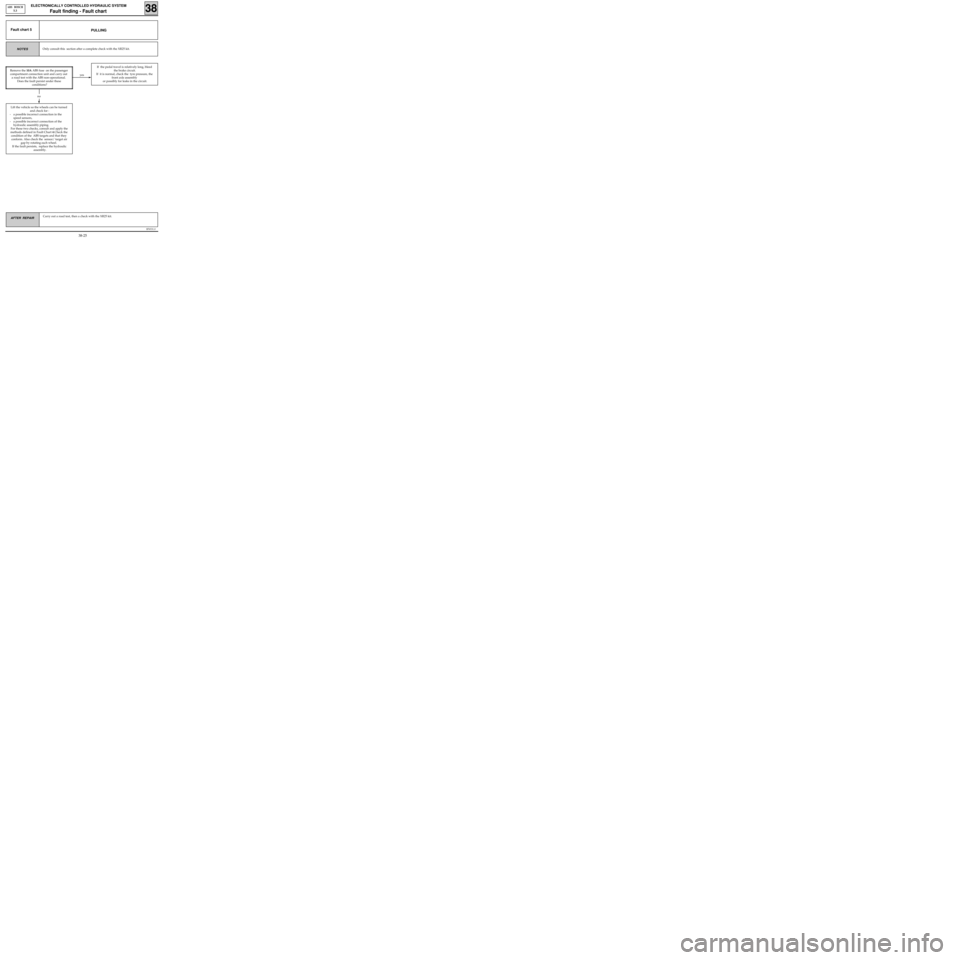

PULLINGFault chart 5

Only consult this section after a complete check with the XR25 kit.NOTES

Lift the vehicle so the wheels can be turned

and check for :

- a possible incorrect connection in the

speed sensors,

- a possible incorrect connection of the

hydraulic assembly piping.

For these two checks, consult and apply the

methods defined in Fault Chart 4.Check the

condition of the ABS targets and that they

conform. Also check the sensor/ target air

gap by rotating each wheel.

If the fault persists, replace the hydraulic

assembly.

If the pedal travel is relatively long, bleed

the brake circuit.

If it is normal, check the tyre pressure, the

front axle assembly

or possibly for leaks in the circuit.

no

Remove the 10A ABS fuse on the passenger

compartment connection unit and carry out

a road test with the ABS non-operational.

Does the fault persist under these

conditions?

38-25

Page 287 of 363

B76531.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault chart 38

ABS BOSCH

5.3

AFTER REPAIR Carry out a road test, then a check with the XR25 kit.

yes

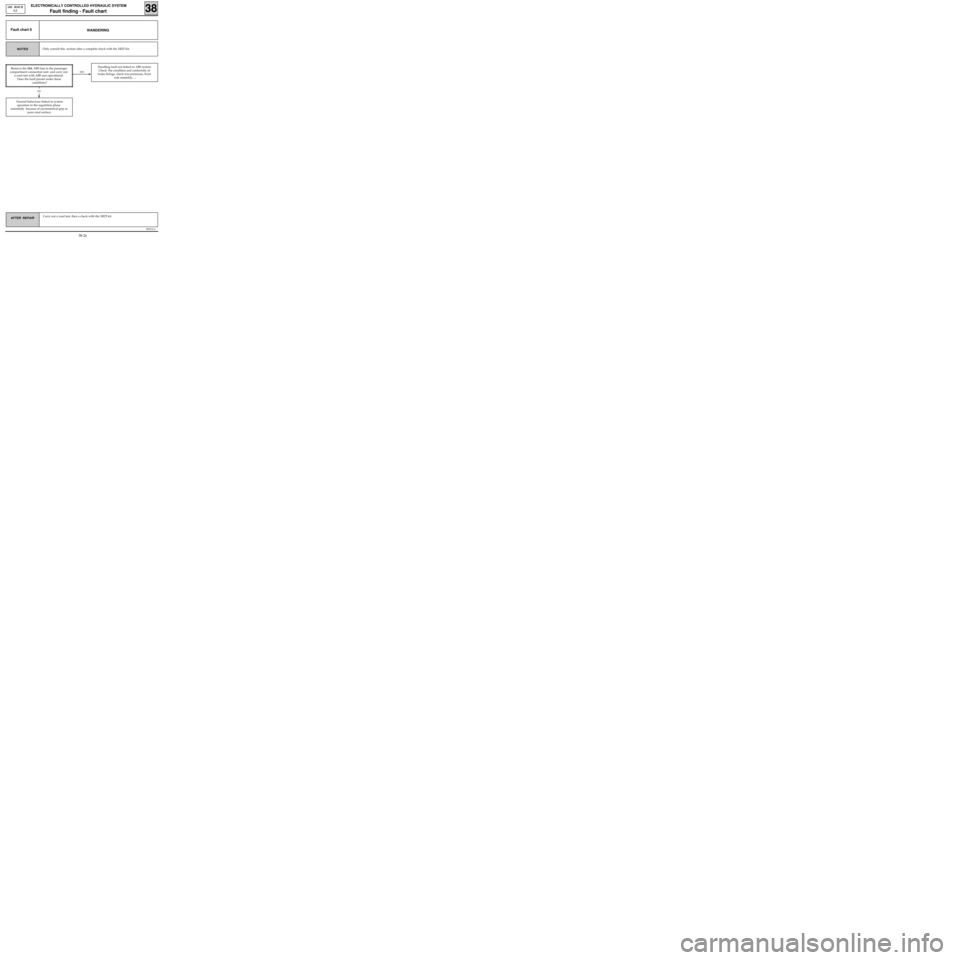

WANDERINGFault chart 6

Remove the 10A ABS fuse in the passenger

compartment connection unit and carry out

a road test with ABS non-operational.

Does the fault persist under these

conditions?

Only consult this section after a complete check with the XR25 kit.NOTES

Normal behaviour linked to system

operation in the regulation phase

essentially because of asymmetrical grip or

poor road surface.

Handling fault not linked to ABS system.

Check the condition and conformity of

brake linings, check tyre pressures, front

axle assembly, ...

no

38-26

Page 289 of 363

B76531.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault chart 38

ABS BOSCH

5.3

AFTER REPAIR Carry out a road test, then a check with the XR25 kit.

UNEXPECTED ABS OPERATION

UNDER POOR ROAD CONDITIONSFault chart 8

Under poor road conditions, it is normal to feel jerky operation and vibration of the pedal and a higher

degree of tyre squeal than on a good road surface.

This results in a feeling that there is variation in efficiency, but this is normal.

Only consult this section after a complete check with the XR25 kit.NOTES

38-28

Page 294 of 363

B76531.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault chart 38

ABS BOSCH

5.3

AFTER REPAIR Carry out a road test, then a check with the XR25 kit.

NOISE FROM THE PUMP, PIPES OR HYDRAULIC ASSEMBLYFault chart 13

- Assembly vibration: check the presence and condition of the rubber assembly mounting pads.

- Vibration of pipes : check that all pipes are well clipped into their fixing clips and that there is no contact

between pipes or between pipes and bodywork.

To determine the origin of the noise, it is possible to use functions G03*, G04*, G05* and G06* on the XR25

kit (consult section "Aid").

Only consult this section after a complete check with the XR25 kit.NOTES

38-33

Page 296 of 363

B76531.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault chart 38

ABS BOSCH

5.3

AFTER REPAIR Carry out a road test, then a check with the XR25 kit.

LACK OF COMMUNICATION WITH

ABS COMPUTERFault chart 15

Only consult this section after a complete check with the XR25 kit.NOTES

If dialogue is still not established after these checks, replace the ABS computer.

Check that the diagnostic socket is receiving the correct power supply:

-+ before ignition on track 16,

-earth on track 5.

Check continuity and insulation of the lines of the diagnostic socket / ABS computer connections:

- between track 12 of the computer connector and track 15 of the diagnostic socket,

- between track 11 of the computer connector and track 7 of the diagnostic socket.

Check the presence and condition of the ABS fuse on the passenger compartment connection unit (10A).

Check the connection of the computer connector and the condition of its connections.

Check the connection and condition of the connections at the R36 dashboard / ABS connector.

Check the ABS earth leads (tighten the two earth bolts above the ABS assembly).

Check that the computer is receiving the proper power supply :

- earth on track 19 of the 31 track connector,

- +after ignition on track 15 of the 31 track connector.

Ensure that the XR25 is not at fault by trying to communicate with a computer on another vehicle. If the

XR25 is not at fault and dialogue is not being established with another computer on the same vehicle, it is

possible that a faulty computer is disturbing diagnostic lines K and L. Proceed with successive disconnec-

tions to localise this computer.

Check that the ISO interface is in position S8, that you are using the most recent version of the XR25 kit

and the correct access code.

Check the battery voltage and carry out the operations necessary to obtain the correct voltage (9.4 volts

< U battery< 17.4 volts).

38-35

Page 301 of 363

v0406.0

IMMOBILISER

Fault finding- Interpretation of XR25 Bargraphs 82

When communication is established, deal with any fault bargraphs which may

be illuminated.

Carry out a conformity check.AFTER REPAIR

Bargraph 1 right hand side extinguished

XR25 KIT / DECODER UNIT COMMUNICATION

1

Check that lines K and L are not being disrupted by another computer.NOTES

Fiche n° 56

Check the condition of +before ignition feed fuse.

Change the fuse if necessary.

Ensure that the XR25 kit is not the cause of the fault by trying to communicate with another computer on

the vehicle (air conditioning computer, injection computer...).

Check that the ISO interface is in position S8, that the most recent version of the XR25 cassette and the

correct access code are being used(D 56).

Check battery voltage (U > 10.5 volts). Recharge the battery if necessary.

Check that the 18 track decoder unit connector is properly connected.

Check that the decoder unit is properly fed :

-earth on track A8 of the decoder unit connector.

-+ before ignition feed on tracks A9 and A1 of the decoder unit connector.

Ensure that the diagnostic socket is correctly fed.

Check and ensure the continuity and insulation of the wiring of tracks A3 and A4 of the decoder unit

connector.

If there is still no dialogue between the XR25 kit and the decoder unit, change the decoder unit.

82-4

Page 303 of 363

v0406.0

IMMOBILISER

Fault finding- Interpretation of XR25 Bargraphs 82

Carry out a conformity check.

Check operation of the immobiliser system.AFTER REPAIR

Bargraph 4 right hand side incorrect illumination

+ AFTER IGNITION PRESENT

4

Reminder: Under normal operation :

- BG 4 right hand side illuminated ignition switch in position+after ignition

- BG 4 RH side extinguished ignition switch in a position other than +after

ignition.NOTES

Fiche n° 56

Check condition of the +after ignition fuse.

Change the fuse if necessary.

Ignition on , check for voltage of + 12 volts on track A7 of the 18 track decoder unit connector.

Are there 12 volts ?

Change the decoder unit.YES

NORepair the electrical wiring between track A7 of the 18 track decoder unit

connector and the passenger compartment fuse board.

82-6

Page 306 of 363

v0406.0

IMMOBILISER

Fault finding- Interpretation of XR25 Bargraphs 82

Erase the memorised fault by entering GO** on the XR25 keyboard.

Carry out a conformity check.

Check operation of the immobiliser system.AFTER REPAIR

Bargraphs 6 left and 6 right hand side illuminated

ACCEPTANCE (CLEARANCE) OF THE SIGNAL BY THE DIESEL

SOLENOID VALVE AND CODED LINE

6

Before beginning the fault finding, switch on the ignition for longer than 30

consecutive seconds, then switch off the ignition.NOTES

Fiche n° 56

Ensure that the connector of the coded electronic unit of the solenoid valve is properly connected.

Set the XR25 to pulse sensor mode (button "G", input on terminal "Vin").

Ignition on, check for pulses on track A6 of the decoder unit connector (test with decoder unit and

solenoid valve coded electronic unit connectors connected).

Are there any pulses?

Replace the solenoid valve side electronic unit.YES

NOReplace the decoder unit.

For the diesel version, if bargraphs 6 right and 6 left are illuminated, check the impact switch.

Check the condition of the electrical wiring between track A6 of the decoder unit and track 8 of the

coded solenoid valve connector and check the 12 Volts supply and earth.

Repair if necessary.

82-9