display RENAULT KANGOO 1997 KC / 1.G Foult Finding - Injection Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 363

Page 186 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

35 tracks

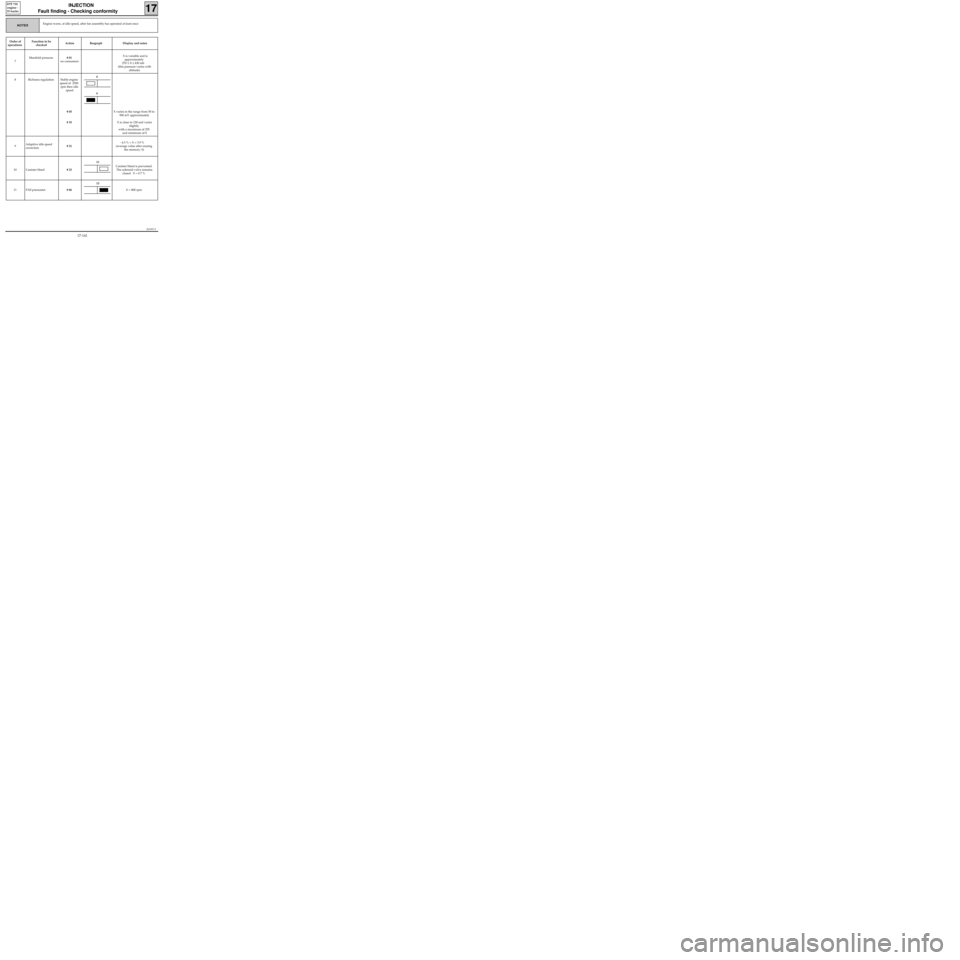

NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

7Manifold pressure# 01

no consumers X is variable and is

approximately

270 ≤ X ≤ 430 mb

(this pressure varies with

altitude)

8 Richness regulation Stable engine

speed of 2500

rpm then idle

speed

# 05

# 35X varies in the range from 50 to

900 mV approximately

X is close to 128 and varies

slightly

with a maximum of 255

and minimum of 0

9Adaptive idle speed

correction# 21- 4.3 % < X < 3.9 %

(average value after erasing

the memory: 0)

10 Canister bleed# 23Canister bleed is prevented.

The solenoid valve remains

closed. X = 0.7 %

11 PAS pressostat# 06X = 800 rpm

Engine warm, at idle speed, after fan assembly has operated at least once

6

6

11

13

17-141

Page 187 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

35 tracks

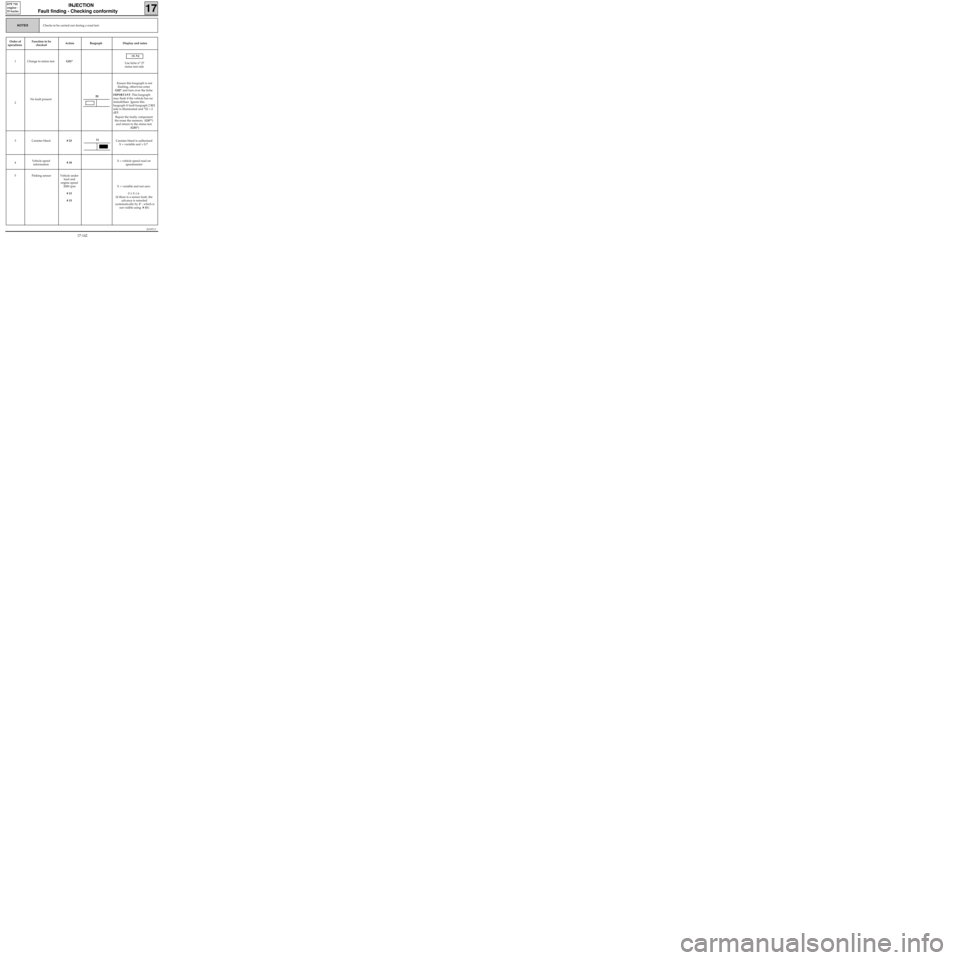

Checks to be carried out during a road test.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

1 Change to status testG01*

10.NJ

Use fiche n° 27

status test side

2No fault presentEnsure this bargraph is not

flashing, otherwise enter

G02* and turn over the fiche.

IMPORTANT: This bargraph

may flash if the vehicle has no

immobiliser. Ignore this

bargraph if fault bargraph 2 RH

side is illuminated and *22 = 2

dEF.

Repair the faulty component

the erase the memory (G0**)

and return to the status test

(G01*)

3 Canister bleed# 23Canister bleed is authorised

X = variable and > 0.7

4Vehicle speed

information# 18X = vehicle speed read on

speedometer

5 Pinking sensor Vehicle under

load and

engine speed

2000 rpm

# 13

# 15X = variable and not zero

0 ≤ X ≤ 6

(if there is a sensor fault, the

advance is retarded

systematically by 4° , which is

not visible using # 15)

11

20

17-142

Page 188 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

35 tracks

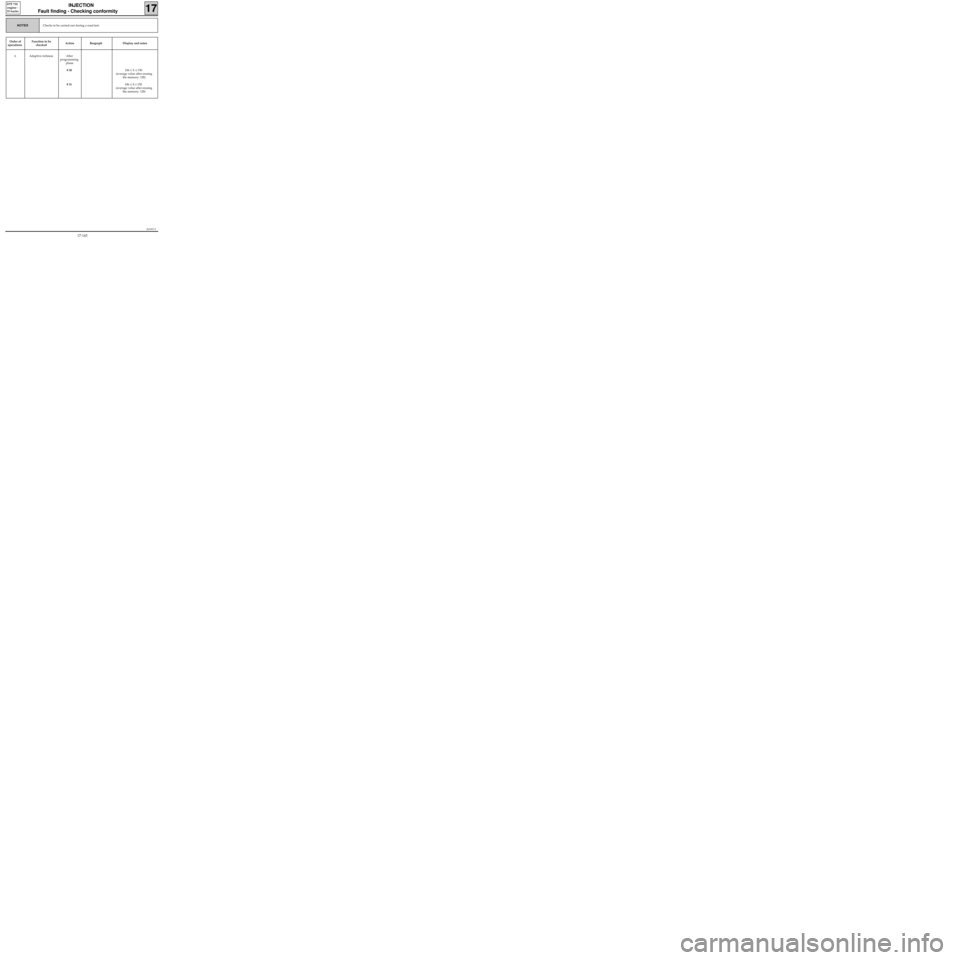

Checks to be carried out during a road test.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

6 Adaptive richness After

programming

phase

# 30

# 31 106 ≤ X ≤ 150

(average value after erasing

the memory: 128)

106 ≤ X ≤ 150

(average value after erasing

the memory: 128)

17-143

Page 190 of 363

JSA052.0

INJECTION

Fault finding- Introduction

17

D7F 710

engine -

55 tracks

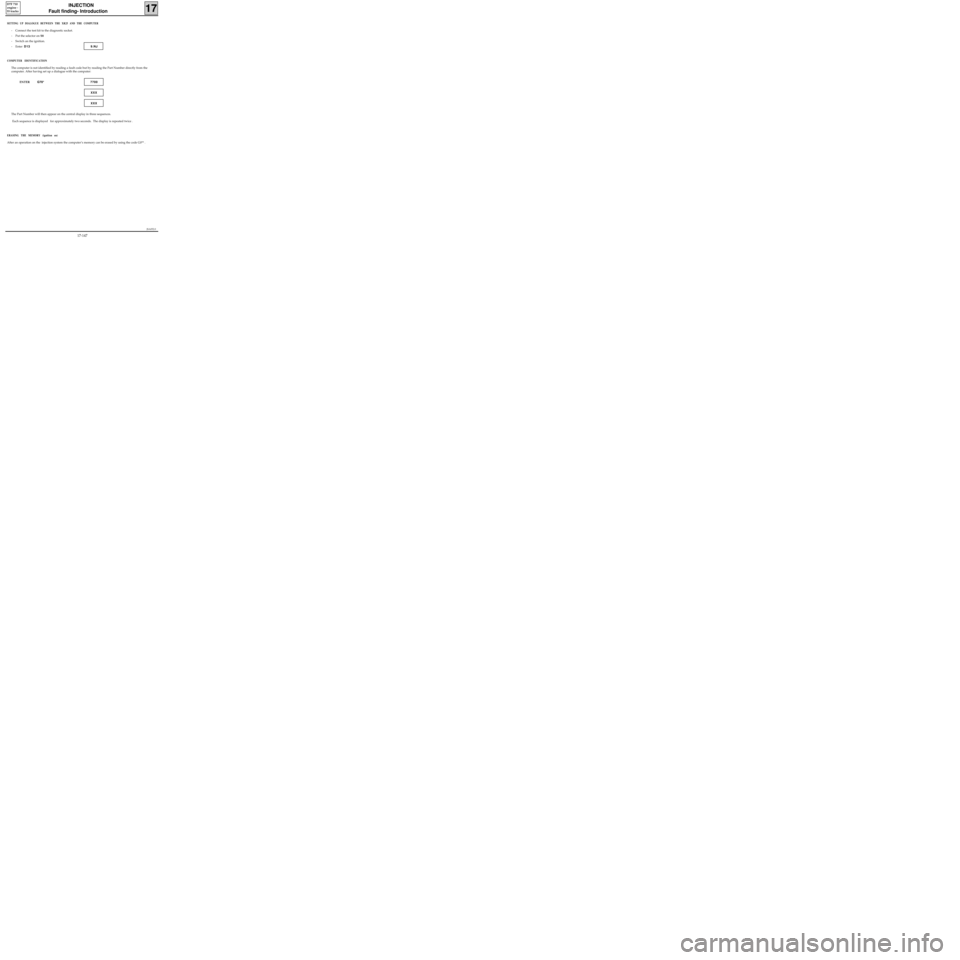

SETTING UP DIALOGUE BETWEEN THE XR25 AND THE COMPUTER

- Connect the test kit to the diagnostic socket.

- Put the selector on S8

- Switch on the ignition.

- Enter D13 9.NJ

COMPUTER IDENTIFICATION

The computer is not identified by reading a fault code but by reading the Part Number directly from the

computer. After having set up a dialogue with the computer:

ENTER G70*7700

XXX

XXX

The Part Number will then appear on the central display in three sequences.

Each sequence is displayed for approximately two seconds. The display is repeated twice .

ERASING THE MEMORY (ignition on)

After an operation on the injection system the computer’s memory can be erased by using the code G0** .

17-147

Page 192 of 363

JSA052.0

INJECTION

Fault finding - Introduction

17

D7F 710

engine -

55 tracks

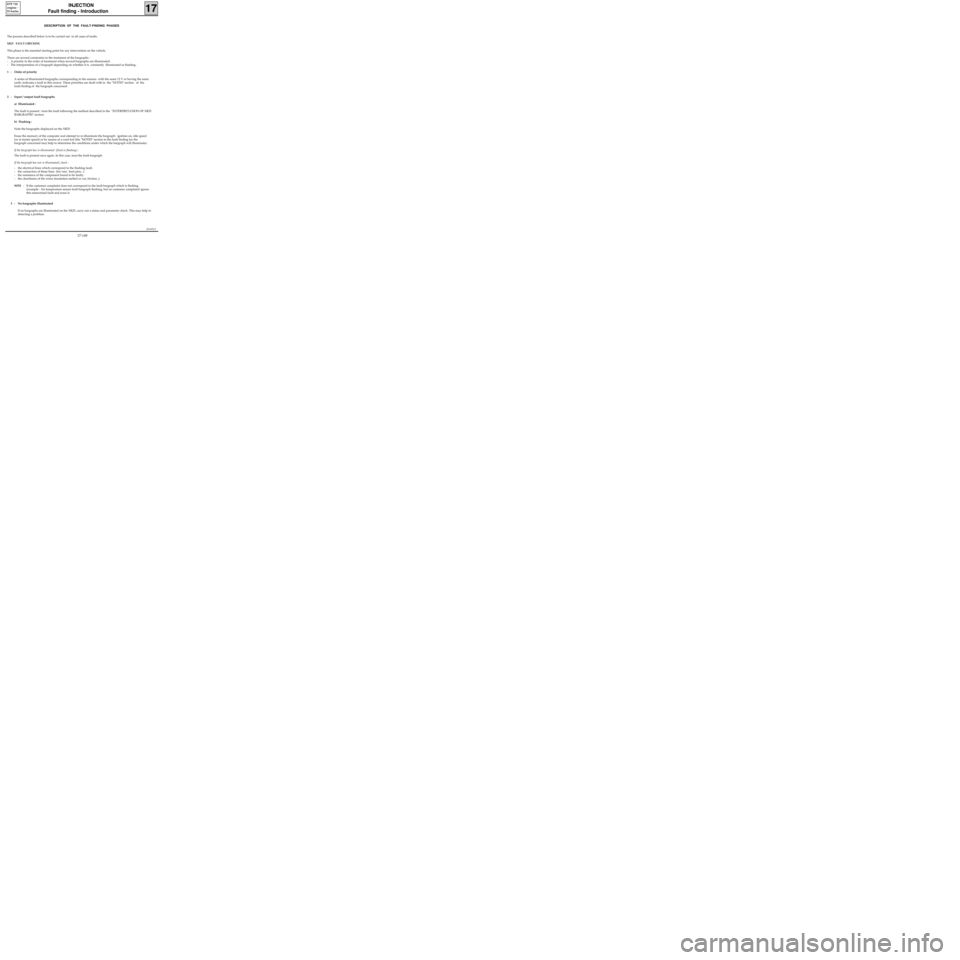

DESCRIPTION OF THE FAULT-FINDING PHASES

The process described below is to be carried out in all cases of faults.

XR25 FAULT-CHECKING

This phase is the essential starting point for any intervention on the vehicle.

There are several constraints to the treatment of the bargraphs :

- A priority in the order of treatment when several bargraphs are illuminated.

- The interpretation of a bargraph depending on whether it is constantly illuminated or flashing .

1 - Order of priority

A series of illuminated bargraphs corresponding to the sensors with the same 12 V or having the same

earth, indicates a fault in this source. These priorities are dealt with in the "NOTES" section of the

fault-finding of the bargraph concerned.

2 - Input / output fault bargraphs

a) Illuminated :

The fault is present : treat the fault following the method described in the "INTERPRETATION OF XR25

BARGRAPHS" section.

b) Flashing :

Note the bargraphs displayed on the XR25.

Erase the memory of the computer and attempt to re-illuminate the bargraph: ignition on, idle speed

(or at starter speed) or by means of a road test (the "NOTES" section in the fault finding for the

bargraph concerned may help to determine the conditions under which the bargraph will illuminate).

If the bargraph has re-illuminated (fixed or flashing) :

The fault is present once again. In this case, treat the fault bargraph.

If the bargraph has not re-illuminated, check :

- the electrical lines which correspond to the flashing fault,

- the connectors of these lines (for rust, bent pins...).

- the resistance of the component found to be faulty.

- the cleanliness of the wires (insulation melted or cut, friction..).

NOTE : If the customer complaint does not correspond to the fault bargraph which is flashing

(example : Air temperature sensor fault bargraph flashing, but no customer complaint) ignore

this memorised fault and erase it.

3 - No bargraphs illuminated

If no bargraphs are illuminated on the XR25, carry out a status and parameter check. This may help in

detecting a problem.

17-149

Page 218 of 363

JSA052.0

INJECTION

Fault finding - Status and parameter checks

17

D7F 710

engine -

55 tracks

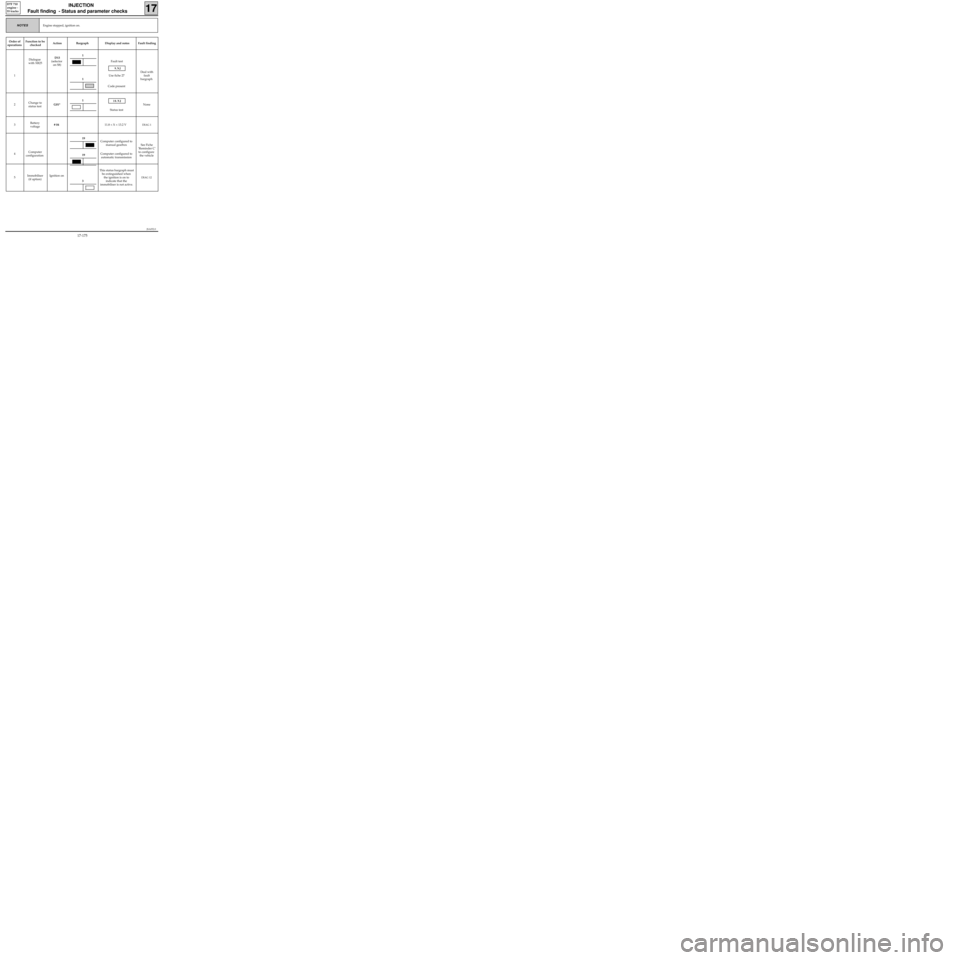

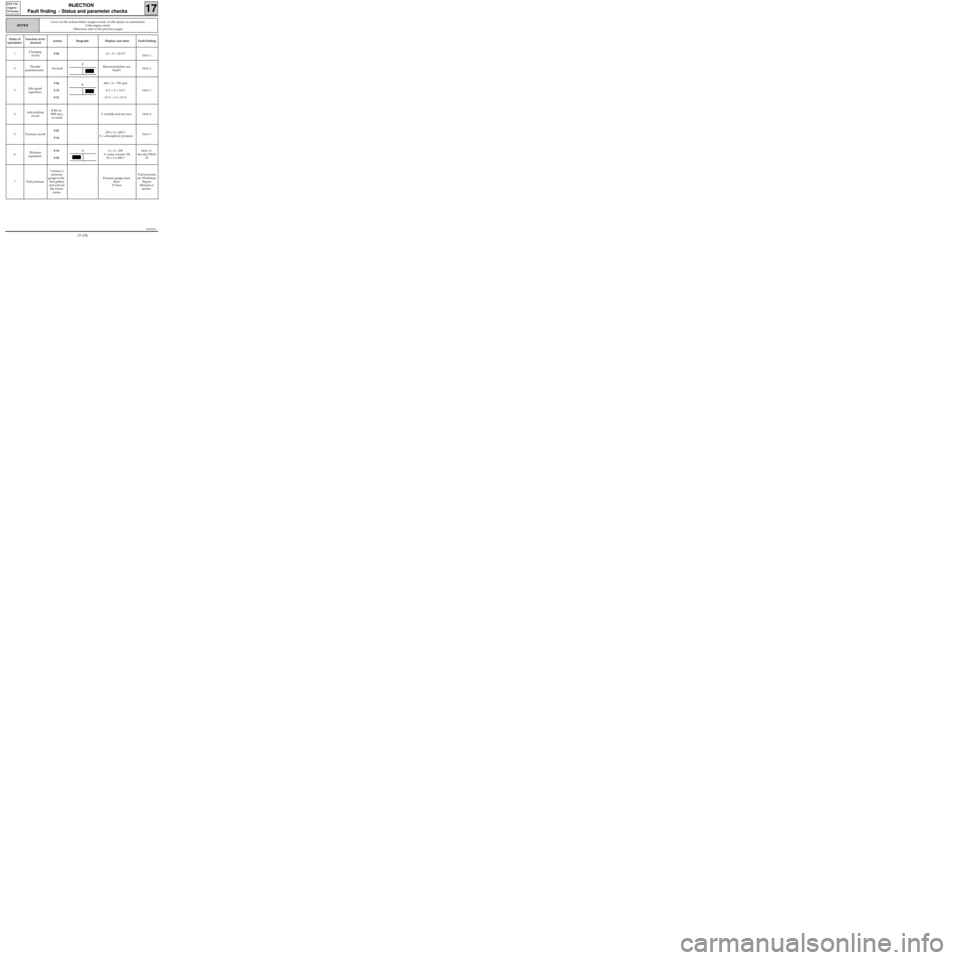

Engine stopped, ignition on.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes Fault finding

1Dialogue

with XR25D13

(selector

on S8)Fault test

9.NJ

Use fiche 27

Code present

Deal with

fault

bargraph

2Change to

status testG01*

10.NJ

Status testNone

3Battery

voltage# 0411.8 < X < 13.2 V

DIAG 1

4Computer

configurationComputer configured to

manual gearbox

Computer configured to

automatic transmissionSee Fiche

’Reminder C’

to configure

the vehicle

5Immobiliser

(if option)Ignition onThis status bargraph must

be extinguished when

the ignition is on to

indicate that the

immobiliser is not active.

DIAG 12

1

19

19

1

1

3

17-175

Page 219 of 363

JSA052.0

INJECTION

Fault finding - Status and parameter checks

17

D7F 710

engine -

55 tracks

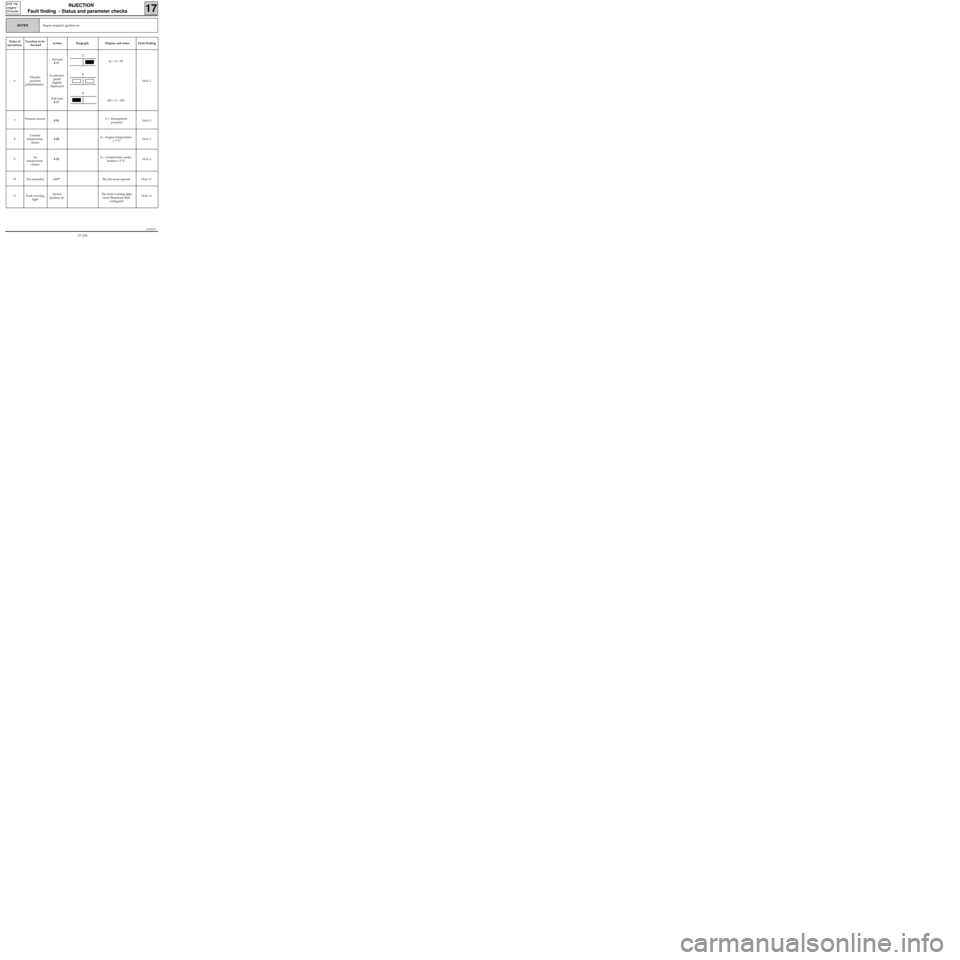

Engine stopped, ignition on.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes Fault finding

6Throttle

position

potentiometer

.No load

# 17

Accelerator

pedal

slightly

depressed

Full load

# 1710 < X < 50

185 < X < 245

DIAG 2

7Pressure sensor

# 01X = Atmospheric

pressureDIAG 9

8Coolant

temperature

sensor# 02X = Engine temperature

± 5 °CDIAG 3

9Air

temperature

sensor# 03X = Temperature under

bonnet ± 5 °CDIAG 4

10 Fan assemblyG17*The fan must operateDIAG 17

11 Fault warning

lightSwitch

ignition onThe fault warning light

must illuminate then

extinguishDIAG 19

2

2

2

17-176

Page 220 of 363

JSA052.0

INJECTION

Fault finding - Status and parameter checks

17

D7F 710

engine -

55 tracks

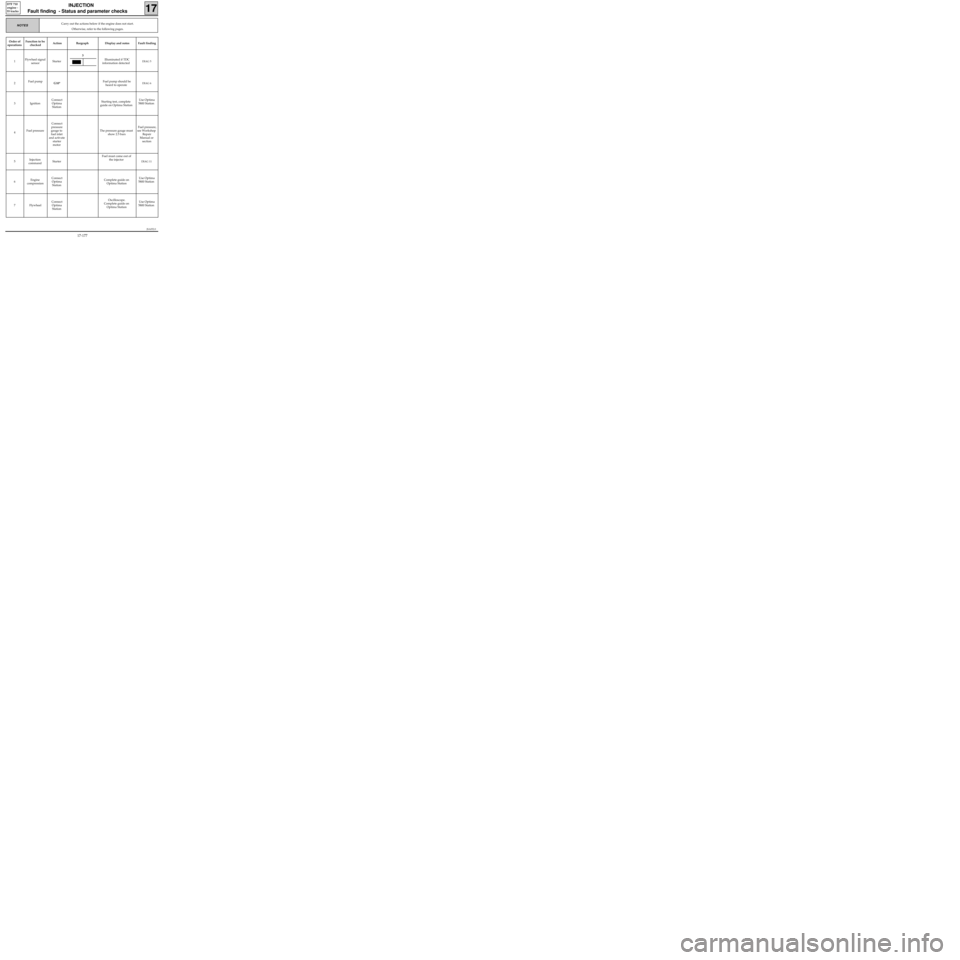

Carry out the actions below if the engine does not start.

Otherwise, refer to the following pages.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes Fault finding

1Flywheel signal

sensorStarterIlluminated if TDC

information detected

DIAG 5

2Fuel pump

G10*Fuel pump should be

heard to operateDIAG 6

3 IgnitionConnect

Optima

StationStarting test, complete

guide on Optima StationUse Optima

5800 Station

4Fuel pressureConnect

pressure

gauge to

fuel inlet

and activate

starter

motorThe pressure gauge must

show 2.5 bars Fuel pressure,

see Workshop

Repair

Manual or

section

5Injection

commandStarterFuel must come out of

the injector

DIAG 11

6Engine

compressionConnect

Optima

StationComplete guide on

Optima StationUse Optima

5800 Station

7 FlywheelConnect

Optima

StationOscilloscope.

Complete guide on

Optima StationUse Optima

5800 Station

3

17-177

Page 221 of 363

JSA052.0

INJECTION

Fault finding - Status and parameter checks

17

D7F 710

engine -

55 tracks

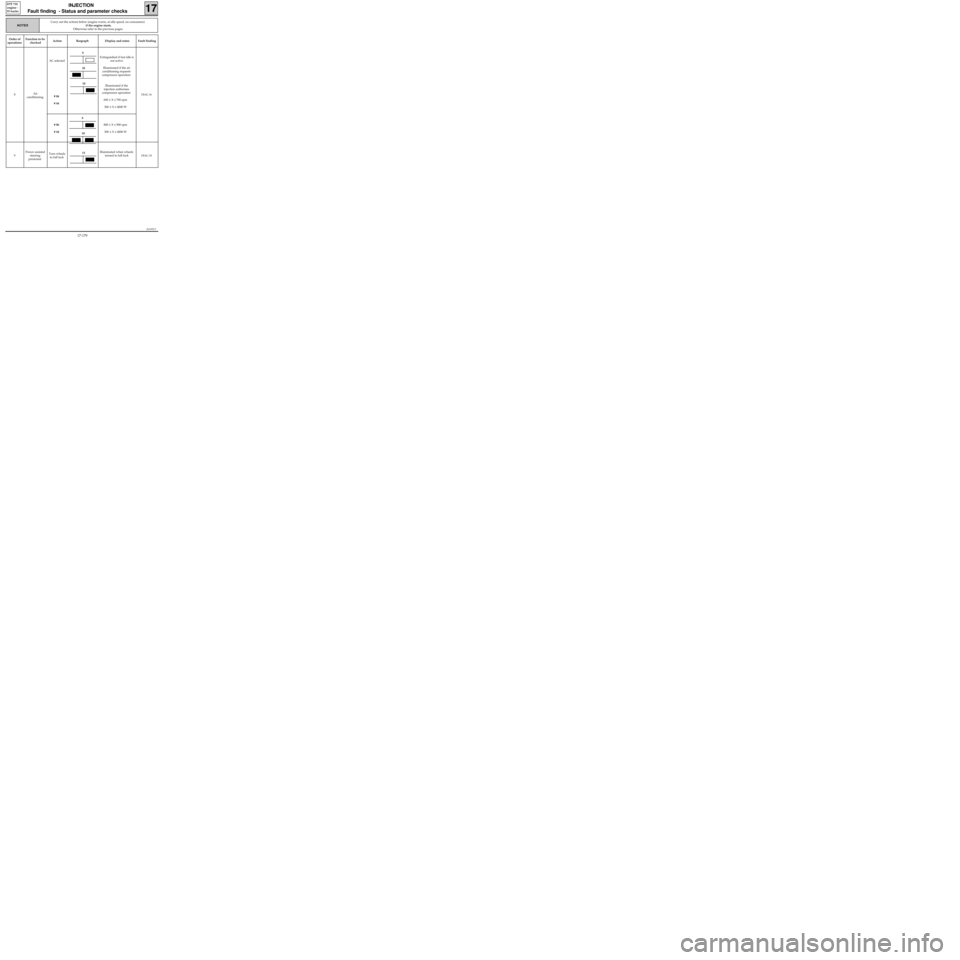

Order of

operationsFunction to be

checkedAction Bargraph Display and notes Fault finding

1Charging

circuit# 0413 < X < 14.5 V

DIAG 1

2Throttle

potentiometerNo loadIlluminated(does not

flash!)DIAG 2

3Idle speed

regulation# 06

# 12

# 21690 < X < 790 rpm

4 % < X < 14 %

- 4.3 % < X < 3.9 %DIAG 7

4Anti-pinking

circuit# 13 (at

3500 rpm,

no load)X variable and not zeroDIAG 8

5 Pressure circuit# 01

# 16270 ≤ X ≤ 430 V

X = atmospheric pressureDIAG 9

6Richness

regulation# 35

# 050 < X < 255

X varies around 128

50 ≤ X ≤ 900 V

DIAG 10

See also DIAG

15

7 Fuel pressureConnect a

pressure

gauge to the

fuel gallery

and activate

the starter

motorPressure gauge must

show

2.5 bars Fuel pressure,

see Workshop

Repair

Manual or

section

Carry out the actions below (engine warm, at idle speed, no consumers)

if the engine starts.

Otherwise refer to the previous pages.

NOTES

6

6

2

17-178

Page 222 of 363

JSA052.0

INJECTION

Fault finding - Status and parameter checks

17

D7F 710

engine -

55 tracks

Order of

operationsFunction to be

checkedAction Bargraph Display and notes Fault finding

8Air

conditioningAC selected

# 06

# 44

# 06

# 44Extinguished if fast idle is

not active

Illuminated if the air

conditioning requests

compressor operation

Illuminated if the

injection authorises

compressor operation

690 ≤ X ≤ 790 rpm

300 ≤ X ≤ 4000 W

800 ≤ X ≤ 900 rpm

300 ≤ X ≤ 4000 W

DIAG 16

9Power assisted

steering

prestostatTurn wheels

to full lockIlluminated when wheels

turned to full lockDIAG 18

Carry out the actions below (engine warm, at idle speed, no consumers)

if the engine starts.

Otherwise refer to the previous pages.

NOTES

10

10

9

13

10

9

17-179