exhaust RENAULT TWINGO RS 2009 2.G Engine And Peripherals Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 320 of 652

12A-55

FUEL MIXTURE

Exhaust manifold: Removal - Refitting

K4M

12A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the engine undertray,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

aDrain the gearbox (see Manual gearbox oils:

Draining - Filling) (21A, Manual gearbox).aRemove:

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the upstream expansion chamber (see 19B, Ex-

haust, Expansion chamber: Removal - Refit-

ting, page 19B-23) .

aRemove:

-the bolts (1) from the driveshaft relay bearing,

-the driveshaft relay bearing. Tightening torquesm

exhaust manifold studs9 N.m

heat shield bolts12 N.m

upstream and down-

stream oxygen sensors44 N.m

strut mounting bolt on

the cylinder block75 N.m

upstream strut bolt (ini-

tial torque)14 N.m

exhaust manifold nuts26 N.m

upstream and down-

streamstrut bolts44

N.m

upstream strut bolts44 N.m

driveshaft relay bearing

bolts21 N.m

IMPORTANT

Wear cut-resistant gloves during the operation.

131770

Page 321 of 652

12A-56

FUEL MIXTURE

Exhaust manifold: Removal - Refitting

K4M

12A

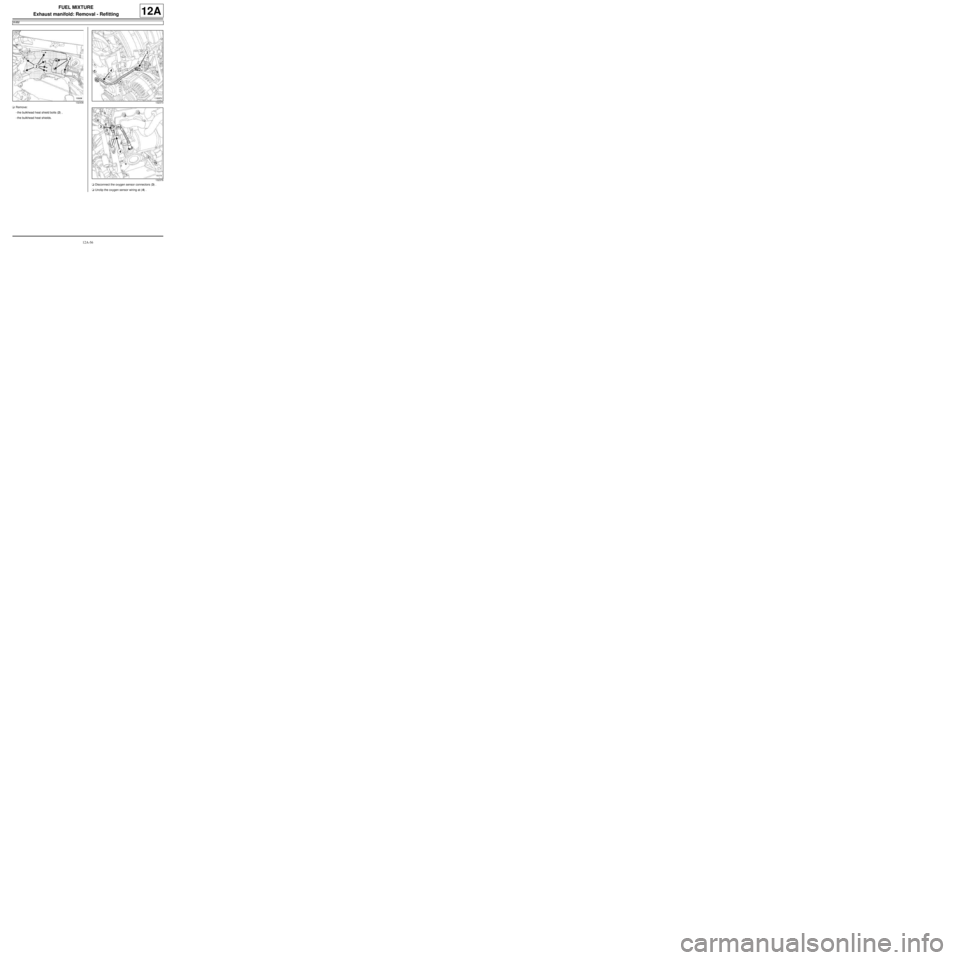

aRemove:

-the bulkhead heat shield bolts (2) ,

-the bulkhead heat shields.

aDisconnect the oxygen sensor connectors (3) .

aUnclip the oxygen sensor wiring at (4) .

132436132373

132378

Page 322 of 652

12A-57

FUEL MIXTURE

Exhaust manifold: Removal - Refitting

K4M

12A

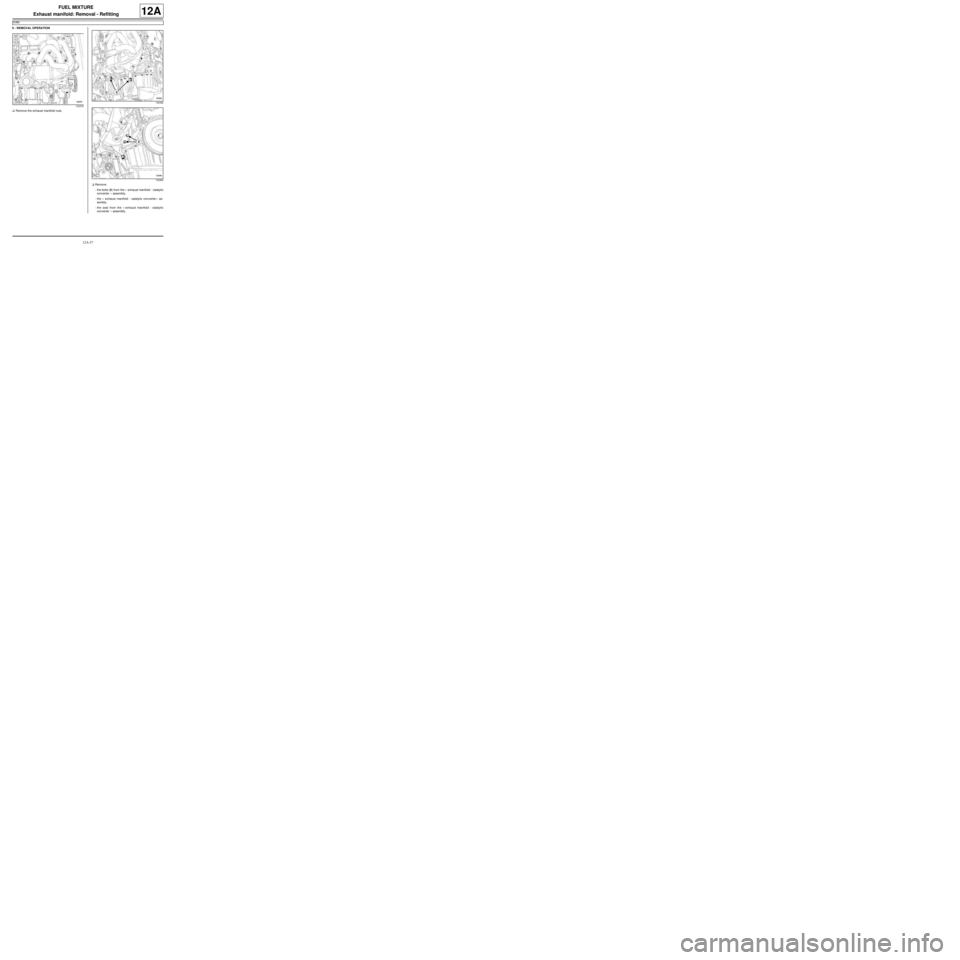

II - REMOVAL OPERATION

aRemove the exhaust manifold nuts.

aRemove:

-the bolts (5) from the « exhaust manifold - catalytic

converter » assembly,

-the « exhaust manifold - catalytic converter » as-

sembly,

-the seal from the « exhaust manifold - catalytic

converter » assembly.

132379

132392

132360

Page 323 of 652

12A-58

FUEL MIXTURE

Exhaust manifold: Removal - Refitting

K4M

12A

If replacing the « exhaust manifold - catalytic

converter » assembly

aRemove:

-the upstream and downstream oxygen sensors (6)

,

-the heat shield (7) .

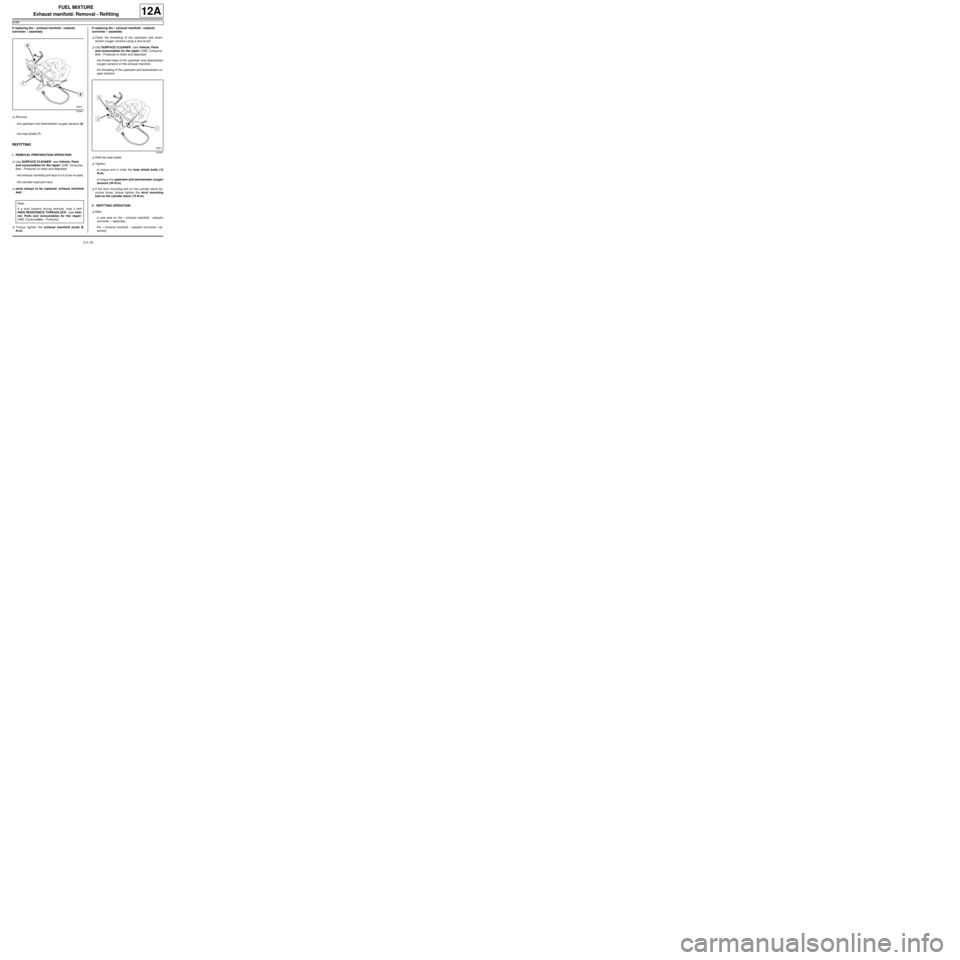

REFITTING

I - REMOVAL PREPARATION OPERATION

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the exhaust manifold joint face if it is to be re-used,

-the cylinder head joint face.

aparts always to be replaced: exhaust manifold

seal.

aTorque tighten the exhaust manifold studs (9

N.m).If replacing the « exhaust manifold - catalytic

converter » assembly

aClean the threading of the upstream and down-

stream oxygen sensors using a wire brush.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the thread holes of the upstream and downstream

oxygen sensors on the exhaust manifold,

-the threading of the upstream and downstream ox-

ygen sensors.

aRefit the heat shield.

aTighten:

-to torque and in order the heat shield bolts (12

N.m),

-to torque the upstream and downstream oxygen

sensors ( 44 N.m).

aIf the strut mounting bolt on the cylinder block be-

comes loose, torque tighten the strut mounting

bolt on the cylinder block ( 75 N.m).

II - REFITTING OPERATION

aRefit:

-a new seal on the « exhaust manifold - catalytic

converter » assembly,

-the « exhaust manifold - catalytic converter » as-

sembly.

132441

Note:

If a stud loosens during removal, coat it with

HIGH RESISTANCE THREADLOCK (see Vehi-

cle: Parts and consumables for the repair)

(04B, Consumables - Products).

132441

Page 324 of 652

12A-59

FUEL MIXTURE

Exhaust manifold: Removal - Refitting

K4M

12A

aPretighten the upstream strut bolt (initial torque)

(14 N.m) (8) .

aTorque tighten in order the exhaust manifold nuts

(26 N.m).aTorque tighten the upstream and downstream

(strut bolts44 N.m) (9) .

aTorque tighten the upstream strut bolts (44 N.m)

(10) .

III - FINAL OPERATION

aClip on the oxygen sensor wiring.

aConnect the oxygen sensor connectors.

aRefit:

-the bulkhead heat shields,

132360

132379132392

132360

Page 325 of 652

12A-60

FUEL MIXTURE

Exhaust manifold: Removal - Refitting

K4M

12A

-the driveshaft relay bearing.

aTorque tighten the driveshaft relay bearing bolts

(21 N.m).

aRefit:

-the upstream expansion chamber (see 19B, Ex-

haust, Expansion chamber: Removal - Refit-

ting, page 19B-23) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts).

aFill the gearbox (see Manual gearbox oils: Drain-

ing - Filling) (21A, Manual gearbox).

aRefit:

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the engine undertray.

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

Page 326 of 652

12B-1

TURBOCHARGING

Turbocharging: Precautions for the repair

D4F or K9K

12B

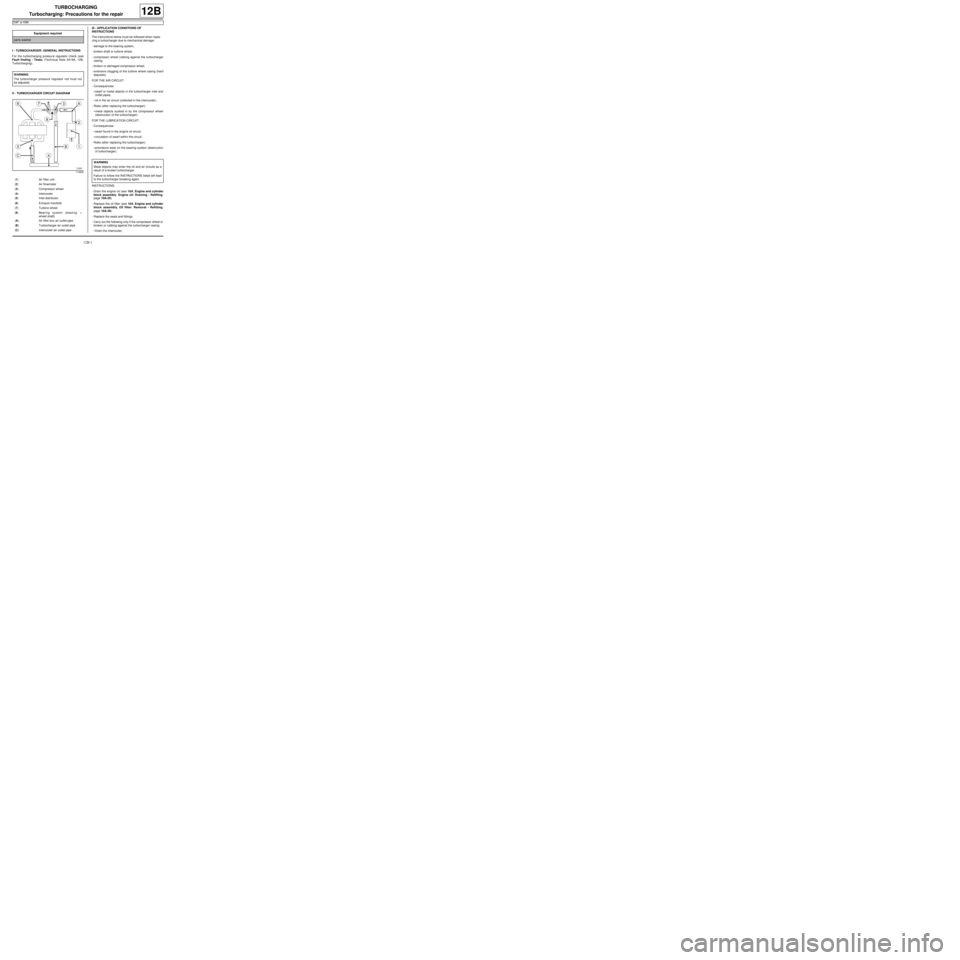

I - TURBOCHARGER: GENERAL INSTRUCTIONS

For the turbocharging pressure regulator check (see

Fault finding - Tests) (Technical Note 3419A, 12B,

Turbocharging).

II - TURBOCHARGER CIRCUIT DIAGRAMIII - APPLICATION CONDITIONS OF

INSTRUCTIONS

The instructions below must be followed when repla-

cing a turbocharger due to mechanical damage:

-damage to the bearing system,

-broken shaft or turbine wheel,

-compressor wheel rubbing against the turbocharger

casing,

-broken or damaged compressor wheel,

-extensive clogging of the turbine wheel casing (hard

deposits).

FOR THE AIR CIRCUIT:

-Consequences:

•swarf or metal objects in the turbocharger inlet and

outlet pipes,

•oil in the air circuit (collected in the intercooler).

-Risks (after replacing the turbocharger):

•metal objects sucked in by the compressor wheel

(destruction of the turbocharger).

FOR THE LUBRICATION CIRCUIT:

-Consequences:

•swarf found in the engine oil circuit,

•circulation of swarf within the circuit.

-Risks (after replacing the turbocharger):

•premature wear on the bearing system (destruction

of turbocharger).

INSTRUCTIONS:

-Drain the engine oil (see 10A, Engine and cylinder

block assembly, Engine oil: Draining - Refilling,

page 10A-22)

-Replace the oil filter (see 10A, Engine and cylinder

block assembly, Oil filter: Removal - Refitting,

page 10A-29) .

-Replace the seals and fittings,

-Carry out the following only if the compressor wheel is

broken or rubbing against the turbocharger casing:

•Drain the intercooler, Equipment required

par ts washer

WARNING

The turbocharger pressure regulator rod must not

be adjusted.

112666

(1) Air filter unit

(2) Air flowmeter

(3) Compressor wheel

(4) Intercooler

(5) Inlet distributor

(6) Exhaust manifold

(7) Turbine wheel

(8) Bearing system (bearing +

wheel shaft)

(A) Air filter box air outlet pipe

(B) Turbocharger air outlet pipe

(C) Intercooler air outlet pipe

WARNING

Metal objects may enter the oil and air circuits as a

result of a broken turbocharger.

Failure to follow the INSTRUCTIONS listed will lead

to the turbocharger breaking again.

Page 329 of 652

12B-4

TURBOCHARGING

Turbocharger: Removal - Refitting

K9K

12B

REMOVAL

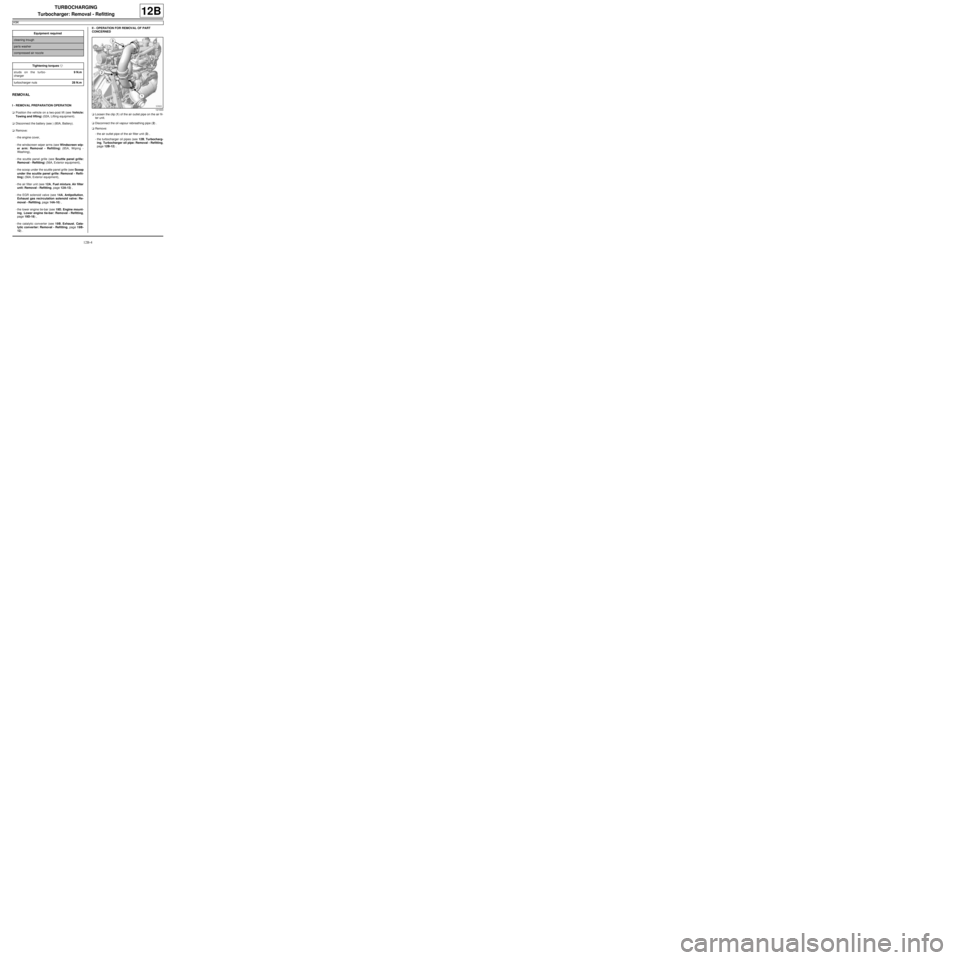

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the engine cover,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the EGR solenoid valve (see 14A, Antipollution,

Exhaust gas recirculation solenoid valve: Re-

moval - Refitting, page 14A-10) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLoosen the clip (1) of the air outlet pipe on the air fil-

ter unit.

aDisconnect the oil vapour rebreathing pipe (2) .

aRemove:

-the air outlet pipe of the air filter unit (3) ,

-the turbocharger oil pipes (see 12B, Turbocharg-

ing, Turbocharger oil pipe: Removal - Refitting,

page 12B-12) . Equipment required

cleaning trough

par ts washer

compressed air nozzle

Tightening torquesm

studs on the turbo-

charger9 N.m

turbocharger nuts28 N.m

121633

Page 331 of 652

12B-6

TURBOCHARGING

Turbocharger: Removal - Refitting

K9K

12B

aRemove:

-the turbocharger nuts (8) ,

-the turbocharger,

-the turbocharger seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: seal between ex-

haust manifold and turbocharger.

aIf there has been a fault in the turbocharger, check

that the inlet circuit assembly is not full of oil. If it is,

remove the components to be cleaned, and clean

them using a cleaning trough or a parts washer

then dry them using a compressed air nozzle.

aIf the turbocharger is being reused, clean it using a

cleaning trough or a parts washer then dry it using

a compressed air nozzle.

aUse ABRASIVE PADS (see Vehicle: Parts and

consumables for the repair) (04B, Consumables -

Products) to clean the bearing faces:

-the exhaust manifold - turbocharger,

-the turbocharger - catalytic converter,

-the turbocharger - oil return pipe.aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) and clean cloths to degrease the

mating faces:

-of the exhaust manifold on the turbocharger side,

-of the turbocharger on the exhaust manifold side,

-of the turbocharger on the catalytic converter side,

-of the turbocharger on the oil return pipe side,

-of the catalytic converter on the turbocharger side.

aIn the event of replacement, torque tighten the

studs on the turbocharger (9 N.m).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the turbocharger fitted with a new seal.

aTorque tighten the turbocharger nuts (28 N.m).

aConnect:

-the turbocharging pressure regulator pipe,

-the intercooler air inlet pipe on the turbocharger

side.

aClip the intercooler air inlet pipe on the turbocharger

side.

aConnect the turbocharger air outlet pipe to the turbo-

charger.

aTighten the clip of the turbocharger air outlet pipe on

the turbocharger.

aRefit the turbocharger oil pipes (see 12B, Turbo-

charging, Turbocharger oil pipe: Removal - Re-

fitting, page 12B-12) .

aRefit the air outlet pipe onto the air filter unit.

112327

WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

K9K, and 718

K9K, and 740

Page 332 of 652

12B-7

TURBOCHARGING

Turbocharger: Removal - Refitting

K9K

12B

III - FINAL OPERATION

aRefit:

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the EGR solenoid valve (see 14A, Antipollution,

Exhaust gas recirculation solenoid valve: Re-

moval - Refitting, page 14A-10) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the engine cover.

aConnect the battery (see ) (80A, Battery).