Seat Ibiza 2020 Directive 2014/53/EU Bluetooth

Manufacturer: SEAT, Model Year: 2020, Model line: Ibiza, Model: Seat Ibiza 2020Pages: 406, PDF Size: 9.22 MB

Page 221 of 406

Page 8 of 88 Report No. : 60404489 001

TR F No. IEC62368_1 C

Name and address of factory (ies) ................. :

Factory #1. LG Electronics Vietnam Hai Phong Co., Ltd.

Lot CN2, Trang Due Industrial Park, Le Loi Com mune, An Duong District, Hai Phong City,

Vietnam

Factory #2. LG INNOTEK YANTAI CO., LTD.

No. 36, Taibei North Road, Development Zone, Yantai 264006 Shandong P.R. China

Factory #3. LG Electronics Mława Sp. z o.o.

ul. LG Electronics 7 06 - 500 Mława Poland

Fac tory #4. LG Electronics Inc.

222, LG - ro, Jinwi - myeon Pyeongtaek - si, Gyeonggi - do 17709 Republic of Korea

Factory #5. LG Electronics(Kunshan) Co., Ltd.

No. 88, Qianjin East Road, Kunshan City 215300 Jiangsu P.R. China

Factory #6. LG ELECTRONICS DO BRASIL LTD A

LG - FILIAL MANAUS RUA JAVARI 1004 DISTRITO INDUSTRIAL MANAUS - AM, 69075 - 110,

Brazil

Factory #7. LG Electronics Nanjing Vehicle Component Co., Ltd.

No.346, Yaoxinda Road, Nanjing Economic and Technological Development Zone, 210038,

P.R. China

Factory #8 . Hitachi - LG Data Storage(Huizhou), Ltd.

Huifeng Fourth Road 42, Zhongkai Hi - Tech Industry Development Zone, Huizhou, Guangdong,

516006 P.R. China

Factory #9. HITACHI ELECTRONIC PRODUCTS (M) SDN. BHD

No. 12, Jalan Kemajuan, Bangi Industrial Estate, 43650 B andar Baru Bangi,

Selangor Darul Ehsan, Malaysia

Page 222 of 406

Page 9 of 88 Report No. : 60404489 001

TR F No. IEC62368_1 C

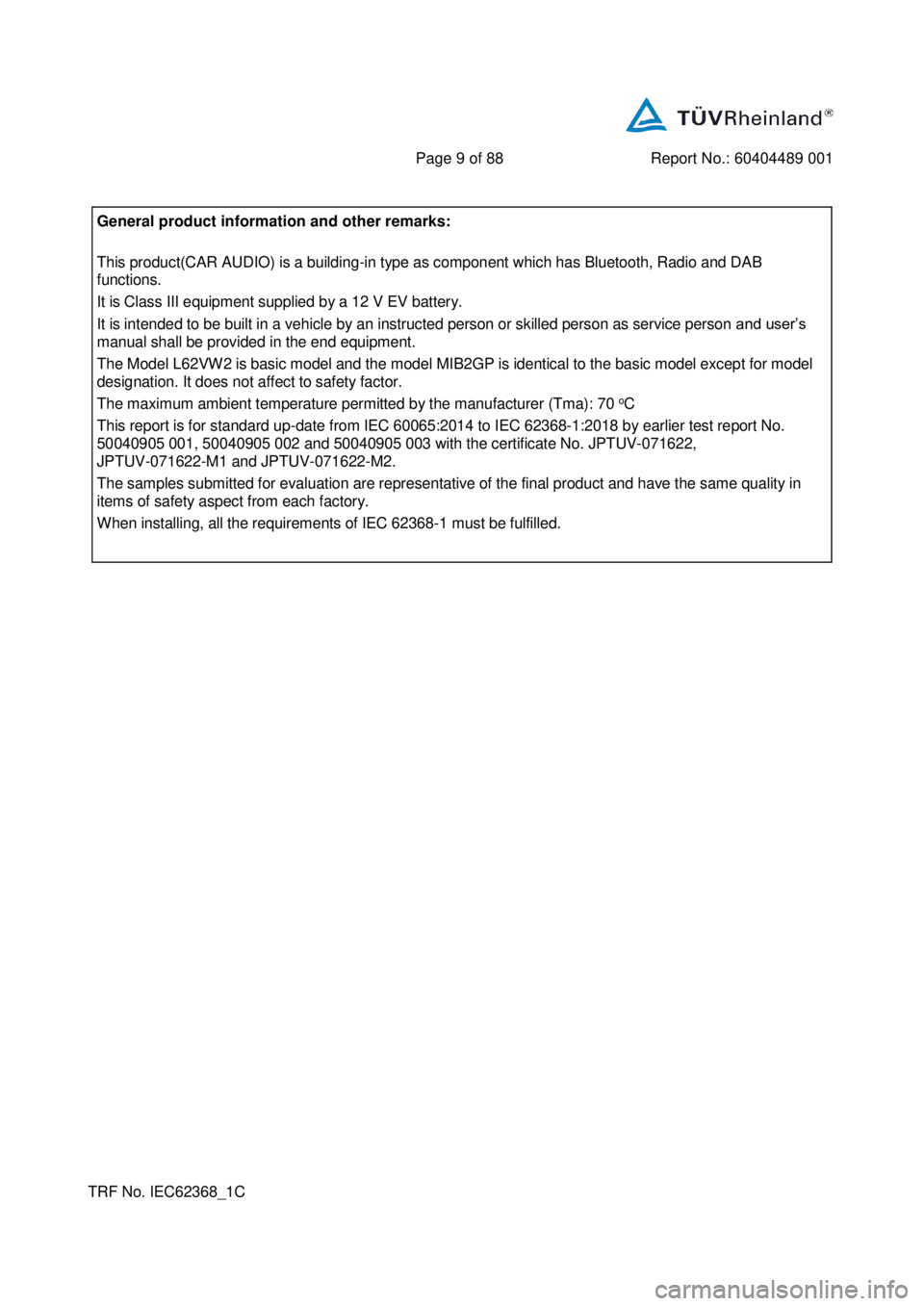

General product information and other remarks:

This product(CAR AUDIO) is a building - in type as component which has Bluetooth, Radio and DAB

functions.

It is Class III equipment supplied by a 12 V EV b attery.

It is intended to be built in a vehicle by an instructed person or skilled person as service person and user’s

manual shall be provided in the end equipment.

The Model L6 2VW 2 is basic model and the model MIB2GP is identical to the basic model excep t for model

designation . It does not affect to safety factor.

The maximum ambient temperature permitted by the manufacturer (Tma): 70 o

C

This report is for standard up - date from IEC 60065:2014 to IEC 62368 - 1:2018 by earlier test report No.

50040905 001, 50 040905 002 and 50040905 003 with the certificate No. JPTUV - 071622,

JPTUV - 071622 - M1 and JPTUV - 071622 - M2.

The samples submitted for evaluation are representative of the final product and have the same quality in

items of safety aspect from each factory.

Whe n installing, all the requirements of IEC 62368 - 1 must be fulfilled.

Page 223 of 406

Page 10 of 88 Report No. : 60404489 001

TR F No. IEC62368_1 C

OVERVIEW OF ENERGY SOURCES AND SAFEGUARDS

Clause Possible Hazard

5 Electrically - caused injury

Class and Energy Source

(e.g. ES3: Primary circuit) Body Part

(e.g. Ordinary) Safeguar ds

B S R

ES1: All parts Ordinary N/A N/A N/A

6 Electrically - caused fire

Class and Energy Source

(e.g. PS2: 100 Watt circuit) Material part

(e.g. Printed board ) Safeguards

B 1 st

S 2 nd

S

PS3: > 100 Watt circuit PCB and combustible

materials within the metallic

enclosure and

mains parts See clause

6.3.1 Control fire

spread,

Min V - 1,

PCB ,

connector

V - 1 See clause

6.4.1

Fire

enclosure is

provided

PS2: > PS1, ≤ 100 W att circuit PCB and combustible

materials i n monitor ,

Keyboard circuits See clause

6.3.1 See clause

6.4.5.2 N/A

7 Injury caused by hazardous substances

Class and Energy Source

(e.g. Ozone) Body Part

(e.g., Skilled) Safeguards

B S R

N/A N/A N/A N/A N/A

8 Mechanically - caused injury

Class and Energy Source

(e.g. MS3: Plastic fan blades) Body Part

(e.g. Ordinary) Safeguards

B S R

MS1: Sharp edges and corners Ordinary N/A N/A N/A

MS1: Equipment mass Ordinary N/A N/A N/A

9 Therm al burn

Class and Energy Source

(e.g. TS1: Keyboard caps) Body Part

(e.g., Ordinary) Safeguards

B S R

TS1:Monitor enclosure Ordinary N/A N/A N/A

TS1:Screen surface Ordinary N/A N/A N/A

TS1:Keyboard enclosure Ordinary N/A N/A N/A

Page 224 of 406

Page 11 of 88 Report No. : 60404489 001

TR F No. IEC62368_1 C

10 Radiation

Cla ss and Energy Source

(e.g. RS1: PMP sound output) Body Part

(e.g., Ordinary) Safeguards

B S R

RS1:Indicating lights Ordinary N/A N/A N/A

Supplementary Information:

“B” – Basic Safeguard; “S” – Supplementary Safeguard; “R” – Reinforced Safeguard

Page 225 of 406

Page 12 of 88 Report No. : 60404489 001

TR F No. IEC62368_1 C

E NERGY SOURCE DIAGRAM

Optional . Manufacturers are to provide the energy sources diagram identify declared energy sources and

identifying the demarcations are between power sources. Recommend diagram be provided included in

power supply and multipart system s.

Insert diagram below. Example diagram designs are; Block diagrams; image(s) with layered data; mechanical

drawings

■ ES ■ PS ■ MS ■ TS ■ RS

ES Classification:

ES1: All parts .

PS Classification:

PS3: Head unit .

PS2: LCD m odule and Keyboard circuits .

MS classification:

MS1 : There are no sharp edges or corners . Equipment mass is under 7 kg .

TS classification:

TS1: All accessible parts including monitor enclosure, screen surface and keyboard enclosure .

RS classification:

R S1: Indicating lights and low power devices.

Page 226 of 406

Page 13 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

4 GENERAL REQUIREMENTS

P

4.1.1 Acceptance of materials, components and

subassemblies (See appended table 4.1.2) P

4.1.2 Use of components

The equipment is so designed

and constructed that, under

normal ope rating conditions

(see Clause B.2), abnormal

operating conditions (see

Clause B.3), and single fault

conditions (see Clause B.4),

safeguards are provided to

reduce the likelihood of injury

or, in the case of fire, property

damage P

4.1.3 Equipment design and construction

P

4.1.4 Specified ambient temperature for outdoor use ( o

C)

................................ ................................ .................... : Not intended for outdoor use N/A

4.1.5 Constructions and components not specifically

covered N/A

4.1.8 Liquids and liquid filled components (LFC) N/A

4.1.15 Markings and instructions (See Annex F) P

4.4.3 Safeguard robustness P

4.4.3.1 General P

4.4.3.2 Steady force tests Building - in equipment N/A

4.4.3.3 Drop tests Building - in equipment N/A

4.4.3.4 Impact tests P

4.4.3.5 Internal accessible safeguard tests No In ternal accessible

safeguard is used N/A

4.4.3.6 Glass impact tests No glass in the equipment N/A

4.4.3.7 Glass fixation tests No laminated glass used N/A

Glass impact test (1J) N/A

Push/pull test (10 N) N/A

4.4.3.8 Thermoplastic material tests P

4.4.3.9 Air comprising a safeguard N/A

4.4.3.10 Accessibility, glass, safeguard effectiveness P

4.4.4 Displacement of a safeguard by an insulating liquid No insulating liquid used N/A

4.4.5 Safety interlocks No Safety interlocks N/A

Page 227 of 406

Page 14 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

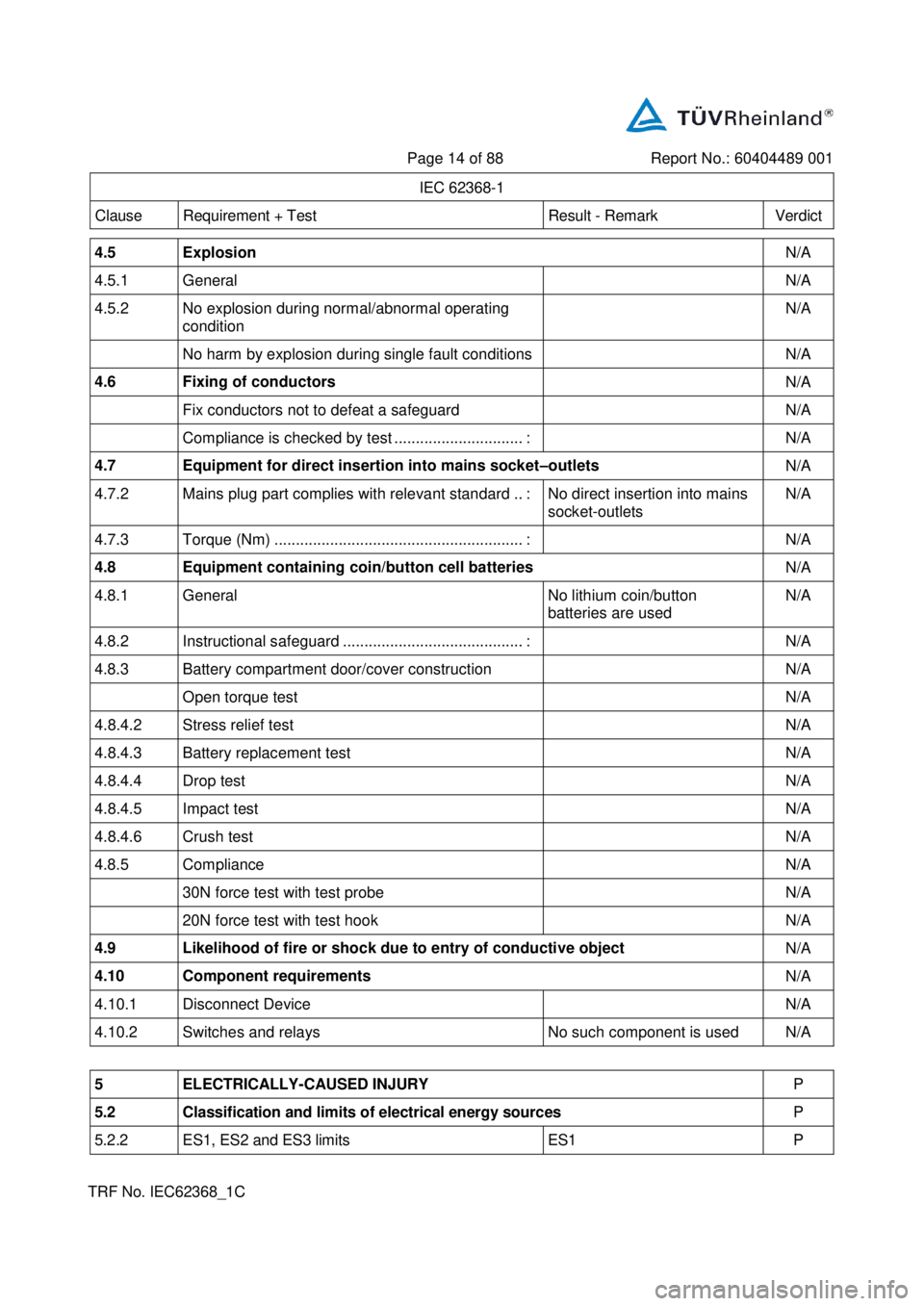

4.5 Explosion

N /A

4.5.1 General N/A

4.5.2 No explosion during normal/abnormal operating

condition N/A

No harm by explosion during single fault conditions N/A

4.6 Fixing of conductors

N/A

Fix conductors not to defeat a safeguard N/A

Compliance is checked by test .............................. : N/A

4.7 Equipment for direct insertion into mains socket – outlets

N/A

4.7.2 Mains plug part complies with relevant standard .. : No direct insertion into mains

socket - outlets N/A

4.7.3 Torque (Nm) ................................ .......................... : N/A

4.8 Equipment containing coin/button cell ba tteries

N/A

4.8.1 General No lithium coin/button

batteries are used N/A

4.8.2 Instructional safeguard ................................ .......... : N/A

4.8.3 Battery compartment door/cover construction N/A

Open torque test N/A

4.8.4.2 Stress relief test N/A

4.8.4.3 Battery replacement tes t N/A

4.8.4.4 Drop test N/A

4.8.4.5 Impact test N/A

4.8.4.6 Crush test N/A

4.8.5 Compliance N/A

30N force test with test probe N/A

20N force test with test hook N/A

4.9 Likelihood of fire or shock due to entry of conductive object

N/A

4.10 Component requirements

N/A

4.10.1 Disconnect Device N/A

4.10.2 Switches and relays No such component is used N/A

5 ELECTRICALLY - CAUSED INJURY

P

5.2 Classification and limits of electrical energy sources

P

5.2.2 ES1, ES2 and ES3 limits ES1 P

Page 228 of 406

Page 15 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.2.2 .2 Steady - state voltage and current limits .................... : (See appended table 5.2) P

5.2.2.3 Capacitance limits ................................ ..................... : N/A

5.2.2.4 Single pulse limits ................................ ..................... : No such single pulse with the

e quipment N/A

5.2.2.5 Limits for repetitive pulses ................................ ........ : No such repetitive pulses with

the e quipment N/A

5.2.2.6 Ringing signals No Ringing signals N/A

5.2.2.7 Audio signals P

5.3 Protection against electrical energy sources

N/A

5.3.1 General Requirements for accessible parts to

ordinary, instructed and skilled persons Only ES1 N/A

5.3. 1 a) Accessible ES1/ES2 derived from ES2/ES3 circuits N/A

5.3.1 b) Skilled persons not unintentional contact ES3 bare

conductors N/A

5.3.2.1 Accessibility to electrical energy sources and

safeguards N/A

Accessibility to outdoor equipment bare parts N/A

5.3.2.2 Contact requirements N/A

Test with test probe from Annex V -

5.3.2.2 a) Air gap – electric strength test potential (V) ............. : N/A

5.3.2.2 b) Air gap – distance (mm) ................................ ........... : N/A

5.3.2.3 Compliance N/A

5.3.2.4 Terminals for connecting strippe d wire N/A

5.4 Insulation materials and requirements

N/A

5.4.1.2 Properties of insulating material N/A

5.4.1.3 Material is non - hygroscopic N/A

5.4.1.4 Maximum operating temperature for insulating

materials ................................ ................................ .... : N/A

5.4.1.5 Pollution degrees ................................ ...................... : N/A

5.4.1.5.2 Test for pollution degree 1 environment and for an

insulating compound N/A

5.4.1.5.3 Thermal cycling test N/A

5.4.1.6 Insulation in transformers with varying dimensions N/A

5.4.1.7 Insulation in circuits generating starting pulses N/A

5. 4.1.8 Determination of working voltage ............................. : N/A

Page 229 of 406

Page 16 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.4.1.9 Insulating surfaces N/A

5.4.1.10 Thermoplastic parts on which conductive metallic

parts are directly mounted N/A

5.4.1.10.2 Vicat test ................................ ................................ .... : N/A

5.4.1.10.3 Ball pressure test ................................ ...................... : N/A

5.4.2 Clearances N/A

5.4.2.1 General requirements N/A

Clearances in circuits connected to AC Mains,

Alternative method N/A

5.4.2.2 Procedure 1 for determining clearance N/A

Temporary overvoltage ................................ ............ :

5.4.2.3 Procedure 2 for determining clearance N/A

5.4.2.3 .2.2 a.c. mains transient voltage ................................ ...... :

5.4.2.3.2.3 d.c. mains transient voltage ................................ ..... :

5.4.2.3.2.4 External circuit transient voltage ............................... :

5.4.2.3.2.5 Transient voltage determined by measurement ...... :

5.4.2.4 Determining the adequacy of a clearance using an

electric strength test ................................ ................. : N/A

5.4.2.5 Multiplication factors for clearances and test voltages

................................ ................................ ................... : N/A

5.4.2.6 Clearance measurement ................................ .......... : N/A

5.4.3 Creepage distances N/A

5.4.3.1 General N/A

5.4.3.3 Material group ................................ ........................... :

5.4.3.4 Creepage distances measurement .......................... : N/A

5.4.4 Solid insulation N/A

5.4.4.1 General requirements N/A

5.4.4.2 Minimum distance through insulation ...................... : N/A

5.4.4.3 Insulating compound forming solid insulation N/A

5.4.4.4 Solid insulation in semiconductor devices N/A

5. 4.4.5 Insulating compound forming cemented joints N/A

5.4.4.6 Thin sheet material N/A

5.4.4.6.1 General requirements N/A

5.4.4.6.2 Separable thin sheet material N/A

Page 230 of 406

Page 17 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Number of layers (pcs) ................................ ............ : N/A

5.4.4.6.3 Non - separable thin sheet material N/A

Number of layers (pcs) ................................ ......... : N/A

5.4.4.6.4 Standard test procedure for non - separable thin

sheet material ................................ ........................ : N/A

5.4.4.6.5 Mandrel test N/A

5.4.4.7 Solid i nsulation in wound components N/A

5.4.4.9 Solid insulation at frequencies >30 kHz, E

P , K

R , d ,

V

PW (V) ................................ ................................ ... : N/A

Alternative by electric strength test, tested voltage

(V), K

R ................................ ................................ .... : N/A

5.4.5 Antenna terminal insulation No a ntenna terminal N/A

5.4.5.1 General N/A

5.4.5.2 Voltage surge test N/A

5.4.5.3

Insulation resistance (M ) ................................ ..... : N/A

Electric st rength test ................................ ................. : N/A

5.4.6 Insulation of internal wire as part of supplementary

safeguard N/A

5.4.7 Tests for semiconductor components and for

cemented joints N/A

5.4.8 Humidity conditioning N/A

Relative humidity (%), temperature (°C), duration

(h) ................................ ................................ .......... :

5.4.9 Electric strength test Class III equipment N/A

5.4.9.1 Test procedure for type test of solid insulation ....... : N/A

5.4.9.2 Test procedure for routine test N/A

5.4.10 Safeguards against transient voltages from external

circuits N/A

5.4.10.1 Par ts and circuits separated from external circuits N/A

5.4.10.2 Test methods N/A

5.4.10.2.1 General N/A

5.4.10.2.2 Impulse test ................................ ........................... : N/A

5.4.10.2.3 Steady - state test ................................ .................... : N/A

5.4.10.3 Verification for insulation breakdown for impulse

test ................................ ................................ ......... : N/A

5.4.11 Separation between external circuits and earth N/A