Seat Ibiza 2020 Directive 2014/53/EU Bluetooth

Manufacturer: SEAT, Model Year: 2020, Model line: Ibiza, Model: Seat Ibiza 2020Pages: 406, PDF Size: 9.22 MB

Page 251 of 406

Page 38 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Instructional safeguard ................................ .......... : N/A

M EQUIPMENT CONTAINING BATTERIES AND THEIR PROTECTION CIRCUITS

N/A

M.1 General re quirements

N/A

M.2 Safety of batteries and their cells

N/A

M.2.1 Batteries and their cells comply with relevant IEC

standards ................................ ............................... : Batteries is not provided N/A

M.3 Protection circuits for batteries provided within

the equipment N/A

M.3.1 Requirements N/A

M.3.2 Test method N/A

Overcharging of a rechargeable battery N/A

Excessive discharging N/A

Unintentional charging of a non - rechargeable

battery N/A

Reverse charging of a rechargeable battery N/A

M.3.3 Compliance N/A

M.4 Additional safe guards for equipment containing a portable secondary lithium

battery N/A

M.4.1 General N/A

M.4.2 Charging safeguards N/A

M.4.2.1 Requirements N/A

M.4.2.2 Compliance ................................ ............................ : N/A

M.4.3 Fire enclosure ................................ ........................ : N/A

M.4.4 Drop test of equipment containing a secon dary

lithium battery N/A

M.4.4.2 Preparation and procedure for the drop test N/A

M.4.4.3 Drop, Voltage on reference and dropped batteries

(V); voltage difference during 24 h period (%): .... : N/A

M.4.4.4 Check of the charge/discharge function N/A

M.4. 4.5 Charge / discharge cycle test N/A

M.4.4.6 Compliance N/A

M.5 Risk of burn due to short - circuit during carrying

N/A

M.5.1 Requirement N/A

M.5.2 Test method and compliance N/A

M.6 Safeguards against short - circuits

N/A

Page 252 of 406

Page 39 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

M.6.1 External and interna l faults N/A

M.6.2 Compliance N/A

M.7 Risk of explosion from lead acid and NiCd batteries

N/A

M.7.1 Ventilation preventing explosive gas concentration N/A

Calculated hydrogen generation rate .................... : N/A

M.7.2 Test method and compliance N/A

Minimum a ir flow rate, Q (m 3

/h) ............................. :

N/A

M.7.3 Ventilation tests N/A

M.7.3.1 General N/A

M.7.3.2 Ventilation test – alternative 1 N/A

Hydrogen gas concentration (%) ........................... : N/A

M.7.3.3 Ventilation test – alternative 2 N/A

Obtained hydrogen generation rate ....................... : N /A

M.7.3.4 Ventilation test – alternative 3 N/A

Hydrogen gas concentration (%) ........................... : N/A

M.7.4 Marking ................................ ................................ .. : N/A

M.8 Protection against internal ignition from external spark sources of batteries

with aqueous electrolyte N/A

M.8.1 General N/A

M.8.2 Test method N/A

M.8.2.1 General N/A

M.8.2.2 Estimation of hypothetical volume V

Z (m 3

/s) ......... :

M.8.2.3 Correction factors ................................ .................. :

M.8.2.4 Calculation of distance d (mm) ............................. :

M.9 Preventing electrolyte spillage

N/A

M.9.1 Protection from electrolyte spillage N/A

M.9.2 Tray for preventing electrolyte spillage N/A

M.10

Instructions to prevent reasonably foreseeable

misuse N/A

Instructional safeguard ................................ .......... : N/A

N ELECTROCHEMICAL POTENTIALS

N/A

Material (s) used ................................ ..................... :

Page 253 of 406

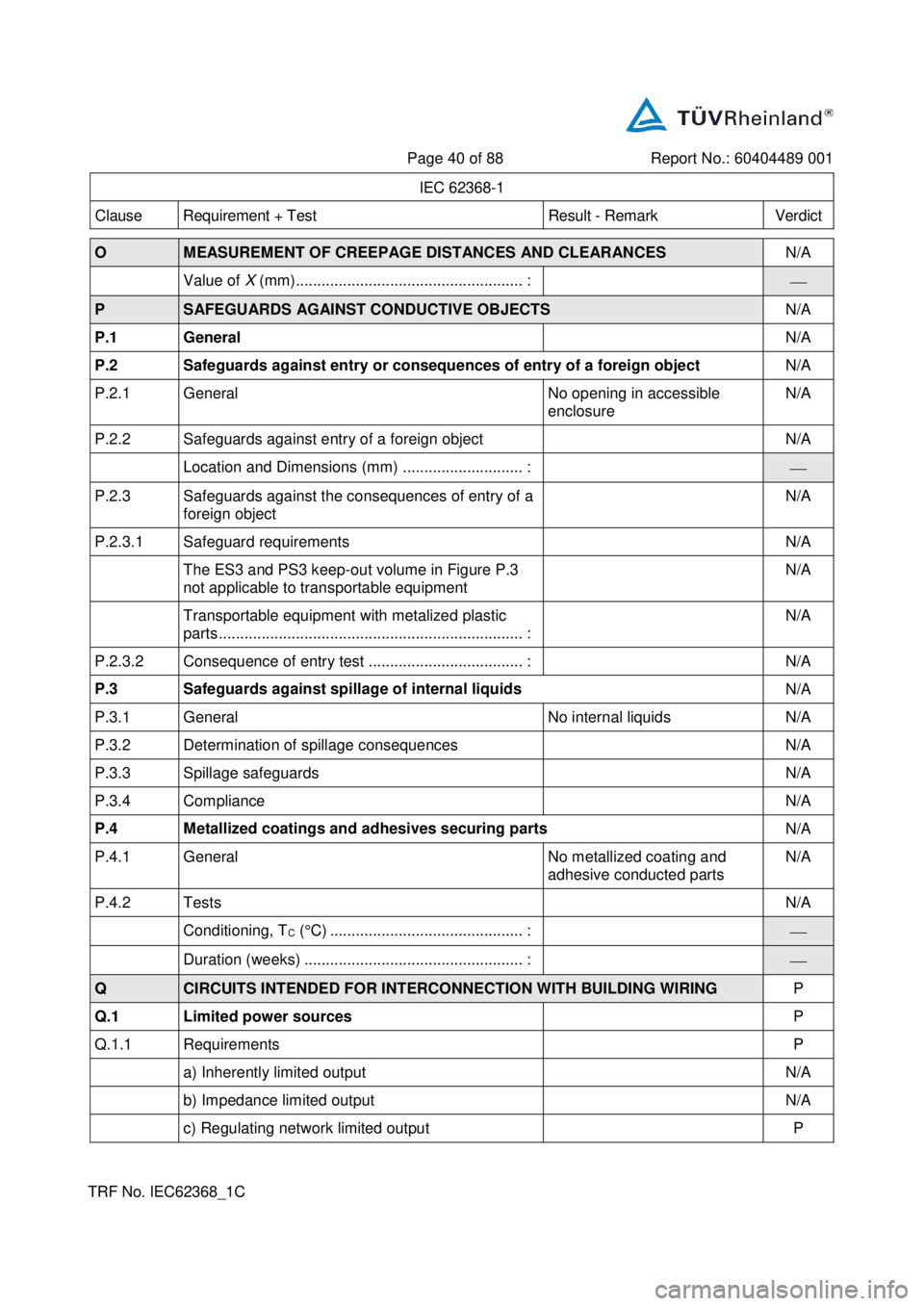

Page 40 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

O MEASUREMENT OF CREEPAGE DISTANCES AND CLEARANCES

N/A

Value of X (mm) ................................ ..................... :

P SAFEGUARDS AGAINST CONDUCTIVE OBJECTS

N/A

P.1 General

N/A

P.2 Safeguards against entry or consequences of entry of a foreign object

N/A

P.2.1 General No opening in accessible

enclosure N/A

P.2.2 Safeguards agai nst entry of a foreign object N/A

Location and Dimensions (mm) ............................ :

P.2.3 Safeguards against the consequences of entry of a

foreign object N/A

P.2.3.1 Safeguard requirements N/A

The ES3 and PS3 keep - out volume in Figure P.3

not applicable to tran sportable equipment N/A

Transportable equipment with metalized plastic

parts ................................ ................................ ....... : N/A

P.2.3.2 Consequence of entry test ................................ .... : N/A

P.3 Safeguards against spillage of internal liquids

N/A

P.3.1 General No internal liquids N/A

P.3.2 Determination of spilla ge consequences N/A

P.3.3 Spillage safeguards N/A

P.3.4 Compliance N/A

P.4 Metallized coatings and adhesives securing parts

N/A

P.4.1 General No meta l lized coating and

adhesive conducted parts N/A

P.4.2 Tests N/A

Conditioning, T

C (°C) ................................ ............. :

Du ration (weeks) ................................ ................... :

Q CIRCUITS INTENDED FOR INTERCONNECTION WITH BUILDING WIRING

P

Q.1 Limited power sources

P

Q.1.1 Requirements P

a) Inherently limited output N/A

b) Impedance limited output N/A

c) Regulating network limited output P

Page 254 of 406

Page 41 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

d) O vercurrent protective device limited output N/A

e) IC current limiter complying with G.9 N/A

Q.1.2 Test method and compliance ................................ : (See appended table Q.1) P

Current rating of overcurrent protective device (A)

................................ ................................ ............... : N/A

Q.2 Test for external circuits – paired conductor

cable N/A

Maximum output current (A) ................................ . : N/A

Current limiting method ................................ ......... :

R LIMITED SHORT CIRCUIT TEST

N/A

R.1 General

N/A

R.2 Test setup

N/A

Overcurrent protective device for test ................... :

R.3 Test method

N/A

Cord/cable use d for test ................................ ........ :

R.4 Compliance

N/A

S TESTS FOR RESISTANCE TO HEAT AND FIRE

N/A

S.1 Flammability test for fire enclosures and fire barrier materials of equipment

where the steady state power does not exceed 4 000 W N/A

Samples, material ................................ .................. :

Wall th ickness (mm) ................................ .............. :

Conditioning ( C) ................................ ................... :

Test flame according to IEC 60695 - 11 - 5 with

conditions as set out N/A

- Material not consumed completely N/A

- Material extinguishes within 30s N/A

- No burning of layer or wrapping tissue N/A

S.2 Fla mmability test for fire enclosure and fire barrier integrity

N/A

Samples, material ................................ .................. :

Wall thickness (mm) ................................ .............. :

Conditioning ( C) ................................ ................... :

S.3 Flammability test for the bottom of a fire enclosure

N/A

S.3.1 Mounting of samples N/A

S.3.2 Test method and compliance N/A

Page 255 of 406

Page 42 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Mounting of samples ................................ ............ :

Wall thickness (mm) ................................ .............. :

S.4 Flammability classification of materials

N/A

S.5 Flammability test for fire enclosures and fire barrier materials of equipment

where the steady state power exceeding 4 000 W N/A

Samples, material ................................ .................. :

Wall thickness (mm) ................................ .............. :

Conditioning ( C) ................................ ................... :

T MECHANICAL STRENGTH TESTS

P

T.1 General

P

T.2 Steady force test, 10 N ................................ ....... :

N/A

T.3 Steady force test, 30 N ................................ ....... :

N/A

T.4 Steady force test, 100 N ................................ ..... :

N/A

T.5 Steady for ce test, 250 N ................................ ..... :

N/A

T.6 Enclosure impact test

P

Fall test P

Swing test N/A

T.7 Drop test ................................ .............................. :

N/A

T.8 Stress relief test ................................ ................... :

(See appended table T.8) P

T.9 Glass Impact Test ................................ ................... :

N/A

T.10 Glass fragmentation test

N/A

Number of particles count ed ................................ .... : N/A

T.11 Test for telescoping or rod antennas

N/A

Torque value (Nm) ................................ ................ : N/A

U MECHANICAL STRENGTH OF CATHODE RAY TUBES (CRT) AND

PROTECTION AGAINST THE EFFECTS OF IMPLOSION N/A

U.1 General

N/A

Instructional safeguard :

No CRT provided within the

equipment N/A

U.2 Test method and compliance for non - intrinsically protected CRTs

N/A

U.3 Protective screen

N/A

V DETERMINATION OF ACCESSIBLE PARTS

N/A

V.1 Accessible parts of equipment

N/A

Page 256 of 406

Page 43 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

V.1.1 General N/A

V.1.2 Surfaces and openings tested w ith jointed test

probes N/A

V.1.3 Openings tested with straight unjointed test probes N/A

V.1.4 Plugs, jacks, connectors tested with blunt probe N/A

V.1.5 Slot openings tested with wedge probe N/A

V.1.6 Terminals tested with rigid test wire N/A

V .2 Accessible part criterion

N/A

X ALTERNATIVE METHOD FOR DETERMINING CLEARANCES FOR INSULATION

IN CIRCUITS CONNECTED TO AN AC MAINS NOT EXCEEDING 420 V PEAK

(300 V RMS) N/A

Clearance ................................ ................................ .. : N/A

Y CONSTRUCTION REQUIREMENTS FOR OUTDOOR ENCLOSURES

N/A

Y.1 G eneral

N/A

Y.2 Resistance to UV radiation

N/A

Y.3 Resistance to corrosion

N/A

Y.3 Resistance to corrosion

N/A

Y.3.1 Metallic parts of outdoor enclosures are resistant to

effects of water - borne contaminants by ................ : N/A

Y.3.2 Test apparatus N/A

Y.3.3 Water – saturated sulphur dioxide atmosphere N/A

Y.3.4 Test procedure ................................ ....................... : N/A

Y.3.5 Compliance N/A

Y.4 Gaskets

N/A

Y.4.1 General N/A

Y.4.2 Gasket tests N/A

Y.4.3 Tensile strength and elongation tests N/A

Alternative test methods ................................ ........ : N/A

Y.4.4 Compression test N/A

Y.4.5 Oil resistance N/A

Y.4.6 Securing means N/A

Y.5 Protection of equipment within an outdoor enclosure

N/A

Y.5.1 General N/A

Y.5.2 Protection from moisture N/A

Page 257 of 406

Page 44 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Relevant tests of IEC 60529 or Y.5.3 .................... : N/A

Y.5.3 Water sp ray test N/A

Y.5.4 Protection from plants and vermin N/A

Y.5.5 Protection from excessive dust N/A

Y.5.5.1 General N/A

Y.5.5.2 IP5X equipment N/A

Y.5.5.3 IP6X equipment N/A

Y.6 Mechanical strength of enclosures

N/A

Y.6.1 General N/A

Y.6.2 Im pact test ................................ ............................. : N/A

Page 258 of 406

Page 45 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.2 TABLE: Classification of electrical energy sources

P

Supply

Voltage Location (e.g.

circuit

designation) Test conditions Parameters ES

Class

U (V) I (mA) Type 1 )

Additional

Info 2 )

12 V d.c. Input power Normal 12 - - - ES1

S upplementary information:

1) Type: Steady state (SS), Capacitance (CP), Single pulse (SP), Repetitive pulses (RP) , etc.

2) Additional Info: Frequency, Pulse duration, Pulse off time, Capacitance value , etc.

5.4.1.8 TABLE: Working voltage measurement

N/A

Location RMS voltage

(V) Peak voltage

(V) Frequency

(Hz) Comments

Supplementary information:

5.4.1.10.2 TABLE: Vicat softening temperature of thermoplastics

N/A

Method ................................ ................................ ............................ : ISO 306 / B50

Object/ Part No./Material Manufacturer/trademark Thickn ess (mm) T softening (°C)

Supplementary information:

5.4.1.10.3 TABLE: Ball pressure test of thermoplastics

N/A

Allowed impression diameter (mm) ................................ ............... :

2 mm

Object/Part No./Material Manufacturer/trademark Thickness (mm) Test

temperature ( C) Impre ssion

diameter (mm)

Supplementary information:

Page 259 of 406

Page 46 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.4.2, 5.4.3 TABLE: Minimum Clearances/Creepage distance

N/A

Clearance (cl) and

creepage distance

(cr) at/of/between: U

p

(V) U

rms

(V) Freq 1 )

(Hz) Required

cl (mm) cl

(mm) E.S. 2)

(V)

Required

cr (mm) cr

(mm)

Supplementary information:

1) O nly for frequency above 30 kHz

2) Complete Electric Strength voltage (E.S. (V) when 5.4.2.4 applied)

5.4.4.2 TABLE: Minimum distance through insulation

N/A

Distance through insulation

(DTI) at/of Peak voltage (V) Insulation Required DTI

(mm) Measured DTI

(mm)

Supplementary information:

5.4.4.9 TABLE: Solid insulation at frequencies >30 kHz

N/A

Insulation material E

P

Frequency

(kHz) K

R

Thickness

d (mm) Insulation V

PW

(Vpk)

Supplementary information:

5.4.9 TABLE: Electric strength tests

N/A

Test voltage applied between: Voltage shape

(Surge, Impulse, AC,

DC, etc.) Test voltage (V) Breakdown

Yes / No

Supplementary information:

Page 260 of 406

Page 47 of 88 Report No. : 60404489 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.5.2.2 TABLE: Stored discharg e on capacitors

N/A

Location Supply voltage (V) Operating and fault

condition 1)

Switch

position Measured

voltage

(Vpk) ES Class

Supplementary information:

X - capacitors installed for testing:

bleeding resistor rating:

ICX:

1) Normal operating condition (e.g., normal operation, or open fuse), SC= short circuit, OC= open circuit

5.6.6 TABLE: Resistance of protective conductors and terminations

N/A

Location Test current

(A) Duration

(min) Voltage drop

(V) Resi stance

( Ω )

Supplementary information:

5.7.4 TABLE: Unearthed accessible parts

N/A

Location Operating and

fault conditions Supply

Voltage (V) Parameters ES

class

Voltage

(V

rms or V

pk ) Current

(A

rms or A

pk ) Freq.

(Hz)

S upplementary information:

Abbreviation: SC= short circuit; OC= open circuit

5.7.5 TABLE: Earthed accessible conductive part

N/A

Supply voltage (V) ........................... :

Phase(s) ................................ ......... : [] Single Phase; [ ] Three Phase : [ ] Delta [ ] W ye

Power Distribution System ............. : TN TT IT

Location Fault Condition No in IEC

60990 clause 6.2.2 Touch current

(mA) Comment

Supplementary Information: