check engine SSANGYONG KORANDO 1997 Service User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 66 of 2053

1B1 -- 34 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

Tools Required

601 589 03 43 00 Crankshaft Rear Seal Installer

Removal & Installation Procedure

1. Unscrew the bolts (1) and (5) and remove the closing

cover by pulling the rear cover lug (arrows).

Notice:Be careful not to damage the oil pan gasket.

2. Clean the sealing surface of the crankcase and the

rear sealing cover.

3. Check the radial shaft seal and replace it if necessary.

4. Apply the Loctite 573 to the rear cover sealing sur-

face.

5. Apply the engine oil to the dust lip of the radial shaft

seal.

Notice:Do not use the grease.

6. Install the crankshaft rear radial seal and the crank-

shaft sealing rear cover, using crankshaft rear seal in-

staller 601 589 03 43 00.

7. Install the crankshaft sealing rear cover mounting

bolts and remove the crankshaft rear seal installer

601 589 03 43 00.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

8. Installation should follow the removal procedure in

the reverse order.

Page 71 of 2053

M162 ENGINE MECHANICAL 1B1 -- 39

D AEW OO M Y_2000

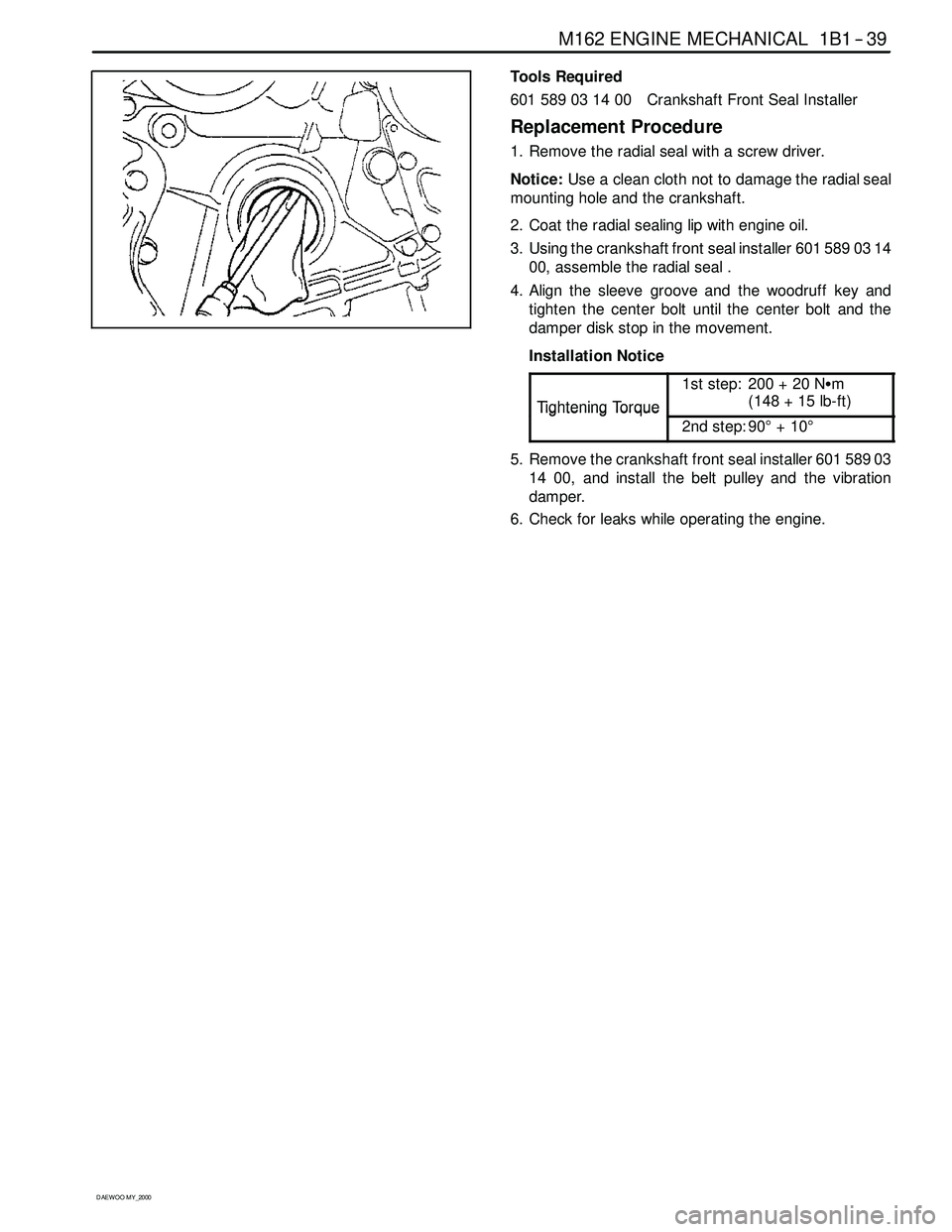

Tools Required

601 589 03 14 00 Crankshaft Front Seal Installer

Replacement Procedure

1. Remove the radial seal with a screw driver.

Notice:Use a clean cloth not to damage the radial seal

mounting hole and the crankshaft.

2. Coat the radial sealing lip with engine oil.

3. Using the crankshaft front seal installer 601 589 03 14

00, assemble the radial seal .

4. Align the sleeve groove and the woodruff key and

tighten the center bolt until the center bolt and the

damper disk stop in the movement.

Installation Notice

Ti

ghteningTo rque

1st step: 200 + 20 NSm

(148 + 15 lb-ft)

TighteningTorque

2nd step: 90°+10°

5. Remove the crankshaft front seal installer 601 589 03

14 00, and install the belt pulley and the vibration

damper.

6. Check for leaks while operating the engine.

Page 72 of 2053

1B1 -- 40 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

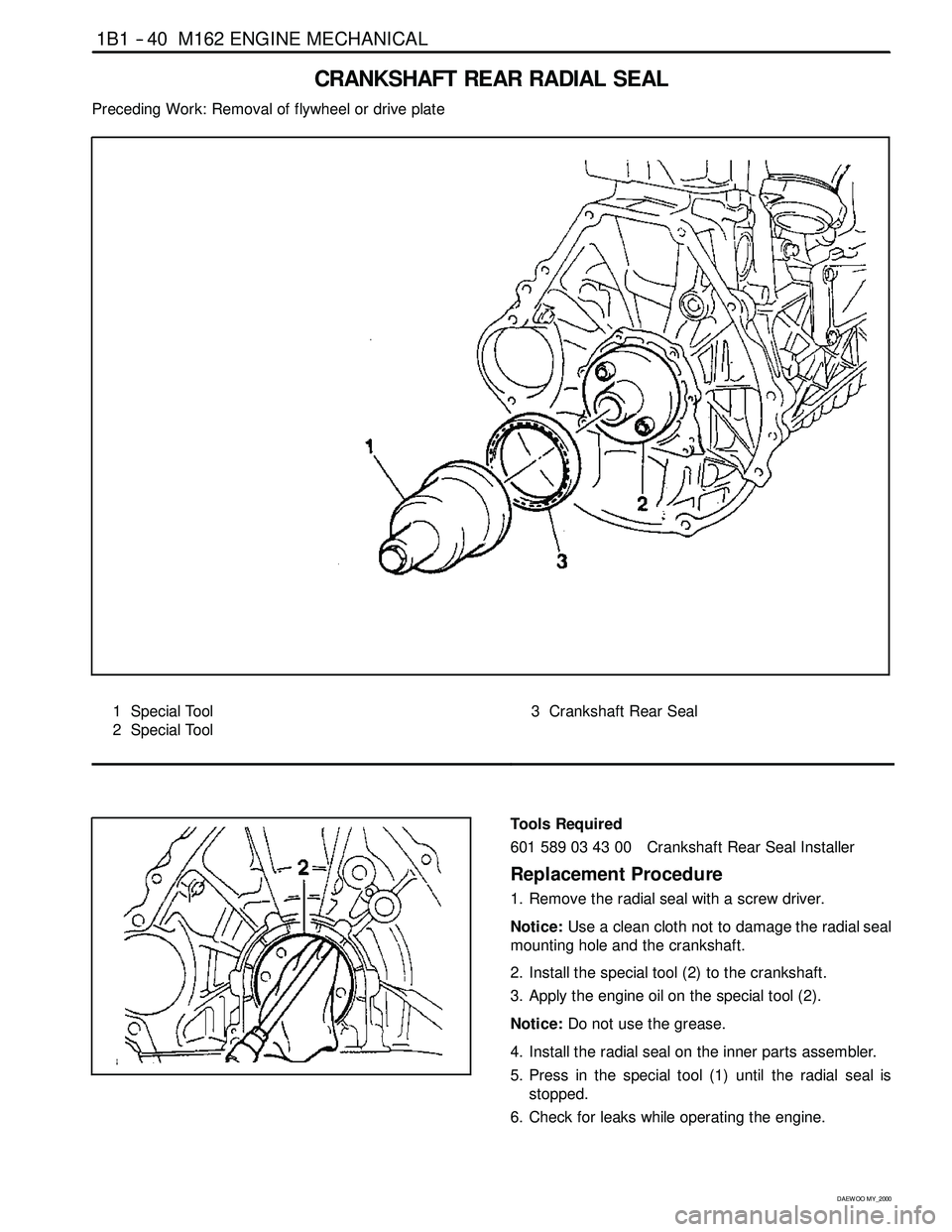

CRANKSHAFT REAR RADIAL SEAL

Preceding Work: Removal of flywheel or drive plate

1 Special Tool

2 Special Tool3 Crankshaft Rear Seal

Tools Required

601 589 03 43 00 Crankshaft Rear Seal Installer

Replacement Procedure

1. Remove the radial seal with a screw driver.

Notice:Use a clean cloth not to damage the radial seal

mounting hole and the crankshaft.

2. Install the special tool (2) to the crankshaft.

3. Apply the engine oil on the special tool (2).

Notice:Do not use the grease.

4. Install the radial seal on the inner parts assembler.

5. Press in the special tool (1) until the radial seal is

stopped.

6. Check for leaks while operating the engine.

Page 76 of 2053

1B1 -- 44 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

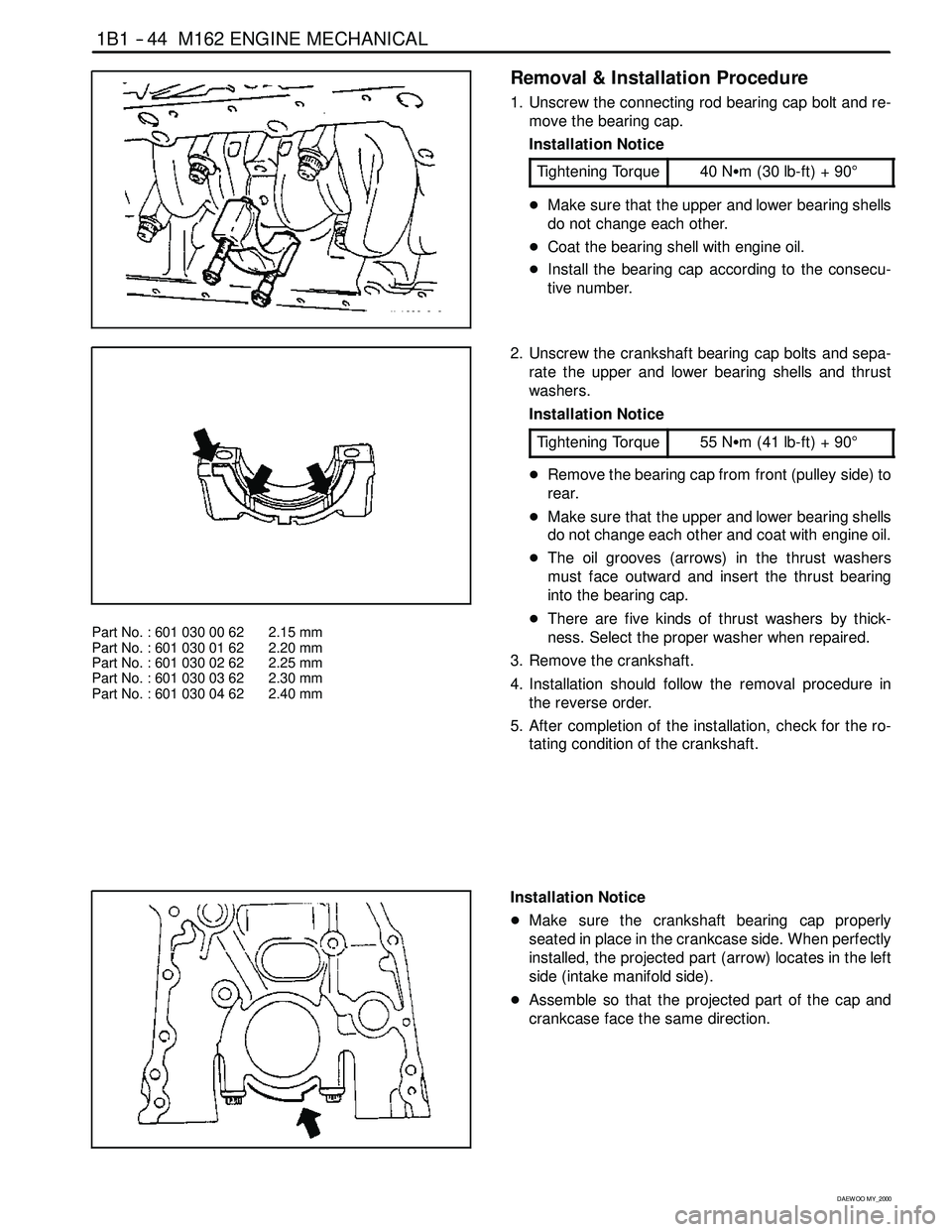

Removal & Installation Procedure

1. Unscrew the connecting rod bearing cap bolt and re-

move the bearing cap.

Installation Notice

Tightening Torque

40 NSm (30 lb-ft) + 90°

DMake sure that the upper and lower bearing shells

do not change each other.

DCoat the bearing shell with engine oil.

DInstall the bearing cap according to the consecu-

tive number.

Part No. : 601 030 00 62 2.15 mm

Part No. : 601 030 01 62 2.20 mm

Part No. : 601 030 02 62 2.25 mm

Part No. : 601 030 03 62 2.30 mm

Part No. : 601 030 04 62 2.40 mm

2. Unscrew the crankshaft bearing cap bolts and sepa-

rate the upper and lower bearing shells and thrust

washers.

Installation Notice

Tightening Torque

55 NSm (41 lb-ft) + 90°

DRemove the bearing cap from front (pulley side) to

rear.

DMake sure that the upper and lower bearing shells

do not change each other and coat with engine oil.

DThe oil grooves (arrows) in the thrust washers

must face outward and insert the thrust bearing

into the bearing cap.

DThere are five kinds of thrust washers by thick-

ness. Select the proper washer when repaired.

3. Remove the crankshaft.

4. Installation should follow the removal procedure in

the reverse order.

5. After completion of the installation, check for the ro-

tating condition of the crankshaft.

Installation Notice

DMake sure the crankshaft bearing cap properly

seated in place in the crankcase side. When perfectly

installed, the projected part (arrow) locates in the left

side (intake manifold side).

DAssemble so that the projected part of the cap and

crankcase face the same direction.

Page 87 of 2053

1B1 -- 60 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

Tools Required

DW110 -- 120 Holding Pin

Inspection

1. Position the No.1 cylinder piston to TDC (OT) by turn-

ing the crankshaft.

Notice:When the OT mark on vibration damper is

aligned with timing gear case cover, the intake and ex-

haust cam of cylinderwill make the slope to the center

and will face up. In this way, the adjustment hole of the

intake and exhaust camshaftwill match in line with the

cylinder head upper end, at 3 o’clock, and 9 o’clock di-

rection each other.

2. Check the timing as below procedure;

-- Check if the camshaft adjustment hole is posi-

tioned to 3 o’clock direction at the intake side and

to 9 o’clock direction at the exhaust side, respec-

tively and align with the cylinder head mating sur-

face.

-- At this condition, check if the OT mark on vibration

damper aligns with the marker on the timing gear

case.

Adjustment Procedure

1. Position the No.1 cylinder to BTDC 30°.

2. Remove the chain tensioner.

3. Remove the exhaust camshaft sprocket.

4. Align the intake and exhaust camshaft flange hole

with the cylinder head upper surface.

DIntake Side : 3 o’clock direction

DExhaust Side : 9 o’clock direction

5. Align the holes on intake and exhaust camshaft to the

hole on cylinder head. Insert the holding pin

DW110-- 120 into the holes.

6. Secure the intake and exhaust camshaft.

7. Position the piston of No.1 cylinder at TDC (OT) by

turning the crankshaft.

8. Turn the camshaft adjuster of the intake camshaft to

the left as much as possible (cam adjuster ‘retarded’

position).

9. Install the chain to the intake camshaft sprocket.

Notice:Timing chain must be placed on the guide rail in

gear case cover.

Page 88 of 2053

M162 ENGINE MECHANICAL 1B1 -- 61

D AEW OO M Y_2000

10. Install the chain to the exhaust camshaft sprocket

and install it to the camshaft.

Installation Notice (Sprocket Bolt)

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

The sprocket bolt is designed to be used only once,

so replace with new one.

11. Install the chain tensioner.

Installation Notice

Ti

ghteningScrew Plug40 NSm

(30 lb-ft)

Tightening

TorqueTensioner

Assembly72 -- 88 NSm

(53 -- 65 lb-ft)

12. Check the camshaft timing.

Page 91 of 2053

1B1 -- 64 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

3. Remove the valve tappet using the valve tappet re-

mover DW110-- 100.

4. Install the connecting hose DW110-- 090 (c) to the

spark plug hole.

5. Install the engine lock 602 589 00 40 00 to the ring

gear to prevent the crankshaft from rotating.

6. Blow up with compressed air.

7. Install the supporting bar 111 589 01 59 00 (d) and

the lever pusher 111 589 18 61 00 (a).

8. Mount the thrust piece 111 589 25 63 00 (b) vertical-

ly to the valve spring retainer (2).

9. Press the valve spring (3) by using the lever pusher

111589186100(a).

10. Remove the valve cotter (1) using the pincette.

11. Remove the upper retainer (2) and the valve spring

(3).

12. Remove the valve stem seal (4) and replace if nec-

essary.

Notice:Check the valve stem seal for damage and re-

place if necessary.

13. Remove the lower retainer (5).

Notice:Check the retainer for damages and replace

with a new one if necessary.

Page 93 of 2053

1B1 -- 66 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

VALVE STEM SEAL

Preceding Work: Removal of valve spring

1 Drift 119 589 00 43 00

2 Valve Stem Seal3 Protective Sleeve

Tools Required

119 589 00 43 00 Drift

Replacement Procedure

1. Remove the valve stem seal (2) using the pliers.

Notice:Check the valve stem seal for damage and re-

place if necessary.

2. Coat the valve stem seal with oil and assemble it with

the protective sleeve.

3. Insert the valve stem seal by pressing it with the drift

119 589 00 43 00.

Page 94 of 2053

M162 ENGINE MECHANICAL 1B1 -- 67

D AEW OO M Y_2000

CHAIN TENSIONER

1 Screw Plug 40 NSm (30 lb-ft) ................

2 Seal

3 Filler Pin

4 Compression Spring

5 Snap Ring6 Thrust Pin

7 Chain Tensioner Housing

72-- 88 NSm (53-- 65 lb-ft) ....................

8Seal

Removal Procedure

1. Position the No.1 cylinder to TDC (OT).

Notice:Remove the oil filler cap at adjustment position,

and check whether the intake camshaft cam’s lobe (ar-

row) stays in the upper side.

2. Cover the generator with a clean cloth.

3. Release the tension by unscrewing the screw plug

once.

Notice:In case that the tension is reduced by unscrew-

ing the screw plug, reinstall after completely removing

the chain tensioner. If the chain tensioner is tightened

again without completely reducing its tension, then the

detent spring doesn’t return to the original position and

the tension gets exceeded.

Page 96 of 2053

M162 ENGINE MECHANICAL 1B1 -- 69

D AEW OO M Y_2000

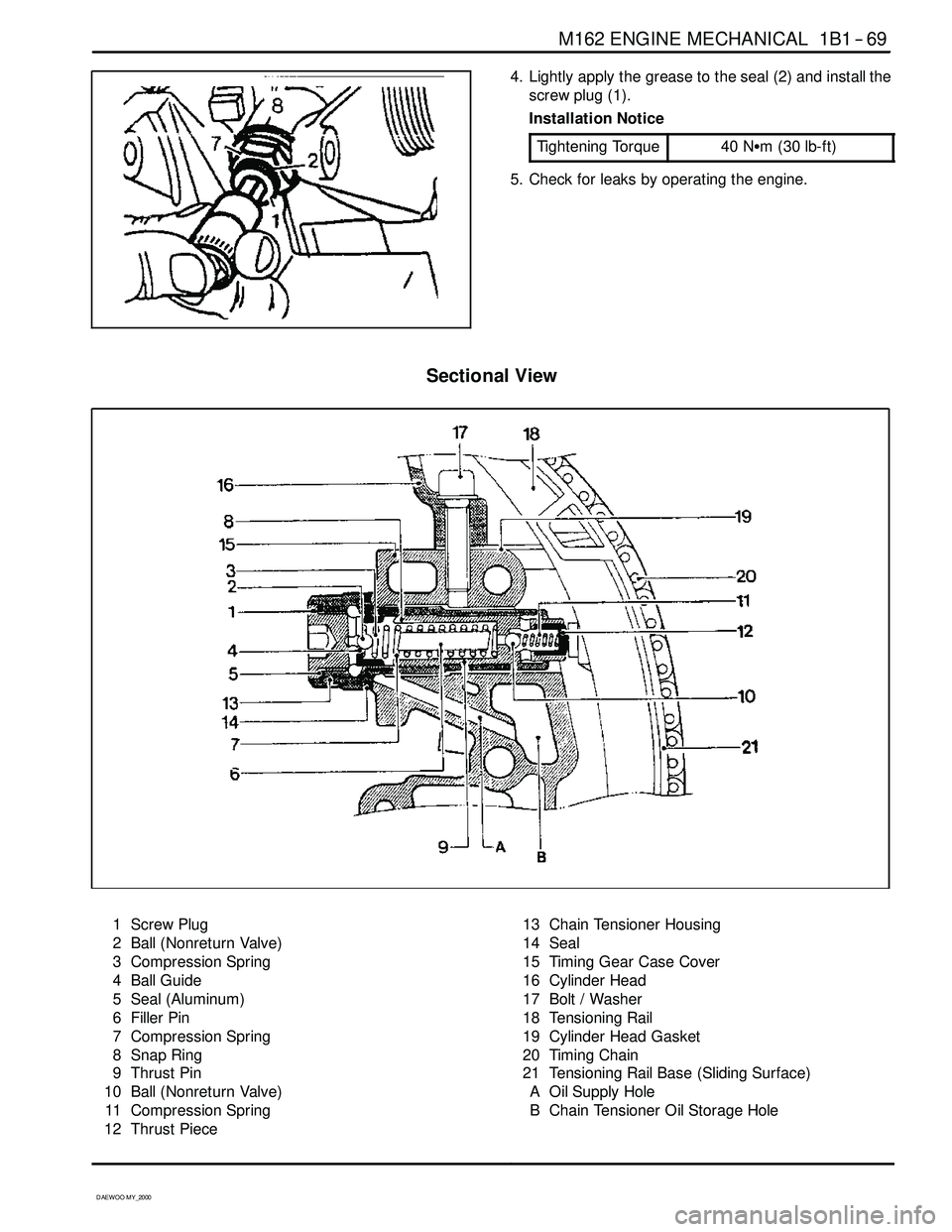

4. Lightly apply the grease to the seal (2) and install the

screw plug (1).

Installation Notice

Tightening Torque

40 NSm (30 lb-ft)

5. Check for leaks by operating the engine.

Sectional View

1 Screw Plug

2 Ball (Nonreturn Valve)

3 Compression Spring

4 Ball Guide

5 Seal (Aluminum)

6 Filler Pin

7 Compression Spring

8 Snap Ring

9 Thrust Pin

10 Ball (Nonreturn Valve)

11 Compression Spring

12 Thrust Piece13 Chain Tensioner Housing

14 Seal

15 Timing Gear Case Cover

16 Cylinder Head

17 Bolt / Washer

18 Tensioning Rail

19 Cylinder Head Gasket

20 Timing Chain

21 Tensioning Rail Base (Sliding Surface)

A Oil Supply Hole

B Chain Tensioner Oil Storage Hole