torque SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 934 of 2053

SSAMGYONG MY2002

4A-14 HYDRAULIC BRAKES

KAA4A120

KAA4A130

KAA4A140

STOPLAMP SWITCH

Removal and Installation Procedure

1. Remove the stoplamp switch connector.

2. Remove the stoplamp switch.

3. Installation should follow the removal procedure

in the reverse order.

BRAKE PEDAL

Removal and Installation Procedure

1. Remove the stoplamp switch connector.

2. Remove the clevis pin and disconnect the brake

booster pushrod.

Installation Notice:

Install in the upper hole.

Install the snap pin fully in the hole of clevis

pin.

Apply the grease around the hold of clevis pin.

3. Remove the brake pedal mounting nut and remove

the brake pedal assembly.

Installation Notice

Tightening Torque 13 Nm (10 lb-ft)

4. Installation should follow the removal procedure

in the reverse order.

KAA4A070

3. Remove the rear bleeder valve from the caliper as

sembly.

Installation Notice

Tightening Torque 10 Nm (89 lb-ft)

Bleed the brake system. Refer to “Manual

Bleeding the Brakes” in this section.

Check the brake system for leaks.

4. Installation should follow the removal procedure in

the reverse order.

Page 938 of 2053

SSANGYONG MY2002

4B-2 MASTER CYLINDER

DESCRIPTION AND OPERATION

GENERAL DESCRIPTION

The master cylinder is designed for use in a parallel

split system. One front and one parallel to rear brakes

are served by the primary piston. The opposite front

and rear brakes are served by the secondary piston.

The master cylinder incorporates the functions of the

standard dual master cylinder, plus a low fluid level

indicator. The brake fluid level switch is attached under

the body of the plastic brake master cylinder reservoir.

Notice: Do not use lubricated shop air on the brake

parts, because oil will damage the rubber components.Important:•Replace all the components included in the repair

kits used to service the master cylinder.

Lubricate the rubber parts with clean brake fluid to

ease assembly.

If any hydraulic component is removed or discon-

nected, it may be necessary to bleed all or part of

the brake system. Refer to Section 4F, Antilock

Brake System and Traction Control System.

The torque values specified are for dry, unlubricated

fasteners.

Perform all service operations on a clean bench,

free from all traces of mineral oil.

Page 942 of 2053

SSANGYONG MY2002

4B-6 MASTER CYLINDER

YAD4A370

Remove the 1st piston and 2nd piston assembly

from the master cylinder assembly.

YAD4A380

YAD4A390

YAD4A400

Check the cylinder for excessive wear.

Notice:

Replace the cylinder assembly when there

occurs any damage or wear in the cylinder.

Clean the contaminated oil of the assembly.

Install the 1st piston and 2nd piston assembly

from the master cylinder assembly.

Installation Procedure

1. Install the retainer ring using the snap ring plier.

2. Install the master cylinder into the booster.

Installation Notice

Tightening Torque8 - 12 Nm

(71 - 106 lb-in)

Page 948 of 2053

POWER BOOSTER 4C-5

SSANGYONG MY2002

REPAIR INSTRUCTIONS

KAA4C030

KAA4A040

KAA4C050

ON-VEHICLE SERVICE

POWER BOOSTER ASSEMBLY

Removal and Installation Procedure

1. Remove the master cylinder. Refer to Section 4B,

Master Cylinder.

2. Remove the vacuum hose from the booster.

3. Remove the clevis pin and disconnect the pedal

and brake booster push rod.

Installation Notice:

•Apply the grease around the hole of clevis pin.

4. Remove the power booster mounting nuts and re-

move the booster from the dash panel.

Installation Notice

Tightening Torque 17 Nm (13 lb-ft)

Install the new gasket.

5. Installation should follow the removal procedure

in the reverse order.

Page 949 of 2053

SSANGYONG MY2002

4C-6 POWER BOOSTER

3. Remove the vacuum hose from the booster.

4. Installation should follow the removal procedure in

the reverse order.

VACUUM HOSE

Removal and Installation Procedure

1. Remove the vacuum hose connection bolt to the

intake manifold.

Installation Notice

2. Remove the vacuum hose retaining bolt located

on the intake manifold.

Installation Notice

KAA4C060

KAA4C070

KAA4C030

Tightening Torque 40 Nm (30 lb-ft)

Tightening Torque 13 Nm (10 lb-ft)

Page 952 of 2053

SSANGYONG MY2002

4D-2 FRONT BRAKES

DESCRIPTION AND OPERATION

GENERAL DESCRIPTION

When the brakes are applied, fluid pressure is sent to

each brake caliper. The pressure at the caliper is ex-

erted equally against the caliper piston. The pressure

applied to the piston is transmitted directly to the

inboard brake pad. This forces the pad against the inner

surface of the brake rotor. At the same time, fluid

pressure within the caliper piston bore forces the caliper

to slide inward on its guide pins. This action brings the

outboard pad into contact with the outer surface of the

brake rotor. This pressure on both sides of the brake

rotor causes friction, bringing the vehicle to a stop.

BRAKE CALIPER

The caliper has a single bore and is mounted to the

steering knuckle with two mounting bolts. Hydraulic

pressure, created by applying the brake pedal, is con-

verted by the caliper to a stopping force. This force

acts equally against the piston and the bottom of the

caliper bore to move the piston outward and to slide

the caliper inward, resulting in a clamping action on

the rotor. This clamping action forces the linings against

the rotor, creating friction to stop the vehicle.Important:

•Replace all components included in the repair kits

used to service the caliper.

Lubricate the rubber parts with clean brake fluid to

ease assembly.

Do not use lubricated shop air on brake parts, as

damage to the rubber components may result.

If any hydraulic component is removed or discon-

nected, it may be necessary to bleed all or part of

the brake system. Refer to Section 4F, Antilock

Brake System And Traction Control System.

Replace the pads in axle sets only.

The torque values specified are for dry, unlubricated

fasteners.

Perform the service operations on a clean bench,

free from all oily material.

BRAKE PADS

There are two brake pads mounted to each caliper, one

inboard and one outboard. As front disc brake pad wear,

master cylinder reservoir brake fluid level will drop. Fluid

level should be checked after replacing pads.

BRAKE ROTOR

Each front disc brake rotor is vented to help cool it dur-

ing and after brake applications.

Page 956 of 2053

SSANGYONG MY2002

4D-6 FRONT BRAKES

KAA4D080

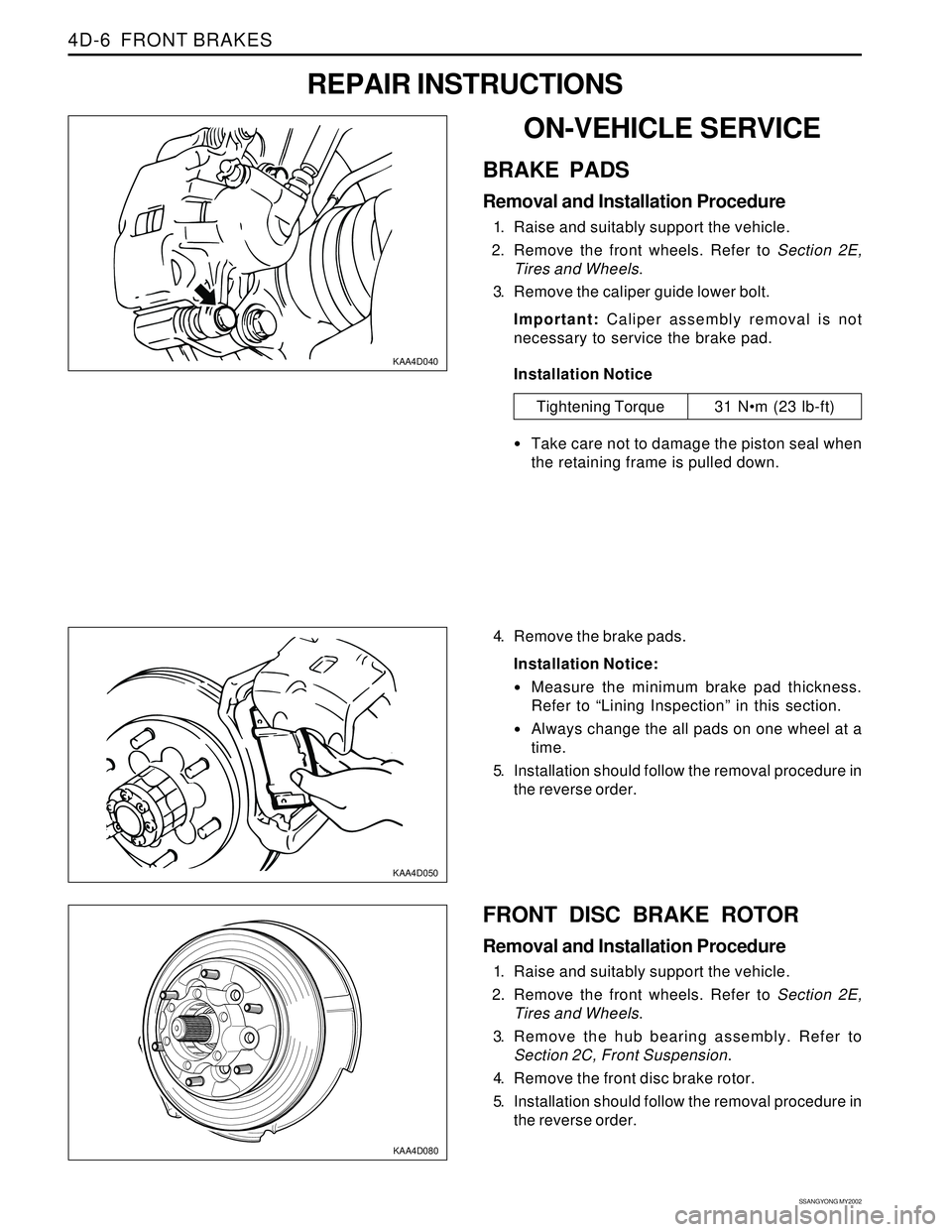

FRONT DISC BRAKE ROTOR

Removal and Installation Procedure

1. Raise and suitably support the vehicle.

2. Remove the front wheels. Refer to Section 2E,

Tires and Wheels.

3. Remove the hub bearing assembly. Refer to

Section 2C, Front Suspension.

4. Remove the front disc brake rotor.

5. Installation should follow the removal procedure in

the reverse order.

KAA4D040

REPAIR INSTRUCTIONS

ON-VEHICLE SERVICE

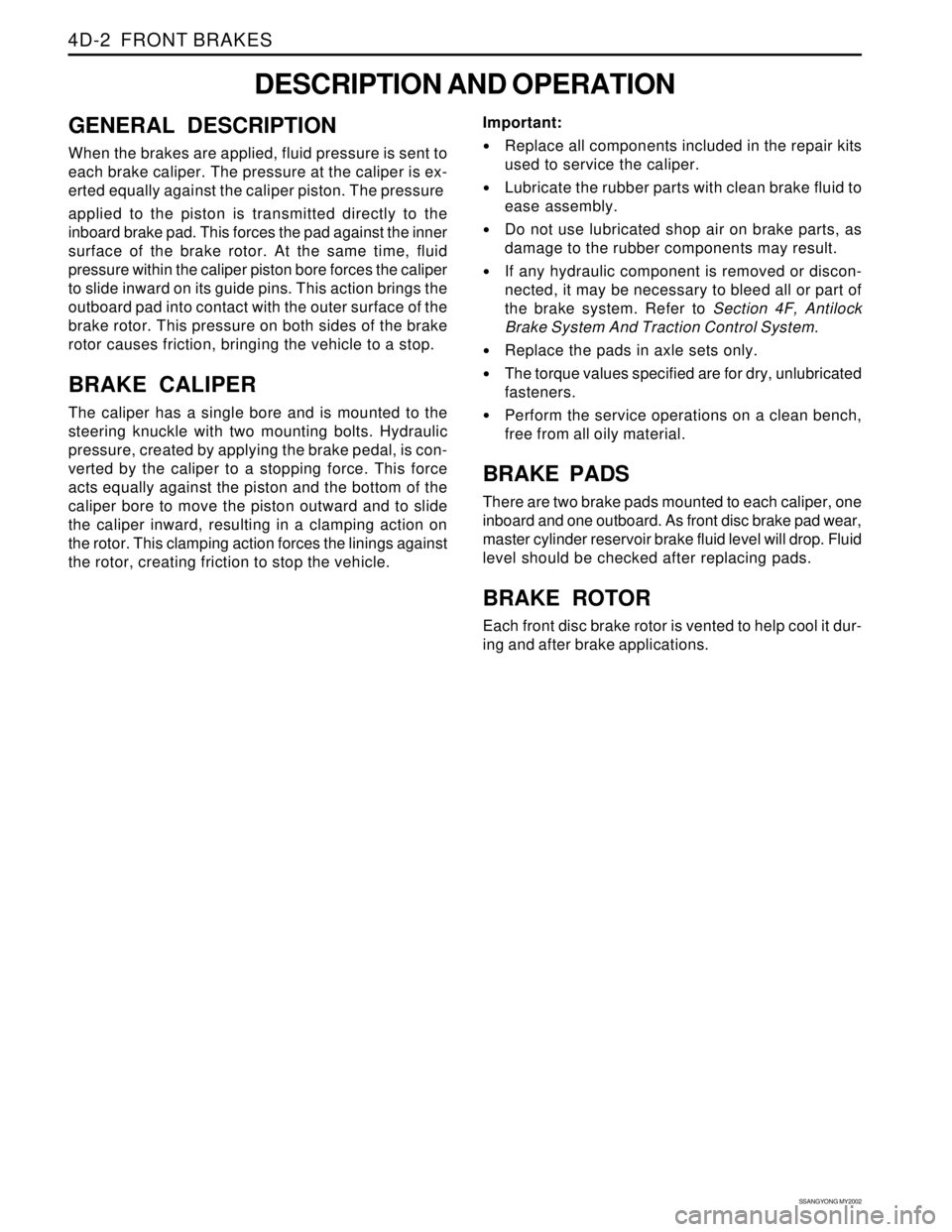

BRAKE PADS

Removal and Installation Procedure

1. Raise and suitably support the vehicle.

2. Remove the front wheels. Refer to Section 2E,

Tires and Wheels.

3. Remove the caliper guide lower bolt.

Important: Caliper assembly removal is not

necessary to service the brake pad.

Installation Notice

Take care not to damage the piston seal when

the retaining frame is pulled down.

Tightening Torque 31 Nm (23 lb-ft)

KAA4D050

4. Remove the brake pads.

Installation Notice:

Measure the minimum brake pad thickness.

Refer to “Lining Inspection” in this section.

Always change the all pads on one wheel at a

time.

5. Installation should follow the removal procedure in

the reverse order.

Page 957 of 2053

FRONT BRAKES 4D-7

SSANGYONG MY2002

KAA4D060

KAA4D070

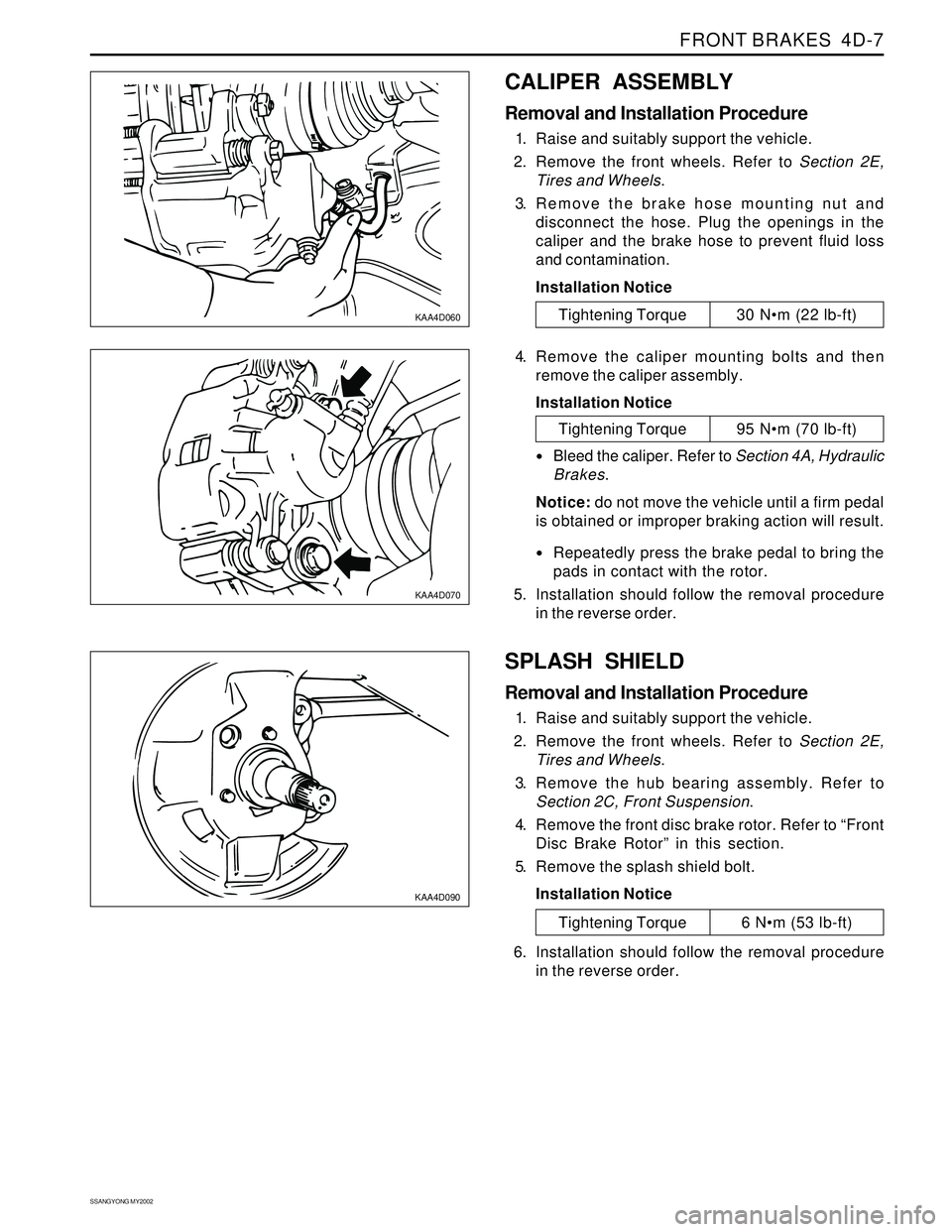

CALIPER ASSEMBLY

Removal and Installation Procedure

1. Raise and suitably support the vehicle.

2. Remove the front wheels. Refer to Section 2E,

Tires and Wheels.

3. Remove the brake hose mounting nut and

disconnect the hose. Plug the openings in the

caliper and the brake hose to prevent fluid loss

and contamination.

Installation Notice

Tightening Torque 30 Nm (22 lb-ft)

4. Remove the caliper mounting bolts and then

remove the caliper assembly.

Installation Notice

Tightening Torque 95 Nm (70 lb-ft)

Bleed the caliper. Refer to Section 4A, Hydraulic

Brakes.

Notice: do not move the vehicle until a firm pedal

is obtained or improper braking action will result.

Repeatedly press the brake pedal to bring the

pads in contact with the rotor.

5. Installation should follow the removal procedure

in the reverse order.

SPLASH SHIELD

Removal and Installation Procedure

1. Raise and suitably support the vehicle.

2. Remove the front wheels. Refer to Section 2E,

Tires and Wheels.

3. Remove the hub bearing assembly. Refer to

Section 2C, Front Suspension.

4. Remove the front disc brake rotor. Refer to “Front

Disc Brake Rotor” in this section.

5. Remove the splash shield bolt.

Installation Notice

KAA4D090

Tightening Torque 6 Nm (53 lb-ft)

6. Installation should follow the removal procedure

in the reverse order.

Page 959 of 2053

FRONT BRAKES 4D-9

SSANGYONG MY2002

YAD4B280

YAD4B290

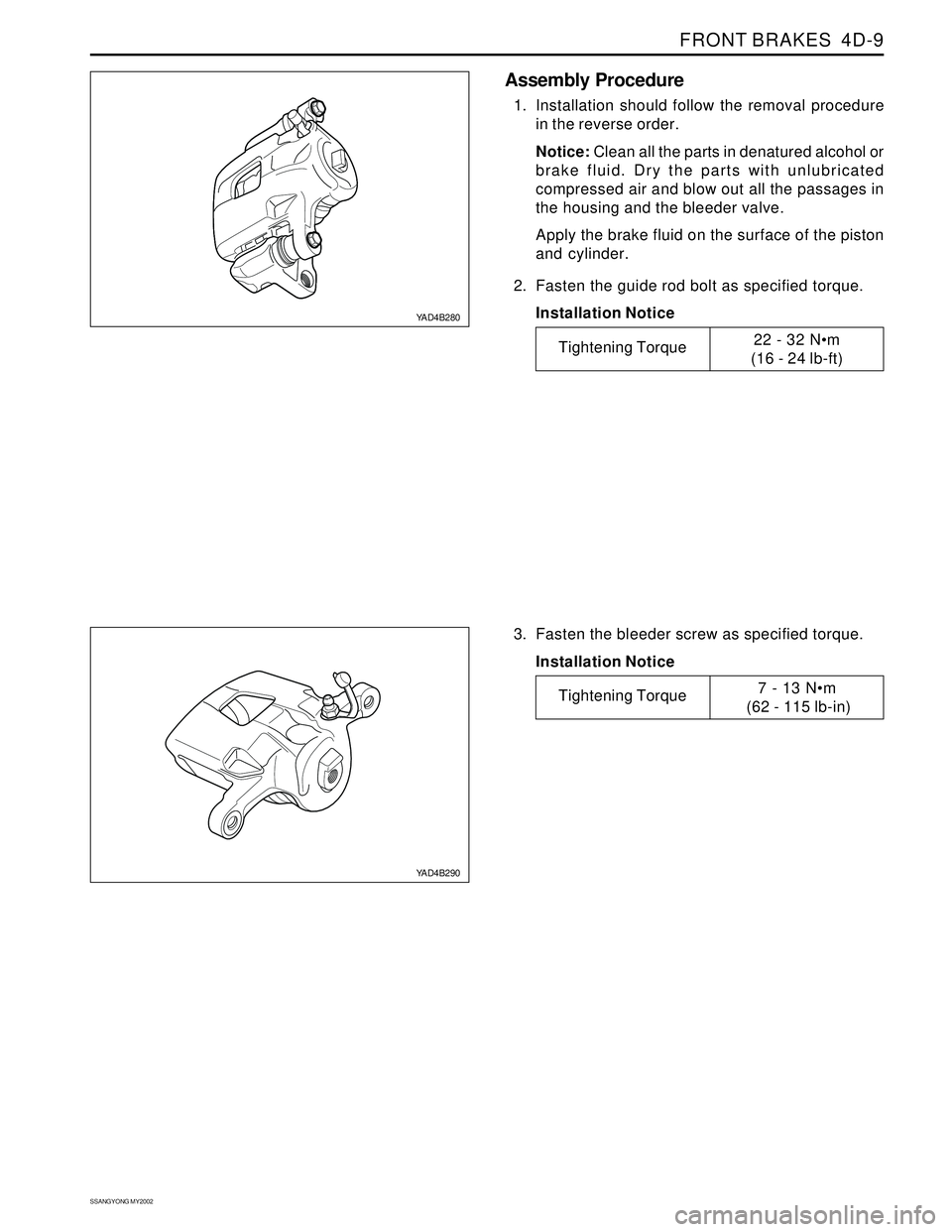

3. Fasten the bleeder screw as specified torque.

Installation Notice

Assembly Procedure

1. Installation should follow the removal procedure

in the reverse order.

Notice: Clean all the parts in denatured alcohol or

brake fluid. Dry the parts with unlubricated

compressed air and blow out all the passages in

the housing and the bleeder valve.

Apply the brake fluid on the surface of the piston

and cylinder.

2. Fasten the guide rod bolt as specified torque.

Installation Notice

Tightening Torque7 - 13 Nm

(62 - 115 lb-in)

Tightening Torque22 - 32 Nm

(16 - 24 lb-ft)

Page 975 of 2053

REAR BRAKES 4E-15

SSANGYONG MY2002

4. Install the caliper cylinder assembly and tighten

the retaining bolt.

Installation Procedure

1. Install the brake lining between the backing plate

and the flange.

Installation Notice

Tightening Torque4 - 8 Nm

(35 - 71 lb-in)

Notice: Apply a certain amount of grease on the

parking brake lining surface.

2. Install the brake disc and connect the parking

brake cable to the lever.

3. Install the caliper to the brake disc.

Installation Notice

Tightening Torque4 - 8 Nm

(35 - 71 lb-in)

YAD4C230

YAD4C240

YAD4C250

YAD4C260