torque SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1193 of 2053

5A-98 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

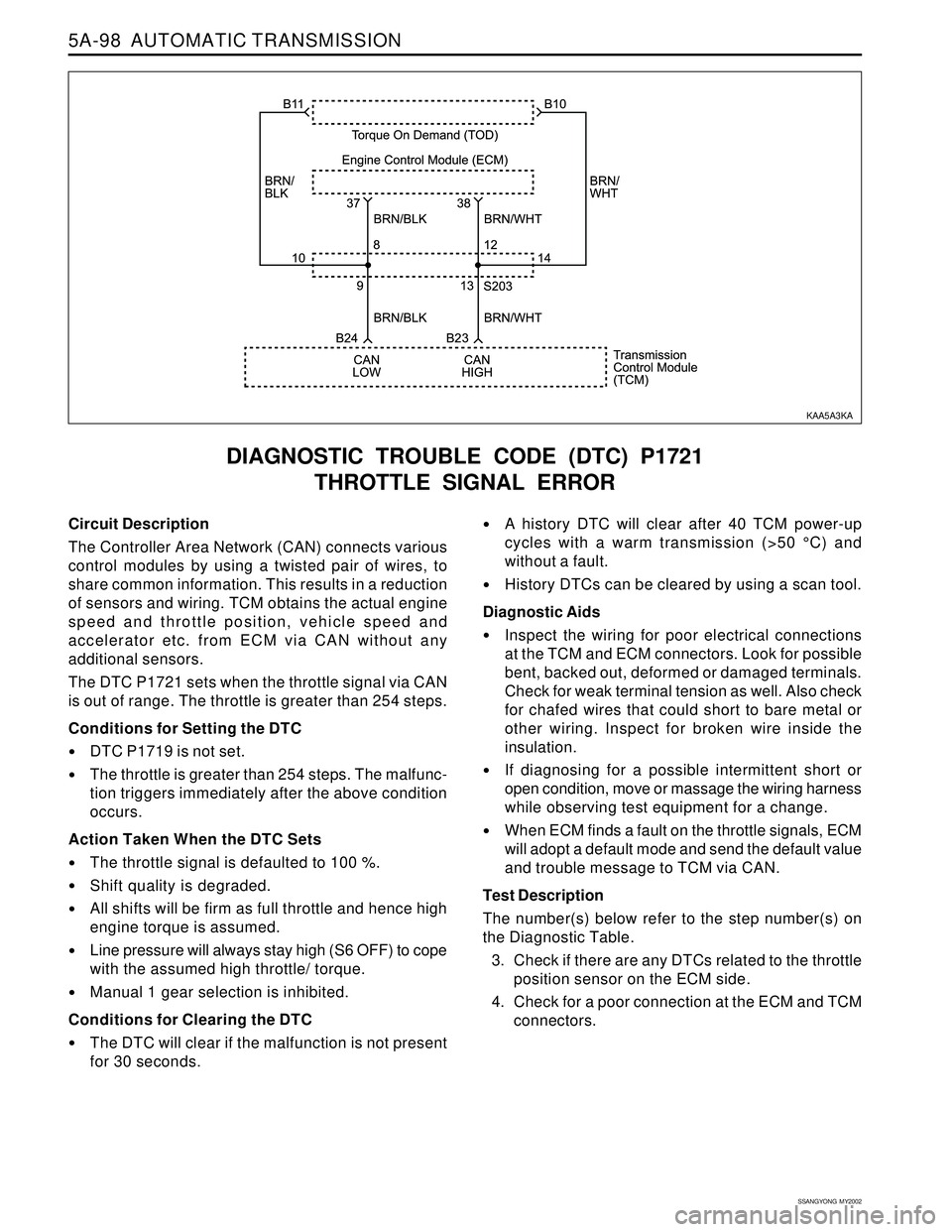

Circuit Description

The Controller Area Network (CAN) connects various

control modules by using a twisted pair of wires, to

share common information. This results in a reduction

of sensors and wiring. TCM obtains the actual engine

speed and throttle position, vehicle speed and

accelerator etc. from ECM via CAN without any

additional sensors.

The DTC P1721 sets when the throttle signal via CAN

is out of range. The throttle is greater than 254 steps.

Conditions for Setting the DTC

DTC P1719 is not set.

The throttle is greater than 254 steps. The malfunc-

tion triggers immediately after the above condition

occurs.

Action Taken When the DTC Sets

The throttle signal is defaulted to 100 %.

Shift quality is degraded.

All shifts will be firm as full throttle and hence high

engine torque is assumed.

Line pressure will always stay high (S6 OFF) to cope

with the assumed high throttle/ torque.

Manual 1 gear selection is inhibited.

Conditions for Clearing the DTC

The DTC will clear if the malfunction is not present

for 30 seconds.

DIAGNOSTIC TROUBLE CODE (DTC) P1721

THROTTLE SIGNAL ERROR

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

Inspect the wiring for poor electrical connections

at the TCM and ECM connectors. Look for possible

bent, backed out, deformed or damaged terminals.

Check for weak terminal tension as well. Also check

for chafed wires that could short to bare metal or

other wiring. Inspect for broken wire inside the

insulation.

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring harness

while observing test equipment for a change.

When ECM finds a fault on the throttle signals, ECM

will adopt a default mode and send the default value

and trouble message to TCM via CAN.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Check if there are any DTCs related to the throttle

position sensor on the ECM side.

4. Check for a poor connection at the ECM and TCM

connectors.

KAA5A3KA

Page 1221 of 2053

5A-126 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The solenoid 7 is a normally open ON/OFF type sole-

noid that is used to control the application of the

Torque Converter Clutch (TCC).

The Solenoid 7 (S7) ON activates the TCC and the S7

is attached to the pump body within the transmission.

Voltage is supplied directly to the solenoid through

the Transmission Control Module (TCM).

The DTC P1739 sets when the solenoid 7, Torque Con-

verter Clutch Solenoid, circuit is open or the switched

leg of the solenoid 7 is shorted to battery positive.

The solenoid 7's driver Integrated Chip (IC) status

indicates a faulty circuit.

Conditions for Setting the DTC

DTCs P1717 and P1718 are not set.

S7 is OFF.

S3 is OFF.

The solenoid 7's driver Integrated Chip (IC) status

indicates a faulty circuit. This condition must be

continuously present for 60 milliseconds.

Action Taken When the DTC Sets

The solenoid 7 is always disabled (OFF) resulting

in the TCC being unlocked always.

DIAGNOSTIC TROUBLE CODE (DTC) P1739

SOLENOID 7 CIRCUIT OPEN

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred after ignition cycle.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

During the TCM's testing, solenoid 7 is turned OFF/

ON by a very small (4 millisecond) pulses. This

pulse is too short for the solenoid to react so the

transmission operation is not affected.

The solenoid feedback voltage is measured before

the (4 millisecond) pulse and again during the pulse.

If the difference is outside the acceptable limits

the relevant fault is recorede.

Typical causes would be an open circuit in the wiring

to or within the solenoid, or a short circuit to power

in the wiring to or within the solenoid.

If several faults of solenoids are present, check the

wiring or connectors that are common to the selected

solenoids, especially the earth connections.

Inspect the wiring for poor electrical connections

at the TCM and at the 10-way transmission

connector.

KAC5A030

Page 1245 of 2053

AUTOMATIC TRANSMISSION 5A-157

SSANGYONG MY2002

ON-VEHICLE SERVICE

TRANSMISSION

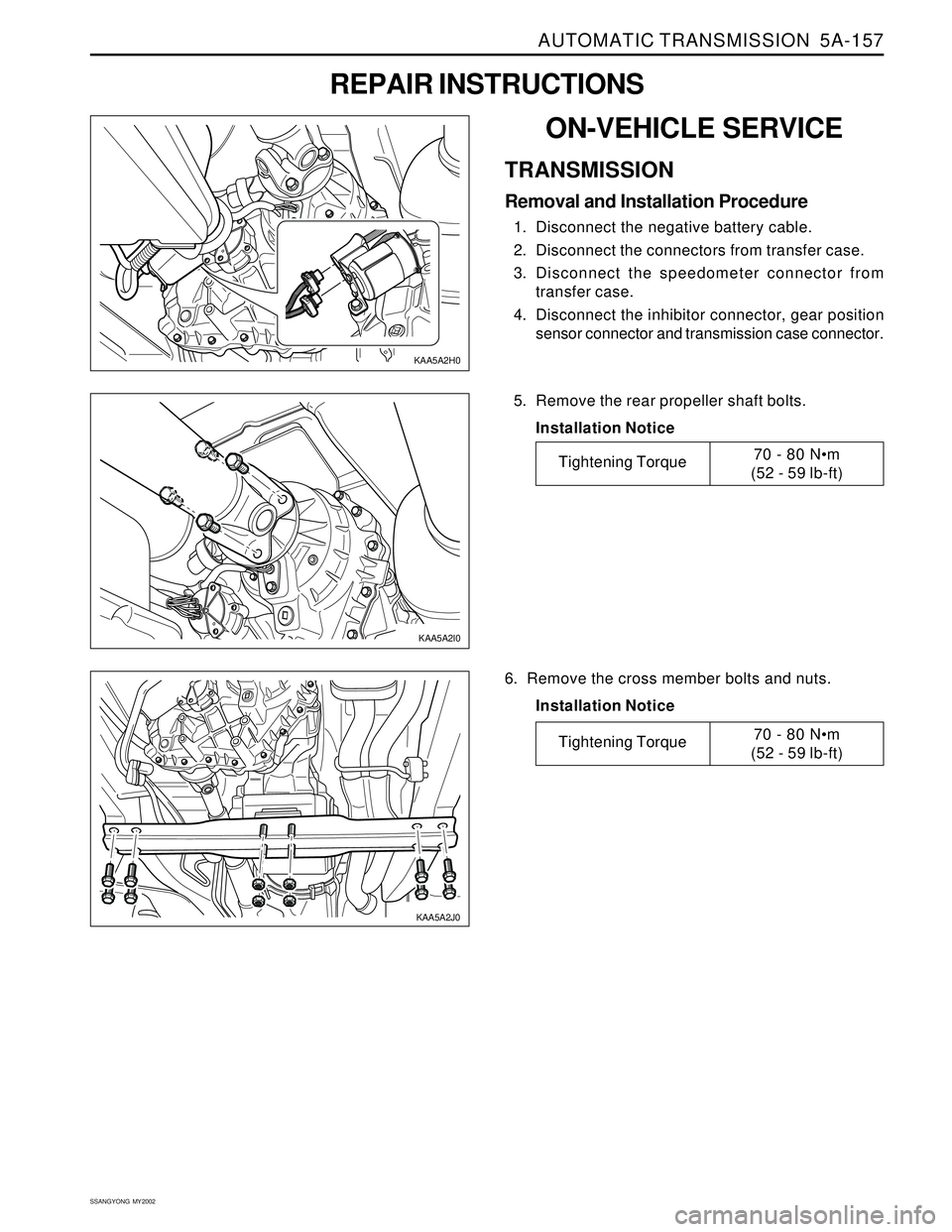

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the connectors from transfer case.

3. Disconnect the speedometer connector from

transfer case.

4. Disconnect the inhibitor connector, gear position

sensor connector and transmission case connector.

REPAIR INSTRUCTIONS

5. Remove the rear propeller shaft bolts.

Installation Notice

6. Remove the cross member bolts and nuts.

Installation Notice

KAA5A2I0

Tightening Torque70 - 80 N•m

(52 - 59 lb-ft)

Tightening Torque70 - 80 Nm

(52 - 59 lb-ft)

KAA5A2H0

KAA5A2J0

Page 1246 of 2053

5A-158 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

8. Remove the transfer case-to-transmission housing

bolts and remove the transfer case.

Installation Notice

10. Separate the locking clip on shift lever and remove

the shift rod.

Notice: Removal and installation performed when

the shift procedure should be lever is in ’D’ range.

11. Remove the oil cooler pipes.

Installation Notice 9. Disconnect the 10-Pins Plug connector from trans-

mission.

7. Remove the front propeller shaft bolts from transfer

case.

Installation Notice

KAA5A5V0

KAA5A2K0

KAA5A2L0

KAA5A2M0

Tightening Torque70 - 80 Nm

(52 - 59 lb-ft)

Tightening Torque35 - 60 Nm

(28 - 44 lb-ft)

Tightening Torque40 - 45 Nm

(29 - 33 lb-ft)

Page 1247 of 2053

AUTOMATIC TRANSMISSION 5A-159

SSANGYONG MY2002

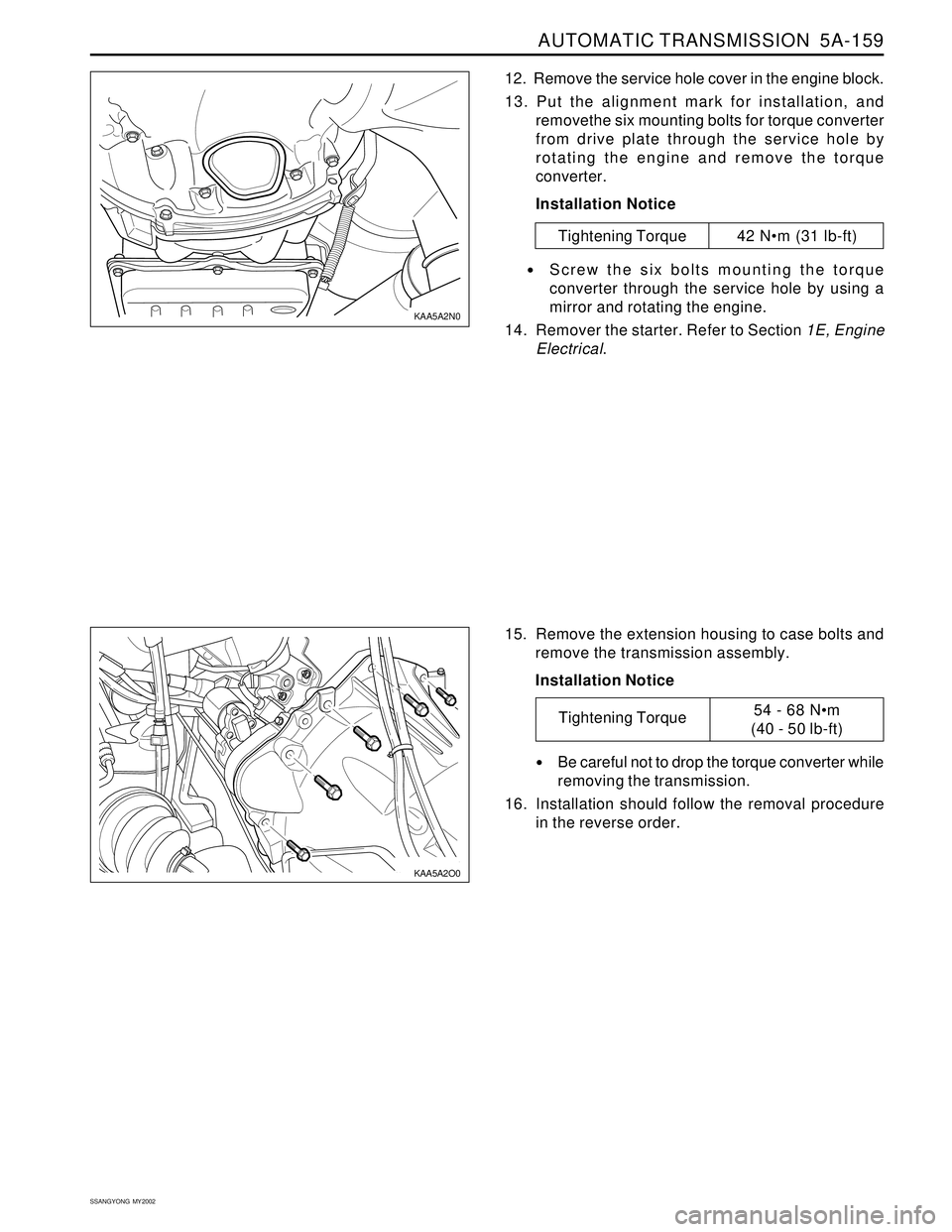

12. Remove the service hole cover in the engine block.

13. Put the alignment mark for installation, and

removethe six mounting bolts for torque converter

from drive plate through the service hole by

rotating the engine and remove the torque

converter.

Installation Notice

Screw the six bolts mounting the torque

converter through the service hole by using a

mirror and rotating the engine.

14. Remover the starter. Refer to Section 1E, Engine

Electrical.

15. Remove the extension housing to case bolts and

remove the transmission assembly.

Installation Notice

Be careful not to drop the torque converter while

removing the transmission.

16. Installation should follow the removal procedure

in the reverse order.

KAA5A2N0

KAA5A2O0

Tightening Torque54 - 68 Nm

(40 - 50 lb-ft)

Tightening Torque 42 Nm (31 lb-ft)

Page 1252 of 2053

5A-154 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

DIAGNOSTIC TROUBLE CODE (DTC) P1747

SOLENOID 7 CIRCUIT SHORT

Circuit Description

The solenoid 7 is a normally open ON/OFF type sole-

noid that is used to control the application of the

Torque Converter Clutch (TCC).

The Solenoid 7 (S7) ON activates the TCC and is at-

tached to the pump body within the transmission. Volt-

age is supplied directly to the solenoid through the

Transmission Control Module (TCM).

The DTC P1747 sets when the solenoid 7, Torque

Converter Clutch Solenoid, circuit is shorted to ground.

The solenoid 7’s driver Integrated Chip (IC) status

indicates a faulty circuit.

Conditions for Setting the DTC

DTCs P1717 and P1718 are not set.

S7 is ON.

The solenoid 7’s driver Integrated Chip (IC) status

indicates a faulty circuit. This condition must be

continuously present for 60 milliseconds.

Action Taken When the DTC Sets

The solenoid 7 is always disabled (OFF) resulting

in the TCC being unlocked continuously.

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred after ignition cycle.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

During the TCM’s testing, solenoid 7 is turned OFF/

ON by a very small (4 millisecond) pulses. This

pulse is too short for the solenoid to react so the

transmission operation is not affected.

The solenoid feedback voltage is measured before

the (4 millisecond) pulse and again during the

pulse. If the difference is outside the acceptable

limits the relevant fault is recorded.

Typical causes would be a short circuit to ground

in the wiring to or within the solenoid.

If several faults of solenoids are present, check

the wiring or connectors that are common to the

selected solenoids, especially the earth

connections.

Inspect the wiring for poor electrical connections

at the TCM and at the 10-way transmission

connector. Look for possible bent, backed out,

deformed or damaged terminals. Check for weak

terminal tension as well. Also check for chafed wires

that could short tobare metal or other wiring. Inspect

for broken wire inside the insulation.

KAC5A030YAD1E080

Page 1268 of 2053

AUTOMATIC TRANSMISSION 5A-173

SSANGYONG MY2002

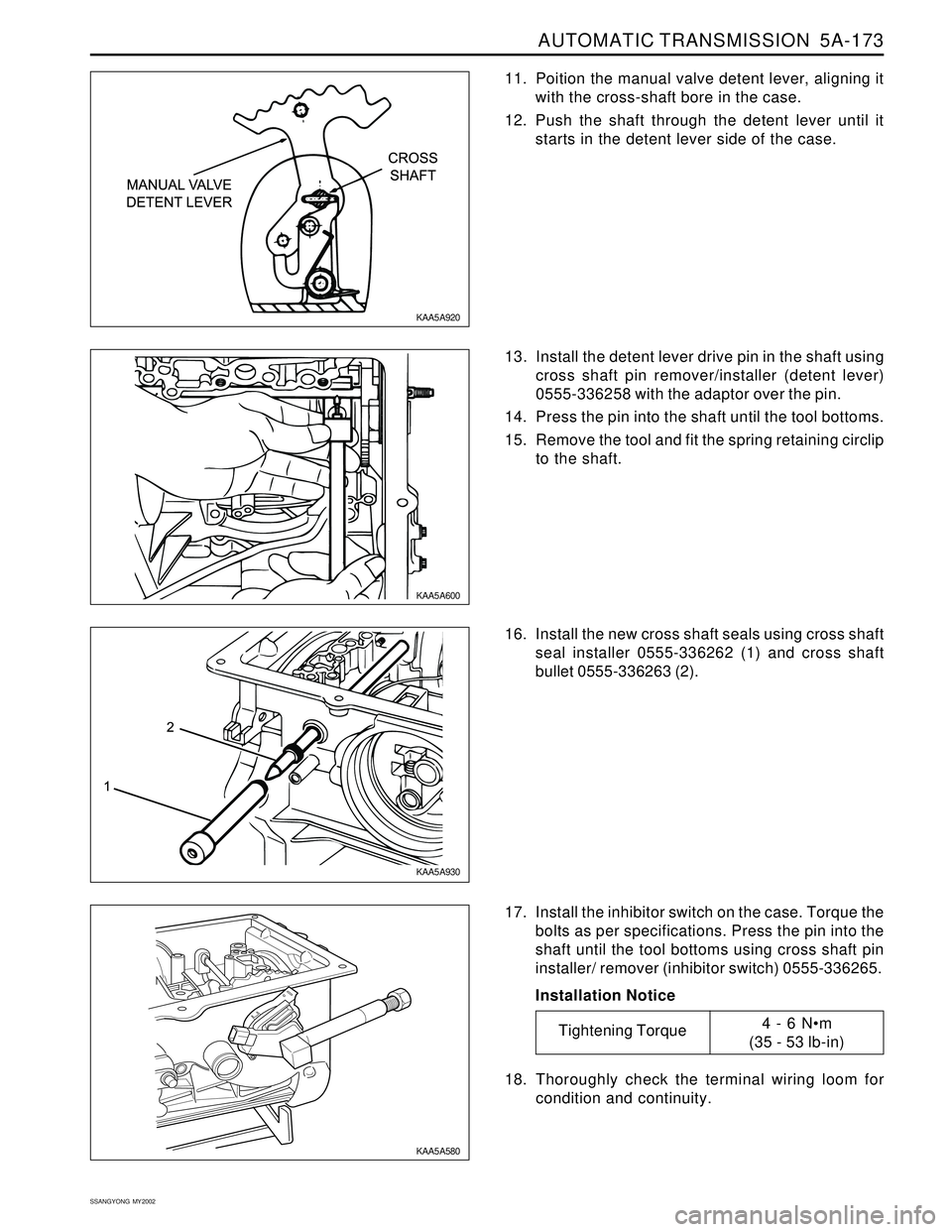

11. Poition the manual valve detent lever, aligning it

with the cross-shaft bore in the case.

12. Push the shaft through the detent lever until it

starts in the detent lever side of the case.

16. Install the new cross shaft seals using cross shaft

seal installer 0555-336262 (1) and cross shaft

bullet 0555-336263 (2).

17. Install the inhibitor switch on the case. Torque the

bolts as per specifications. Press the pin into the

shaft until the tool bottoms using cross shaft pin

installer/ remover (inhibitor switch) 0555-336265.

Installation Notice

18. Thoroughly check the terminal wiring loom for

condition and continuity. 13. Install the detent lever drive pin in the shaft using

cross shaft pin remover/installer (detent lever)

0555-336258 with the adaptor over the pin.

14. Press the pin into the shaft until the tool bottoms.

15. Remove the tool and fit the spring retaining circlip

to the shaft.

KAA5A920

KAA5A600

KAA5A930

KAA5A580

Tightening Torque4 - 6 Nm

(35 - 53 lb-in)

Page 1270 of 2053

AUTOMATIC TRANSMISSION 5A-175

SSANGYONG MY2002

Rear Band Assembly

1. Check the rear band for any cracks or damage

along the lining and metal backing.

2. Install the reaction anchor strut into the main case,

without shims.

3. Carefully install the rear band into the transmission

case and ensure that it is properly fitted in the

case.

Notice: If fitting a new band, soak the new band in

automatic transmission fluid for a minimum of five

minutes prior to assembly.

4. Position the apply strut on the rear band then

engage the apply strut in the servo lever.

5. Install the cam plate and tighten the screws to

specification.

Installation Notice

Rear Servo Assembly

1. Check the servo piston ‘O’ rings and gasket for

any damage.

2. Lubricate the servo piston ‘O’ rings with

automatic transmission fluid, and fit the ‘O’ rings

to the piston grooves.

3. Assemble the piston to the cover, ensuring that

‘O’ ring compression is adequate but not

excessive.

4. Align the spring on the piston spigot, then position

the rear servo rod into the spigot.

5. Assemble the gasket to the cover and fit the

assembly to the case.

Notice: Do not use petroleum jelly on the gasket.

6. Apply additional Loctite 202 or equivalent as

required to the rear servo to case bolts. Install

the bolts and tighten to specification.

Installation Notice

KAA5A950

KAA5A960

KAA5A630

KAA5A990

Tightening Torque30 - 35 Nm

(22 - 26 lb-ft)

Tightening Torque16 - 22 Nm

(12 - 16 lb-ft)

Page 1271 of 2053

5A-176 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Planet Carrier Assembly and Centre Support

1. Check the carrier and planet assembly for any

damage or irregularity and ensure that all pinions

rotate freely and that the pinion end float is within

0.10 mm - 0.50 mm.

2. Install the One Way Clutch (OWC) retainer (1) to

the planet carrier with the inner edge pointing down-

wards. Inspect the OWC race and the sprag

assemblies for wear or damage. Replace if

necessary.

3. Install the outer (3) race in the drum. Press the

race to the bottom of the drum and install the

retaining circlip (2). Ensure the circlip is firmly

seated in its groove.

4. Install the OWC (1) into the outer race with the lip

edge uppermost. Lubricate the sprags with auto-

matic transmission fluid.

5. Check that the plugs are fitted to the centre

support, then assemble the centre support into

the OWC, ensuring that the support will rotate in

an anti-clock-wise direction only.

6. Lubricate the No. 9 needle bearing and washer

with petroleum jelly and fit them to the rear face

of the planet carrier.

7. In s t a l l th e

KAA5A0A0

KAA5A760

KAA5A750

KAA5A560

Tightening Torque20 - 27 Nm

(15 - 20 lb-ft)

Page 1272 of 2053

AUTOMATIC TRANSMISSION 5A-177

SSANGYONG MY2002

Adaptor Housing Assembly

1. Install a new seal to the adaptor housing.

2. Position a new gasket onto the adaptor housing.

Notice: Do not use petroleum jelly to hold the gasket

in position.

3. Apply additional Loctite 202 or equivalent as required

to the adapter housing bolts. Install the adaptor

housing and torque the bolts to specification.

Installation Notice

Front Servo Assembly

1. Lubricate the cover ‘O’ ring with automatic

transmission fluid and fit to the cover.

2. Lubricatethepiston‘O’ rings with automatic trans-

mission fluid and fit to the piston.

3. Assemble the piston, push rod, spring, belleville

washer, seat and retaining ring.

4. Fit the piston push rod assembly into the front

servo cover.

5. Install the front servo block and spring into the

case.

6. Install the front servo assembly into the case.

KAA5A0C0

KAA5A520 KAA5A0B0

Tightening Torque30 - 35 Nm

(22 - 26 lb-ft)

7. Compress the servo cover and fit the servo cover

retaining circlip, aligning the gap with the pan rail,

and ensuring that it is completely seated in its

groove.

Notice: Ensure that the front servo snap ring is

installed correctly. Orient the circlip with the gap at

the bottom, near the pan rail.

KAA5A0D0