torque SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 976 of 2053

SSANGYONG MY2002

4E-16 REAR BRAKES

4. Install the brake hose.

Notice: The washer should be replaced new part.

5. Tighten the air bleeder screw.

Installation Notice

Tightening Torque7 - 13 Nm

(62 - 115 lb-in)

6. Bleed the brake system after replacement.

YAD4C270

Page 979 of 2053

REAR BRAKES 4E-19

SSANGYONG MY2002

9. Remove the wheel cylinder mounting bolt and

remove the wheel cylinder.

Inspection

1. Measure the inside diameter of the brake drum

and replace as needed.

I.D.

φ 254 mmWear Limitφ 255.5 mm

Notice: Measure two more position.

2. Inspect the surface between the lining and brake.

Mark the brake drum inside using chalk and scrub

the shoe & lining assembly. If there is excessive

contact problem, replace the shoe & lining

assembly or the brake drum.

Notice: Clean any chalk mark after inspection

complete.

YAD4C370

YAD4C380

YAD4C390

Installation Procedure

1. Install the wheel cylinder to the backing plate.

Installation Notice

Tightening Torque8 - 12 Nm

(71 - 106 lb-in)

YAD4C400

Page 981 of 2053

REAR BRAKES 4E-21

SSANGYONG MY2002

7. Connect the brake pipe to the wheel cylinder.

Installation Notice

Tightening Torque15 - 19 Nm

(11 - 14 lb-ft)

8. Bleed the brake system and verify the parking

brake operation.

Install the tire.

YAD4C450

Page 982 of 2053

SSANGYONG MY2002

4E-22 REAR BRAKES

UNIT REPAIR

WHEEL CYLINDER

Disassembly Procedure

1. Remove the upper brake return spring and remove

the wheel cylinder with pulling the upper lining

outside.

2. Disassembly the wheel cylinder assembly.

Remove the dust boot and do not reuse them

(1).

Remove the piston (2).

Remove the piston cup and do not reuse it (3).

Remove the spring assembly (4).

Remove the bleeder screw (5).

3. Clean all the parts with the denatured alcohol. Dry

the parts with unlubricated compressed air.

Bleeder Screw7 - 10 Nm

(62 - 89 lb-in)

8 - 12 Nm

(71 - 106 lb-in)

Wheel Cylinder

Mounting Bolt

Notice: Lubricate the new seals, the piston, the

piston cup and the wheel cylinder bore with clean

brake fluid before assembly. 4. Installation should follow the removal procedure

in the reverse order.

5. Tighten the bleeder screw and wheel cylinder as

specified torque.

YAD4C460

YAD4C470

YAD4C480

Page 987 of 2053

ABS AND TCS 4F-3

SSANGYONG MY2002

GENERAL DESCRIPTION AND SYSTEM OPERATION

BASIC KNOWLEDGE REQUIRED

Before using this section, it is important that you have

a basic knowledge of the following items. Without this

knowledge, it will be difficult to use the diagnostic

procedures contained in this section.

•Basic Electrical Circuits - You should understand

the basic theory of electricity and know the meaning

of voltage, current (amps), and resistance (ohms).

You should understand what happens in a circuit

with an open or shorted wire. You should be able to

read and understand a wiring diagram.

Use of Circuit Testing Tools - You should know

how to use a test light and how to bypass

components to test circuits using fused jumper

wires. You should be familiar with a digital

multimeter. You should be able to measure voltage,

resistance, and current, and be familiar with the

controls and how to use them correctly.

ABS SYSTEM COMPONENTS

The ABS 5.3 Antilock Braking System (ABS) consists

of a conventional hydraulic brake system plus antilock

components. The conventional brake system includes

a vacuum booster, master cylinder, front disc brakes,

rear disc brakes, interconnecting hydraulic brake pipes

and hoses, brake fluid level switch and the BRAKE

indicator.

The ABS components include a hydraulic unit, an elec-

tronic brake control module (EBCM), two system fuses,

four wheel speed sensors (one at each wheel), intercon-

necting wiring, the ABS indicator, the EBD indicator

and the TCS indicator. See “ABS Component Locator”

in this section for the general layout of this system.

The hydraulic unit with the attached EBCM is located

between the surge tank and the bulkhead on the left

side of the vehicle.

The basic hydraulic unit configuration consists of hy-

draulic check valves, two solenoid valves for each

wheel, a hydraulic pump, and two accumulators. The

hydraulic unit controls hydraulic pressure to the front

calipers and rear calipers by modulating hydraulic

pressure to prevent wheel lockup.

Units equipped with TCS add two more valves for each

drive wheel for the purpose of applying the brake to a

wheel that is slipping. This is done with pressure from

the hydraulic pump in the unit. There is also a TCS

indicator lamp on the instrument panel to alert the driver

to the fact that the TCS system is active. The

components identified in the drawing are those added

to the basic ABS 5.3 system to provide traction control.

Nothing in the hydraulic unit or the EBCM is serviceable.

In the event of any failure, the entire ABS unit withattached EBCM must be replaced. For more

information, refer to “Base Braking Mode” and

“Antilock Braking Mode” in this section.

TRACTION CONTROL SYSTEM

(TCS) DESCRIPTION

General Information

The traction control system (TCS) is a traction system

by means of brake intervention only, available in a low

speed range (< 60kph).

It workes on µ - split roads with sidewise different friction

coefficients.

The spinning driven wheel is braked and the drive

torque can be transferred to the wheel on the high-µ

side. During TCS active, the TCS information lamp is

blinking.

The temperature of the brakes is calculated by a mathe-

matical model and TCS is switched passive if the calcu-

lated temperature is greater than a threshold value (500

°C).

TCS is permitted again, when the calculated tempera-

ture is less than 350 °C.

Control Algorithm

The input signals for the control algorithm are the

filtered wheel speed signals from the ABS speed

processing.

With the speed difference of the driven wheels, the

control deviation is calculated.

If the control deviation exceeds a certain threshold

value, the wheel with the greater slip is braked actively.

The threshold value depends on the vehicle speed:

It is reduced with increasing vehicle speed down to a

constant value.

KAA4F010

Page 1078 of 2053

ABS AND TCS 4F-95

SSANGYONG MY2002

EBCM CONNECTION FACE VIEW

(WITHOUT TRACTION CONTROL SYSTEM)

EBCM CONNECTOR

KAA4F300

Color

BLK/DK GRN

BRN/BLK

-

BRN/WHT

BRN/BLK

BLK/RED

BRN/RED

BRN/YEL

BLK/DK GRN

YEL

BRN/DK GRN

-

RED/YEL

DK GRN/YEL

WHT/RED

BLK Pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16Circuit

Right Rear Ground

Right Rear Sensor

Not Used

Right Front Ground

Right Front Sensor

Left Front Ground

Left Front Sensor

Left Rear Ground

Left Rear Sensor

Acceleration Sensor

Signal Voltage

Data Link Connector

Not Used

Torque On Demand

Stoplamp Switch

Ignition

GroundColor

RED/WHT

RED/WHT

-

BLK

LT GRN

DK GRN/BRN

-

-

-

-

-

RED

-

DK BLU

- Pin

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31Circuit

Battery

Battery

Ground

ABS Warning Lamp

EBD Warning Lamp

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Acceleration Sensor

Supply Voltage

Not Used

Acceleration Sensor

Ground

Not Used

Page 1080 of 2053

ABS AND TCS 4F-97

SSANGYONG MY2002

KAA4F320

Color

WHT/RED

BLK/DK GRN

YEL/DK GRN

RED/BRN

BRN

LT GRN/BLK

DK BLU/BLK

-

-

BLK/RED

BRN/BLK

BRN/YEL

BLK/LT GRN

BRN/WHT

BRN/BLK

-

-

RED/YEL

RED/BRN

-

-

-

-

-

DK GRN

DK BLU/BLK

- Pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27Circuit

Ignition

Relay Supply Voltage

Pilot Valve

Prime Valve

Left Front Inlet Valve

Right Rear Inlet Valve

Motor Relay Actuation

Not Used

Not Used

Left Front Ground

Right Rear Sensor

Left Rear Ground

Left Rear Sensor

Right Front Ground

Right Front Sensor

Not Used

Not Used

Torque On Demand

Motor Monitoring

Not Used

Not Used

Not Used

Not Used

Not Used

Left Rear Outlet Valve

Right Front Inlet Valve

Not UsedColor

BLK

BLK

RED/BLK

LT GRN

DK BLU

RED

DK GRN/BRN

-

BRN/RED

YEL/DK GRN

BLK/DK GRN

DK BLU

-

-

-

RED

-

-

BRN/DK GRN

-

DK GRN/YEL

-

DK BLU/WHT

YEL Pin

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51Circuit

Ground

Ground

EBD Warning Lamp

ABS Warning Lamp

TCS Warning Lamp

Left Front Outlet Valve

Right Rear Outlet

Valve

Not Used

Left Front Sensor

Valve Relay Actuation

Right Rear Ground

Acceleration Sensor

Ground

Not Used

Not Used

Not Used

Acceleration Sensor

Supply Voltage

Not Used

Not Used

Data Link Connector

Not Used

Stoplamp Switch

Not Used

Battery

Acceleration Sensor

Signal Voltage

Page 1082 of 2053

ABS AND TCS 4F-99

SSANGYONG MY2002

REPAIR INSTRUCTIONS

ON-VEHICLE SERVICE

SERVICE PRECAUTIONS

Caution: Brake Fluid may irritate eyes and skin. In

case of contact, take the following actions:

Eye contact - rinse thoroughly with water.

Skin contact - wash with soap and water.

Ingestion - consult a physician immediately.

Caution: To help avoid personal injury due to poor

braking. DO NOT Tap into the vehicle’s brake system

to operate a trailer brake system.

Notice: When fasteners are removed, always reinstall

them at the same location from which they were

removed. If a fastener needs to be replaced, use the

correct part number fastener for is not available, a

fastener of equal size and strength (or stronger) may

be used. Fasteners that are not reused, and those

requiring thread-locking compound will be called out.

The correct torque values must be used when installing

fasteners that require them. If the above procedures

are not followed, parts or system damage could result.

Notice: Use only DOT-3 equivalent hydraulic brake

fluid. The use of DOT-5 (silicone) brake fluid is not

recommended. Reduced brake performance or

durability may result.

Notice: Avoid spilling brake fluid on any the vehicle’s

painted surfaces, wiring, cables or electrical

connectors. Brake fluid will damage paint and electrical

connections. If any fluid is spilled on the vehicle, flush

the area with water to lessen the damage.

Electronic System Service Precautions

Take care to avoid electronic brake control module

(EBCM) circuit overloading. In testing for opens or

shorts, do not ground or apply voltage to any circuit

unless instructed to do so by the diagnostic procedure.

Test circuits only with a high-impedance multi-meter.

Never remove or apply power to any control module

with the ignition switch in the ON position. Always turn

the ignition to the OFF position before removing or

connecting battery cables, fuses or connectors.

General Service Precautions

Disconnect the EBCM connector before performing any

vehicle welding work using an electric arc welder.

Do not attempt to disassemble any component

designated as nonserviceable. The hydraulic modulator

and the EBCM can be separated from each other and

replaced separately but cannot be serviced. They have

no replaceable parts, and there is no replaceable parts,

and there is no access to the components they contain.

Bleeding System

Replacement modulators are shipped already filled

and bled. In normal procedures requiring removal of

the modulator, such as to replace the EBCM, air will

not enter the modulator, and normal bleeding will be

all that is needed.

If air enters the hydraulic modulator, or if an unfilled

modulator is installed, use the brake bleeding program

in the scan tool to bleed the modulator. Manual

bleeding of the hydraulic modulator is not possible.

Page 1083 of 2053

SSANGYONG MY2002

4F-100 ABS AND TCS

1

KAA4F330

KAA4F340

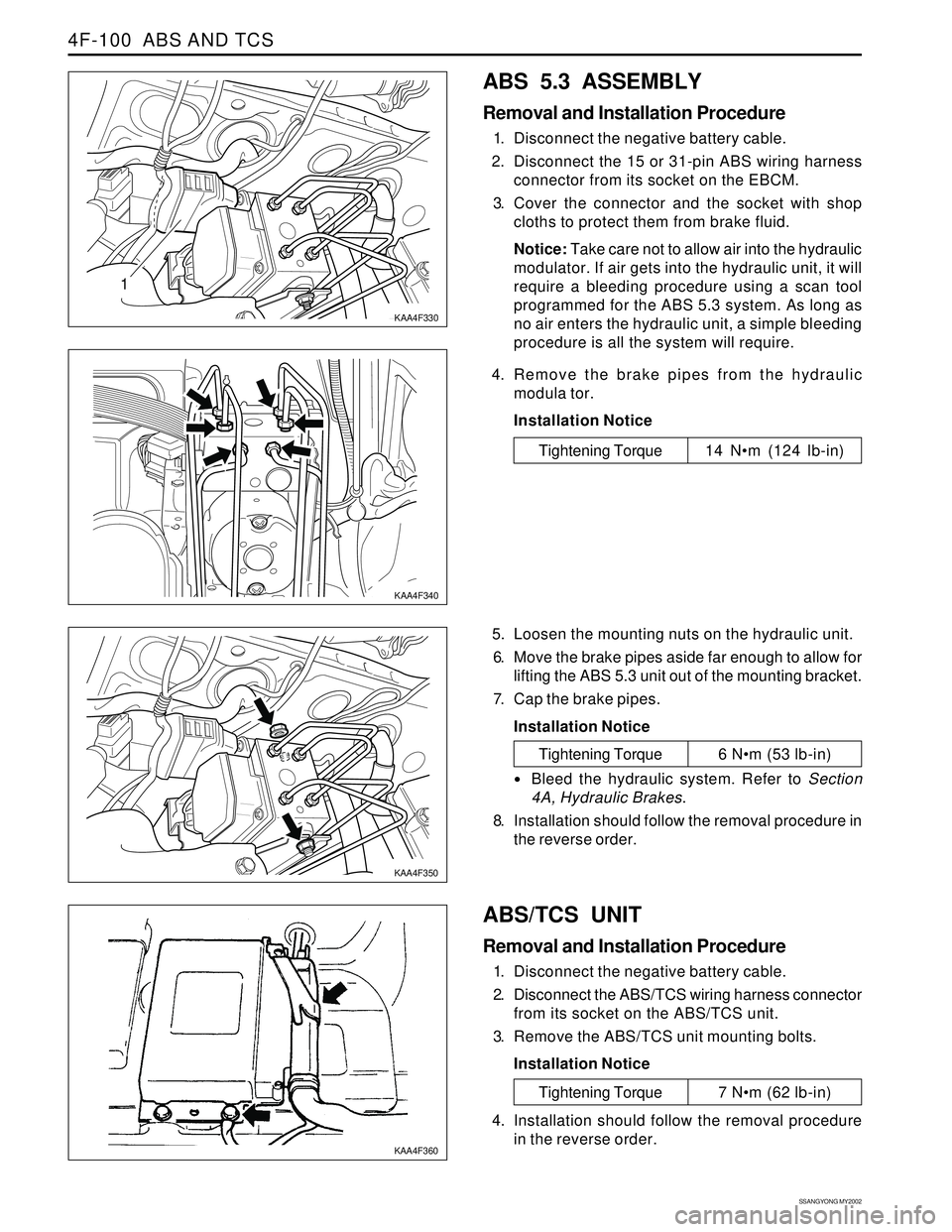

ABS 5.3 ASSEMBLY

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the 15 or 31-pin ABS wiring harness

connector from its socket on the EBCM.

3. Cover the connector and the socket with shop

cloths to protect them from brake fluid.

Notice: Take care not to allow air into the hydraulic

modulator. If air gets into the hydraulic unit, it will

require a bleeding procedure using a scan tool

programmed for the ABS 5.3 system. As long as

no air enters the hydraulic unit, a simple bleeding

procedure is all the system will require.

4. Remove the brake pipes from the hydraulic

modula tor.

Installation Notice

Tightening Torque 14 Nm (124 lb-in)

5. Loosen the mounting nuts on the hydraulic unit.

6. Move the brake pipes aside far enough to allow for

lifting the ABS 5.3 unit out of the mounting bracket.

7. Cap the brake pipes.

Installation Notice

ABS/TCS UNIT

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the ABS/TCS wiring harness connector

from its socket on the ABS/TCS unit.

3. Remove the ABS/TCS unit mounting bolts.

Installation Notice

KAA4F350

KAA4F360

Tightening Torque 6 Nm (53 lb-in)

Bleed the hydraulic system. Refer to Section

4A, Hydraulic Brakes.

8. Installation should follow the removal procedure in

the reverse order.

Tightening Torque 7 Nm (62 lb-in)

4. Installation should follow the removal procedure

in the reverse order.

Page 1084 of 2053

ABS AND TCS 4F-101

SSANGYONG MY2002

FRONT WHEEL SPEED SENSOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the front wheel speed sensor electrical

connector.

3. Raise and suitably support the vehicle.

4. Turn the steering wheel to expose the front wheel

speed sensor. It is located at the rear of the steering

knuckle near tie rod end.

5. Remove the bolt and the front wheel speed sensor

from the steering knuckle.

Installation Notice

KAA4F370

KAA4F380

Tightening Torque 7 Nm (62 lb-in)

6. Installation should follow the removal procedure in

the reverse order.

REAR WHEEL SPEED SENSOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the rear wheel speed sensor electrical

connector. It is located under the rear seat.

3. Raise and suitably support the vehicle.

4. Remove the rear wheel speed sensor.

Installation Notice

KAA4F390

KAA4F400

Tightening Torque 7 Nm (62 lb-in)

5. Installation should follow the removal procedure

in the reverse order.