torque SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1085 of 2053

SSANGYONG MY2002

4F-102 ABS AND TCS

ACCELERATION SENSOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the acceleration sensor connector. It

is located at the rear of audio system.

3. Remove the acceleration sensor mounting bolts.

Installation Notice

SYSTEM FUSE

Removal and Installation Procedure

The ABS/TCS system fuse, EF11, is located in the

engine fuse block. Counting from the battery toward

the surge tank, it is the first system fuse in the row.

KAA4F410

KAA4F420

Tightening Torque 7 Nm (62 lb-in)

4. Installation should follow the removal procedure in

the reverse order.

INDICATORS

The indicator lamps ABS and EBD and TCS are part of

the instrument cluster. Refer to Section 9E, instrumenta-

tion/ Driver information, for removal and replacement

details.

Page 1092 of 2053

PARKING BRAKE 4G-5

SSANGYONG MY2002

KAA4G040

KAA4G050

KAA4G060

KAA4G070

PARKING BRAKE LEVER

Removal and Installation Procedure

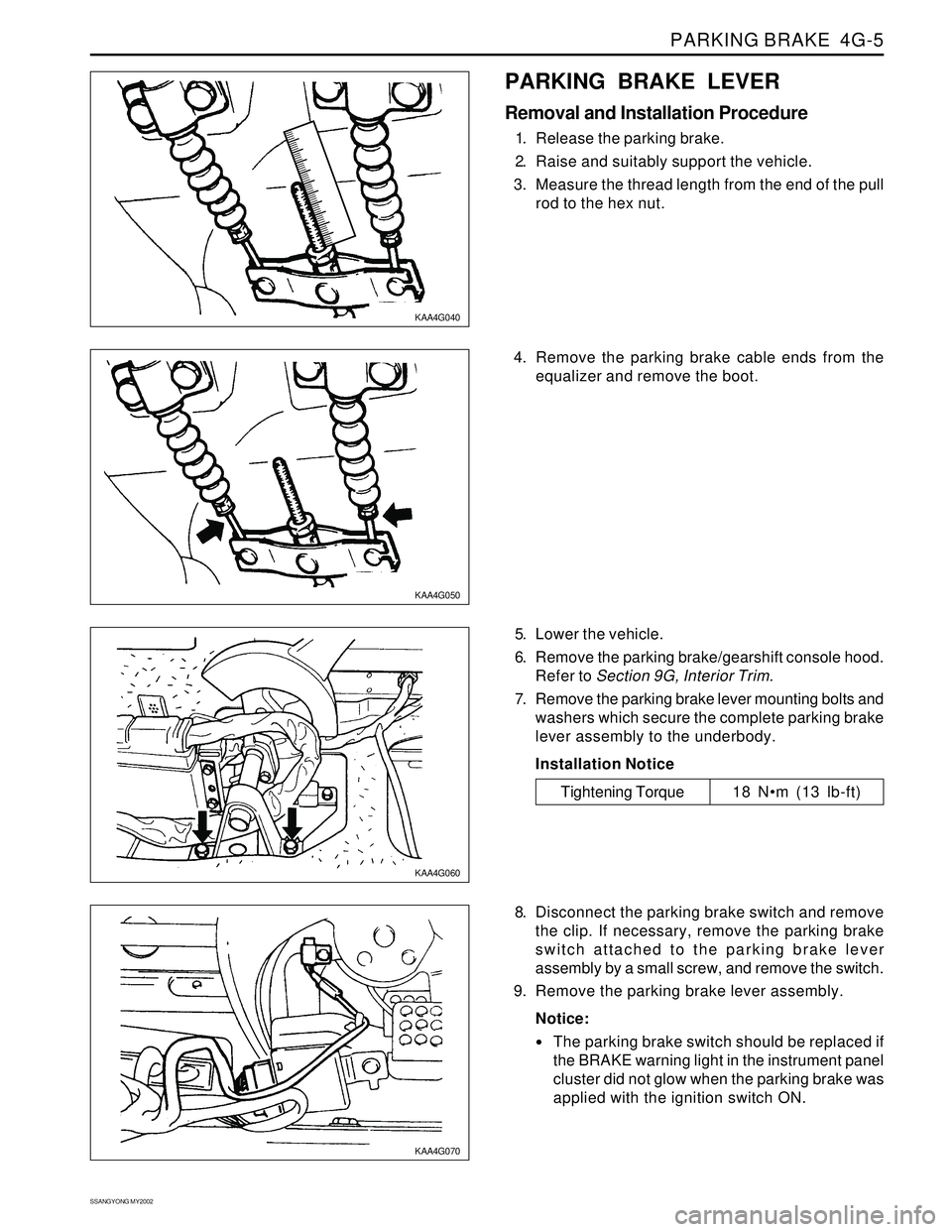

1. Release the parking brake.

2. Raise and suitably support the vehicle.

3. Measure the thread length from the end of the pull

rod to the hex nut.

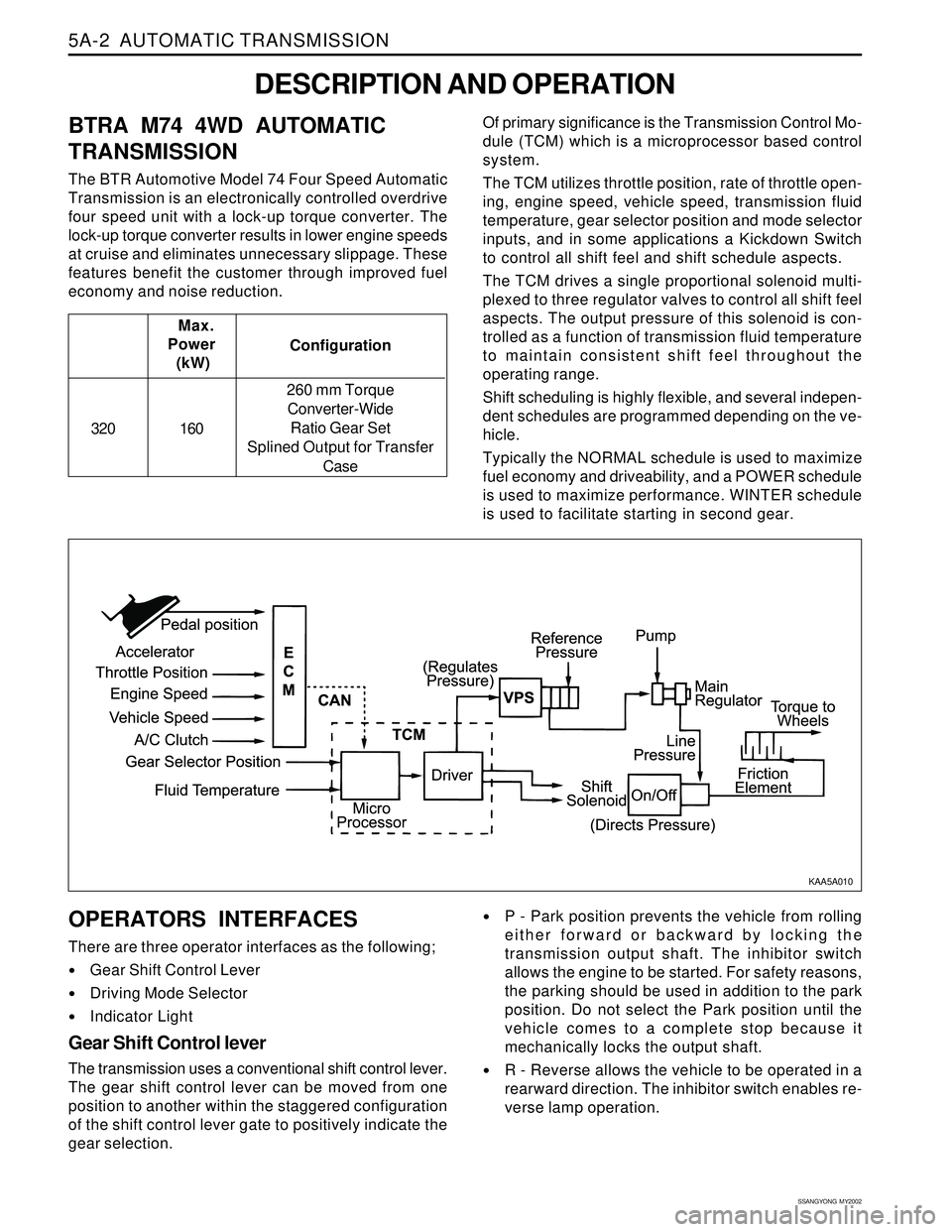

5. Lower the vehicle.

6. Remove the parking brake/gearshift console hood.

Refer to Section 9G, Interior Trim.

7. Remove the parking brake lever mounting bolts and

washers which secure the complete parking brake

lever assembly to the underbody.

Installation Notice

8. Disconnect the parking brake switch and remove

the clip. If necessary, remove the parking brake

switch attached to the parking brake lever

assembly by a small screw, and remove the switch.

9. Remove the parking brake lever assembly.

Notice:

The parking brake switch should be replaced if

the BRAKE warning light in the instrument panel

cluster did not glow when the parking brake was

applied with the ignition switch ON.

Tightening Torque 18 Nm (13 lb-ft) 4. Remove the parking brake cable ends from the

equalizer and remove the boot.

Page 1093 of 2053

SSANGYONG MY2002

4G-6 PARKING BRAKE

KAA4G020

KAA4G080

KAA4G050

PARKING BRAKE CABLE

Removal and Installation Procedure

1. Release the parking brake.

2. Raise and suitably support the vehicle.

3. Remove the clip that holds the cable into the rear

knuckle assembly.

6. Remove the parking brake cable ends from the

equalizer.

Tightening Torque 9 Nm (80 lb-in) 5. Remove the bolts securing the parking brake cable

to a holding bracket attached to the trailing link

brackets on both the driver and passenger sides

of the vehicle.

Installation Notice

Page 1096 of 2053

5A-2 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

OPERATORS INTERFACES

There are three operator interfaces as the following;

•Gear Shift Control Lever

Driving Mode Selector

Indicator Light

Gear Shift Control lever

The transmission uses a conventional shift control lever.

The gear shift control lever can be moved from one

position to another within the staggered configuration

of the shift control lever gate to positively indicate the

gear selection.

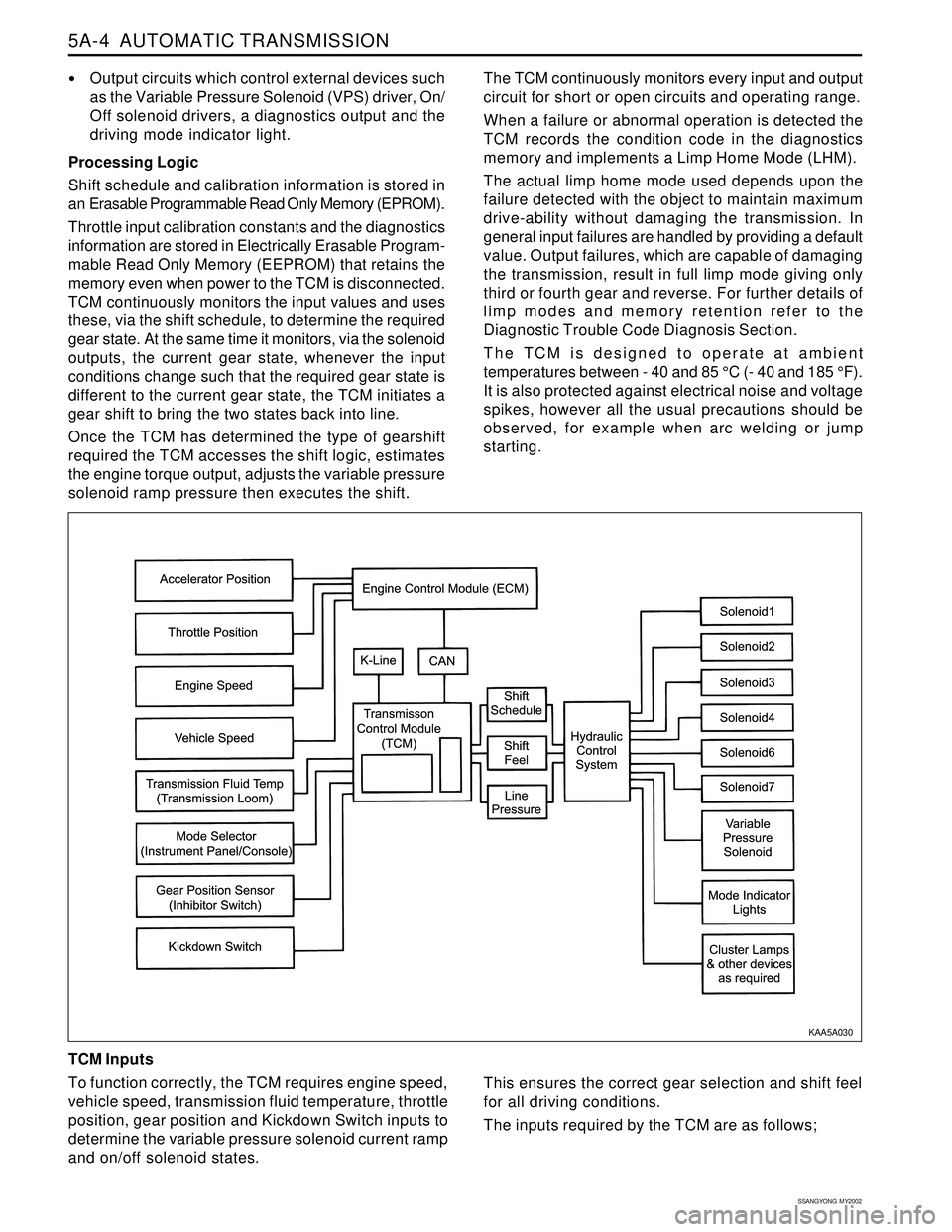

DESCRIPTION AND OPERATION

BTRA M74 4WD AUTOMATIC

TRANSMISSION

The BTR Automotive Model 74 Four Speed Automatic

Transmission is an electronically controlled overdrive

four speed unit with a lock-up torque converter. The

lock-up torque converter results in lower engine speeds

at cruise and eliminates unnecessary slippage. These

features benefit the customer through improved fuel

economy and noise reduction.Of primary significance is the Transmission Control Mo-

dule (TCM) which is a microprocessor based control

system.

The TCM utilizes throttle position, rate of throttle open-

ing, engine speed, vehicle speed, transmission fluid

temperature, gear selector position and mode selector

inputs, and in some applications a Kickdown Switch

to control all shift feel and shift schedule aspects.

The TCM drives a single proportional solenoid multi-

plexed to three regulator valves to control all shift feel

aspects. The output pressure of this solenoid is con-

trolled as a function of transmission fluid temperature

to maintain consistent shift feel throughout the

operating range.

Shift scheduling is highly flexible, and several indepen-

dent schedules are programmed depending on the ve-

hicle.

Typically the NORMAL schedule is used to maximize

fuel economy and driveability, and a POWER schedule

is used to maximize performance. WINTER schedule

is used to facilitate starting in second gear. Configuration Max.

Power

(kW)

320 160260 mm Torque

Converter-Wide

Ratio Gear Set

Splined Output for Transfer

Case

P - Park position prevents the vehicle from rolling

either forward or backward by locking the

transmission output shaft. The inhibitor switch

allows the engine to be started. For safety reasons,

the parking should be used in addition to the park

position. Do not select the Park position until the

vehicle comes to a complete stop because it

mechanically locks the output shaft.

R - Reverse allows the vehicle to be operated in a

rearward direction. The inhibitor switch enables re-

verse lamp operation.

KAA5A010

Page 1097 of 2053

AUTOMATIC TRANSMISSION 5A-3

SSANGYONG MY2002

N - Neutral allows the engine to be started and oper-

ated while driving the vehicle. The inhibitor switch

allows the engine to be started. There is no power

transferred through the transmission in Neutral. But

the final drive is not locked by the parking pawl, so

thewheels are free to rotate.

D - Overdrive range is used for all normal driving

conditions. 4th gear (overdrive gear) reduces the

fuel consumption and the engine noise. Engine

braking is applied with reduced throttle.

First to second (1 → 2), first to third (1 → 3), second

to third (2 → 3), second to fourth (2 → 4), third to

fourth (3 → 4), fourth to third (4 → 3), fourth to

second (4 → 2), third to second (3 → 2), third to

first (3 → 1) and second to first (2 → 1) shifts are

all available as a function of vehicle speed, throttle

position and the time change rate of the throttle

position.

Downshifts are available for safe passing by

depress-ing the accelerator. Lockup clutch may be

enabled in 3rd and 4th gears depending on vehicle

type.

3 - Manual 3 provides three gear ratios (first through

third) and prevents the transmission from operating

in 4th gear. 3rd gear is used when driving on long

hill roads or in heavy city traffic. Downshifts are

available by depressing the accelerator.

2 - Manual 2 provides two gear ratios (first and

second). It is used to provide more power when

climbing hills or engine braking when driving down

a steep hill or starting off on slippery roads.

1 - Manual 1 is used to provide the maximum engine

braking when driving down the severe gradients.When NORMAL mode is selected upshifts will occur

to maximize fuel economy. When POWER mode is se-

lected, upshifts will occur to give maximum

performance and the POWER mode indicator light is

switched ON.

When WINTER mode is selected, starting in second

gear is facilitated, the WINTER mode indicator light is

switched ON and the POWER mode indicator light is

switched OFF.

Indicator Light

The indicator light is located on the instrument panel.

Auto shift indicator light comes ON when the ignition

switch ON and shows the gear shift control lever

position.

POWER mode indicator light comes ON when the

POWER mode is selected and when the kickdown

switch is depressed.

WINTER mode indicator light comes ON when the

WINTER mode is selected.

CONTROL SYSTEMS

BTRA M74 4WD automatic transmission consists of

two control systems. One is the electronic control

system that monitors vehicle parameters and adjusts

the transmission performance. Another is the hydraulic

control system that implements the commands of the

electronic control system commands.

ELECTRONIC CONTROL SYSTEM

The electronic control system comprises of sensors, a

TCM and seven solenoids. The TCM reads the inputs

and activates the outputs according to values stored

in Read Only Memory (ROM).

The TCM controls the hydraulic control system. This

control is via the hydraulic valve body, which contains

seven electromagnetic solenoids. Six of the seven

solenoids are used to control the line pressure, operate

the shift valves and the torque converter lock-up clutch,

and to turn ON and OFF the two regulator valves that

control the shift feel.

The seventh solenoid is the proportional or Variable

Pressure Solenoid (VPS) which works with the two regu-

lator valves to control shift feel.

Transmission Control Module (TCM)

The TCM is an in-vehicle micro-processor based trans-

mission management system. It is mounted under the

driver’s side front seat in the vehicle cabin.

The TCM contains:

Processing logic circuits which include a central mi-

croprocessor controller and a back-up memory

system.

Input circuits.

Driving Mode Selector

The driving mode selector consists of a driving mode

selector switch and indicator light. The driving mode

selector is located on the center console and allows

the driver to select the driving mode.

The driving modes available to be selected vary with

vehicle types. Typically the driver should have the

option to select among NORMAL, POWER and

WINTER modes.

KAA5A020

Page 1098 of 2053

5A-4 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

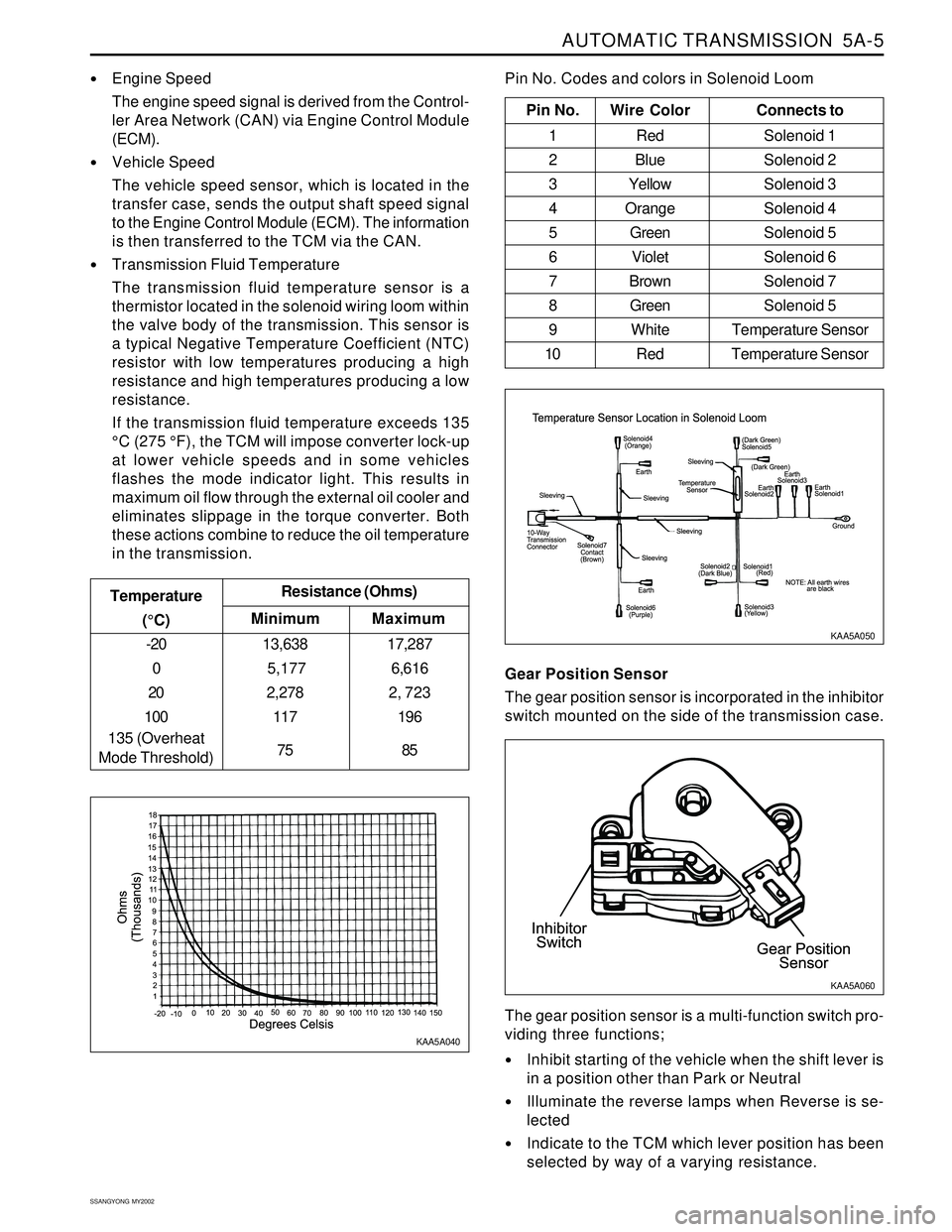

Output circuits which control external devices such

as the Variable Pressure Solenoid (VPS) driver, On/

Off solenoid drivers, a diagnostics output and the

driving mode indicator light.

Processing Logic

Shift schedule and calibration information is stored in

an Erasable Programmable Read Only Memory (EPROM).

Throttle input calibration constants and the diagnostics

information are stored in Electrically Erasable Program-

mable Read Only Memory (EEPROM) that retains the

memory even when power to the TCM is disconnected.

TCM continuously monitors the input values and uses

these, via the shift schedule, to determine the required

gear state. At the same time it monitors, via the solenoid

outputs, the current gear state, whenever the input

conditions change such that the required gear state is

different to the current gear state, the TCM initiates a

gear shift to bring the two states back into line.

Once the TCM has determined the type of gearshift

required the TCM accesses the shift logic, estimates

the engine torque output, adjusts the variable pressure

solenoid ramp pressure then executes the shift.The TCM continuously monitors every input and output

circuit for short or open circuits and operating range.

When a failure or abnormal operation is detected the

TCM records the condition code in the diagnostics

memory and implements a Limp Home Mode (LHM).

The actual limp home mode used depends upon the

failure detected with the object to maintain maximum

drive-ability without damaging the transmission. In

general input failures are handled by providing a default

value. Output failures, which are capable of damaging

the transmission, result in full limp mode giving only

third or fourth gear and reverse. For further details of

limp modes and memory retention refer to the

Diagnostic Trouble Code Diagnosis Section.

The TCM is designed to operate at ambient

temperatures between - 40 and 85 °C (- 40 and 185 °F).

It is also protected against electrical noise and voltage

spikes, however all the usual precautions should be

observed, for example when arc welding or jump

starting.

TCM Inputs

To function correctly, the TCM requires engine speed,

vehicle speed, transmission fluid temperature, throttle

position, gear position and Kickdown Switch inputs to

determine the variable pressure solenoid current ramp

and on/off solenoid states.

KAA5A030

This ensures the correct gear selection and shift feel

for all driving conditions.

The inputs required by the TCM are as follows;

Page 1099 of 2053

AUTOMATIC TRANSMISSION 5A-5

SSANGYONG MY2002

Engine Speed

The engine speed signal is derived from the Control-

ler Area Network (CAN) via Engine Control Module

(ECM).

Vehicle Speed

The vehicle speed sensor, which is located in the

transfer case, sends the output shaft speed signal

to the Engine Control Module (ECM). The information

is then transferred to the TCM via the CAN.

Transmission Fluid Temperature

The transmission fluid temperature sensor is a

thermistor located in the solenoid wiring loom within

the valve body of the transmission. This sensor is

a typical Negative Temperature Coefficient (NTC)

resistor with low temperatures producing a high

resistance and high temperatures producing a low

resistance.

If the transmission fluid temperature exceeds 135

°C (275 °F), the TCM will impose converter lock-up

at lower vehicle speeds and in some vehicles

flashes the mode indicator light. This results in

maximum oil flow through the external oil cooler and

eliminates slippage in the torque converter. Both

these actions combine to reduce the oil temperature

in the transmission.

Minimum Temperature

(°C)Resistance (Ohms)

-20

0

20

100

135 (Overheat

Mode Threshold)13,638

5,177

2,278

117

75

Maximum

17,287

6,616

2, 723

196

85

Pin No. Wire ColorConnects to

1 Red Solenoid 1

2 BlueSolenoid 2

3 YellowSolenoid 3

4 OrangeSolenoid 4

5 GreenSolenoid 5

6 VioletSolenoid 6

7 BrownSolenoid 7

8 GreenSolenoid 5

9 White Temperature Sensor

10 Red Temperature Sensor

Pin No. Codes and colors in Solenoid Loom

KAA5A040KAA5A050

Gear Position Sensor

The gear position sensor is incorporated in the inhibitor

switch mounted on the side of the transmission case.

Inhibit starting of the vehicle when the shift lever is

in a position other than Park or Neutral

Illuminate the reverse lamps when Reverse is se-

lected

Indicate to the TCM which lever position has been

selected by way of a varying resistance. The gear position sensor is a multi-function switch pro-

viding three functions;

KAA5A060

Page 1103 of 2053

AUTOMATIC TRANSMISSION 5A-9

SSANGYONG MY2002

The DLC connector is located within the driver’s

compartment, directly below the instrument panel on

the driver’s side.

HYDRAULIC CONTROL SYSTEM

The hydraulic controls are located in the valve body,

pump body and main case.

The valve body contains the following;

Manual valve

Three shift valves

Sequence valve

Solenoid supply pressure regulator valve

Line pressure control valve

Clutch apply feed regulator valve

Band apply feed regulator valve

Solenoid S1 to S6

Reverse lockout valveThe pump cover contains the following;

Primary regulator valve for line pressure

Converter clutch regulator valve

Converter clutch control valve

Solenoid S7

The main case contains the following;

B1R exhaust valve

All upshifts are accomplished by simultaneously

switching on a shift valve(s), switching VPS pressure

to the band and/or clutch regulator valve, and then

sending the VPS a ramped current. The shift is

completed by switching the regulators OFF and at the

same time causing the VPS to reach maximum

pressure.

All downshifts are accomplished by switching VPS pres-

sure to the band and/or clutch regulator valve and send-

ing a ramped current to the VPS. The shift is completed

by simultaneously switching the regulators OFF,

switching the shift valves and at the same time causing

the VPS to return to stand-by pressure.

The primary regulator valve is located in the pump

cover and supplies four line pressures; high and low

for forward gears, and high and low for reverse. This

pressure has no effect on shift quality and merely

provides static clutch capacity during steady state

operation. Low pressure can be obtained by activating

an ON/OFF solenoid with high line pressure being the

default mode.

Torque converter lock-up is initiated by toggling the

converter clutch control valve with an ON/OFF solenoid.

The actual apply and release of the clutch is regulated

by the VPS via the converter clutch regulator valve.

The solenoid supply pressure regulator valve provides

reference pressure for all the solenoids.

KAA5A080

Page 1108 of 2053

5A-14 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

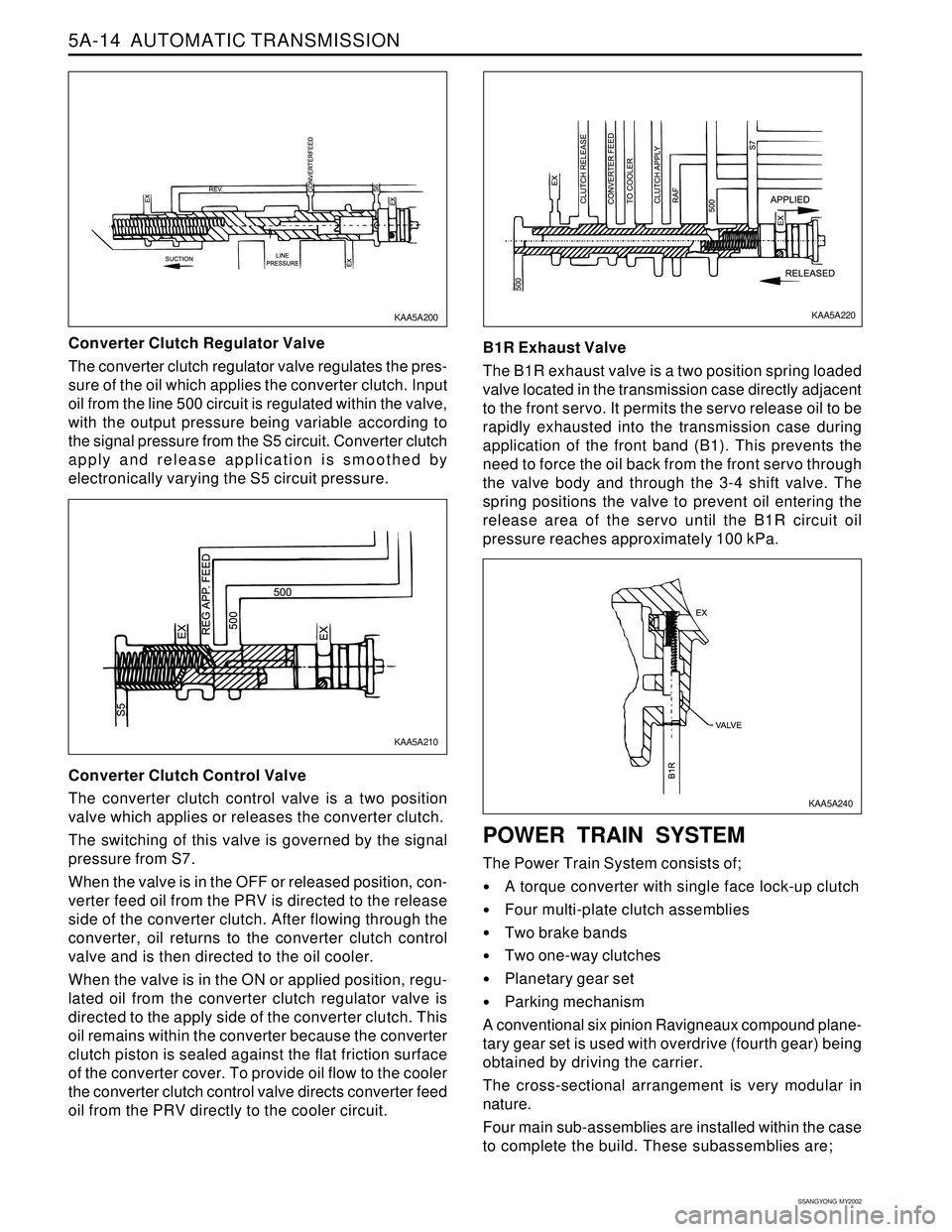

Converter Clutch Regulator Valve

The converter clutch regulator valve regulates the pres-

sure of the oil which applies the converter clutch. Input

oil from the line 500 circuit is regulated within the valve,

with the output pressure being variable according to

the signal pressure from the S5 circuit. Converter clutch

apply and release application is smoothed by

electronically varying the S5 circuit pressure.

Converter Clutch Control Valve

The converter clutch control valve is a two position

valve which applies or releases the converter clutch.

The switching of this valve is governed by the signal

pressure from S7.

When the valve is in the OFF or released position, con-

verter feed oil from the PRV is directed to the release

side of the converter clutch. After flowing through the

converter, oil returns to the converter clutch control

valve and is then directed to the oil cooler.

When the valve is in the ON or applied position, regu-

lated oil from the converter clutch regulator valve is

directed to the apply side of the converter clutch. This

oil remains within the converter because the converter

clutch piston is sealed against the flat friction surface

of the converter cover. To provide oil flow to the cooler

the converter clutch control valve directs converter feed

oil from the PRV directly to the cooler circuit.B1R Exhaust Valve

The B1R exhaust valve is a two position spring loaded

valve located in the transmission case directly adjacent

to the front servo. It permits the servo release oil to be

rapidly exhausted into the transmission case during

application of the front band (B1). This prevents the

need to force the oil back from the front servo through

the valve body and through the 3-4 shift valve. The

spring positions the valve to prevent oil entering the

release area of the servo until the B1R circuit oil

pressure reaches approximately 100 kPa.

POWER TRAIN SYSTEM

The Power Train System consists of;

A torque converter with single face lock-up clutch

Four multi-plate clutch assemblies

Two brake bands

Two one-way clutches

Planetary gear set

Parking mechanism

A conventional six pinion Ravigneaux compound plane-

tary gear set is used with overdrive (fourth gear) being

obtained by driving the carrier.

The cross-sectional arrangement is very modular in

nature.

Four main sub-assemblies are installed within the case

to complete the build. These subassemblies are;

KAA5A220KAA5A200

KAA5A210

KAA5A240

Page 1110 of 2053

5A-16 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Torque Converter

The torque converter consists of a turbine, stator pump,

impeller and a lock-up damper and piston assembly.

As in conventional torque converters, the impeller is

attached to the converter cover, the turbine is splined

to the input shaft and the stator is mounted on the

pump housing via a one way clutch (sprag).

The addition of the damper and piston assembly en-

ables the torque converter to lock-up under favorable

conditions. Lock-up is only permitted to occur in third

and fourth gears under specified throttle and vehicle

speed conditions.

Lock-up is achieved by applying hydraulic pressure

to the damper and piston assembly which couples the

turbine to the converter cover, locking-up the converter

and eliminating unwanted slippage. Whenever lock-

up occurs, improved fuel consumption is achieved.

Torsional damper springs are provided in the damper

and piston assembly to absorb any engine torque

fluctuations during lock-up.

Clutch Packs

There are four clutch packs. All clutch packs are com-

posed of multiple steel and friction plates.

C1 CLUTCH: When applied, this clutch pack allows

the input shaft to drive the planet carrier. This occurs

in third and fourth gears.

C2 CLUTCH: When applied this clutch pack allows

the input shaft to drive the forward sun gear via the 3-

4 OWC. This occurs in all forward gears.

C3 CLUTCH: When applied this clutch pack allows

the input shaft to drive the reverse sun gear. This only

occurs in reverse gear.

C4 CLUTCH: When applied this clutch provides engine

braking on overrun. This occurs in Manual 1, 2 and 3

and also Drive 2 and Drive 3 to prevent objectionable

free wheel coasting.

KAA5A260

KAA5A270