torque SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1111 of 2053

AUTOMATIC TRANSMISSION 5A-17

SSANGYONG MY2002

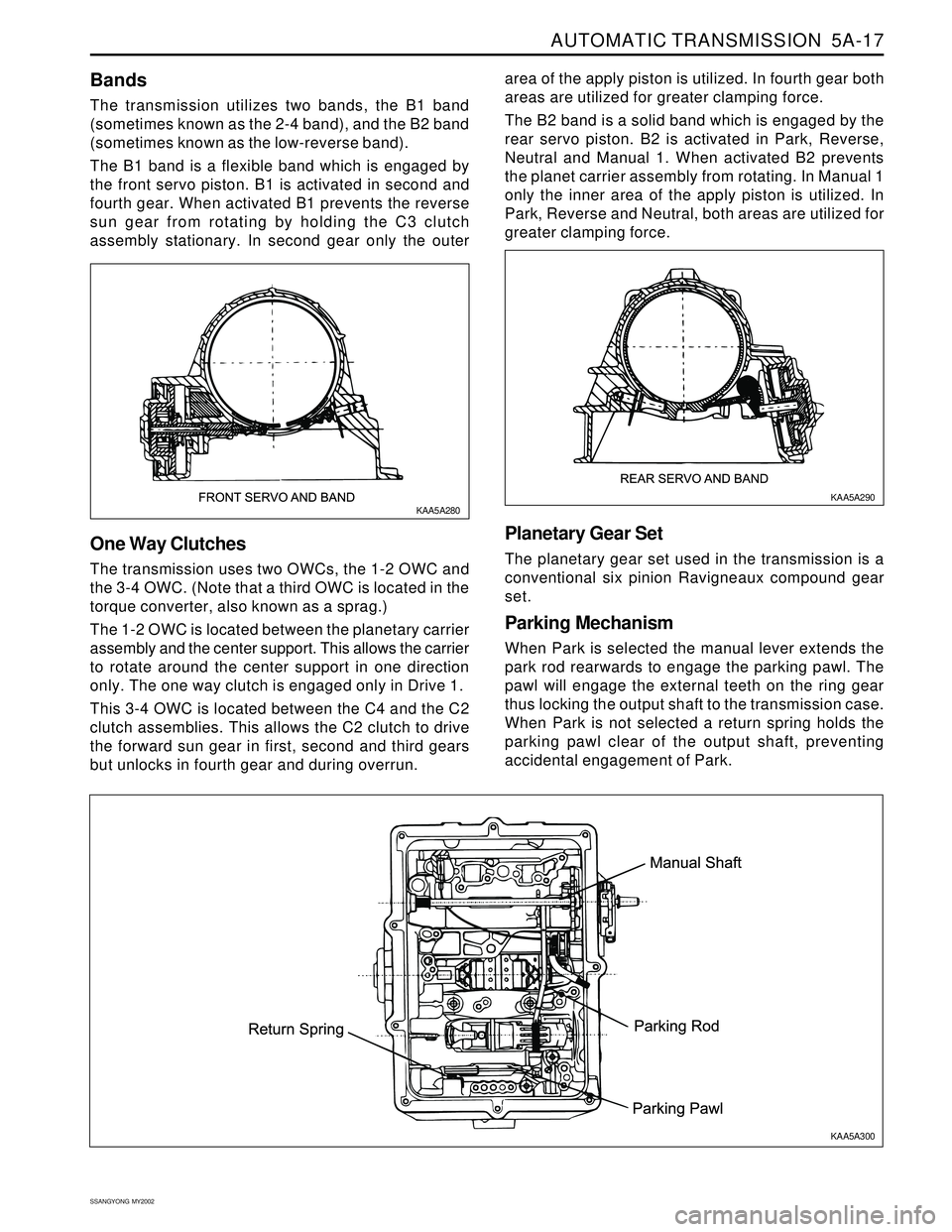

Bands

The transmission utilizes two bands, the B1 band

(sometimes known as the 2-4 band), and the B2 band

(sometimes known as the low-reverse band).

The B1 band is a flexible band which is engaged by

the front servo piston. B1 is activated in second and

fourth gear. When activated B1 prevents the reverse

sun gear from rotating by holding the C3 clutch

assembly stationary. In second gear only the outerarea of the apply piston is utilized. In fourth gear both

areas are utilized for greater clamping force.

The B2 band is a solid band which is engaged by the

rear servo piston. B2 is activated in Park, Reverse,

Neutral and Manual 1. When activated B2 prevents

the planet carrier assembly from rotating. In Manual 1

only the inner area of the apply piston is utilized. In

Park, Reverse and Neutral, both areas are utilized for

greater clamping force.

One Way Clutches

The transmission uses two OWCs, the 1-2 OWC and

the 3-4 OWC. (Note that a third OWC is located in the

torque converter, also known as a sprag.)

The 1-2 OWC is located between the planetary carrier

assembly and the center support. This allows the carrier

to rotate around the center support in one direction

only. The one way clutch is engaged only in Drive 1.

This 3-4 OWC is located between the C4 and the C2

clutch assemblies. This allows the C2 clutch to drive

the forward sun gear in first, second and third gears

but unlocks in fourth gear and during overrun.

Planetary Gear Set

The planetary gear set used in the transmission is a

conventional six pinion Ravigneaux compound gear

set.

Parking Mechanism

When Park is selected the manual lever extends the

park rod rearwards to engage the parking pawl. The

pawl will engage the external teeth on the ring gear

thus locking the output shaft to the transmission case.

When Park is not selected a return spring holds the

parking pawl clear of the output shaft, preventing

accidental engagement of Park.

KAA5A300 KAA5A280KAA5A290

Page 1134 of 2053

5A-40 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Dye and Black Light Method

1. Add dye to the transmission through the transmission

fluid filler plug. Follow the manufacturer’s recommen-

dation for the amount of dye to be used.

2. Use the black light to find the fluid leak.

3. Make the necessary repairs.

Repairing the Fluid Leak

Once the leak point is found the source of the leak

must be determined. The following list describes the

potential causes for the leak:

Fasteners are not torqued to specification.

Fastener threads and fastener holes are dirty or

corroded.

Gaskets, seals or sleeves are misaligned, damaged

or worn.

Damaged, warped or scratched seal bore or gasket

surface.

Loose or worn bearing causing excess seal or sleeve

wear.

Case or component porosity.

Fluid level is too high.

Plugged vent or damaged vent tube.

Water or coolant in fluid.

Fluid drain back holes plugged.

ELECTRICAL / GARAGE SHIFT

TEST

This preliminary test should be performed before a hoist

or road test to make sure electronic control inputs are

connected and operating. If the inputs are not checked

before operating the transmission, a simple electrical

condition could be misdiagnosed as a major

transmission condition.

A scan tool provides valuable information and must

be used on the automatic transmission for accurate

diagnosis.

1. Move gear shift control lever to P (Park) and set

the parking brake.

2. Connect scan tool to Data Link Connector (DLC)

terminal.

3. Start engine.

4. Turn the scan tool ON.

5. Verify that the appropriate signals are present.

These signals may include:

ENGINE SPEED

VEHICLE SPEED

THROTTLE POSITION

ACCEL. PEDAL POSITION

TRANSMISSION GEAR STATE

GEAR SHIFT LEVER POSITION

TRANSMISSION FLUID TEMPERATURE

CLOSED THROTTLE POSITION LEARN

OPEN THROTTLE POSITION LEARNT

CLOSED ACCEL. PEDAL POSITION LEARNT

OPEN ACCEL. PEDAL POSITION LEARNT

A/C COMPRESSOR STATUS

KICKDOWN SWITCH STATUS

4WD STATUS

MODE SWITCH

THROTTLE POSITION VOLTAGE

GEAR SHIFT LEVER POSITION VOLTAGE

TRANS. FLUID TEMPERATURE VOLTAGE

A/C SWITCH

KICKDOWN SWITCH VOLTAGE

4WD LAMP LOW VOLTAGE

4WD LAMP HIGH VOLTAGE

MODE SWITCH VOLTAGE

BATTERY VOLTAGE

6. Monitor the A/C COMPRESSOR STATUS signal

while pushing the A/C switch.

The A/C COMPRESSOR STATUS should come

ON when the A/C switch is pressed, and turn

OFF when the A/C switch is repushed.

7. Monitor the GEAR SHIFT LEVER POSITION signal

and move the gear shift control lever through all

the ranges.

Verify that the GEAR SHIFT LEVER POSITION

value matches the gear range indicated on the

instrument panel or console.

Gear selections should be immediate and not

harsh.

8. Move gear shift control lever to neutral and monitor

the THROTTLE POSITION signal while increasing

and decreasing engine speed with the accelerator

pedal.

THROTTLE POSITION should increase with en-

gine speed.

ROAD TEST PROCEDURE

Perform the road test using a scan tool.

This test should be performed when traffic and road

conditions permit.

Observe all traffic regulations.

ELECTRONIC ADJUSTMENTS

Idle Speed Adjustments

Carry out the adjustments to the idle speed as detailed

in the workshop manual.

Vehicle Coding

The vehicle coding is integrated as part of the

diagnostic software. A scan tool has the function to

code the ve-hicle through the K-line.

Page 1135 of 2053

5A-40 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Dye and Black Light Method

1. Add dye to the transmission through the transmission

fluid filler plug. Follow the manufacturer’s recommen-

dation for the amount of dye to be used.

2. Use the black light to find the fluid leak.

3. Make the necessary repairs.

Repairing the Fluid Leak

Once the leak point is found the source of the leak

must be determined. The following list describes the

potential causes for the leak:

Fasteners are not torqued to specification.

Fastener threads and fastener holes are dirty or

corroded.

Gaskets, seals or sleeves are misaligned, damaged

or worn.

Damaged, warped or scratched seal bore or gasket

surface.

Loose or worn bearing causing excess seal or sleeve

wear.

Case or component porosity.

Fluid level is too high.

Plugged vent or damaged vent tube.

Water or coolant in fluid.

Fluid drain back holes plugged.

ELECTRICAL / GARAGE SHIFT

TEST

This preliminary test should be performed before a hoist

or road test to make sure electronic control inputs are

connected and operating. If the inputs are not checked

before operating the transmission, a simple electrical

condition could be misdiagnosed as a major

transmission condition.

A scan tool provides valuable information and must

be used on the automatic transmission for accurate

diagnosis.

1. Move gear shift control lever to P (Park) and set

the parking brake.

2. Connect scan tool to Data Link Connector (DLC)

terminal.

3. Start engine.

4. Turn the scan tool ON.

5. Verify that the appropriate signals are present.

These signals may include:

ENGINE SPEED

VEHICLE SPEED

THROTTLE POSITION

ACCEL. PEDAL POSITION

TRANSMISSION GEAR STATE

GEAR SHIFT LEVER POSITION

TRANSMISSION FLUID TEMPERATURE

CLOSED THROTTLE POSITION LEARN

OPEN THROTTLE POSITION LEARNT

CLOSED ACCEL. PEDAL POSITION LEARNT

OPEN ACCEL. PEDAL POSITION LEARNT

A/C COMPRESSOR STATUS

KICKDOWN SWITCH STATUS

4WD STATUS

MODE SWITCH

THROTTLE POSITION VOLTAGE

GEAR SHIFT LEVER POSITION VOLTAGE

TRANS. FLUID TEMPERATURE VOLTAGE

A/C SWITCH

KICKDOWN SWITCH VOLTAGE

4WD LAMP LOW VOLTAGE

4WD LAMP HIGH VOLTAGE

MODE SWITCH VOLTAGE

BATTERY VOLTAGE

6. Monitor the A/C COMPRESSOR STATUS signal

while pushing the A/C switch.

The A/C COMPRESSOR STATUS should come

ON when the A/C switch is pressed, and turn

OFF when the A/C switch is repushed.

7. Monitor the GEAR SHIFT LEVER POSITION signal

and move the gear shift control lever through all

the ranges.

Verify that the GEAR SHIFT LEVER POSITION

value matches the gear range indicated on the

instrument panel or console.

Gear selections should be immediate and not

harsh.

8. Move gear shift control lever to neutral and monitor

the THROTTLE POSITION signal while increasing

and decreasing engine speed with the accelerator

pedal.

THROTTLE POSITION should increase with en-

gine speed.

ROAD TEST PROCEDURE

Perform the road test using a scan tool.

This test should be performed when traffic and road

conditions permit.

Observe all traffic regulations.

ELECTRONIC ADJUSTMENTS

Idle Speed Adjustments

Carry out the adjustments to the idle speed as detailed

in the workshop manual.

Vehicle Coding

The vehicle coding is integrated as part of the

diagnostic software. A scan tool has the function to

code the ve-hicle through the K-line.

Page 1149 of 2053

5A-54 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

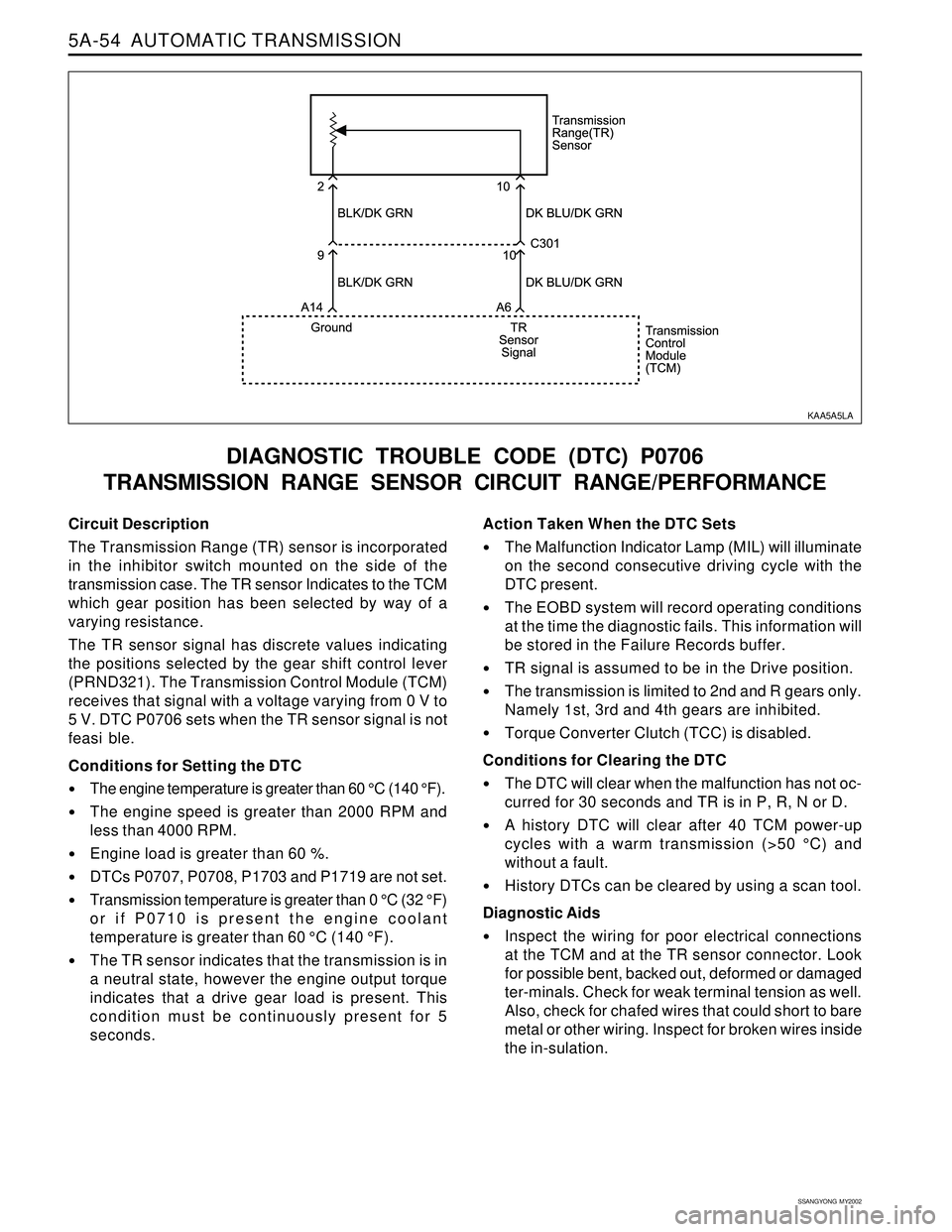

Circuit Description

The Transmission Range (TR) sensor is incorporated

in the inhibitor switch mounted on the side of the

transmission case. The TR sensor Indicates to the TCM

which gear position has been selected by way of a

varying resistance.

The TR sensor signal has discrete values indicating

the positions selected by the gear shift control lever

(PRND321). The Transmission Control Module (TCM)

receives that signal with a voltage varying from 0 V to

5 V. DTC P0706 sets when the TR sensor signal is not

feasi ble.

Conditions for Setting the DTC

•The engine temperature is greater than 60 °C (140 °F).

The engine speed is greater than 2000 RPM and

less than 4000 RPM.

Engine load is greater than 60 %.

DTCs P0707, P0708, P1703 and P1719 are not set.

Transmission temperature is greater than 0 °C (32 °F)

or if P0710 is present the engine coolant

temperature is greater than 60 °C (140 °F).

The TR sensor indicates that the transmission is in

a neutral state, however the engine output torque

indicates that a drive gear load is present. This

condition must be continuously present for 5

seconds.

DIAGNOSTIC TROUBLE CODE (DTC) P0706

TRANSMISSION RANGE SENSOR CIRCUIT RANGE/PERFORMANCE

Action Taken When the DTC Sets

The Malfunction Indicator Lamp (MIL) will illuminate

on the second consecutive driving cycle with the

DTC present.

The EOBD system will record operating conditions

at the time the diagnostic fails. This information will

be stored in the Failure Records buffer.

TR signal is assumed to be in the Drive position.

The transmission is limited to 2nd and R gears only.

Namely 1st, 3rd and 4th gears are inhibited.

Torque Converter Clutch (TCC) is disabled.

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not oc-

curred for 30 seconds and TR is in P, R, N or D.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

Inspect the wiring for poor electrical connections

at the TCM and at the TR sensor connector. Look

for possible bent, backed out, deformed or damaged

ter-minals. Check for weak terminal tension as well.

Also, check for chafed wires that could short to bare

metal or other wiring. Inspect for broken wires inside

the in-sulation.

KAA5A5LA

Page 1151 of 2053

5A-56 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The Transmission Range (TR) sensor is incorporated

in the inhibitor switch mounted on the side of the

transmis sion case. The TR sensor Indicates to the

TCM which gear position has been selected by way of

a varying resistance.

The TR sensor signal has discrete values indicating

the positions selected by the gear shift control lever

(PRND321). The Transmission Control Module (TCM)

receives that signal with a voltage varying from 0 V to

5 V. DTC P0707 sets when the TR sensor signal is

faulty, causing the gear lever position signal to be less

than 0.87 V.

Conditions for Setting the DTC

TR sensor signal is less than 0.87 V.

The above condition must be continuously present

for 100 milliseconds.

Action Taken When the DTC Sets

The Malfunction Indicator Lamp (MIL) will illuminate

on the second consecutive driving cycle with the

DTC present.

The EOBD system will record operating conditions

at the time the diagnostic fails. This information will

be stored in the Failure Records buffer.

Transmission range is assumed to be in the Drive

position.

The transmission is limited to 2nd and R gears only.

Namely 1st, 3rd and 4th gears are inhibited.

Torque Converter Clutch (TCC) is disabled.

DIAGNOSTIC TROUBLE CODE (DTC) P0707

TRANSMISSION RANGE SENSOR CIRCUIT LOW INPUT

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred for 3 seconds.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

The voltage measured by the TCM across the TR

sensor input terminals has been below on

acceptable level for a significant length of time.

This would typically be caused by a short to ground

in the wiring to, or within, the inhibitor switch which

has caused the signal at the TCM to read about 0

V.

Inspect the wiring for poor electrical connections

at the TCM and at the TR sensor connector. Look

for possible bent, deformed or damaged terminals.

Also, check for chafed wires that could short to bare

metal or other wiring.

In searching for a possible intermittent short or open

condition, move or massage the wiring harness

while observing the test equipment for a change.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. This step simulates a DTC P0708 condition. If the

scan tool displays the specified value, the TR

sensor signal circuit and the TCM are OK.

KAA5A5LA

Page 1153 of 2053

5A-58 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The Transmission Range (TR) sensor is incorporated

in the inhibitor switch mounted on the side of the

transmission case. The TR sensor Indicates to the

TCM which gear position has been selected by way of

a varying resistance.

The TR sensor signal has discrete values indicating

the positions selected by the gear shift control lever

(PRND321). The Transmission Control Module (TCM)

receives that signal with a voltage varying from 0 V to

5 V.

The transmission range sensor is faulty, causing the

gear lever position signal to be greater than 4.12 V.

Conditions for Setting the DTC

TR sensor signal is greater than 4.12 V.

The above condition must be continuously present

for 100 milliseconds.

Action Taken When the DTC Sets

The Malfunction Indicator Lamp (MIL) will illuminate

on the second consecutive driving cycle with the

DTC present.

The EOBD system will record operating conditions

at the time the diagnostic fails. This information

will be stored in the Failure Records buffer.

Transmission range (gear lever) is assumed to be

in the Drive position.

The transmission is limited to 2nd and R gears only.

Namely 1st, 3rd and 4th gears are inhibited.

Torque Converter Clutch (TCC) is disabled.

Manually initiated downshifts will not be available.

DIAGNOSTIC TROUBLE CODE (DTC) P0708

TRANSMISSION RANGE SENSOR CIRCUIT HIGH INPUT

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred for 3 seconds.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50°C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

The voltage measured by the TCM across the shift

lever input terminals has been above an acceptable

level for a significant length of time.

This would typically be caused by a loose

connection or an open or short to B+ in the wiring

to, or within, the inhibitor switch which has caused

the signal at the TCM to read 5 V.

If the DTC sets when an accessory is operated,

check for a poor connection or excessive current

draw.

Inspect the wiring for poor electrical connections

at the TCM and at the TR sensor connector. Look

for possible bent, backed out, deformed or damaged

terminals. Check for weak terminal tension as well.

Also, check for chafed wires that could short to

other wiring. Inspect for broken wires inside the

insulation.

In searching for a possible intermittent short or open

condition, move or massage the wiring harness

while observing test equipment for a change.

KAA5A5LA

Page 1157 of 2053

5A-62 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The Transmission Fluid Temperature (TFT) sensor is a

thermistor located in the solenoid wiring loom within

the valve body of the transmission. This sensor is a

typical Negative Temperature Coefficient (NTC) resistor

with low temperatures producing a high resistance and

high temperatures producing a low resistance.

If the transmission fluid temperature exceeds 135 °C

(275 °F), the TCM will impose converter lock-up at lower

vehicle speeds. Favour a lower gear to increase engine

speed, and in some vehicles flashes the mode indicator

lamp. This results in maximum oil flow through the exter-

nal oil cooler and eliminates slippage in the torque

converter. Both these actions combine to reduce the

oil temperature in the transmission.

The DTC P0710 sets when the TFT sensor signal is not

feasible.

Conditions for Setting the DTC

Transmission fluid temperature sensor signal is

greater than 4.88 volts (immediate detection).

Transmission fluid temperature sensor signal is less

than 0.21 volts (immediate detection).

Transmission temperature has not changed by 2 °C

in 15 minutes since ignition on and temperature is

less than 20 °C or greater than 125 °C.

Action Taken When the DTC Sets

Transmission fluid temperature is assumed to be

120 °C (248 °F).

All shifts will be firm until the transmission has

warmed up because a high transmission fluid

temperature is assumed.

DIAGNOSTIC TROUBLE CODE (DTC) P0710

TRANSMISSION FLUID TEMPERATURE SENSOR CIRCUIT

MALFUNCTION

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not oc

curred for 3 seconds.

A history DTC will clear after 40 TCM power-up cycles

with a warm transmission (>50 °C) and without a

fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

The voltage measured by the TCM across the trans-

mission fluid temperature input terminals has been

outside acceptable levels.

If the DTC sets when an accessory is operated,

check for a poor connection or excessive current

draw.

Inspect the wiring for poor electrical connections

at the TCM and at the 10-way transmission

connector. Look for possible bent, backed out,

deformed or damaged terminals. Check for weak

terminal tension as well. Also, check for chafed wires

that could short to bare metal or other wiring. Inspect

for broken wires inside the insulation.

In searching for a possible intermittent short or open

condition, move or massage the wiring harness

while observing test equipment for a change.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

5. This step simulates a DTC P0710 condition. If the

scan tool displays the specified value, the TFT

sensor signal circuit and the TCM are OK.

KAA5A5M0

Page 1167 of 2053

5A-72 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The Controller Area Network (CAN) connects various

control modules by using a twisted pair of wires, to

share common information. This results in a reduction

of sensors and wiring. TCM obtains the actual engine

speed and throttle position, vehicle speed and

accelerator position etc. from ECM via CAN without

any additional sensors.

The DTC P1704 sets when the indicated drive shaft

speed signal via CAN is out of range or not feasible or

a shaft speed of 0 is present while other signals indicate

the vehicle is being driven.

Conditions for Setting the DTC

Immediately upon the test indicating malfunction

as follows.

The shaft speed signal is greater than 9000 rpm or

less than 0 rpm under the precondition that DTC

P1719 is not set.

The shaft speed indicates 0 rpm while all other sig-

nals indicate the car is moving under the following

precondition;

- Driving gear is selected.

- The transmission range sensor has not recently

changed state.

- The engine speed is greater than 2800 rpm.

- DTCs P0706, P0707, P0708, P1703 and P1719

are not set.

The shaft speed has dropped from above 2100 rpm

to 0 rpm within 20 ms.

DIAGNOSTIC TROUBLE CODE (DTC) P1704

SHAFT SPEED SIGNAL ERROR

Action Taken When the DTC Sets

All skip downshifts disabled and fourth gear will

be in-hibited.

The torque converter will be unlocked at all times.

Gears are selected by the shift control lever but all

downshifts are inhibited by engine speed limits to

prevent over-revving.

D position selects 3rd gear.

1st and 2nd gears can be manually selected.

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred for 30 seconds and a non-zero speed is

detected.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

Inspect the wiring for poor electrical connections

at the TCM and ECM connectors. Look for possible

bent, backed out, deformed or damaged terminals.

Check for weak terminal tension as well. Also check

for chafed wires that could short to bare metal or

other wiring. Inspect for broken wire inside the

insulation.

KAA5A5KA

Page 1173 of 2053

5A-78 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The Air Conditioning Switch circuit indicates the state

of the air conditioning compressor clutch (on or off).

This signal is available to the TCM only on vehicles

fitted with air conditioning.

The DTC 1710 sets when an intermittent connection in

the air conditioning switch circuit has been detected.

The switch input is rapidly changing states and the

switching frequency is greater than 8.3 Hz.

Conditions for Setting the DTC

The mode switching frequency is greater than 8.3

Hz.

The above condition must be continuously present

for 4 state changes.

Action Taken When the DTC Sets

The TCM does not compensate for torque variation

due to air conditioning compressor clutch activation.

DIAGNOSTIC TROUBLE CODE (DTC) P1710

AIR CONDITIONING SWITCH CIRCUIT MALFUNCTION

Conditions for Clearing the DTC

The DTC will clear after 3 seconds without the fault.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

This fault is caused by too many changes in the

mode input signal over a period of time.

Typical causes would be an intermittent connection

in the switch or wiring or an intermittent short to

ground in the wiring.

KAA5A5T0

Page 1181 of 2053

5A-86 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The Controller Area Network (CAN) connects various

control modules by using a twisted pair of wires, to

share common information. This results in a reduction

of sensors and wiring. TCM obtains the actual engine

speed and throttle position, vehicle speed and

accelerator pedal position etc. from ECM via CAN

without any additional sensors.

The DTC P1713 sets when the accelerator pedal signal

via CAN is out of range. The accelerator pedal signal

is greater than 254 steps.

Conditions for Setting the DTC

DTCs P1719 is not set.

The accelerator pedal signal is greater than 254

steps. The malfunction is triggered immediately

after this condition exists.

Action Taken When the DTC Sets

4th gear is inhibited.

Torque Converter Clutch (TCC) is inhibited.

Default value is adopted for shift point decisions.

Accelerator pedal is not used for P, R, or N B2

activation decisions.

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not

occurred for 30 seconds.

DIAGNOSTIC TROUBLE CODE (DTC) P1713

PEDAL SIGNAL ERROR

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

Inspect the wiring for poor electrical connections

at the TCM and ECM connectors. Look for possible

bent, backed out, deformed or damaged terminals.

Check for weak terminal tension as well. Also check

for chafed wires that could short to bare metal or

other wiring. Inspect for broken wire inside the

insulation.

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring harness

while observing test equipment for a change.

When ECM finds a fault on the accelerator pedal

signals, ECM will adopt a default mode and send

the default value and trouble message to TCM via

CAN.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Check if there are any DTCs related to the accelera-

tor pedal sensor on the ECM side.

4. Check for a poor connection at the ECM and TCM

connectors.

KAA5A5KA